Page 2 of 2

Posted: Fri May 27, 2005 11:14 am

by hotgemini

Maddog;

I think you've misunderstood me, do the front legs run all the way to the floor (as they should) or do they do the american jeepers 'trick' of bolting onto the a pillar inside of the door jam near the dash? If its the former then ignore what I said earlier. I wasn't referring to the brackets for the fold-down windscreen.

Posted: Fri May 27, 2005 11:22 am

by `maddog

hotgemini wrote:Maddog;

I think you've misunderstood me, do the front legs run all the way to the floor (as they should) or do they do the american jeepers 'trick' of bolting onto the a pillar inside of the door jam near the dash? If its the former then ignore what I said earlier. I wasn't referring to the brackets for the fold-down windscreen.

It's a full 6 point cage, meaning the front legs go all the way to the floor (through the back of the dash)

Re: Cages for winch events

Posted: Fri May 27, 2005 11:42 am

by Tiny

`maddog wrote:sierrajim wrote:1. The rules say that back braces must be straight. Many vehicles that are competing do not have straight back braces, does this mean this is allowable or are these people just getting away with it?

2. Cages must be made from DOM tube. I have seen some trucks with square tube back braces. Can you get square DOM?

3. Can external cages be used on their own or would you require a 6 point internal cage as well?

Here's my understanding after reading CCDA and CAMS manuals on the subject.

1. Backstays must be straight, no bends allowed, no exceptions (unless you want to homogulate your own cage <read: good luck>)

2. DOM == Drawn Over Mandrel (also known as CDS, Cold Drawn Steel). There's no square DOM

3. My understanding is that it has to be internal, unless you're cab-chassis, which has its own section of rules on cages.

My inderstanding of cab chassis id a 4 point internal, 4 pinot on rear (read tray) and conected together through cab

Re: Cages for winch events

Posted: Fri May 27, 2005 11:55 am

by hotgemini

`maddog wrote:2. DOM == Drawn Over Mandrel (also known as CDS, Cold Drawn Steel).

Thats simply out and out wrong, DOM is hot rolled from flat sheet (or by piercing bar), electric resistance welded mild stell which is then drawn over a mandrel under fairly significant pressure to press out the seam thereby reducing the stress raiser.

CDS is cold-drawn seamless, its forced through a round die under simply massive pressure and never has a seam created.

Two completely different processes for making a steel tube. Because of the significant cold working in making CDS it has a much better and more consistent grain structure than anything hot rolled giving it better mechanical properties, furthermore it doesn't have the seam to act as a stress raiser.

Re: Cages for winch events

Posted: Fri May 27, 2005 12:16 pm

by `maddog

hotgemini wrote:`maddog wrote:2. DOM == Drawn Over Mandrel (also known as CDS, Cold Drawn Steel).

Thats simply out and out wrong, DOM is hot rolled from flat sheet (or by piercing bar), electric resistance welded mild stell which is then drawn over a mandrel under fairly significant pressure to press out the seam thereby reducing the stress raiser.

CDS is cold-drawn seamless, its forced through a round die under simply massive pressure and never has a seam created.

Two completely different processes for making a steel tube. Because of the significant cold working in making CDS it has a much better and more consistent grain structure than anything hot rolled giving it better mechanical properties, furthermore it doesn't have the seam to act as a stress raiser.

I was under the impression neither DOM or CDS had seams?

Posted: Fri May 27, 2005 12:29 pm

by hotgemini

DOM has a welded seam which is mostly pressed into invisibility but it is still there.

Posted: Fri May 27, 2005 12:29 pm

by Tiny

Posted: Fri May 27, 2005 12:51 pm

by `maddog

Interesting.

The type of steel was probably the least important part of what I was trying to convey. I was commenting mostly on the design.

Posted: Fri May 27, 2005 12:54 pm

by Tiny

`maddog wrote:Interesting.

The type of steel was probably the least important part of what I was trying to convey. I was commenting mostly on the design.

I understand, the type of steel is for the better part irrelevent in the strenght of a given design. but in sayiing that the strengh of the design is relitive to the grade and strenght of the material used

Me just thinking maybe a SAF cage.....it would cost more than the car but be unbreakable

Posted: Fri May 27, 2005 11:10 pm

by Bartso

guys i have a question i am in a GQ cab with bugger all room i plan on running a exo a internal is going to take up to much room (as i am tall)

lets say internally i have the normal internal cage but insted of going to the floor behind the seats i go out the back of the cab and join up with the hoop bar for the exo will this be ok to run in comps that require a internal cage?

Posted: Sat May 28, 2005 8:15 am

by Tiny

Bartso wrote:guys i have a question i am in a GQ cab with bugger all room i plan on running a exo a internal is going to take up to much room (as i am tall)

lets say internally i have the normal internal cage but insted of going to the floor behind the seats i go out the back of the cab and join up with the hoop bar for the exo will this be ok to run in comps that require a internal cage?

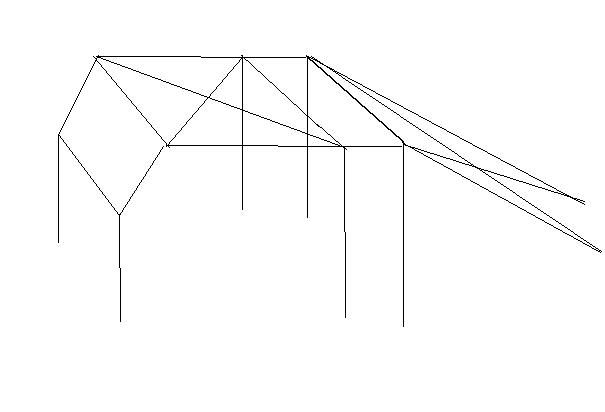

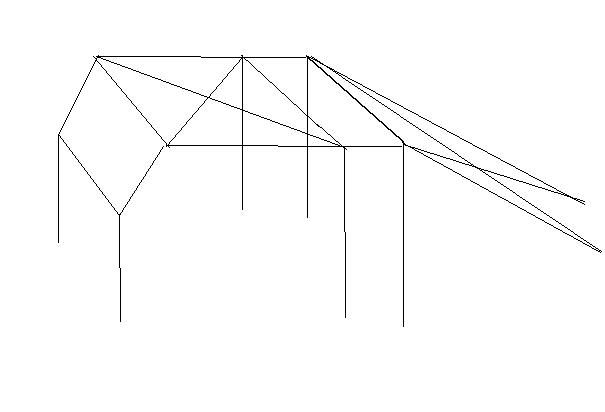

you are required to run a 4 point in the cab joined to the rear "4 point" through the cab.......joins may be removable

ie

Posted: Sat May 28, 2005 10:01 pm

by ludacris

We fabricate Internal rollcages now with fast turn arounds of around two days. Prices average around $1500 depending if you want extras and if you want us to get it approved.

LudaCris