Page 8 of 12

Posted: Mon May 11, 2009 9:45 am

by matt.mcinnes

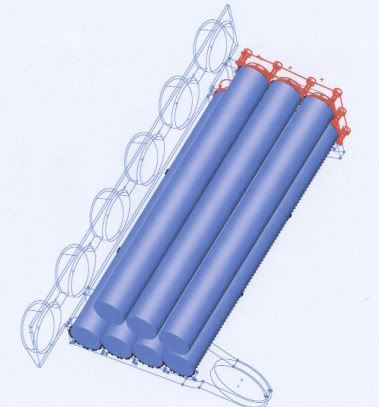

End caps are in

Plus a few spares

Posted: Thu May 14, 2009 6:03 pm

by matt.mcinnes

Posted: Thu May 14, 2009 8:32 pm

by Z()LTAN

niice

~!!!

Posted: Fri May 15, 2009 1:26 am

by marin

I think we may have to pull mine off again and make it shiny, and then clear coat it!!!!!

Or maybe just anodised red

marin

Posted: Fri May 15, 2009 8:29 am

by neilpatrol

Matt that is bloody good work, my tig work is good but wow not that good, lol. Can't wait to send you my manifold mate.

Posted: Fri May 15, 2009 8:35 am

by matt.mcinnes

neilpatrol wrote:Matt that is bloody good work, my tig work is good but wow not that good, lol. Can't wait to send you my manifold mate.

I can take no credit for Awill4x4's welding he's the genius here. The welding is as always top notch. The fabrication here is a work of art too it goes from one end at the intake 3" round, to completely flat at the other end, not to mention the inverted curve to the top of the intercooler. Awill4x4 managed this out on one sheet of Ali.

Posted: Fri May 15, 2009 8:40 am

by neilpatrol

Ok i take it back Awill4x4 beautiful work mate

Posted: Fri May 15, 2009 8:42 am

by matt.mcinnes

Posted: Fri May 15, 2009 8:45 am

by neilpatrol

Keep up the good work, you guys do some awesome work.

Posted: Fri May 15, 2009 9:57 am

by benhl

I want shiney too now!!

Posted: Fri May 15, 2009 10:43 am

by matt.mcinnes

benhl wrote:I want shiney too now!!

$100 extra

Posted: Sun May 17, 2009 8:47 pm

by 300WinMag

Hi Matt,

Q1; Are any of your clients using your IC's for touring on rough roads?

Q2; I know you have good vibration mounting but I was wondering how the manifolds are handling the extra weight?

Q3; Also do you mount them with standard gasket or something that insulates the manifold from cylinder head heat?

Regards Andrew.

Posted: Mon May 18, 2009 3:08 am

by marin

300WinMag wrote:Hi Matt,

Q1; Are any of your clients using your IC's for touring on rough roads?

Q2; I know you have good vibration mounting but I was wondering how the manifolds are handling the extra weight?

Q3; Also do you mount them with standard gasket or something that insulates the manifold from cylinder head heat?

Regards Andrew.

1. ?

2. My manifold seems to be handling the weight fine, but as a just in case, as with matt's, I have a supporting rod that I'm about to put in that will go from the block to the angled side of the cooler... i'll post a pic when it's on.

3. Mine is mounted with a standard gasket, but we have discussed getting something made to help stop heat soak from the block to the manifold/cooler

If you know anything about these types of spacers, i.e. material etc, let me know/post up here.

marin

Posted: Mon May 18, 2009 12:29 pm

by love ke70

how much of the heat in the manifold from the block actually gets absorbed by the air though? theres alot of air moving through there very quickly, with not alot of surface area, i dont think you would be picking much heat up there...

Posted: Mon May 18, 2009 1:17 pm

by marin

Who knows, but might be worth pricing them at least, if not too much may look into getting a few made (after I pay for the damage on matt's car that I may or may not have caused at Vic Winch LOL)

marin

Posted: Mon May 18, 2009 2:20 pm

by matt.mcinnes

marin wrote:Who knows, but might be worth pricing them at least, if not too much may look into getting a few made (after I pay for the damage on matt's car that I may or may not have caused at Vic Winch LOL)

marin

Might

I have seen the video evidence

Here is me reduced to the push bike while you repair mine when your home. Good job the new job is only 2.6k's from home rather than the 20k's to my old place.

Looking at a insulating options but not a great concern for the bolt on.

Marin's has a much larger contact area so it maybe more of an issue there but again the gains would only be small I think.

Just a note on Marin's I had it on the dyno last week and tested air intake temps at 1 and 6 simultaneously, there is a 10C difference.

The cold water enters the intercooler at No6's end, we have always tested and measured at No1. Easy fix just have to run 2 of the feeds from 1 to 6 and 2 from 6 to 1. This would balance things out bringing No1 down 5C and No 6 up 5C.

The bolt on version will not have this issue as all the air has to pass through the narrower intake.

So Marin's intake temps would be on a 32C day with corrected flow 40C only 8C above ambient and flat lined at that. I was always a little disappointed we did not closer to ambient and now why.

Now I'm a very happy chap

Posted: Mon May 18, 2009 2:51 pm

by bogged

matt.mcinnes wrote:marin wrote:Who knows, but might be worth pricing them at least, if not too much may look into getting a few made (after I pay for the damage on matt's car that I may or may not have caused at Vic Winch LOL)

marin

Might

I have seen the video evidence

Here is me reduced to the push bike while you repair mine when your home. Good job the new job is only 2.6k's from home rather than the 20k's to my old place.

Looking at a insulating options but not a great concern for the bolt on.

Marin's has a much larger contact area so it maybe more of an issue there but again the gains would only be small I think.

Just a note on Marin's I had it on the dyno last week and tested air intake temps at 1 and 6 simultaneously, there is a 10C difference.

The cold water enters the intercooler at No6's end, we have always tested and measured at No1. Easy fix just have to run 2 of the feeds from 1 to 6 and 2 from 6 to 1. This would balance things out bringing No1 down 5C and No 6 up 5C.

The bolt on version will not have this issue as all the air has to pass through the narrower intake.

So Marin's intake temps would be on a 32C day with corrected flow 40C only 8C above ambient and flat lined at that. I was always a little disappointed we did not closer to ambient and now why.

Now I'm a very happy chap

u need to put one on my car to see how they go with Garrets

Posted: Mon May 18, 2009 3:04 pm

by matt.mcinnes

bogged wrote:U need to put one on my car to see how they go with Garrets

Nah were just going to bolt my Turbo on Marin's Mav and see how a GT3082R spools up, if it's to high in the rev range or laggie, then Marin will switch to a GT28 of some sort, my guess would be a 76R. But it will be interesting as my 40 works well and is limited to 5000rpm. Both are around the same cc.

Once ha can afford the new turbo manifold

he has a few expenses a the moment

Posted: Mon May 18, 2009 4:03 pm

by marin

matt.mcinnes wrote:bogged wrote:U need to put one on my car to see how they go with Garrets

Nah were just going to bolt my Turbo on Marin's Mav and see how a GT3082R spools up, if it's to high in the rev range or laggie, then Marin will switch to a GT28 of some sort, my guess would be a 76R. But it will be interesting as my 40 works well and is limited to 5000rpm. Both are around the same cc.

Once ha can afford the new turbo manifold

he has a few expenses a the moment

That's after the injector pump as well.... no point bolting on all this stuff if it aint gona get the fuel to make it go!

marin

Posted: Mon May 18, 2009 4:09 pm

by love ke70

put gas on it and save your money on the pump work...

Posted: Mon May 18, 2009 6:42 pm

by 300WinMag

With Marins set up he should have enough room to move, to put bigger pump and gas on it.

The reason I asked about vibrations and rough roads is that my IC has had issues with cracking after long trips on rough roads, ie 4000km + .

The water flow in my IC was designed to give even cooling accross all the cylinders as it is divided accross the two primary cores and then loops around via end tanks to flow back through the secondary cores thus evening out heat transfer.

As for heatsoke from head, this mainly occurs at low revs or at the lights, I have put some heat insulation around my IC to test this theroy and it has dropped my stand still temp from 110F to 100F +/- 2F at 32deg C ambient. Still like to try a different gasket aswell.

I wish I had someone of Awills skill with a tig to do my Fab though, it has cracked again after a wknd trip in NT. I will have to use my limited skill to repair and strengthen it myself.

Cann't wait to see your results Marin and also Andy's monster, may have to get one myself.

Posted: Tue May 19, 2009 9:58 am

by matt.mcinnes

The heat exchanges are extruded, so no welds or joints to fail, in fact personally the only way I can see these cores failing is due to catastrophic failure: (tree in engine bay)

The heat exchanger cores themselves mount on 2 O Rings, one at each end, so have no actual contact with the intercooler housing, this will also dampen any vibration.

The quality of welding and design of the housing will determine the durability of the intercooler. Hence our 10mm end plates, plenty to weld to.

I designed the first one for my 40 as I wanted something extremely robust running water to air as there was nothing I had confidence in on the market. I’m sure you know how hard I play.

As you say long journeys with large K’s corrugated roads are the most arduous of environments.

Posted: Thu May 21, 2009 10:18 pm

by matt.mcinnes

Posted: Fri May 22, 2009 4:31 pm

by 300WinMag

That is just rediculessly good work. Dare I ask how much $$$.

Posted: Fri May 22, 2009 6:03 pm

by matt.mcinnes

300WinMag wrote:That is just rediculessly good work. Dare I ask how much $$$.

The price for a 1 off custom M3 BMW is like the BMW M3 if you have to ask you can't afford

Posted: Fri May 22, 2009 9:09 pm

by GUte

Dya reckon it'll fit?

Al.

Posted: Fri May 22, 2009 9:12 pm

by matt.mcinnes

Yes all easy the car is in the USA we made it in Metric like the BMW

If it does not fit it's there fault for been imperial

Posted: Fri May 22, 2009 9:15 pm

by awill4x4

There's been some serious effort by both of us on this one hasn't there Matt? At present it's winging it's way to the USA.

Regards Andrew.

Posted: Fri May 22, 2009 9:19 pm

by GUte

Good stuff fella's.

Al.

Posted: Fri May 22, 2009 9:20 pm

by GUte

Will you be getting any feedback once fitted etc. figures?

Al.

I have seen the video evidence

Here is me reduced to the push bike while you repair mine when your home. Good job the new job is only 2.6k's from home rather than the 20k's to my old place.

he has a few expenses a the moment