Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

injector wiring

Moderator: -Scott-

injector wiring

just been rewiring a vp 3.8 commo loom and noticed that the + are joined together but so are all the triggers. why would you trigger all injectrs at the same time. how does that effect economy etc. any info appreciated thanks

Multi-point injection is rarely (if ever?) sequential fired.

At max power, injectors are typically running at about 80% duty cycle - on for 80% of the time. So there's little point trying to "time" the injection to the valve train.

Think about what's happening at idle. Using 600 rpm as a nice round number, that's 10 cycles per second, or each cylinder is firing 5 times per second, and the inlet valve would be open for perhaps 30% of that time. Worst case, the injected fuel is "stationary" for less than a fifth of a second - not a lot will happen to the fuel in that time.

At max power, injectors are typically running at about 80% duty cycle - on for 80% of the time. So there's little point trying to "time" the injection to the valve train.

Think about what's happening at idle. Using 600 rpm as a nice round number, that's 10 cycles per second, or each cylinder is firing 5 times per second, and the inlet valve would be open for perhaps 30% of that time. Worst case, the injected fuel is "stationary" for less than a fifth of a second - not a lot will happen to the fuel in that time.

Also allows an even spread of fuel throughout the intake charge, rather than dumped all at once.

This is good for less sophisticated cylinder head arrangements that do not have optimised swirl ("stratified charge").

Not quite as economical, but more fault tolerant as one dead injector simply makes the others open a bit longer (under closed loop conditions), whereas one faulty injector in sequential injection makes that cyl misfire.

This is good for less sophisticated cylinder head arrangements that do not have optimised swirl ("stratified charge").

Not quite as economical, but more fault tolerant as one dead injector simply makes the others open a bit longer (under closed loop conditions), whereas one faulty injector in sequential injection makes that cyl misfire.

George Carlin, an American Comedian said; "Think of how stupid the average person is, and realise that half of them are stupider than that".

More and more modern vehicles are utilising ssequential injection and have been since the mid 90's.

I can't see a reason for all of your switching circuits to be joined into one. I don't know of any manufacturer that does or would do this. Most manufactures will bank two or at tops three injectors together. One of the major reasons for this is the ECU circuits and the transitors that are used to switch the earth are not capable of switching enough current to power 6 injectors.

One faulty injector will still cause a missfire as the injectors direct fuel into the port, not the manifold. If the Vacuum form another cylinder was enough to attract fuel from a different cylinder then the whole swirl effect wouldn't happen!

You will usually find that banked injectors will be timed to suit cam profiles so they get close to optimum timing without being sequential.

At 80 degrees petrol will only stay vapourised for milliseconds, so even at 10 cycles per second it is imperitive to get the fuel into the cylinder rapdily to maximise efficiency. If all the injector are firing at the same time you will find the the cylinders that are receiving their fuel last will be far less efficient that those receiving it first.

Without knowing what ECU or software you're running i can't say wether or not all of this applies, but if it's the cenuine ecu i'd be wary of why it is this way.

Dan

I can't see a reason for all of your switching circuits to be joined into one. I don't know of any manufacturer that does or would do this. Most manufactures will bank two or at tops three injectors together. One of the major reasons for this is the ECU circuits and the transitors that are used to switch the earth are not capable of switching enough current to power 6 injectors.

One faulty injector will still cause a missfire as the injectors direct fuel into the port, not the manifold. If the Vacuum form another cylinder was enough to attract fuel from a different cylinder then the whole swirl effect wouldn't happen!

You will usually find that banked injectors will be timed to suit cam profiles so they get close to optimum timing without being sequential.

At 80 degrees petrol will only stay vapourised for milliseconds, so even at 10 cycles per second it is imperitive to get the fuel into the cylinder rapdily to maximise efficiency. If all the injector are firing at the same time you will find the the cylinders that are receiving their fuel last will be far less efficient that those receiving it first.

Without knowing what ECU or software you're running i can't say wether or not all of this applies, but if it's the cenuine ecu i'd be wary of why it is this way.

Dan

[quote="Uhhohh"]As far as an indecent proposal goes, I'd accept nothing less than $100,000 to tolerate buggery. Any less and it's just not worth the psychological trauma. [/quote]

Re: injector wiring

Ruffy wrote:More and more modern vehicles are utilising ssequential injection and have been since the mid 90's.

scratcher wrote:just been rewiring a vp 3.8 commo loom

You're talking the era of the intel 486, when a 100MHz clock speed was leading edge, and we're also talking Commodore, which wasn't leading edge.Wikipedia wrote:VP (1991–1993)

I wouldn't be concerned about the wiring - unless a factory wiring manual shows they shouldn't be common.

Re: injector wiring

I didn't say the particular engine in question was sequential.. I merely stated that it is common as oppossed to your comment about it being rare.-Scott- wrote:Ruffy wrote:More and more modern vehicles are utilising ssequential injection and have been since the mid 90's.scratcher wrote:just been rewiring a vp 3.8 commo loomYou're talking the era of the intel 486, when a 100MHz clock speed was leading edge, and we're also talking Commodore, which wasn't leading edge.Wikipedia wrote:VP (1991–1993)

I wouldn't be concerned about the wiring - unless a factory wiring manual shows they shouldn't be common.

The transistor in the computer are NOT designed to switch that amount of current..

SCOTT's advice is poor advice in my opinion. Seek profeesional advice?!

[quote="Uhhohh"]As far as an indecent proposal goes, I'd accept nothing less than $100,000 to tolerate buggery. Any less and it's just not worth the psychological trauma. [/quote]

Re: injector wiring

Fair enough.Ruffy wrote:I didn't say the particular engine in question was sequential.. I merely stated that it is common as oppossed to your comment about it being rare.

Good point. When I first read scratcher's post I presumed he was talking about the factory arrangement. If it's a backyard bodge job (and NOT the way the system was designed) then it could be an issue - depending on how the ECU works, and how the outputs have been commoned.Ruffy wrote:The transistor in the computer are NOT designed to switch that amount of current..

Never hurts to seek professional advice. But while we're all here, anybody got a wiring diagram for a VP commodore?Ruffy wrote:SCOTT's advice is poor advice in my opinion. Seek profeesional advice?!

Thinking back I think my old Jag V12 fired four sets of three and that was made back in 1976. But I think my Rover V8 (c. 1994) fires four injectors (one side of the vee) at a time, although I can't quite remember for certain as it's been a while since I had to look at it and maybe it's four sets of two.

I agree with Dan except that from what I can tell, VN-VR commodores really do batch fire the whole six injectors all at once! I am not a commodore fan but if you google batch vs sequential you will find that they are always talking about how the VN to VRs are batch injection (all six) and the VS on are sequential. I could be wrong because as I say, commodores are not my thing, but that is what I have heard people saying.

I think when they batch fire the six injectors at once, they do a tricky thing of injecting half the fuel twice for each cycle, so three would be getting their first half of fuel and the other three would be getting their second half, for any given injection event. I assume this would reduce the problem Dan mentioned of fuel not being vaporised any more, as well as keeping the fuel rail pressure more stable (another problem with batch injecting too many injectors at once).

Again, it could be wrong but someone could google it (my internet is capped until tomorrow grrr).

edit:

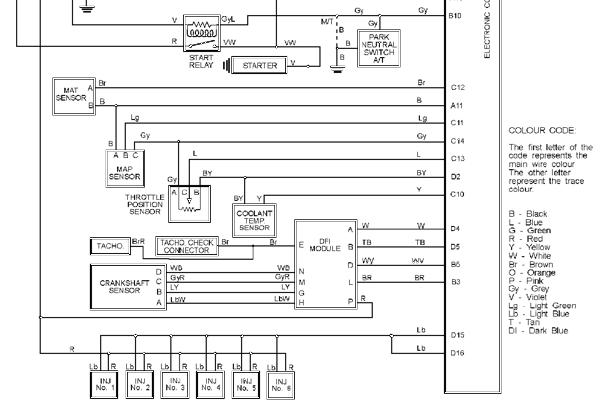

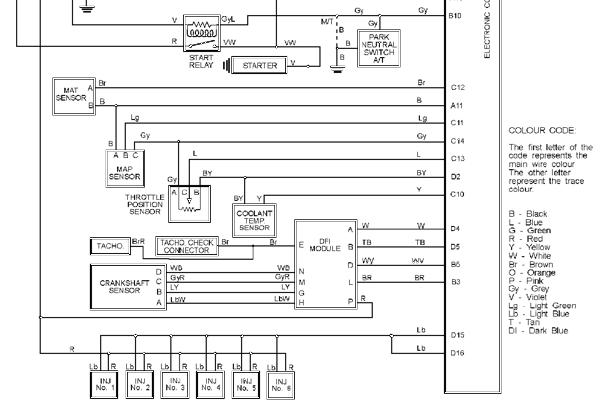

from http://www.memcals.com/rcc_info_wiring.html (download all of them and save them somewhere, I say to myself)...

This is VN:

VR has terminals 15 and 16 separate, going to three injectors each but I suspect they may still just be firing at the same time.

Sorry I can't find VP but I understand it to be the same as VN. So it seems that maybe Scott's advice was sound, not poor

I agree with Dan except that from what I can tell, VN-VR commodores really do batch fire the whole six injectors all at once! I am not a commodore fan but if you google batch vs sequential you will find that they are always talking about how the VN to VRs are batch injection (all six) and the VS on are sequential. I could be wrong because as I say, commodores are not my thing, but that is what I have heard people saying.

I think when they batch fire the six injectors at once, they do a tricky thing of injecting half the fuel twice for each cycle, so three would be getting their first half of fuel and the other three would be getting their second half, for any given injection event. I assume this would reduce the problem Dan mentioned of fuel not being vaporised any more, as well as keeping the fuel rail pressure more stable (another problem with batch injecting too many injectors at once).

Again, it could be wrong but someone could google it (my internet is capped until tomorrow grrr).

edit:

from http://www.memcals.com/rcc_info_wiring.html (download all of them and save them somewhere, I say to myself)...

This is VN:

VR has terminals 15 and 16 separate, going to three injectors each but I suspect they may still just be firing at the same time.

Sorry I can't find VP but I understand it to be the same as VN. So it seems that maybe Scott's advice was sound, not poor

This is not legal advice.

Well, thanks for the support, but the more I think about it the more I realised I haven't thought about it much.chimpboy wrote:So it seems that maybe Scott's advice was sound, not poor

Dan is right - although I didn't think a few hundred milliseconds is significant it must be enough to affect the injected fuel; why else would injected cars have a high idle when they're cold? If the atomisation can be severely disrupted at low temperatures then it can also be disrupted in the same period at higher temperatures.

I'm also not sure where/when I read the bit about sequential injection not being common - either I read bad information recently, or I haven't read new information for too long.

Either way, it looks like scratcher's wiring may be "normal" for a VP, and Dan and Chimp have both taught me more about fuel injection systems.

And I've identified a potential alternative to MegaSquirt, for if I ever get off my backside and play some more with my Sigma.

I used to work on Delco EFI systems (which is what is being discussed) and install them onto all sorts of engines (eg. old mechanical injection Porsches, Daihatsu 3 cylinder turbos, Cordias etc.)

Back when I was doing this work we would use looms out of Commodores (VN/VP?) or Nissan Pulsars (N13). They were all group fired injection ie. all the injectors wired in parallel. I believe the Commondoor V6 went sequential with the introduction of the "Ecotec" V6 - which is probably VR/VS era?

Sequential injection is the norm now, I doubt there would be any "group fired" injection vehicles being made??? (But I've been out of the industry for many years now.)

Back when I was doing this work we would use looms out of Commodores (VN/VP?) or Nissan Pulsars (N13). They were all group fired injection ie. all the injectors wired in parallel. I believe the Commondoor V6 went sequential with the introduction of the "Ecotec" V6 - which is probably VR/VS era?

Sequential injection is the norm now, I doubt there would be any "group fired" injection vehicles being made??? (But I've been out of the industry for many years now.)

David

thanks everyone for input to my subject.This engine is for a conversion job and Ive been going through it part by part just so I better understand it.The only sensor that was faulty was the AIR INTAKE SENSOR with measured 0 ohms but with a clean back to OK readings.It was covered in black soot, would it be better mounted in air intake like jap cars preventing heatsoak etc. Next time I will purchase VS VT if someone can help me around the security features. Happy New Year

Well, you got me thinking, and I found this forum which looks like it might be of use to you when that day comes:-Scott- wrote:And I've identified a potential alternative to MegaSquirt, for if I ever get off my backside and play some more with my Sigma.

http://www.delcohacking.net/forums/viewforum.php?f=3

I really wonder if it is worth playing with megasquirt or aftermarket ECUs when it seems to be possible to do whatever you like with very inexpensive bits and pieces from wrecked Holden donor vehicles.

I would really like to learn more about this stuff.

This is not legal advice.

Well, I had a Delco system off a N13 Pulsar 1.8l running a Jap import Daihatsu 1 litre 3 cylinder DOHC turbo engine. It ran it very well too- 75kW @ the wheels running only 6PSI. Daihatsu rated them stock at 80kW @ the flywheel running more boost IIRC.

The biggest issue is finding someone to do the programming, the wiring isn't too hard (get yourself a Nissan Pulsar N13 factory workshop manual as they explain everything and give excellent wiring diagrams.)

For turbo engines you just need to purchase a Delco 2Bar MAP sensor (it's off a Yank GM engine - most likely the supercharged Buick V6?) Remove the plug keyway and it will even plug straight onto the stock loom.

There should be stacks of info out there on how to do it. I did mine back in 1994. Finding looms from wreckers might be an issue these days?

The biggest issue is finding someone to do the programming, the wiring isn't too hard (get yourself a Nissan Pulsar N13 factory workshop manual as they explain everything and give excellent wiring diagrams.)

For turbo engines you just need to purchase a Delco 2Bar MAP sensor (it's off a Yank GM engine - most likely the supercharged Buick V6?) Remove the plug keyway and it will even plug straight onto the stock loom.

There should be stacks of info out there on how to do it. I did mine back in 1994. Finding looms from wreckers might be an issue these days?

David

Who is online

Users browsing this forum: No registered users and 1 guest