Was driving the cruiser home one day, heard a serious clunk, normal revving sound replaced by spluttering, then she revved out to redline.

Turned off the ignition and she was still running, white smoke blasting out with some hot oil. Tried to stall it in 5th but burnt the clutch off (which needed to be replaced soon). Stopped and watched helplessly as it ran itself out of engine oil

Fireys arrived when all was quiet to mop up my exhaust slick. They apparently see this all the time in trucks when the turbo seals blow.

Had some guys take 'a look' (I don't really think they did much more than kick the tyres and point at the oil leaking from the turbo. One even bloody started it

Was not going to let our old warhorse die this way. I don't have years of experience around engines, but I can handle myself in a workshop. So it was decided between myself, a mate and my old man to rebuild it ourselves.

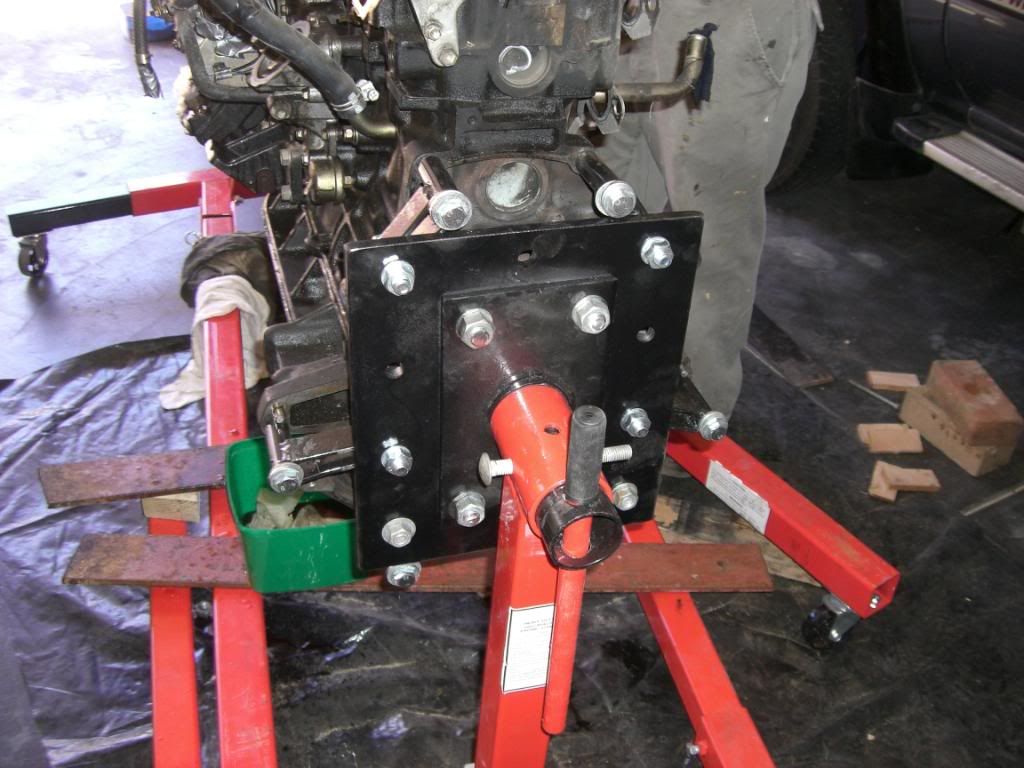

We have a mate who is lending us a garage, we bought some measuring tools, an engine stand and an engine crane (I know of a good shop in Dandenong Victoria), and we are cracking away at it, admittedly slowly.

-----PROGRESS------

Got all the grille and easy stuff off, no worries.

So far we have had to grind back an exhaust nut to failure after stripping it.

I just want to ask some advice before I actually yank it out of the car.

For securing it to the engine stand, are there tapped holes into the block, or is it more of a flange where you use a nut to retain the engine against the engine stand arms?

If there are tapped holes, about how deep are they and (more importantly) what thread are they? If it is a flange, whats the diameter of the holes (I need to buy some bolts)?

I'll keep everybody posted as we progress through this.

EDIT: All pictures on photobucket.

http://s679.photobucket.com/albums/vv157/overflow255/