Page 2 of 3

Posted: Wed Jan 13, 2010 10:27 am

by nicbeer

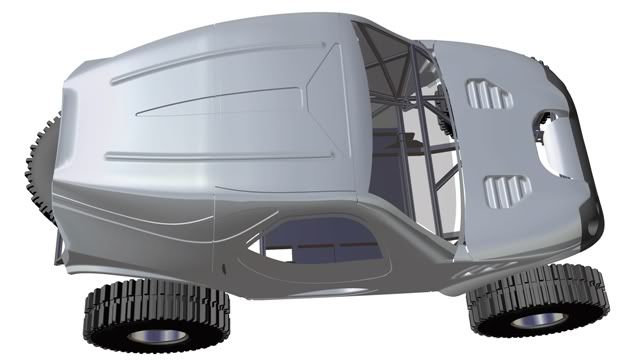

wicked drafts.

almost has the silhouette of a datsun 240z

whats the car in the corner of the workshop? another buggy?

Taifun TAT

Posted: Thu Jan 14, 2010 9:48 pm

by TaifunOffroad

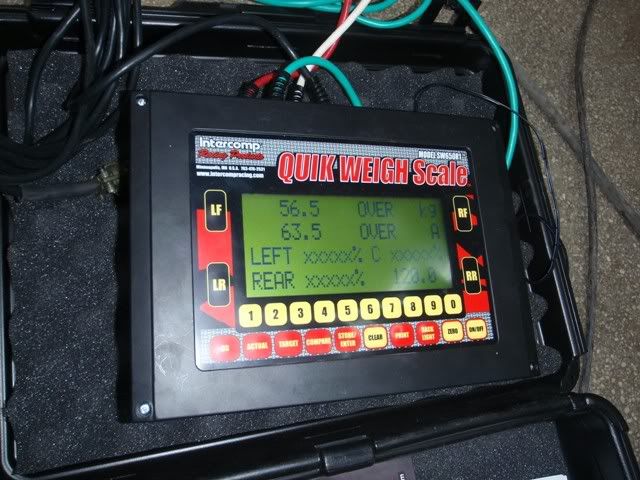

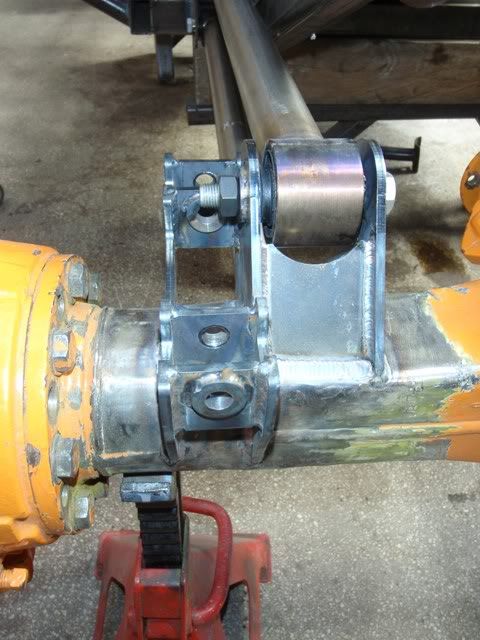

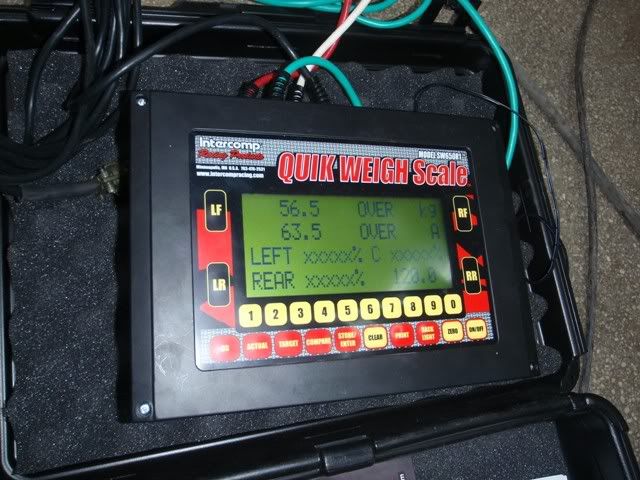

We just weighted the structures. With the windscreen (and a lot of Bondo…) it hit the scale at 249.5 kg. A little bit more than we expected, but it’s not bad.

The axles (Toyota HDJ80) weights: 120 kg front, 135 kg rear, complete axles.

So, we are still on the target of 1350 kg.

Thanks for looking

Posted: Fri Jan 15, 2010 6:39 pm

by Gabriel

nicbeer wrote:wicked drafts.

almost has the silhouette of a datsun 240z

whats the car in the corner of the workshop? another buggy?

Well, this is my good ol' Nissan Y60. The one in my signature. It was good enough, at the date when we build it. Even now is good enough, but what we are building now is "the next generation".

thanks,

Posted: Fri Jan 15, 2010 8:25 pm

by uninformed

excellent workmanship, very very cool

care to discuss your suspension set up? As values? front axle roll axis? rear axle roll aixs? vehicle roll axis? etc

cheers,

Serg

Posted: Fri Jan 15, 2010 11:43 pm

by atari4x4

WOW, this thing is going to take EPIC to another level.

the fabrication & attention to detail is outstanding. to use flat patch to find out the corner weights etc shows how much thought has been put into it, i can't wait to see the finished product!

Taifun TAT

Posted: Tue Jan 19, 2010 11:10 pm

by TaifunOffroad

Posted: Wed Jan 20, 2010 6:31 am

by PJ.zook

Fantastic fab work there, keep it up!

Posted: Thu Jan 21, 2010 2:10 pm

by Guy

Gabriel wrote:MightyMouse wrote:Welding looks like TIG not MIG to my very inexperienced eye.....

I would have expected TIG with the mention of alloy steel earlier on.

Hello,

Sorry, it was our "internet - IT" guy who made the confusions... Of course it is TIG, with a specific alloy wire. But, you know, the IT and building cars do not have a close relationship...;-)))

Thanks for looking,

Gabi

PS: the Dracula staff...nice ;-))

'

Nice work .. very quick, and neat (and neat workshop as well ) Great to see some cool non US based stuff as well.

Regarding IT and Cars .. you will find plenty of computer nerds on here who know their way around a workshop\building cars

Taifun - TAT

Posted: Wed Jan 27, 2010 5:29 am

by TaifunOffroad

Taifun - TAT

Posted: Tue Feb 16, 2010 4:29 pm

by TaifunOffroad

Posted: Wed Feb 17, 2010 9:42 am

by ludacris

Very nice work. Any chance of getting some photos of the other rigs in the shed.

Cris

Posted: Wed Feb 17, 2010 9:49 am

by tas80

Loving this thread!!!

Keep the pics coming.

Taifun TAT

Posted: Mon Feb 22, 2010 6:23 pm

by TaifunOffroad

Taifun TAT

Posted: Sat Feb 27, 2010 4:00 am

by TaifunOffroad

Posted: Sat Feb 27, 2010 6:07 pm

by granborismo

this is too awesome

Taifun TAT

Posted: Wed Mar 10, 2010 4:22 pm

by TaifunOffroad

Posted: Thu Mar 11, 2010 8:00 am

by bru21

I might point out that the steering wheel is on the wrong side!

Ha, ha!

Awesome build, well done!

Taifun TAT

Posted: Fri Mar 12, 2010 12:44 am

by TaifunOffroad

Re: Taifun TAT

Posted: Fri Mar 12, 2010 9:35 pm

by fester2au

TaifunOffroad wrote:And the fuel deposits. In the TAT the capacity is 106.8 liters and in the C2C is 113.2 liters Our target was to have 100 liters plus, so its not bad…;-) The “canister” is stainless steel, and the welds will be done with a technique calls “pillow”, which means that you have to use a second argon gas bottle to fill the canister while you weld. That way the welds are strong, no strange interior garbage, etc. After that we will use a “substance” for stainless steel welding, in order to clean the burns.

Thanks,

Ah, so you are going to purge weld (pillow) the tank and then pickle/passivate (clean the burn) the weld after to neutralise the heat affected zone.

Love the welds and those neat corner gussets everywhere.

Posted: Sat Mar 13, 2010 6:16 pm

by GRPABT1

Nice welds, is it the pressure that makes it bead on the outside like that or just the nature of the weld?

Posted: Sat Mar 13, 2010 6:23 pm

by Gabriel

GRPABT1 wrote:Nice welds, is it the pressure that makes it bead on the outside like that or just the nature of the weld?

No, its just the weld. We finished the fuel deposit welding, btw.

thanks,

Taifun TAT

Posted: Sat Mar 20, 2010 10:47 pm

by TaifunOffroad

Posted: Sun Mar 21, 2010 5:41 pm

by falco80

Damn, this is good to watch! You guys have excellent fabbing skills....those welds are beautiful. Looking forward to more updates!

Posted: Mon Mar 22, 2010 8:12 pm

by opindown

ummmmmm........ HORN!

Top work guys keep it up.

Taifun TAT

Posted: Sat Apr 17, 2010 3:45 am

by TaifunOffroad

Re: Taifun TAT

Posted: Sat Apr 17, 2010 10:01 am

by RUFF

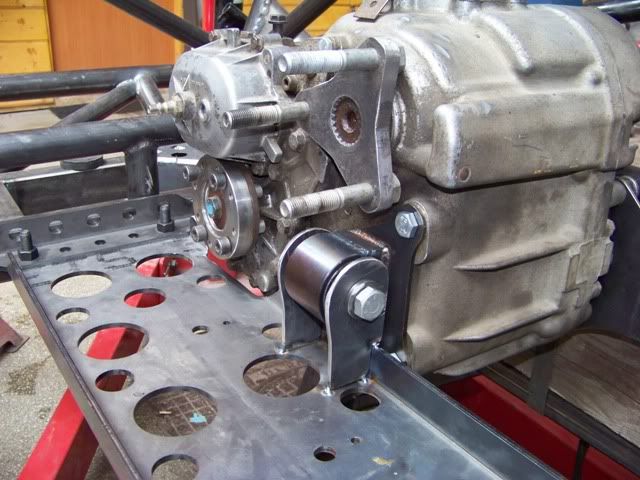

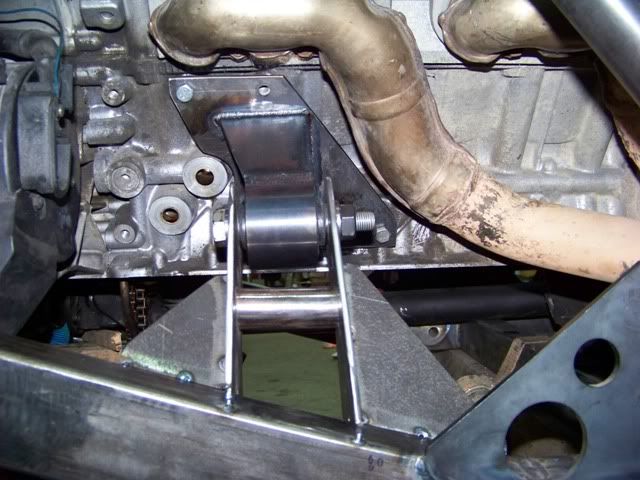

TaifunOffroad wrote:

You have the gearstick mounted to the Gearbox and the Chassie? Will this not cause problems when the gearbox moves around on its rubber mounts?

Re: Taifun TAT

Posted: Sun Apr 18, 2010 7:49 pm

by 80's_delirious

RUFF wrote:TaifunOffroad wrote:

You have the gearstick mounted to the Gearbox and the Chassie? Will this not cause problems when the gearbox moves around on its rubber mounts?

looks odd. It looks like it has a pivot where it mounts to the box, and looks like a rubber sleeve where it mounts in the tube on the chassis, so there would be some flex there ??

Posted: Mon Apr 19, 2010 5:03 pm

by Gabriel

Thanks, we know that. We mount it in order to check if everything is ok with the gears. We will add a silent block, a soft one.

thanks for looking,

Posted: Mon Apr 19, 2010 6:34 pm

by RUFF

Gabriel wrote:Thanks, we know that. We mount it in order to check if everything is ok with the gears. We will add a silent block, a soft one.

thanks for looking,

Thanks. Keep up the great work.

Posted: Mon Apr 19, 2010 7:23 pm

by was a 75

Wow.