Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

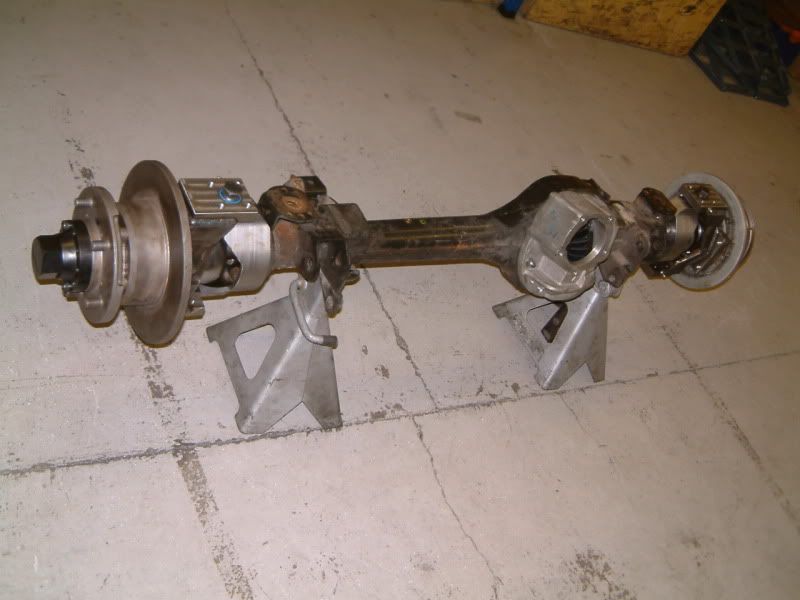

Nissota 9" into Rover

Moderator: Micka

is there not a known weakness of using an ARB in a 9 inch? Not in the design of the ARB but fitting it in a 9 inch? I think alot of the crawler guys over there are having problems with them, especially when 'crash' locked or used with cutting brakes?

Ben Napier BNMotorsports

Nitto Tires, King Shocks, Rigid Industries LED, Raceline Wheels, Dynomax Exhaust, Wombat Crossing Vineyard

[url]www.facebook.com/ben.bnmotorsports[/url]

[url]www.bnmotorsports.com[/url]

Nitto Tires, King Shocks, Rigid Industries LED, Raceline Wheels, Dynomax Exhaust, Wombat Crossing Vineyard

[url]www.facebook.com/ben.bnmotorsports[/url]

[url]www.bnmotorsports.com[/url]

Hi,

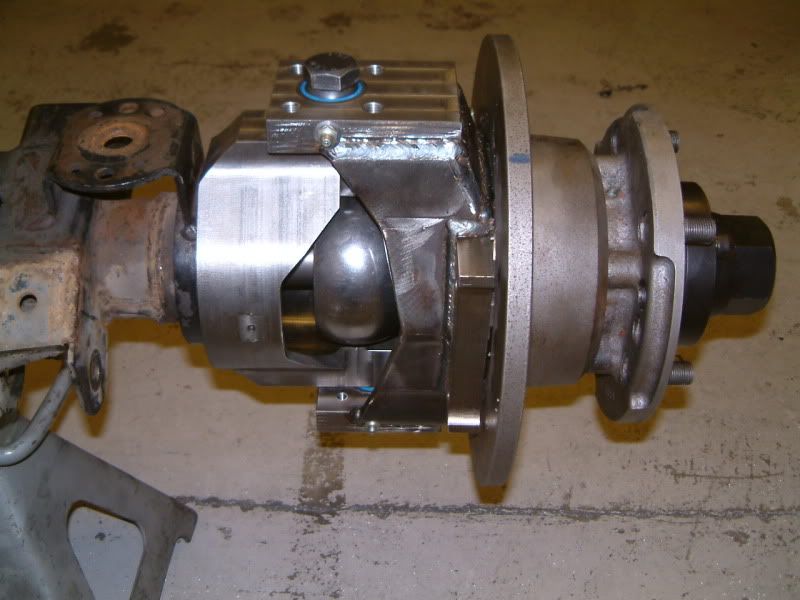

we make 4 mods to the 9" ARB RD99,

1) to fit to our new housing we have to machine the ARB on the non crown wheel side to pull the journal bearing in closer to the centre,

the other 3 mods are to improve the poor dog clutch engagement,

2) there are 12 small but strong disengagement springs, this is a huge force for the pneumatic piston to overcome on engagement, we remove 4.

3) the dog clutch only has 2.5mm engagement, we machine it to add 1mm more.

4) the internal air feed holes are 1mm, we open these up to 1.5mm.

not tested any of the above yet but hopefully it will improve the problems the 9" ARB suffers from.

we make 4 mods to the 9" ARB RD99,

1) to fit to our new housing we have to machine the ARB on the non crown wheel side to pull the journal bearing in closer to the centre,

the other 3 mods are to improve the poor dog clutch engagement,

2) there are 12 small but strong disengagement springs, this is a huge force for the pneumatic piston to overcome on engagement, we remove 4.

3) the dog clutch only has 2.5mm engagement, we machine it to add 1mm more.

4) the internal air feed holes are 1mm, we open these up to 1.5mm.

not tested any of the above yet but hopefully it will improve the problems the 9" ARB suffers from.

Dave

www.ashcroft-transmissions.co.uk

www.ashcroft-transmissions.co.uk

Great info Dave. I'm sure you have your own ARB contacts, but daniel bongard (dbongard) on here is an ARB engineer...ashtrans wrote:Hi,

we make 4 mods to the 9" ARB RD99,

1) to fit to our new housing we have to machine the ARB on the non crown wheel side to pull the journal bearing in closer to the centre,

the other 3 mods are to improve the poor dog clutch engagement,

2) there are 12 small but strong disengagement springs, this is a huge force for the pneumatic piston to overcome on engagement, we remove 4.

3) the dog clutch only has 2.5mm engagement, we machine it to add 1mm more.

4) the internal air feed holes are 1mm, we open these up to 1.5mm.

not tested any of the above yet but hopefully it will improve the problems the 9" ARB suffers from.

_____________________________________________________________

RUFF wrote:Beally STFU Your becoming a real PITA.

Product development supervisor for the Airlockers and compressors at that!ISUZUROVER wrote:Great info Dave. I'm sure you have your own ARB contacts, but daniel bongard (dbongard) on here is an ARB engineer...ashtrans wrote:Hi,

we make 4 mods to the 9" ARB RD99,

1) to fit to our new housing we have to machine the ARB on the non crown wheel side to pull the journal bearing in closer to the centre,

the other 3 mods are to improve the poor dog clutch engagement,

2) there are 12 small but strong disengagement springs, this is a huge force for the pneumatic piston to overcome on engagement, we remove 4.

3) the dog clutch only has 2.5mm engagement, we machine it to add 1mm more.

4) the internal air feed holes are 1mm, we open these up to 1.5mm.

not tested any of the above yet but hopefully it will improve the problems the 9" ARB suffers from.

Cheers

Slunnie

Discovery TD5, Landy IIa V8 ute.

Slunnie

Discovery TD5, Landy IIa V8 ute.

double post...

Last edited by ISUZUROVER on Mon Jun 08, 2009 1:30 am, edited 1 time in total.

_____________________________________________________________

RUFF wrote:Beally STFU Your becoming a real PITA.

Well at the very least you need to cut off the pan and weld a new one on...Slunnie wrote:Is this a full bolt up conversion with the Rover axle that requires no fabrication etc?

Thanks for posting the pics Dave, looks great!!!

Am I seeing it right, that you need to bolt the centre casing to the housing, then install the pinion???

_____________________________________________________________

RUFF wrote:Beally STFU Your becoming a real PITA.

Think so, Ben.ISUZUROVER wrote:Slunnie wrote:Is this a full bolt up conversion with the Rover axle that requires no fabrication etc?

Am I seeing it right, that you need to bolt the centre casing to the housing, then install the pinion???

Would make it REALLY hard to get to the other 2 or 3 nuts and bolts for the centre casing.

Yes it will need a new pan/sewercap fitting,ISUZUROVER wrote:Well at the very least you need to cut off the pan and weld a new one on...Slunnie wrote:Is this a full bolt up conversion with the Rover axle that requires no fabrication etc?

Thanks for posting the pics Dave, looks great!!!

Am I seeing it right, that you need to bolt the centre casing to the housing, then install the pinion???

the diff can be fitted complete with the pinion, we just didn't have one made up when we took the photos,

Dave

www.ashcroft-transmissions.co.uk

www.ashcroft-transmissions.co.uk

sorry, got that wrong, on this later design yes the diff casing will need fitting to the axle then the pinion fitting to the casingashtrans wrote:Yes it will need a new pan/sewercap fitting,ISUZUROVER wrote:Well at the very least you need to cut off the pan and weld a new one on...Slunnie wrote:Is this a full bolt up conversion with the Rover axle that requires no fabrication etc?

Thanks for posting the pics Dave, looks great!!!

Am I seeing it right, that you need to bolt the centre casing to the housing, then install the pinion???

the diff can be fitted complete with the pinion, we just didn't have one made up when we took the photos,

Dave

www.ashcroft-transmissions.co.uk

www.ashcroft-transmissions.co.uk

video of the first test run here :

video

we were very pleased, the ticking is the CV boot clip fouling, now fixed, the diff was silent and the oil feed to the pinion bearings worked well,

should be on a car for real testing very soon,

video

we were very pleased, the ticking is the CV boot clip fouling, now fixed, the diff was silent and the oil feed to the pinion bearings worked well,

should be on a car for real testing very soon,

Dave

www.ashcroft-transmissions.co.uk

www.ashcroft-transmissions.co.uk

Dave that is looking excellent!!!! Nice testing bench by the way!!!!

http://www.youtube.com/watch?v=nwaU_fqhk3I

http://www.youtube.com/watch?v=nwaU_fqhk3I

Cheers

Slunnie

Discovery TD5, Landy IIa V8 ute.

Slunnie

Discovery TD5, Landy IIa V8 ute.

Who is online

Users browsing this forum: No registered users and 2 guests