Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Borg Warner T98 gearbox to Series transfer questions

Moderator: Micka

Borg Warner T98 gearbox to Series transfer questions

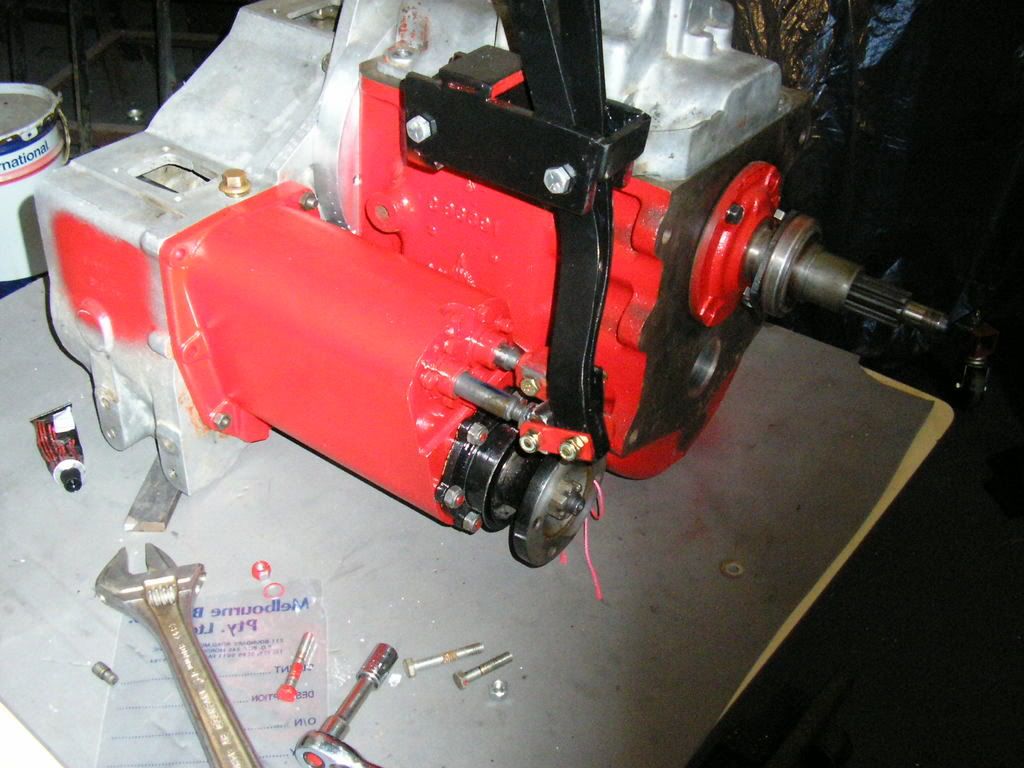

I have just brought Borg Warner T98 which came with an adaptor bolted to the back to mate it up to a series transfer case. The adaptor looks to be very well made and has been milled out of Aluminium. Its been secured to the back of the gearbox with countersunk cap screws.

The questions/s i have are: The transfercase input gear is a slightly sloppy fit on the output shaft splines . It looks like the Borg Warner output shaft splines are a bit narrower than those of the Rover gearbox. Should i get a transfer input gear cut specially for the purpose?

Also the output shaft is a bit shorter than the rover one and does not have a machined spot to take the small rear bearing that the rover mainshaft does. Will this affect strength? Is the Borg Warner output shaft bearing up to supporting the extra load?

Also, is the mating face of the transfer case up to supporting the additional weight of this gearbox. I'm not sure what engine i will use in front of the gearbox yet--will probably be a 3.5 if i can adapt it to the T98.

Thanks

Nick

Nick

The questions/s i have are: The transfercase input gear is a slightly sloppy fit on the output shaft splines . It looks like the Borg Warner output shaft splines are a bit narrower than those of the Rover gearbox. Should i get a transfer input gear cut specially for the purpose?

Also the output shaft is a bit shorter than the rover one and does not have a machined spot to take the small rear bearing that the rover mainshaft does. Will this affect strength? Is the Borg Warner output shaft bearing up to supporting the extra load?

Also, is the mating face of the transfer case up to supporting the additional weight of this gearbox. I'm not sure what engine i will use in front of the gearbox yet--will probably be a 3.5 if i can adapt it to the T98.

Thanks

Nick

Nick

The adaptor was probably made by myself or my mates, Arnold Taylor

or Mal Green. There is an additional large ball bearing in the adaptor to provide supprt for the mainshaft. If the mainshaft gear is sloppy on the shaft then either it and or the maishaft is worn. a new or used gear in good order can be modified be having the internal diameter ground out to provide a slidig fit over the mainshaft. Note that the outside diameter of the splined section of mainshaft has also been ground down, so if you fit a new mainshaft you will have to do that mod first.

Bill.

or Mal Green. There is an additional large ball bearing in the adaptor to provide supprt for the mainshaft. If the mainshaft gear is sloppy on the shaft then either it and or the maishaft is worn. a new or used gear in good order can be modified be having the internal diameter ground out to provide a slidig fit over the mainshaft. Note that the outside diameter of the splined section of mainshaft has also been ground down, so if you fit a new mainshaft you will have to do that mod first.

Bill.

Another couple of points are . The front hole of the T/case on our conversions used to be line bored to spigot securely over the machined diameter of the adaptor, therefore not relying on the two standard locating dowels. this provide much greater support. The front input shaft of the T98 was shortened and resplined so that a series Landrover bell housing would bolt on, allowing you to use any of the popular engine conversion kits available, including 3.5/4.4 Rover Leyland v8's.

Thanks very much for the reply Bill.

I brought the gearbox with adaptor from Fred Smith--it was on a car that came into his workshop, but was later wrecked for bits. I decided to go this way with a shorter gearbox to avoid moving the engine foward and having to put the longer stage 1 bonnet and grill in--i wanted to keep the early series look. I also have an aircompressor as well as a hydraulic pump which drives my winch, driving off the rear PTO outlet. I had hoped to use the PTO output on the T98, but its on the wrong side.

The gearbox does already have a bellhousing bolted to the front--not sure wether or not its to suit a 2.25 or 2.6. I'll sift through my collection of transfer case housings and see if it does indeed fit on the adaptor as you describe.

Not being completely familiar with Borg Warners, does the later T18 4x4 gearbox use the same 10 spline output shaft? I'm guessing that this would probably be easier to get hold of second hand. So the mainshaft as well as the well input gear have been slightly ground down to fit it sounds like? The gear supplied has a lot of backlash left and right but no play in any other direction.

I was planning to use a 3.5 with the Range Rover 10.5 in clutch. I would probably have to source a bellhousing from a manual F100 to suit the gearbox if i went this way. Or is the 9.5in clutch up to the additional power?

Thanks for the help

Nick

I brought the gearbox with adaptor from Fred Smith--it was on a car that came into his workshop, but was later wrecked for bits. I decided to go this way with a shorter gearbox to avoid moving the engine foward and having to put the longer stage 1 bonnet and grill in--i wanted to keep the early series look. I also have an aircompressor as well as a hydraulic pump which drives my winch, driving off the rear PTO outlet. I had hoped to use the PTO output on the T98, but its on the wrong side.

The gearbox does already have a bellhousing bolted to the front--not sure wether or not its to suit a 2.25 or 2.6. I'll sift through my collection of transfer case housings and see if it does indeed fit on the adaptor as you describe.

Not being completely familiar with Borg Warners, does the later T18 4x4 gearbox use the same 10 spline output shaft? I'm guessing that this would probably be easier to get hold of second hand. So the mainshaft as well as the well input gear have been slightly ground down to fit it sounds like? The gear supplied has a lot of backlash left and right but no play in any other direction.

I was planning to use a 3.5 with the Range Rover 10.5 in clutch. I would probably have to source a bellhousing from a manual F100 to suit the gearbox if i went this way. Or is the 9.5in clutch up to the additional power?

Thanks for the help

Nick

Hi nick, As far as I am aware T18's all have longer mainshafts with fine splines. There are still plenty of T98's lying around the older established truck wreckers. If you have trouble let me know as I still have a couple of spares in my collection. The front hole on standard Landrover T/cases is only rough cast and not concentric with the pto hole. Try to get the T/case housing that the gearbox came off from Fred. We usually drilled 2 extra bolt holes to attach the Rover bellhousing to the t98. If you have to change the bellhousing you should do the same for extra support.

We usually converted only International boxes because the have a longer input shaft that can be shortened and resplined to Rover pattern.

Ford ones are a bit short. The international gearboxes also have a different bellhousing bolt pattern to Fords, so the Ford bell housing wont fit.

The 9.5 inch clutch were adequate with engines up to 4.4 litres. The standard Rover pto will work, but you must bore out the front of the pto shaft to clear the large T98 mainshaft nut.

Regards Bill.

We usually converted only International boxes because the have a longer input shaft that can be shortened and resplined to Rover pattern.

Ford ones are a bit short. The international gearboxes also have a different bellhousing bolt pattern to Fords, so the Ford bell housing wont fit.

The 9.5 inch clutch were adequate with engines up to 4.4 litres. The standard Rover pto will work, but you must bore out the front of the pto shaft to clear the large T98 mainshaft nut.

Regards Bill.

because the last T98 conversion I did was over 15 years ago, my memory is a bit fuzzy so I forgot to mention that we machined the back face of the bell housing and counterbored it to centre over the T98 front bearing, so try to avoid having to change bell housings. The six cylinder bell housings have a little ear with a bolt hole where the starter motor clearance boss is . 4 cyl's don't.

bill.

bill.

IIRC, the later T18 is a stronger box as the mainshaft is slightler larger in diameter, as well as being a finer spline. (1.125" vs 1" ??)

The T98 was used behind big US 6's and 8's in the sixties, so any Rover engine wont tax it.

That granny first is bloody usefull. Used one for years in a Jeep J3000, and my old man had one in his Wagoneer, just remember your double de clutching needs to be ok for any downchanges back to first, its a big drop from second.

Rick.

The T98 was used behind big US 6's and 8's in the sixties, so any Rover engine wont tax it.

That granny first is bloody usefull. Used one for years in a Jeep J3000, and my old man had one in his Wagoneer, just remember your double de clutching needs to be ok for any downchanges back to first, its a big drop from second.

Rick.

300Tdi Defender 130 CC

Bill, maybe I'm thinking of the input shaft diameter, or maybe I'm just plain wrong  although I'm pretty sure the T18 had a larger input shaft at the least.

although I'm pretty sure the T18 had a larger input shaft at the least.

It's been a while since I played with Jeep stuff, and I didn't keep any T98's, although for some reason I've got one of the crappy T14a three speeds in the shed, complete with new shafts, bearings and synchros, as well as a Dana 20 T/case.

Cheers,

Rick.

It's been a while since I played with Jeep stuff, and I didn't keep any T98's, although for some reason I've got one of the crappy T14a three speeds in the shed, complete with new shafts, bearings and synchros, as well as a Dana 20 T/case.

Cheers,

Rick.

300Tdi Defender 130 CC

Rick, Yes the input shafts varied a bit depending on the brand of vehicle they were fitted to . we always cut down and resplined Internation ones for Landeys unless the vehicle was fitted with a Ford or Chrysler engine, in which case we would their bellhousings. These gearboxes are a bit old and agricultural these days and unless you have a big torquey engine to bridge the ratio gaps they can be a pain in the arse to drive.

Bill.

Bill.

Well i've now test fitted the gearbox to a spare transfer case that i had in the workshop and yes it will need to be bored out a small amount to be a sliding fit in the adaptor. Removed the Landrover bellhousing and confirmed that it had been milled to center on the T98 input bearing housing.

Ive now pulled the gearbox apart to check the internals and all looks ok--ist gear looks to be a bit worn and the bearings definantly need replacing--looks like water has gotten in somewhere along the way.

For the moment, all going ok, i will probably just fit it in behind the existing 2.25 until i can work out what engine i will mate it to. It looks to be only slightly longer than the LR gearbox so hopefullt will fit in the same position ok. I'm guessing that from reading the earlier posts, that if i do want to use it with another type of bellhousing--ie International, that i will need to use an original input shaft as this one has been shortened to suit an LR. Internationals are the best source for used T98's?

I did read in a post a while ago that you mentioned about a Ford Dseries Gearbox that you had fitted to one of your projects. Is this a T98 or another type?

Thanks again for the advice

Nick

Ive now pulled the gearbox apart to check the internals and all looks ok--ist gear looks to be a bit worn and the bearings definantly need replacing--looks like water has gotten in somewhere along the way.

For the moment, all going ok, i will probably just fit it in behind the existing 2.25 until i can work out what engine i will mate it to. It looks to be only slightly longer than the LR gearbox so hopefullt will fit in the same position ok. I'm guessing that from reading the earlier posts, that if i do want to use it with another type of bellhousing--ie International, that i will need to use an original input shaft as this one has been shortened to suit an LR. Internationals are the best source for used T98's?

I did read in a post a while ago that you mentioned about a Ford Dseries Gearbox that you had fitted to one of your projects. Is this a T98 or another type?

Thanks again for the advice

Nick

Hi Nick, The Ford T98's have a different case to the Inter ones, although the internals are interchangeable. The Inter boxes do not have external bolt holes to attach to their bellhousing but Fords do. The gearbox I have in my shorty hybrid was from a D series ford truck but it has a rare aluminium case . the basic box for D series was cast iron T98. the other option were 6 and 8 speed ZF I think. Earlier Ford F 250's and 350's had the choice of T98's or New Process 435's. so there are a few choices out there in wrecking yards.

Bill.

Bill.

Yep Ben,

the Jeep ones I used to use were about 6.3:1 1st, and up to aprox. 3:1 2nd, etc.

Basically a three speed with a granny/crawler gear.

The T18 used in later (70's/80's) Jeeps used a 4:1 first, but you could fit the 6.3:1 first out of a T98.

It is quite a heavy change, with slow synchro performance on the top three gears. The up change is OK, but you are quicker to double shuffle going down the gears.

It's also a big, heavy box.

Rick.

the Jeep ones I used to use were about 6.3:1 1st, and up to aprox. 3:1 2nd, etc.

Basically a three speed with a granny/crawler gear.

The T18 used in later (70's/80's) Jeeps used a 4:1 first, but you could fit the 6.3:1 first out of a T98.

It is quite a heavy change, with slow synchro performance on the top three gears. The up change is OK, but you are quicker to double shuffle going down the gears.

It's also a big, heavy box.

Rick.

300Tdi Defender 130 CC

Ben,would you believe I still have the 2.25 L petrol engine in mine.

There definately are other engines with more power and torque. And there are engines that go longer distances before they start to lose compression and burn oil. But I have yet to find another engine that is so utterly dependable, tolerant and abusable.

Rick 130, I agree with you about the slow synchro's, but I fixed mine by filing more radial grooves in the brass baulk rings, this breaks down the oil film better and lets the synchro bite harder.

The aluminium T98 in my truck is 45 pounds lighter than the iron box. Also it has a 6.55:1 first gear. the top three ratios are identical at 3.09:1,

1.68:1 and 1:1.

The overall length of the complete gearbox/t/case assembly is 36mm more than the standard series Landy. So you will have to either modify propshafts or move engine forward.

Bill.

There definately are other engines with more power and torque. And there are engines that go longer distances before they start to lose compression and burn oil. But I have yet to find another engine that is so utterly dependable, tolerant and abusable.

Rick 130, I agree with you about the slow synchro's, but I fixed mine by filing more radial grooves in the brass baulk rings, this breaks down the oil film better and lets the synchro bite harder.

The aluminium T98 in my truck is 45 pounds lighter than the iron box. Also it has a 6.55:1 first gear. the top three ratios are identical at 3.09:1,

1.68:1 and 1:1.

The overall length of the complete gearbox/t/case assembly is 36mm more than the standard series Landy. So you will have to either modify propshafts or move engine forward.

Bill.

Bill, I know what you mean about the dependability of the 2.25 P. My old one (that had been abused for many years by the military) kept going for years after I bought it, and still kept going after the top compression ring on no 3 piston shattered into 7 pieces. Although the 2.25D I have nw doesn't have the best reputation, so far I have found it just as dependable and reliable as the petrols.

How hard would it be to mate a T-98 to an LT230 T-case? I know Sam mated a T-98 to the T-case from an LT95. I don't suppose there is a 5-speed equivalent of the T-98???

How hard would it be to mate a T-98 to an LT230 T-case? I know Sam mated a T-98 to the T-case from an LT95. I don't suppose there is a 5-speed equivalent of the T-98???

_____________________________________________________________

RUFF wrote:Beally STFU Your becoming a real PITA.

I don't suppose there is a 5-speed equivalent of the T-98???

Ben, I think the closest modern equivalent is the NV4500. Not sure about availability on this side of the Pacific.

For a brief run down and specs go here

Rick

300Tdi Defender 130 CC

Ben, the T98's are a bit difficult to adapt to the Lt230 because the mainshafts are not long enough to reach right through the t/case mainsheft gear to attach the mainshaft retaining nut. A gearbox I have adapted to the LT230 is the similar New Process 435 available concurrently in Ford F series and Dodge trucks. The front of the mainshaft on these is supported by a tapered roller bearing and does not depend on the mainshaft nut to stop the shaft from floating forward in the gearbox. You still need a spud shaft (from marks adaptors)and thick adaptor plate, so the transmission assembly is about 6 inches longer than the series/T98 assembly.

A far better alternative to the NV4500 if you can afford it is to put a Ranger two speed "27 %Torque Splitter" overdrive on the front of a NP435.

You can pick up 435's for a couple of hundred dollars, but the torque splitter is about $ 3200 ready to bolt on. This is still cheaper than a new

NV4500, you get a lower 1st gear (6.69:1 verses 5.6:1)and 7 more very usable gears besides. Yes I know, I can't afford it either, but I am working on a very similar thing by cutting a Rangerover LT95 gearbox in half and using third and top gears reversed, which will give a 34% split.

The casing is already welded back together, I have modified the old mainshaft to become the input shaft, cut down and machined the layshaft

modified the rangey input gear to become a short internally splined output gear . A short splined coupling shaft will connect this to a similarly modified T98 input gear. It is not quite as complex as it sounds, but I have to find room in the drive line to accommodate the additional 7.5 inches of transmission length.

Bill.

A far better alternative to the NV4500 if you can afford it is to put a Ranger two speed "27 %Torque Splitter" overdrive on the front of a NP435.

You can pick up 435's for a couple of hundred dollars, but the torque splitter is about $ 3200 ready to bolt on. This is still cheaper than a new

NV4500, you get a lower 1st gear (6.69:1 verses 5.6:1)and 7 more very usable gears besides. Yes I know, I can't afford it either, but I am working on a very similar thing by cutting a Rangerover LT95 gearbox in half and using third and top gears reversed, which will give a 34% split.

The casing is already welded back together, I have modified the old mainshaft to become the input shaft, cut down and machined the layshaft

modified the rangey input gear to become a short internally splined output gear . A short splined coupling shaft will connect this to a similarly modified T98 input gear. It is not quite as complex as it sounds, but I have to find room in the drive line to accommodate the additional 7.5 inches of transmission length.

Bill.

Re: Borg Warner T98 gearbox to Series transfer questions

Hi Nick any updates ? pics ?Woop wrote:I have just brought Borg Warner T98 which came with an adaptor bolted to the back to mate it up to a series transfer case. The adaptor looks to be very well made and has been milled out of Aluminium. Its been secured to the back of the gearbox with countersunk cap screws.

The questions/s i have are: The transfercase input gear is a slightly sloppy fit on the output shaft splines . It looks like the Borg Warner output shaft splines are a bit narrower than those of the Rover gearbox. Should i get a transfer input gear cut specially for the purpose?

Also the output shaft is a bit shorter than the rover one and does not have a machined spot to take the small rear bearing that the rover mainshaft does. Will this affect strength? Is the Borg Warner output shaft bearing up to supporting the extra load?

Also, is the mating face of the transfer case up to supporting the additional weight of this gearbox. I'm not sure what engine i will use in front of the gearbox yet--will probably be a 3.5 if i can adapt it to the T98.

Thanks

Nick

Nick

Looking to do the same with a Ford NP435.

Bill - are you still around ? any advice? looking for cash work ?

Cheers

Simon

Thanks

I reckon i've got it sussed now anyway. adapting the series case should be an easy job - found this..... (jeep but same shit)

http://isitcrunchy.com/swap.htm

I'll be doing the same, except with a 1" thick piece of 220mm (diam) alloy billit. Instead of line boaring the series case (for alignment), I'll be looking to use machined shank bolts - and reaming a couple of the mounting holes to size. The whole setup will only be around 1" longer than the series drivetrain. So hopefully I can still use the standard driveshafts ?

Just got to sort out the bellhousing and clutch mods.....

anyone got a six cylinder s111 bell they want to offload for beer ?

http://isitcrunchy.com/swap.htm

I'll be doing the same, except with a 1" thick piece of 220mm (diam) alloy billit. Instead of line boaring the series case (for alignment), I'll be looking to use machined shank bolts - and reaming a couple of the mounting holes to size. The whole setup will only be around 1" longer than the series drivetrain. So hopefully I can still use the standard driveshafts ?

Just got to sort out the bellhousing and clutch mods.....

anyone got a six cylinder s111 bell they want to offload for beer ?

well .......... got the shaft and case adapter done.

Had the shaft annealed then machined then case hardened.

$50 annealing

$200 machining

$50 case hardening to 1mm

EDIT - from my thread on lr4x4 http://forums.lr4x4.com/index.php?showtopic=7598

well at least it's done - would've just spent the money on beer 'n crap anyway.

Had the shaft annealed then machined then case hardened.

$50 annealing

$200 machining

$50 case hardening to 1mm

EDIT - from my thread on lr4x4 http://forums.lr4x4.com/index.php?showtopic=7598

Did you know that the short mainshaft International and some F259 Np 435's had almost the correct spline for the landrover transfer case gear. you just have to bore ID of the gear out a little and grind theID of the shaft for a perfect fit. You don't get the tail bearing, but you can fit an additional bearing in that adaptor plate to compensate.

Bill.

well at least it's done - would've just spent the money on beer 'n crap anyway.

Who is online

Users browsing this forum: No registered users and 0 guests