(before anyone comments, the plate ontop of the diff goes right over between the two U-bolts, effectively clamping the housing. It isn't relying on just weld.)

Then a couple of months ago the rear springs started getting really noisy. Now they make huge noises all the time. Like when I reverse out the driveway, park the car. Even go around some bends. I have retorqued the U-bolts to 123Nm as per the factory spec. but is still noisy.

I know the noise is the springs moving. see the photo below

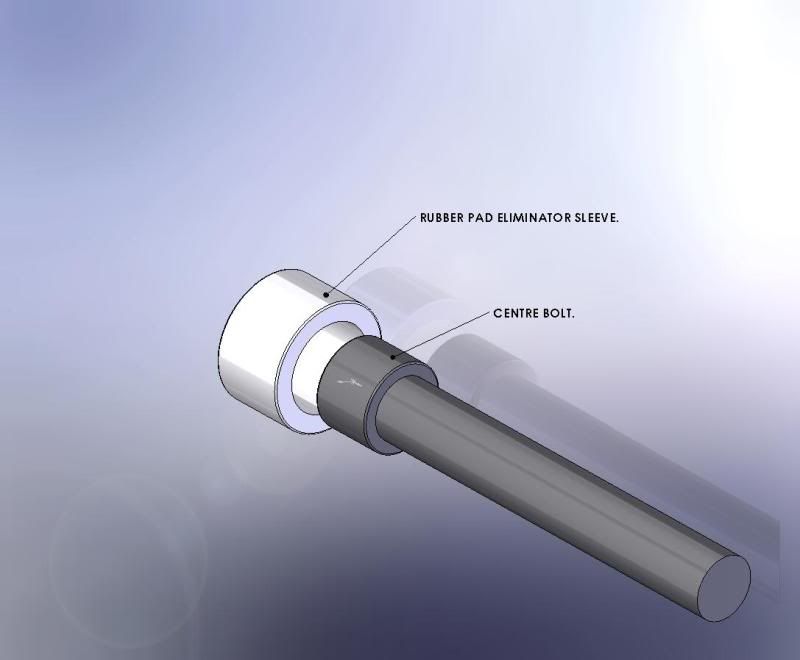

Could it possibly be because there is no plate under the spring or do you think one would help keep the bolts straight and also provide more friction to stop the springs moving.

I am thinking something like this.

Could be either Alloy or steel, milled out. It would also offer some protection for centre bolt.

My other line of thinking is that if I make it easier for the leaves to move then they won't suddenly move, making a big clunk. This could possibly be done with either a rubber or teflon pad between the new plate and the spring.

[/img]

[/img]Well those are basically my thoughts so far, any input would be much appreciated.

Sam