I need to run a 24V Hydraulic Power Pack. It will not be used very often and only for short periods of time. While the Hydraulic pump is not being used. I want the dual battery system to function as per normal.

Proposed Solution

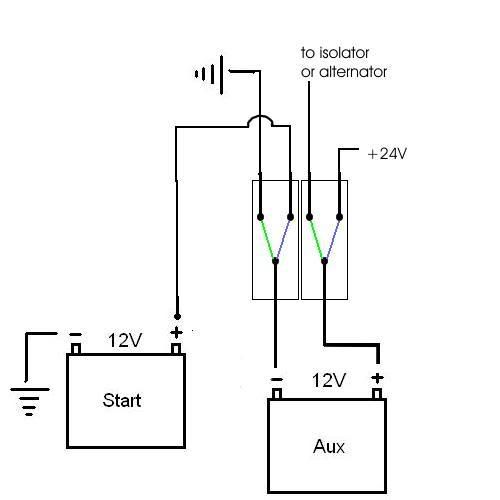

Have a normal dual battery system. Have an NC relay on the dual isolator cable and Aux Battery Neg cable and a NO on a series connection between the two batteries. When I need 24V, switch the three relays (protecting the dual isolator) and get 24V from a series connection of the two batteries.

Will this blow anything up? Will I have issues using 12V (stereo etc) from 1 battery while I get 24V from the two?

I understand the purpose of the dual battery system in that it is meant to keep your starter battery charged. I can see problems associated with one battery being more charged then the other and the current flows between the batteries in this case.

I want to get 24V without running a three battery system.

This is a hydraulic suspension related project and I only will need 24V whilst the car is running. (Wont be draining battery when the car is off).

I have read most of the 24V related posts in the forum.

Your opinion and guidance towards this setup will be greatly appreciated.

Dave

--