SuperiorEngineering wrote:I would love to see a finite element analysis to show us how these arms are stronger than a "properly" manufactured radius arm ?

What is a properly manufactured arm?

How i see it, the arm will only flex as far as the bushes will allow, which has been used as an example for a super flex arm.

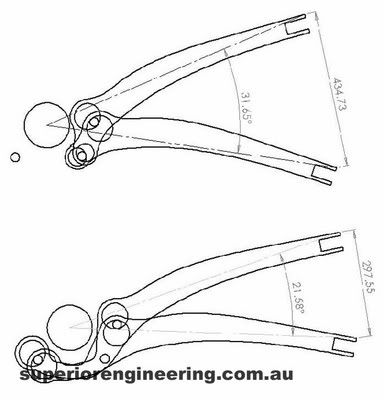

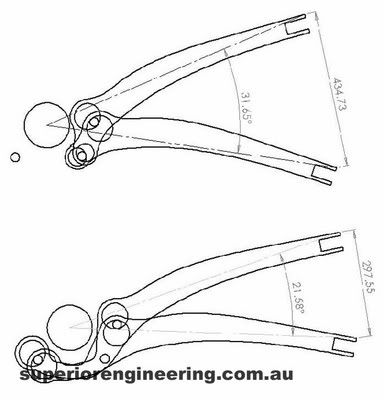

Above pic shows by relocating the bushes closer together (also using a smaller diameter one as well) greatly improves arc you can make before "bushes" max out.

This is the main claim for the super flex arm.

Note: I am only going off what info i could find on how the super flex arm works. If i am wrong by all means correct me. This is just how i see what info i have read. Just interested and tryng to understand.

So mostly, movement of arm comes back to bush size, how much they compress and where they are positioned.

If your bump stops, stop the diff at the bushes limit of up travell, and the shock length is right for bushes limit of down travell, the arm is not really doing much flexing at all.

The FAT ams aren't fabricated for flexing as really every pivot point is the same old nissan position.

I fabricate track frames to carry 60 to 70 ton, majority of its mild steel.

My point, engineered right, cant see a problem with fabricated arms.

The main problem i see with these arms is the extended section to reach arond to front bush of the diff, its weak point.

Not putting down suprerior here at all, imo they have the best arm available.

But its only one arm, on one side that dose all the work.

Not really even distribution, balance.

Nothing is perfect when i comes to road and off road i guess.

Super flex arms aren't perfect either, it cant be when flex is dedicated to one arm?

They are not a complete billet arm, it still has welded sections.