Page 3 of 4

Posted: Mon Apr 13, 2009 6:04 pm

by guzzla

The main reason for a flip arm is best explained as follows:

If you were to c`arry a wheel barrow full of bricks with the handles held up high, you'd have great difficulty trying to steer it. Likewise, because the barrow's handles are up so high, hitting bumps would cause considersble jarring.

On the other hand, if were were to push the same barrow with your arms at full length and the barrow's handles near paralell with the ground, steering is heaps easier and the wheel floeats over bumps much easier.

This is the main advantage of a flip arm, as it puts the arms in a more neutral postion. Now when you nudge the front wheels up to a large rock step, the wheels don't have to overcome being forced backwards anywhere near as much and make climbing larger obstacles much eaier.

Additional benefits include clearing the steering linkages and getting your castor 100%.

The down side is if you change your suspension height in any way, you have to have the mounts modified to suit the new castor setting.

If you are 100% satisfied with the height your 4WD (3-6in over), a fliparm along with a high steer kit and panhard rod mount extention will make your 4WD handle 1000 time better than it does now.

Posted: Mon Apr 13, 2009 7:35 pm

by killalux

Is the high steer and panhard mount extension required to do this?

And don't know if its possible but instead of using high steer to get the steer arm flat, could i drop pitman arm be used? I was thinking along the lines of an IFS hilux arm, from memory they are around 2" more drop than the 80 series?

Posted: Mon Apr 13, 2009 9:43 pm

by crankycruiser

g35me wrote:crankycruiser wrote:yer mate.. i have a j mac one as well.. the arm on mine is slightly higher but basically the same.. last time i talked to John, he wasnt selling them unless he actually installed them.. but thats not to say that things havent changed...

It looks like a 10min install, did he give you any reason?

yer doesnt take much.. cant remember the reason now.. was like 4 or 5 years ago since i did mine!

Posted: Mon Apr 13, 2009 9:45 pm

by crankycruiser

killalux wrote:Is the high steer and panhard mount extension required to do this?

And don't know if its possible but instead of using high steer to get the steer arm flat, could i drop pitman arm be used? I was thinking along the lines of an IFS hilux arm, from memory they are around 2" more drop than the 80 series?

no u dont need to move ur panhard to do this, but remember if u put a drop pitman arm on then u will also need to move the panhard to suit

Posted: Mon Apr 13, 2009 11:39 pm

by 65Mog

crankycruiser wrote:g35me wrote:crankycruiser wrote:yer mate.. i have a j mac one as well.. the arm on mine is slightly higher but basically the same.. last time i talked to John, he wasnt selling them unless he actually installed them.. but thats not to say that things havent changed...

It looks like a 10min install, did he give you any reason?

yer doesnt take much.. cant remember the reason now.. was like 4 or 5 years ago since i did mine!

I'd say it has to do with each one being custom made, they're not an off the shelf item, each one is made to suit the suspension lift and the offset of the wheel and tyre combo.

And it's not a 10 minute install! If they're fitted and the panhard isn't adjusted to suit the result is a vehicle that will change lanes when it hits even a modest dip or bump in the road.

Posted: Tue Apr 14, 2009 8:04 am

by guzzla

killalux wrote:Is the high steer and panhard mount extension required to do this?

And don't know if its possible but instead of using high steer to get the steer arm flat, could i drop pitman arm be used? I was thinking along the lines of an IFS hilux arm, from memory they are around 2" more drop than the 80 series?

It's not necessary but if certainly completes the over all driving package as all the steering geometry is returned to normal. Doing the panhard rod will also greatly reduce the wheels scrubbing on the inner wheel arches under full suspension compression. The hi steer component takes a heap of stress of the ball joints so the last longer.

Posted: Tue Apr 14, 2009 9:00 am

by 1MadEngineer

guzzla wrote:The main reason for a flip arm is best explained as follows:

If you were to c`arry a wheel barrow full of bricks with the handles held up high, you'd have great difficulty trying to steer it. Likewise, because the barrow's handles are up so high, hitting bumps would cause considersble jarring.

On the other hand, if were were to push the same barrow with your arms at full length and the barrow's handles near paralell with the ground, steering is heaps easier and the wheel floeats over bumps much easier.

This is the main advantage of a flip arm, as it puts the arms in a more neutral postion. Now when you nudge the front wheels up to a large rock step, the wheels don't have to overcome being forced backwards anywhere near as much and make climbing larger obstacles much eaier.

Additional benefits include clearing the steering linkages and getting your castor 100%.

The down side is if you change your suspension height in any way, you have to have the mounts modified to suit the new castor setting.

If you are 100% satisfied with the height your 4WD (3-6in over), a fliparm along with a high steer kit and panhard rod mount extention will make your 4WD handle 1000 time better than it does now.

this scenario ONLY applies to moving the mounting on the chassis not on the diff = change in IC. You are explaing drop boxes NOT flipped arms.

RE-read your example - now keep your hands/arms at the exact same position. (same IC pivot point). 2 different wheelbarrows same wheel size different handle position = same forces. SAME tire + same length + same pivot = SAME!

Posted: Tue Apr 14, 2009 6:12 pm

by Graham Stirling

Thanks everyone, I've sat back and watched the discussion an it's given me the confidence that flipping the arms is worth it.

MUD80D mentioned that flipped arms were less likely to bend. I recon between that, the extra clearence and the castor correction it's worth doing.

65Mog's pictures are ideal, cheers. G

Posted: Tue Apr 14, 2009 6:51 pm

by killalux

1MadEngineer wrote:guzzla wrote:The main reason for a flip arm is best explained as follows:

If you were to c`arry a wheel barrow full of bricks with the handles held up high, you'd have great difficulty trying to steer it. Likewise, because the barrow's handles are up so high, hitting bumps would cause considersble jarring.

On the other hand, if were were to push the same barrow with your arms at full length and the barrow's handles near paralell with the ground, steering is heaps easier and the wheel floeats over bumps much easier.

This is the main advantage of a flip arm, as it puts the arms in a more neutral postion. Now when you nudge the front wheels up to a large rock step, the wheels don't have to overcome being forced backwards anywhere near as much and make climbing larger obstacles much eaier.

Additional benefits include clearing the steering linkages and getting your castor 100%.

The down side is if you change your suspension height in any way, you have to have the mounts modified to suit the new castor setting.

If you are 100% satisfied with the height your 4WD (3-6in over), a fliparm along with a high steer kit and panhard rod mount extention will make your 4WD handle 1000 time better than it does now.

this scenario ONLY applies to moving the mounting on the chassis not on the diff = change in IC. You are explaing drop boxes NOT flipped arms.

RE-read your example - now keep your hands/arms at the exact same position. (same IC pivot point). 2 different wheelbarrows same wheel size different handle position = same forces. SAME tire + same length + same pivot = SAME!

I think one thing point that you are missing that i don't think anyone has mentioned, is that by flipping the arms on top of the diff you are actually moving the diff mounting points higher.

ie, with the arms below the diff the mounting point (diff end) is below the centre line of the diff housing, but when you flip the arms and make new diff end mounts, The new mounting point is now above the centre line of the diff housing.

As i se it it doesn't matter if you drop the chassis end (drop boxes) or raise the diff end (flip arms) it should have the same result right?? You are still making the arms more parralel with the ground.

Posted: Tue Apr 14, 2009 6:56 pm

by killalux

did a quick example, yellow line being the new mounting position, red being roughly the old mounting position

Posted: Tue Apr 14, 2009 7:30 pm

by 80's_delirious

1MadEngineer wrote:guzzla wrote:The main reason for a flip arm is best explained as follows:

If you were to c`arry a wheel barrow full of bricks with the handles held up high, you'd have great difficulty trying to steer it. Likewise, because the barrow's handles are up so high, hitting bumps would cause considersble jarring.

On the other hand, if were were to push the same barrow with your arms at full length and the barrow's handles near paralell with the ground, steering is heaps easier and the wheel floeats over bumps much easier.

This is the main advantage of a flip arm, as it puts the arms in a more neutral postion. Now when you nudge the front wheels up to a large rock step, the wheels don't have to overcome being forced backwards anywhere near as much and make climbing larger obstacles much eaier.

Additional benefits include clearing the steering linkages and getting your castor 100%.

The down side is if you change your suspension height in any way, you have to have the mounts modified to suit the new castor setting.

If you are 100% satisfied with the height your 4WD (3-6in over), a fliparm along with a high steer kit and panhard rod mount extention will make your 4WD handle 1000 time better than it does now.

this scenario ONLY applies to moving the mounting on the chassis not on the diff = change in IC. You are explaing drop boxes NOT flipped arms.

RE-read your example - now keep your hands/arms at the exact same position. (same IC pivot point). 2 different wheelbarrows same wheel size different handle position = same forces. SAME tire + same length + same pivot = SAME!

I thought the wheelbarrow analogy was a good one.

1MadEngineer wrote:different handle position = same forces.

I cant figure out how this is correct, I even got my sons lego out to experiment

Got a link to the pirate calculator??

Posted: Tue Apr 14, 2009 8:04 pm

by TheBigBoy

So are you cutting and rewelding the lower control arm mounting points higher? If not Im with MAD. Apart from clearance, the points are the same. I can imagine there is very minimal extra travel (maybe a bit more in the bushs). I can imagine if there was flex in your arms themselves then it would ride better and roll over things a bit better "logs etc" wanting to flex up but...

Lifting your panhard rod diff mount and a high steer will make it like a stock responce 1 to drive. im doing that myself.

The picture of the 80 series with flipped arms is running a xlink in the pic which is giving people false veiws.

Posted: Tue Apr 14, 2009 8:14 pm

by TheBigBoy

Ah, sorry just read your post killalux. Then yes i can now that it will get more wheel travel down. The arms will bind at the same point but the wheel will be lower. Will make a difference to ride and bumps aswell.

Posted: Tue Apr 14, 2009 8:45 pm

by Struth

The main point here is the fact that the height difference between the chassis mounts and the centre of the axles remains the same whether the radius arm is mounted below, on top of or even in the middle of the axle.

Also remaining the same is the line you could draw from the chassis mount to the centre of the axle, the angle of this line will not change no matter where you mount the radius arm to the axle. This angle will only change if you raise or lower the suspension.

The rotational forces applied to the RA bushes at the axle mount will change, but I am not sure if this would have any detrimental effect, even though it would be applying force in the opposite direction that the RA was designed to accept.

I still cannot see any bad points to flipping the RAs only small gains such as clearence, as long as there is adequate room for the flipped RA to travel upward under suspension compression, which on an 80 series RA should be fine because of the curve built into the arm.

This raises the next question, the RA has a curve built into it that will suddenly be accepting forces in the opposite direction to the way it was designed. Will this become a weak point?

Cheers

Posted: Tue Apr 14, 2009 9:24 pm

by 1MadEngineer

Struth wrote:The main point here is the fact that the height difference between the chassis mounts and the centre of the axles remains the same whether the radius arm is mounted below, on top of or even in the middle of the axle.

Also remaining the same is the line you could draw from the chassis mount to the centre of the axle, the angle of this line will not change no matter where you mount the radius arm to the axle. This angle will only change if you raise or lower the suspension.

The rotational forces applied to the RA bushes at the axle mount will change, but I am not sure if this would have any detrimental effect, even though it would be applying force in the opposite direction that the RA was designed to accept.

I still cannot see any bad points to flipping the RAs only small gains such as clearence, as long as there is adequate room for the flipped RA to travel upward under suspension compression, which on an 80 series RA should be fine because of the curve built into the arm.

This raises the next question, the RA has a curve built into it that will suddenly be accepting forces in the opposite direction to the way it was designed. Will this become a weak point?

Cheers

perfect explanation!

The new Superflex drop arms i am working on will certainly, make a big difference! plenty of flex and clearance.... and sort of a mix between a flip arm and a std arm

Posted: Wed Apr 15, 2009 12:48 am

by pinkfloyddsotm

1MadEngineer wrote:Struth wrote:The main point here is the fact that the height difference between the chassis mounts and the centre of the axles remains the same whether the radius arm is mounted below, on top of or even in the middle of the axle.

Also remaining the same is the line you could draw from the chassis mount to the centre of the axle, the angle of this line will not change no matter where you mount the radius arm to the axle. This angle will only change if you raise or lower the suspension.

The rotational forces applied to the RA bushes at the axle mount will change, but I am not sure if this would have any detrimental effect, even though it would be applying force in the opposite direction that the RA was designed to accept.

I still cannot see any bad points to flipping the RAs only small gains such as clearence, as long as there is adequate room for the flipped RA to travel upward under suspension compression, which on an 80 series RA should be fine because of the curve built into the arm.

This raises the next question, the RA has a curve built into it that will suddenly be accepting forces in the opposite direction to the way it was designed. Will this become a weak point?

Cheers

perfect explanation!

The new Superflex drop arms i am working on will certainly, make a big difference! plenty of flex and clearance.... and sort of a mix between a flip arm and a std arm

More drop arms for pootrols ?

Posted: Wed Apr 15, 2009 8:56 am

by Auto-Craft

Flipping the arm keeps it in a horizontal plain, so it means the wheel will go up when hitting a bump, and not have to move much fore or aft of its position at ride height, where as when the arms point down, the wheels have to go forward, to go up, in an arc.

Bit like swapping 40 series shackles to the rear of the front springs years ago, improves the feel under power, and on the road/offroad over bumps.

A better option would be longer arms also, to reduce angle, and impove flex, made to fit over the diff to the existing mounts.

Having said that, a 5 link that works well is a much better option overall.

Less lift and more travel [suspension lift and wheel travel arent always as well connected as they should be, and dont mean the same thing] is really the ideal situation, overall.

Draw it on paper [or the computer] as much as you like, driving it, is the real test of improvement, and downside. [every mod has a down side as well.]

Posted: Wed Apr 15, 2009 9:15 am

by TheBigBoy

I can see it as say puttuing the next size up tyres on it. Thats the affect it will have.

Posted: Wed Apr 15, 2009 9:45 am

by 1MadEngineer

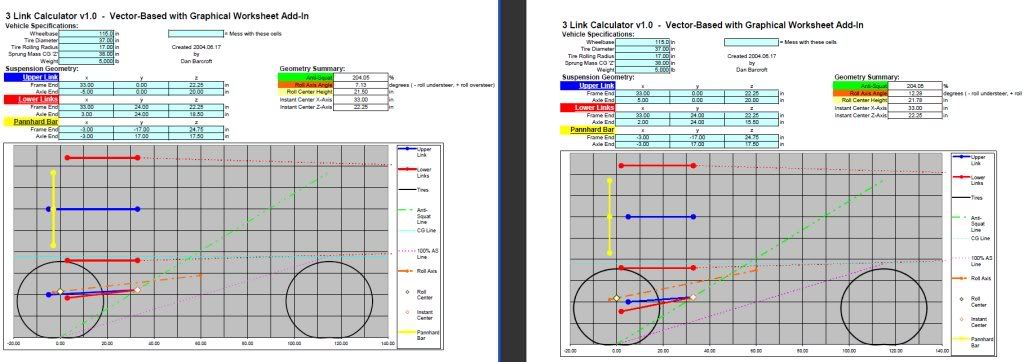

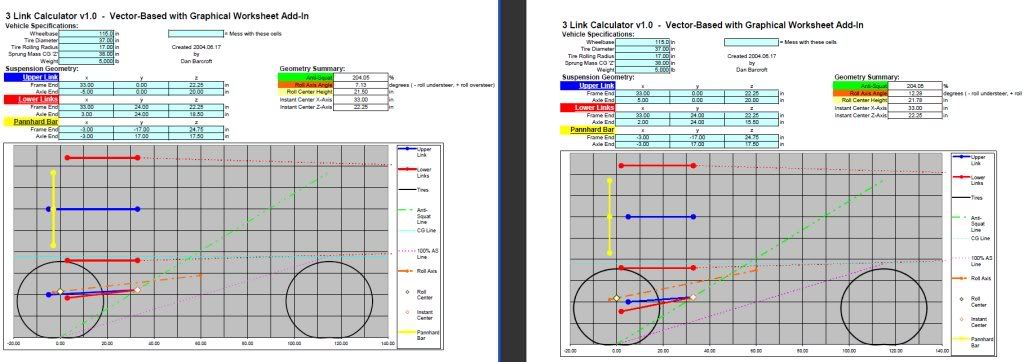

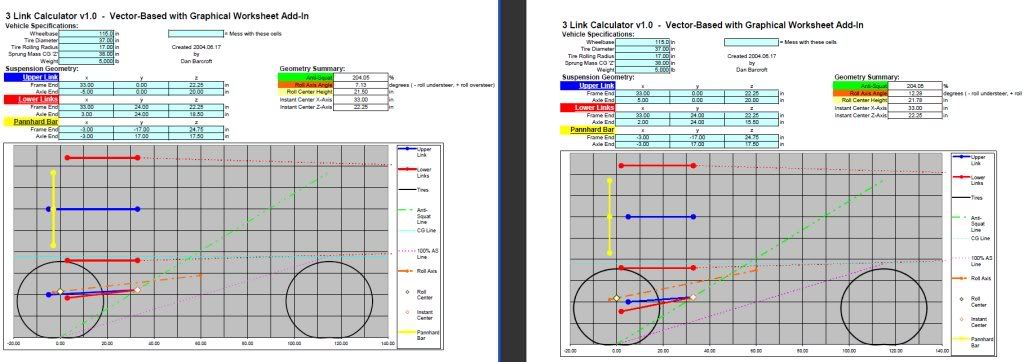

flipped arm on left, as you can see the AntiSquat (and AntiDive is the same) mounted position on the diff has no effect.

There is however a small difference in feel, this is mainly due to initial take-up and deflection in the bushs which create a slight rotational force on the arm, BUT this has a downside as well as it induces unwanted stress on the arms in a flipped orientation (Struth picked up on it

)

as darren mentioned 5links have big advantages, But sadly packaging them in to places they weren't designed for is really hard. Being able to reduce the AS/AD give great ride and the ability to absorb bumps IF setup with low AS. But the downside is little Antidive which makes them not so great for a mums DD driven to the shops in the wet

.

Posted: Wed Apr 15, 2009 9:49 am

by pinkfloyddsotm

1MadEngineer wrote:

i can never understand how to use the 4/3 link calculator.

Posted: Wed Apr 15, 2009 10:21 am

by guzzla

killalux wrote:1MadEngineer wrote:guzzla wrote:The main reason for a flip arm is best explained as follows:

If you were to c`arry a wheel barrow full of bricks with the handles held up high, you'd have great difficulty trying to steer it. Likewise, because the barrow's handles are up so high, hitting bumps would cause considersble jarring.

On the other hand, if were were to push the same barrow with your arms at full length and the barrow's handles near paralell with the ground, steering is heaps easier and the wheel floeats over bumps much easier.

This is the main advantage of a flip arm, as it puts the arms in a more neutral postion. Now when you nudge the front wheels up to a large rock step, the wheels don't have to overcome being forced backwards anywhere near as much and make climbing larger obstacles much eaier.

Additional benefits include clearing the steering linkages and getting your castor 100%.

The down side is if you change your suspension height in any way, you have to have the mounts modified to suit the new castor setting.

If you are 100% satisfied with the height your 4WD (3-6in over), a fliparm along with a high steer kit and panhard rod mount extention will make your 4WD handle 1000 time better than it does now.

this scenario ONLY applies to moving the mounting on the chassis not on the diff = change in IC. You are explaing drop boxes NOT flipped arms.

RE-read your example - now keep your hands/arms at the exact same position. (same IC pivot point). 2 different wheelbarrows same wheel size different handle position = same forces. SAME tire + same length + same pivot = SAME!

I think one thing point that you are missing that i don't think anyone has mentioned, is that by flipping the arms on top of the diff you are actually moving the diff mounting points higher.

ie, with the arms below the diff the mounting point (diff end) is below the centre line of the diff housing, but when you flip the arms and make new diff end mounts, The new mounting point is now above the centre line of the diff housing.

As i se it it doesn't matter if you drop the chassis end (drop boxes) or raise the diff end (flip arms) it should have the same result right?? You are still making the arms more parallel with the ground.

This is correct. It doesn't matter if you lower the chassis mounting point or move the front mounting points of the radius arm to the top of the axle housing, the effect is still the same - you are still making the arm sit in a more neutral position.

You can calculate and graph it as much as you like, but pushing a loaded wheelbarrow with your arms in different positions will prove beyond doubt that my example is 100% correct - try it for yourself.

Posted: Wed Apr 15, 2009 10:41 am

by 1MadEngineer

guzzla wrote:

You can calculate and graph it as much as you like, but pushing a loaded wheelbarrow with your arms in different positions will prove beyond doubt that my example is 100% correct - try it for yourself.

your comparison is similar to a 2" lift compared to a 10" lift...... have a REAL think about it! get your wheelbarrow take the tub off it, push it in the normal way, then flip it over so the wood handle are now on top of the axle..... it will feel exactly the same. Hands in the same position! as this simulates the mounting point on the chassis, which is the common! NOT a variable. Or do you have hydraulic suspension??

Posted: Wed Apr 15, 2009 5:00 pm

by Graham Stirling

Am I missing something here?

The graphs don't seem to take into account the arc which the hub centre moves though. With the arms in the standard mounting position, on a lifted vehicle, the axle has to move forward as it moves up, ie against the direction of travel when moving forward. With the arms flipped the arc doesn't have so much effect therefore the horizontal forces are reduced.

G

Posted: Wed Apr 15, 2009 7:13 pm

by 65Mog

Just a comment on the 3 link calculator, the point that the link attaches to the chassis looks too low, even on a standard height 80 the link is higher than that? You would only do an arm flip if you had a 5 or 6 inch lift. What happens when you lift the chassis mounting point 6 or 8 inches? And the mounting points at the diff looks wrong on the standard graph, the bottom link should be in front of the axle centre line and the rear one should be lower, also they are different lengths.

I don't know if this makes any difference?

Posted: Wed Apr 15, 2009 7:27 pm

by Struth

Yes you are missing one very important point in this.

The arc scribed by the axle when it moves up or down does not change when the radius arms are flipped, if the axle had to move forward when travelling up with unflipped arms it will still need to move forward when travelling up with flipped arms, the only way to get it neutral is to lower the chassis RA mount to the same height as the centre of the axle, if you do this then the axle will move rearward when travelling up and rearward when travelling down.

Whether or not the RAs are flipped have no effect whatsoever on the axles travel. The relationship between the chassis mount of the RA and the axle centre remains the same.

The effect you guys are suggesting comes from a flipped RA actually will only come from a lowered RA chassis mount (drop boxes) or lowered suspension.

Cheers

Posted: Wed Apr 15, 2009 8:28 pm

by RUFF

Struth wrote:Yes you are missing one very important point in this.

The arc scribed by the axle when it moves up or down does not change when the radius arms are flipped,

Firstly i hate the internet for this one reason. Its very hard to explain something so everyone understands what you are trying to say. But please bare with me.

I agree the arc does not change. But the distance measured at 90* (or Square/At right angles maybe

)from the fixed point changes. Which effectivly means the axle moves in an upward motion much easier if the RA is flat. It doesn't have to move forward first then up. It just moves up and back.

Try this. Take 2 books and lay them seperated and flat on the table. Now take a biro and place it between the 2 books at its longest point. Now pivot only one end of the biro downwards. As it moves down it moves away from the other book. This is what a radius arm does as you lift a vehicle. And then to compress (lift it back up) that arm it now needs to move forward again. Am i making Sence?

Im not sure i can explain it differently here. I can't draw you a picture or a graph sorry

I also agree with Greg that your not going to change the Squat,Anti Squat properties by flipping the arms. But i beleive you will deffianatly make the suspension more supple when hitting ledges or even pot holes.

Bottom line. The steaper the RA angle(or even links for that matter) The harsher the ride is going to be.

Im off to bed now. You may not get a reply from me till later tomorrow if i haven't explained this well enough. Actually if its not clear enough you prob wont get a reply from me again

Keep in mind when you flip the radius arms you effectlivly move the axle forward at the same time as the RA does not mount at the centre line of the axle.

Posted: Wed Apr 15, 2009 8:55 pm

by pinkfloyddsotm

RUFF wrote:Struth wrote:Yes you are missing one very important point in this.

The arc scribed by the axle when it moves up or down does not change when the radius arms are flipped,

Firstly i hate the internet for this one reason. Its very hard to explain something so everyone understands what you are trying to say. But please bare with me.

I agree the arc does not change. But the distance measured at 90* (or Square/At right angles maybe

)from the fixed point changes. Which effectivly means the axle moves in an upward motion much easier if the RA is flat. It doesn't have to move forward first then up. It just moves up and back.

Try this. Take 2 books and lay them seperated and flat on the table. Now take a biro and place it between the 2 books at its longest point. Now pivot only one end of the biro downwards. As it moves down it moves away from the other book. This is what a radius arm does as you lift a vehicle. And then to compress (lift it back up) that arm it now needs to move forward again. Am i making Sence?

Im not sure i can explain it differently here. I can't draw you a picture or a graph sorry

I also agree with Greg that your not going to change the Squat,Anti Squat properties by flipping the arms. But i beleive you will deffianatly make the suspension more supple when hitting ledges or even pot holes.

Bottom line. The steaper the RA angle(or even links for that matter) The harsher the ride is going to be.

Im off to bed now. You may not get a reply from me till later tomorrow if i haven't explained this well enough. Actually if its not clear enough you prob wont get a reply from me again

Keep in mind when you flip the radius arms you effectlivly move the axle forward at the same time as the RA does not mount at the centre line of the axle.

makes sense to me.

Posted: Wed Apr 15, 2009 10:10 pm

by Struth

pinkfloyddsotm wrote:RUFF wrote:Struth wrote:Yes you are missing one very important point in this.

The arc scribed by the axle when it moves up or down does not change when the radius arms are flipped,

Firstly i hate the internet for this one reason. Its very hard to explain something so everyone understands what you are trying to say. But please bare with me.

I agree the arc does not change. But the distance measured at 90* (or Square/At right angles maybe

)from the fixed point changes. Which effectivly means the axle moves in an upward motion much easier if the RA is flat. It doesn't have to move forward first then up. It just moves up and back.

Try this. Take 2 books and lay them seperated and flat on the table. Now take a biro and place it between the 2 books at its longest point. Now pivot only one end of the biro downwards. As it moves down it moves away from the other book. This is what a radius arm does as you lift a vehicle. And then to compress (lift it back up) that arm it now needs to move forward again. Am i making Sence?

Im not sure i can explain it differently here. I can't draw you a picture or a graph sorry

I also agree with Greg that your not going to change the Squat,Anti Squat properties by flipping the arms. But i beleive you will deffianatly make the suspension more supple when hitting ledges or even pot holes.

Bottom line. The steaper the RA angle(or even links for that matter) The harsher the ride is going to be.

Im off to bed now. You may not get a reply from me till later tomorrow if i haven't explained this well enough. Actually if its not clear enough you prob wont get a reply from me again

Keep in mind when you flip the radius arms you effectlivly move the axle forward at the same time as the RA does not mount at the centre line of the axle.

makes sense to me.

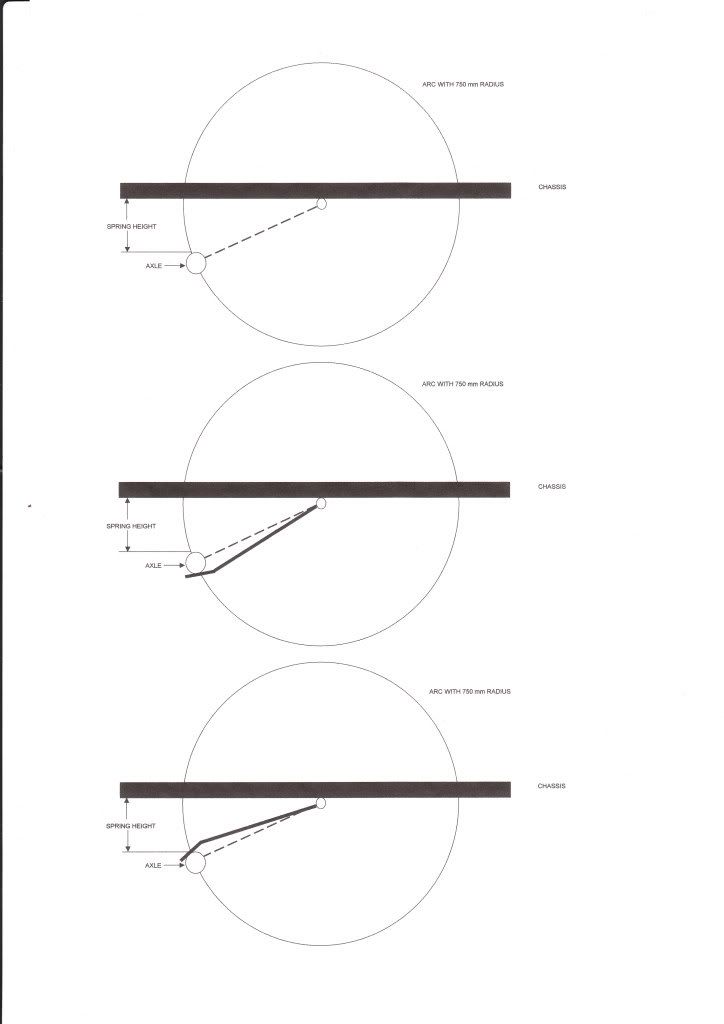

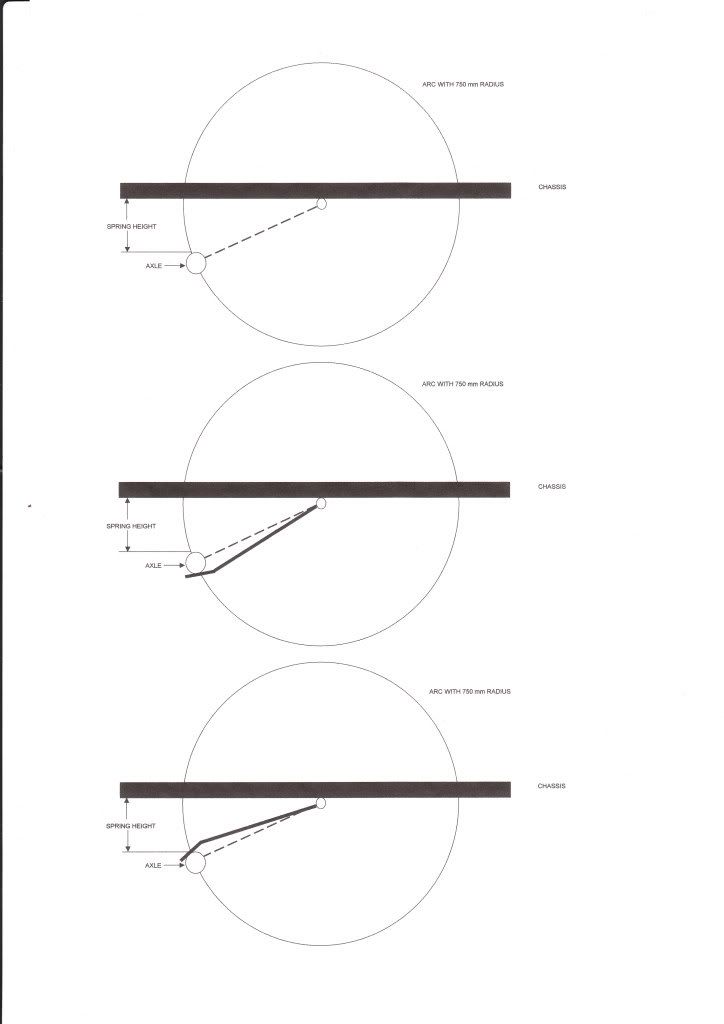

OK guys this time I bring a picture,

The top diagram shows the relationship between the axle centre and the RA chassis mount as a dotted radius line, it is set by the length of the RA and the spring height, it has and angle between the radius line and the chassis of say 30 degrees in this example.

The middle diagram shows a traditional underslung RA with the same RA length and the same spring height and same angle of 30 degrees.

The bottom diagram shows a flipped radius arm with the same spring height, it is the same radius arm so the same RA length, therefore the same angle of 30 degrees.

The key to my point is the dotted radius line, it does not change when you flip the RA, nor does the spring height or the angle, so the dynamics of the axle moving forward as it moves up are exactly the same as they were before the RA flip.

Moving the axle forward when doing an RA flip will have two effects, it will overcome the fact that the axle moved rearward when a lift was fitted and it will lengthen the radius of the axles arc when travelling up or down which is also the same effect as fitting drop boxes to a very small degree.

In my case I am deciding whether or not to RA flip on an SAS that hasn't reached fabrication stage yet and moving the front axles forward is a necessity anyway.

If you flipped on a standard 80 you would fab your RA to axle brackets to bring the axle forward slightly and yes this would increase (slightly) subtleness in the suspension.

Cheers

Posted: Thu Apr 16, 2009 6:48 am

by Graham Stirling

Ok, i undestand that but when the axle is pushed forward by the effect of correcting the castor the distance between the hub center and the chassis mounting point increases as the axle has to rotate around the front arm mount.

So...the axle doesn't move in the same arc, it's a parrallel arc with a bigger diameter. Therefore the horizontal movement is less with flipped arms. I doubt that this increase in arc diameter is more than say 50mm but it will have a marked effect on how the suspension acts.

I guess thats what you mean here.

Struth wrote:

Moving the axle forward when doing an RA flip will have two effects, it will overcome the fact that the axle moved rearward when a lift was fitted and it will lengthen the radius of the axles arc when travelling up or down which is also the same effect as fitting drop boxes to a very small degree.

Cheers, G

Posted: Thu Apr 16, 2009 8:51 am

by 1MadEngineer

Graham Stirling wrote:Ok, i undestand that but when the axle is pushed forward by the effect of correcting the castor the distance between the hub center and the chassis mounting point increases as the axle has to rotate around the front arm mount.

So...the axle doesn't move in the same arc, it's a parrallel arc with a bigger diameter. Therefore the horizontal movement is less with flipped arms. I doubt that this increase in arc diameter is more than say 50mm but it will have a marked effect on how the suspension acts.

I guess thats what you mean here.

Struth wrote:

Moving the axle forward when doing an RA flip will have two effects, it will overcome the fact that the axle moved rearward when a lift was fitted and it will lengthen the radius of the axles arc when travelling up or down which is also the same effect as fitting drop boxes to a very small degree.

Cheers, G

castor correction ONLY should have no increase in the radius of the arm, although correction is performed on lifted vehicles which tend to have clearance issues, wether it be tire/suspension/steering. So you find you try to move the diff a small amount forward to regain some clearance on the critical parts. The amount the diff is moved forward is generally only 10-20mm MAX as any more you are starting to create more dramas with binding of steering and suspension parts. SO with an arm that is 850mm c-c, then 15mm is a whole ~1.8% increase in lever arm length......