Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

wrap bars

Moderators: toaddog, TWISTY, V8Patrol, Moderators

wrap bars

i've read and read and read. i still can't get my head around how to design a wrap bar that won't introduce too much wheel hop.

i'm looking at doing a 2 seperate bar, heim jointed style like on the back of guts' hilux

any experts out there want to throw some suggestions around? and if you do say "aim for 75% anti squat", please tell me how to work the fawker out... i have only seen it worked out for 4 links etc.

i'm looking at doing a 2 seperate bar, heim jointed style like on the back of guts' hilux

any experts out there want to throw some suggestions around? and if you do say "aim for 75% anti squat", please tell me how to work the fawker out... i have only seen it worked out for 4 links etc.

Spit my last breath

At diff housing have about 8-10" seperation with lower bush about a 1/4 of total seperation below axle height. Lower mount is forward of upper mount by about 1.5-2".

At chassis end do a shackle style mount (4" seperation) with the upper pin attached to crossmember & lower attached to johnny joint style bush & trackbar frame. Have your lower bush about 10 deg forward of your chassis crossmember mount pivot point at ride height.

This is how I set mine up with trackbar being roughly 900-1000mm in length & if possible follow the same angle as the driveshaft & below to aid in protecting the driveshaft.

brooksy

At chassis end do a shackle style mount (4" seperation) with the upper pin attached to crossmember & lower attached to johnny joint style bush & trackbar frame. Have your lower bush about 10 deg forward of your chassis crossmember mount pivot point at ride height.

This is how I set mine up with trackbar being roughly 900-1000mm in length & if possible follow the same angle as the driveshaft & below to aid in protecting the driveshaft.

brooksy

C44F-Custom 4x4 Fabrications

0400 443 802

brooksy72@live.com.au

0400 443 802

brooksy72@live.com.au

not a fan of caltracs. the bottom link would be a rock finder in the terrain i drive (my spring plates are too low already), plus my understanding of it is they rely on the leaf itself to finalise the triangulation.alien wrote:or go for a caltracs/oztraks style setup (see my build thread in link below). Hasnt affected ground clearance for me and has stopped all wrap and tramp.

Brooksy, are you talking about a ladder bar, or having both seperate links terminate at the same point on the shackle?

Spit my last breath

i've seen that one, interesting concept, but my tub height will be too low for that i recon... ATM my axle has full travel to chassis (no bumpstops)RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Spit my last breath

That in itself is not a good start.bad_religion_au wrote:i've seen that one, interesting concept, but my tub height will be too low for that i recon... ATM my axle has full travel to chassis (no bumpstops)RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Bumpstops are essentail at 1. Stoping the diff housing contacting the frame at a great rate of knots, 2. Forcing articulation.

Have you looked at the torque fork design ?

http://4wheelonline.com/jeep/Categories ... ryId=25810

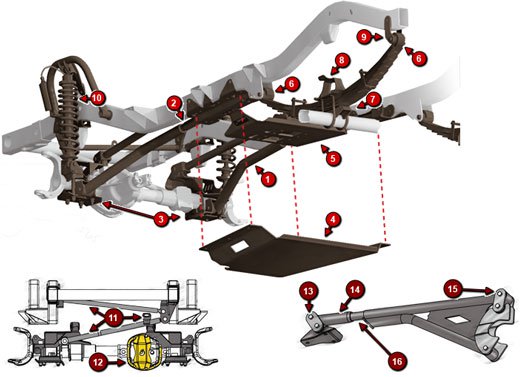

Supposed to work very very well (13, 14, 15 bit)

" If governments are involved in the covering up the knowledge of aliens, Then they are doing a much better job of it than they do of everything else "

trust me, the housing won't be hitting the frame at a great rate of knots unless it's dropped off a 20 story building... but i think i'd have more to worry aboutlove_mud wrote:That in itself is not a good start.bad_religion_au wrote:i've seen that one, interesting concept, but my tub height will be too low for that i recon... ATM my axle has full travel to chassis (no bumpstops)RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Bumpstops are essentail at 1. Stoping the diff housing contacting the frame at a great rate of knots, 2. Forcing articulation.

Have you looked at the torque fork design ?

http://4wheelonline.com/jeep/Categories ... ryId=25810

Supposed to work very very well (13, 14, 15 bit)

the torque fork is no different to a regular ladder bar setup, complete with their pro's and cons.

Spit my last breath

bad_religion_au wrote:

Brooksy, are you talking about a ladder bar, or having both seperate links terminate at the same point on the shackle?

Yes mate, a ladder bar that has 2 points at diff housing & comes together at a single point on the lower pin point of the shackle. This design has brought excellent ledge climbing ability & zero wheel hop.

brooksy

C44F-Custom 4x4 Fabrications

0400 443 802

brooksy72@live.com.au

0400 443 802

brooksy72@live.com.au

A torque fork is subtley but importantly very very different to a regular ladder bar. You obviously are looking for someone to validate your idea .. so why not say that instead of rubbishing any ideas that are put before you.bad_religion_au wrote:trust me, the housing won't be hitting the frame at a great rate of knots unless it's dropped off a 20 story building... but i think i'd have more to worry aboutlove_mud wrote:That in itself is not a good start.bad_religion_au wrote:i've seen that one, interesting concept, but my tub height will be too low for that i recon... ATM my axle has full travel to chassis (no bumpstops)RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Bumpstops are essentail at 1. Stoping the diff housing contacting the frame at a great rate of knots, 2. Forcing articulation.

Have you looked at the torque fork design ?

http://4wheelonline.com/jeep/Categories ... ryId=25810

Supposed to work very very well (13, 14, 15 bit)

. even with the low profile bumpstops in there, there will be nowhere near enough room between the tub and the housing to run one of those things (no B/L, gastank recessed under the floor, almost standard height springs).

the torque fork is no different to a regular ladder bar setup, complete with their pro's and cons.

It does not bind the leaves anywhere near as much as a regular ladder bar .. but I cant see why you would need one if your leaves are anywhere near as stiff as you say they are

" If governments are involved in the covering up the knowledge of aliens, Then they are doing a much better job of it than they do of everything else "

instead of getting all defensive over a product on the internet, explain to me how their "different".love_mud wrote:A torque fork is subtley but importantly very very different to a regular ladder bar. You obviously are looking for someone to validate your idea .. so why not say that instead of rubbishing any ideas that are put before you.bad_religion_au wrote:trust me, the housing won't be hitting the frame at a great rate of knots unless it's dropped off a 20 story building... but i think i'd have more to worry aboutlove_mud wrote:That in itself is not a good start.bad_religion_au wrote:i've seen that one, interesting concept, but my tub height will be too low for that i recon... ATM my axle has full travel to chassis (no bumpstops)RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Bumpstops are essentail at 1. Stoping the diff housing contacting the frame at a great rate of knots, 2. Forcing articulation.

Have you looked at the torque fork design ?

http://4wheelonline.com/jeep/Categories ... ryId=25810

Supposed to work very very well (13, 14, 15 bit)

. even with the low profile bumpstops in there, there will be nowhere near enough room between the tub and the housing to run one of those things (no B/L, gastank recessed under the floor, almost standard height springs).

the torque fork is no different to a regular ladder bar setup, complete with their pro's and cons.

It does not bind the leaves anywhere near as much as a regular ladder bar .. but I cant see why you would need one if your leaves are anywhere near as stiff as you say they are

2 points diff end, 1 point on a crossmember. check.

methods (shackles, slip joints, Heims, whatever) to allow the flex movement. check.

i was asking how to calculate the antisquat, not for ideas on what bar to go with. if i got the "torque fork", i would still need to know the best length/angles to mount it on.

i don't "need" validation of "my idea", it works flawlessly on heaps of rigs. i'm just trying to find out how to optimise it to fit my setup.

but considering you have such a profound understanding of my setup, considering you assume (wrongly) that i'm smashing the housing on the chassis, why don't you tell me what lengths to make it?

Spit my last breath

also on further research, that's a variation on a single bar design. which means your leafs are being used to complete the triangle. not good if you have soft leafs!RAY185 wrote:I bookmarked this a long time ago for interest.

http://www.jeepaholics.com/tech/bambar/

Spit my last breath

Who is online

Users browsing this forum: No registered users and 1 guest