Page 5 of 12

Posted: Thu Mar 05, 2009 4:28 pm

by matt.mcinnes

Picked up 60 more tubes today I can't believe the first 50 have all gone. Last of the first run of 100 end caps are all allocated too.

So now onward with the Bolt on's, first up machining the tubes to interlock together. After the long weekend

Just so you have some idea of how small the second generation are here is a pick with a standard size business card

Once the tubes are interlocked then time for a little of Awill4x4's magic before drilling and taping the holes for the end caps.

Posted: Thu Mar 05, 2009 8:55 pm

by brad-chevlux

PGS 4WD wrote:brad-chevlux wrote:matt.mcinnes wrote:azzad wrote:What I meant was if the petrol exhaust is hotter the intake air through the turbo will pick up more heat.

Therefore requiring more IC capacity.

Dazza

Most of the heat in the compressed air actually comes from the compressing itself not the exhaust heat. When you compress the air a by product is heat the more compression/boost more heat.

Heat transfer through the turbo from the exhausts is not the issue.

we could get picky here. The amount of heat doesn't, the temperature does.

the temp rises because you have X heat in Y space befor the compression. after the compression you have X heat Z space, (Z=1/4Y)

because the heat is in a smaller space the temp rises.

this is why we compress A/C gas to remove heat from it, and then let it expand so it will remove heat from air.

Compressing A/C gas heats the gas but forms the gas to a liquid, the job of the condensor is to cool the A/C gas, the controlled vaporization of liquid into the evaporator is what takes the heat from the air.

I wouldn't suggest leaning against the high pressure (liquid)side of a running A/C system.

Matt is correct the heat is due to the compression, it's how a diesel works, high compression causes heat, diesel is injected into the hot air mixture, hence the need for glow plugs and why worn out low comp diesel engines are hard to start.

Another example is the supercharger, no exhaust heat enters the supercharger yet they all produce high air outlet temps. They don't call EATON superchargers Heatons for nothing.

Plenums don't store boost, the throttle blade is before the plenum so there is vacuum in the plenum at idle and cruise. A plenum creates higher cylinder pressures as the mass of air, once accellerated continues to charge into the cylinder at increased levels, it does when under boost give each intake runner a high speed column of air to feed from.

Joel

the amount of heat still doesn't change. the temperature raises.

and yes you basicly said what i did about the A/C using different words.

we compress the A/C gas to raise its temp, the greater the temp difference the more heat will be transfered. We then vaporize the the now liquid, wich is also the point in the system that it goes from high pressure to low pressure.

Anyway my point was compressing air doesn't make heat, it raises the temperature. (large amount of heat in a small area)

Posted: Thu Mar 05, 2009 9:47 pm

by marin

brad-chevlux wrote:SNIP

Anyway my point was compressing air doesn't make heat, it raises the temperature. (large amount of heat in a small area)

???????????? wtf??????????? isn't that 1 and the same thing?

If not, explain to me the difference please.

marin

Posted: Fri Mar 06, 2009 12:44 am

by matt.mcinnes

If you want to discuss in detail why air heats up when compressed please start a thread for it.

Tks

Oh and yes compressing air does make heat as it involves friction.

Posted: Fri Mar 06, 2009 8:23 am

by matt.mcinnes

One ready to collect Tuesday evening

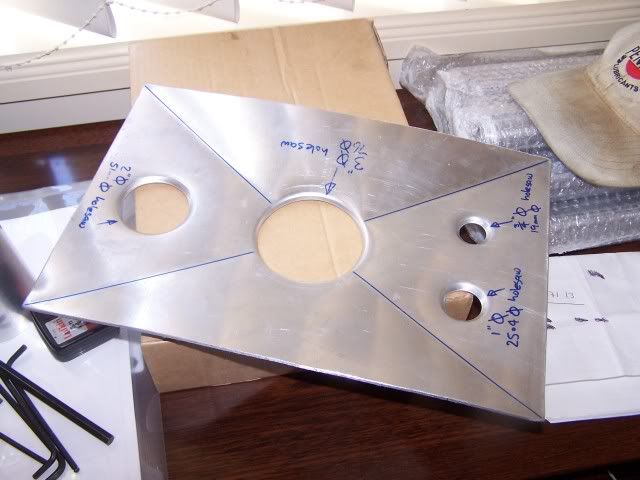

While I was prepping the above I thought I might as well do the 1st of the bolt on ones too.

End caps to suit are yet to be done.

As Awill4x4 would say it's Miller time

Posted: Fri Mar 06, 2009 9:12 am

by lolergram

Looks good, Could you please give a measure of the 'ready made' as it is?

On first estimate it looks good to fit up to a WRX motor (forester xt 09) top mount allocation without too much alteration to the air ram tunnel area. Here is a pic of the TMIC original.

(x3 on air compression = heat, a good example is the air in a compressor storage tank is warm/hot just after fill, but when you open the bleed valve, you should see water condensation around the valve, sometimes freezing even because air is reducing in density)

-Chris

Thanks Matt

Posted: Fri Mar 06, 2009 1:45 pm

by matt.mcinnes

Bolt on as is 378 x 196 x 75 without end caps and fabrication.

Posted: Fri Mar 06, 2009 2:29 pm

by bogged

matt.mcinnes wrote:As Awill4x4 would say it's Miller time

I knew he was strange, but drinking warm yank softdrink???

Posted: Fri Mar 06, 2009 2:39 pm

by Gwagensteve

Miller welding equipment?

http://www.millerwelds.com/

Steve.

Posted: Fri Mar 06, 2009 3:05 pm

by lolergram

matt.mcinnes wrote:Bolt on as is 378 x 196 x 75 without end caps and fabrication.

Cheers Matt.

Posted: Fri Mar 06, 2009 3:49 pm

by matt.mcinnes

Posted: Fri Mar 06, 2009 4:52 pm

by lolergram

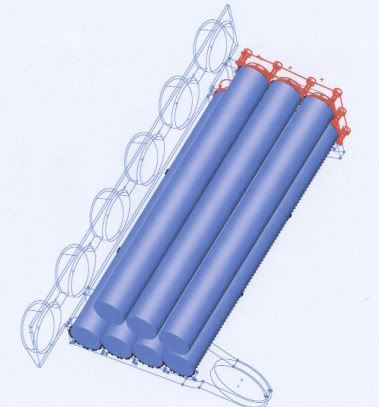

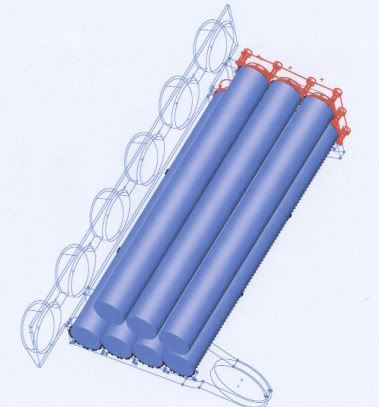

The more I think about it, the more I love this design.

Air will travel to the point of lowest pressure and will exit at an even pressure...

Is there any gap between the rod holders?

Posted: Fri Mar 06, 2009 5:14 pm

by matt.mcinnes

No the tubes are machined to interlock.

Posted: Mon Mar 09, 2009 3:48 pm

by matt.mcinnes

Posted: Mon Mar 09, 2009 6:15 pm

by 80's_delirious

matt.mcinnes wrote:

Did this monster cause a few headaches??

Looks good

Posted: Mon Mar 09, 2009 6:33 pm

by benhl

Looks super trick! Good work again Boys...

Posted: Mon Mar 09, 2009 7:17 pm

by mickyd555

cost on the 4 core patrol ones yet?

Posted: Mon Mar 09, 2009 7:26 pm

by lolergram

80's_delirious wrote:matt.mcinnes wrote:

Did this monster cause a few headaches??

Looks good

Looks like its the monster's 'forte' har har harrr

Posted: Mon Mar 09, 2009 10:23 pm

by matt.mcinnes

mickyd555 wrote:cost on the 4 core patrol ones yet?

Page before has an estimate Awill4x4 has the first bolt on to work with, were keeping it simple so all been well final price for a bolt on 2-3 weeks away, it just depending on a project that may take priority for an M3 E46 BMW in the USA. The model I posted last week fitted and if we get the business this will be an urgent job.

Now that I will need head ache tablets for

Posted: Fri Mar 13, 2009 4:56 pm

by matt.mcinnes

Well Dzltec's tomorrow will be pressure tested.

This will be done a pair of cores at a time that way if any of the O- rings have been nipped on installation it will be easier to find. But not expecting any

I also have the headache of the E46 M3 1000hp BMW

they are sending the blow off valve, cores, one T/B rubber and meth/water injector system that we are integrating into it.

Posted: Sat Mar 14, 2009 6:49 pm

by matt.mcinnes

DZLTEC's

Dry weight 18kg

Pressure tested and ready for delivery Monday afternoon, now where did I put that bill

Also ordered the end plates for a 2 core unit for a HighLux

DJ, I need to look at doing an 80 series too you up for been a test subject?

Posted: Sat Mar 21, 2009 12:11 pm

by matt.mcinnes

Posted: Sun Mar 22, 2009 11:20 am

by Z()LTAN

Let me know when u got a 1HZ mock up done matt, ill be real keen!

Oh and size dosnt realy bother me... I want/need the cooling!

Posted: Sun Mar 22, 2009 8:57 pm

by marin

Finally got to give my cooler a little bit of a test 2day, I have the 35's on the car (cooper st's), still got 4.1 gears, 13psi boost on the standard DTS turbo with a 3 litre GU airbox, had the back of the car loaded up and a loaded up trailer (6x4) on the back.

Test hill, 4th gear, 100km/h and wasn't accelerating much more (plus I ran outa hill) and was holding 450C pretty steady.

marin

Posted: Sat Mar 28, 2009 11:45 am

by matt.mcinnes

The hole press for transition to the flange was perfect.

The first of the new end caps are in with another 100 to come

Next weekend should see us weld the first one up and from there

Busmans will be the first one up followed by BASSYK and benhl's GU's

Posted: Sat Mar 28, 2009 9:29 pm

by eliteforce32

can you pm me a confirmed price on the complete minus fittings generic bolt on cooler for a gu ..... as benhl is in brissie too so may save on freight

.... if price is right

Posted: Sun Mar 29, 2009 1:18 pm

by matt.mcinnes

matt.mcinnes wrote:Kit form without cores $670 with cores $1070.

Water splitters $100 a pair.

Until me and Awill4x4 have fabricated the bolt on one I can't give an exact price. I'm going to do a run of 5 so Awill4x4 can replicate a lot of the pieces.

Fabrication is not so much about materials but labour. So until Awill4x4 puts one together I prefer to sit on the fence a little. I would expect to be no more than $1700 including splitters. But hoping for less.

Heat exchanger such as Marin's $400 approx, Telstar Rad new with custom end tanks.

Davies Craig pump I would search the net or give Bursons, Repco, ect a call.

So if you go with hose tails and no bling, I would expect to have one installed and working if you fitted it yourself for no more than $2500.

As you can see the costs soon add up.

Well all the pieces are in place so I will stick my neck out and say $1500 with cores (while available as I have limited stock of cores) for the intercooler without cores $1100.

As above you will need a heat exchanger and pump along with the plumbing.

Posted: Sun Mar 29, 2009 11:00 pm

by matt.mcinnes

A little peek at what I'm working on in the mean time.

Posted: Wed Apr 01, 2009 4:29 pm

by matt.mcinnes

Well our intercoolers are getting bigger an bigger

Here is the latest

Now for a test subject

Posted: Wed Apr 01, 2009 7:10 pm

by PJ.zook

lol im hoping thats an april fools joke