the only concern and question i have is this.

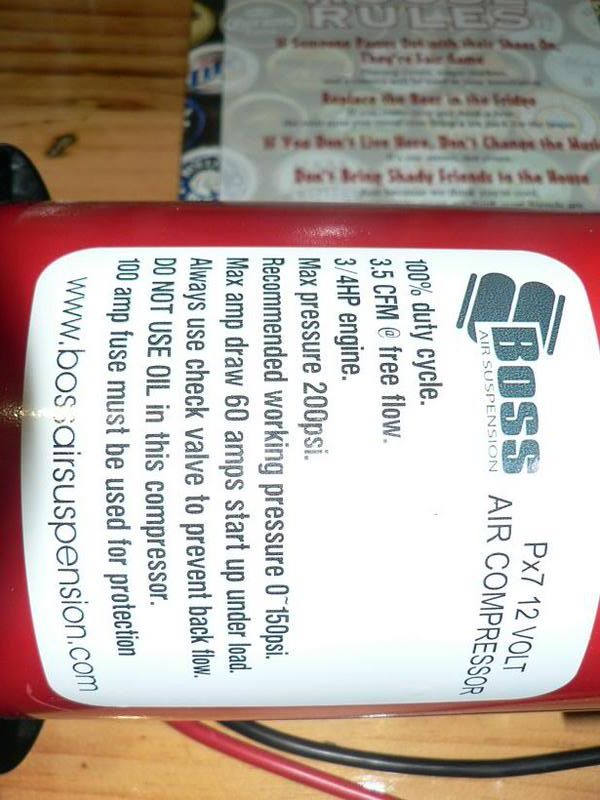

it states in the wiring setup to run 15mm cable through a 100A fuse. the compressor draws at max approx 60A on startup. is that size cable overkill? (compressor will be behind seats of a GU cab chassis, distance approx 2m max)

where abouts would i have the switch to turn it on and off?

the scary thing is though, the compressor has a + and - lead out of it, now they are only approx 5mm in diameter. the instructions say to connect the 15mm cable direct to the 5mm.

thanks

PAUL

p.s thought it would be better here than auto elec. more opinions