Page 3 of 4

Posted: Wed Aug 13, 2008 1:25 pm

by benhl

how expensive is expensive? I hearing figures aroun $14/m for plasma... is it that steep?

Posted: Wed Aug 13, 2008 1:46 pm

by David_S

I bought mine a year ago. Here are some typical prices at that time in NZ dollars and including GST of 12.5%

Dynex Dux 75 Overbraid

7mm 7,500kg $8.49/m from 4wd Bits in NZ

9mm 12,00kg $15.69/m from Hampidjan, $18.95 from 4wd Bits

Dynex Dux 75

9mm 12,000kg $12.95/m from 4wd bits

11mm 18,400kg $18.25/m from 4wd bits

Hope that helps. It pays to shop around.

Posted: Wed Aug 13, 2008 9:15 pm

by lux kid

haha luven this thread. taken my old mans estwing hammer back to the shop 2moza.

ok back on topic of winchs.

im about to start to mine. basicly widen as far as my front bar can go, but not crazy long. shrink dia to 2" and bearing the end cap.

im taken a stanard drum and cutting every thing off apart from the first ring from the drive end. then ill put in the lathe and bore a hole about 20mm in to the drive boss.

be for i mount the 2" tube i will turn a down a piece 2" solid bar to take what eva ID the bearing i end up using. ( some where between 30 and 40mm)

then ill turn the other end of the boss to suit the tube.

taken newly turned boss and and tube ill press them together. care full to keep them running true.

also adding an new outer ring at the same time. with the new end piece pressed to together time to tac it up.

using the centres of the lathe ill put the new drum thats just been prssd together in and check thats shes all true and tac it all nice.

then its time to weld her up paint.

as for the end cap ill turn up a mild steel bush the can be pressed and locked in to the standard warn unit. the ID of this bush with suit the what eva bearing i get.

ill also do tie bars and fill/drain plugsand extra top hat mounts.

hope this all makes sence.

drum

Posted: Wed Aug 13, 2008 10:06 pm

by KYSI

With the widened drum do you need to get a wider fair lead?

Posted: Wed Aug 13, 2008 10:11 pm

by lux kid

yeah there would be no reason to widen it. as it would stop the rope from winding on to that part of the drum.

Posted: Wed Aug 13, 2008 10:20 pm

by KYSI

lux kid wrote:yeah there would be no reason to widen it. as it would stop the rope from winding on to that part of the drum.

so do i leave it normal width or widen it? that didnt really make sense

Posted: Wed Aug 13, 2008 10:21 pm

by lux kid

sorry lil smashed!!

if you widen your drum widen your fair lead.

drum

Posted: Wed Aug 13, 2008 10:27 pm

by KYSI

lol thanks....can anyone tell me how i go about widening the fair lead?

cheers kyal

Re: drum

Posted: Thu Aug 14, 2008 7:41 am

by David_S

KYSI wrote:lol thanks....can anyone tell me how i go about widening the fair lead?

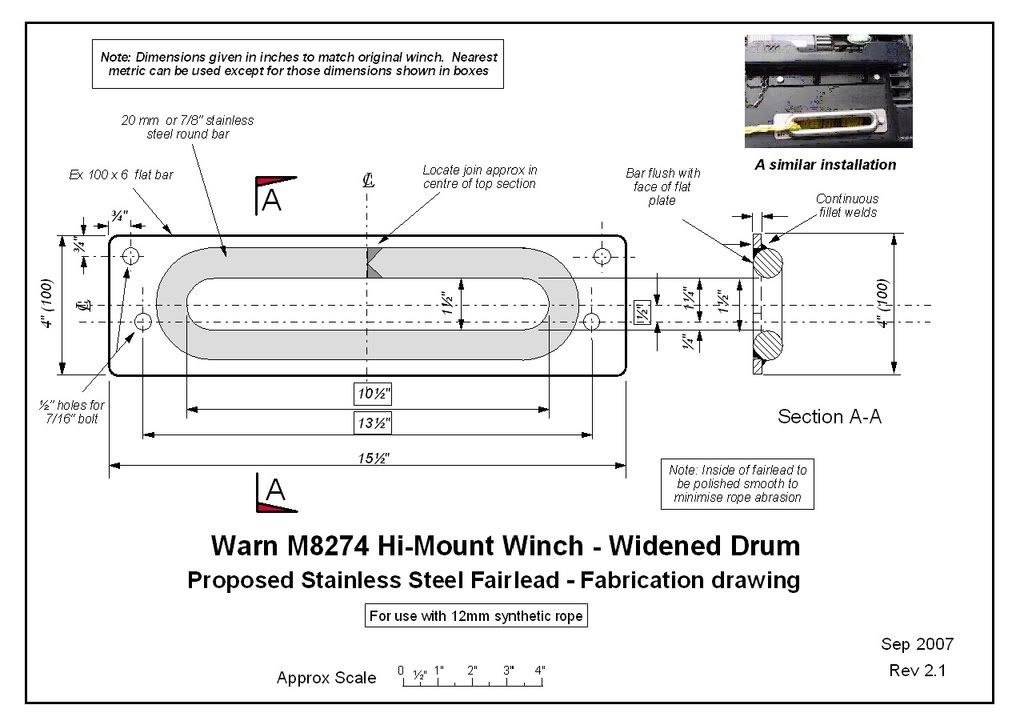

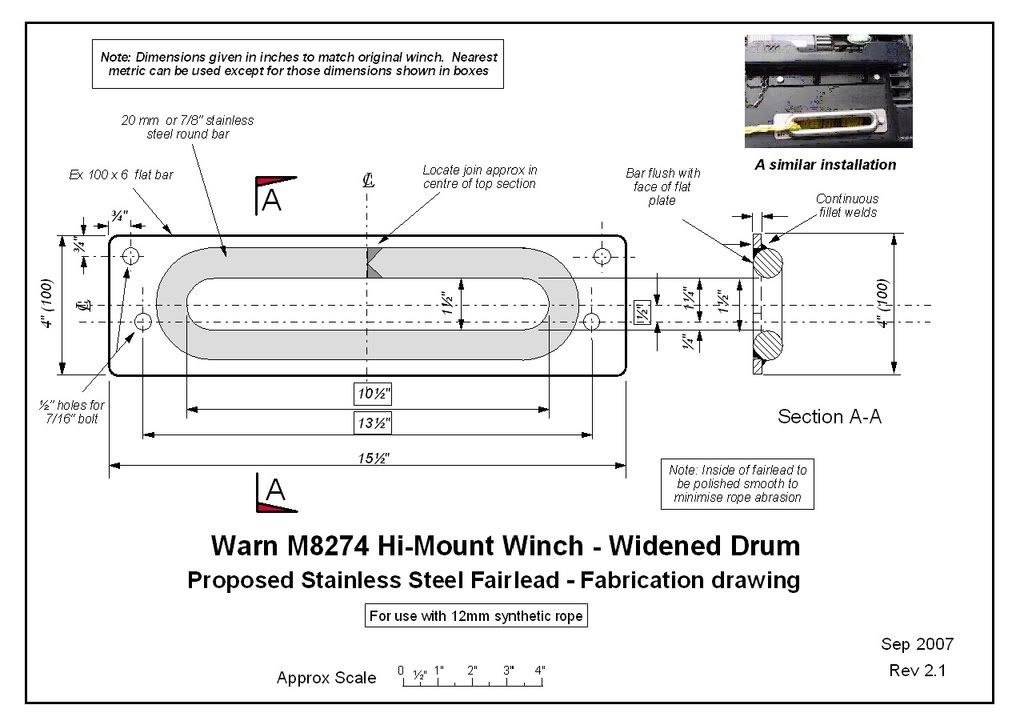

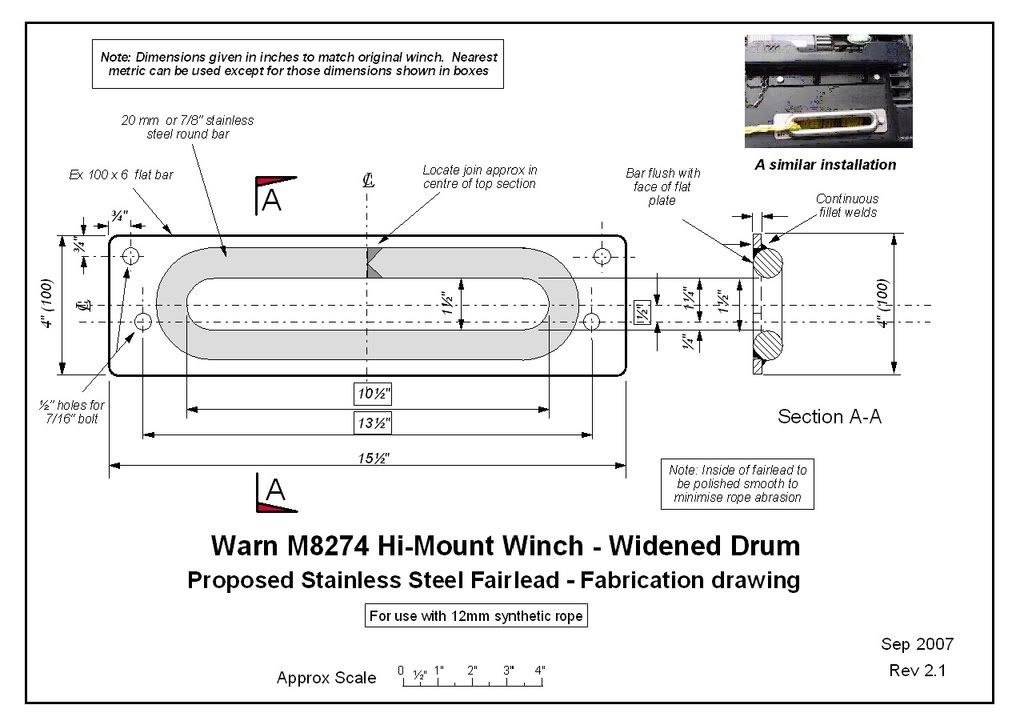

Generally you need to make a new one. If you are going from the std 3.5" dia drum to 2" dia you will have to use synthetic rope NOT wire as wire will not take kindly to the sharp radius. So if you are changing from wire you will have to dump your roller fairlead and buy or fabricate a hawse type fairlead from alloy, stainless steel or kevlar or something. Roller fairleads, especially ones which have had wire over them, are not recommended for synthetic rope.

You will also have to enlarge the hole in your front winch plate and probably change its vertical position to accommodate the increased vertical rope movement - 5 layers on the original drum, up to 7 on the modified. It pays to give this a bit of thought.

I got a stainless steel fairlead fabricated as in the drawing below and this has worked well for my 12" x 2" dia drum. The bolt holes would need to be amended to suit your bracket. I had a bit of concern about the possibility of heat build up in stainless as it is not a good conductor of heat - synthetic ropes don't like heat - but this has not been a problem.

David

Posted: Thu Aug 14, 2008 10:18 am

by benhl

that's a very bling drawing David_S - top work!

Posted: Thu Aug 14, 2008 10:20 am

by nzdarin

I use either 2x 6hp with 24v or 2 x 7.8 24v Superduty motors. I have fried one of each due to completely different reasons.

The Superduty was due to a manufacturing fault and Traxion were extremely good at replacing quickly and without any hassle. They're really very good to deal with.

The 6hp died because of a nut that came loose on the main power feed. Drop in voltage and the motor completely disintergrated. To the point even the bolts that hold the motor on were melted! It really was quite spectacular inside.

The 6hp with 24v it so much faster than the 24v it isn't funny BUT the 7.8's will pull all day without any worry of overheating. You will run out of battery power first.

So the next como which is in 3 weeks I will be running the 7.8's as it is a wet comp and will have a lot of serious winching (NZ style) so the 6hp are not a viable option for this. For dry weather comps they are as fast as a PTO winch.

Also I run 90m of 10mm Dymanica on my winch but it is rear mounted so you can run a lot more safely. That is a wdened drum with freespool and still with a 3.5" shaft. With twin motors I couldn't see the need for lower gearing.

Posted: Thu Aug 14, 2008 10:27 am

by nzdarin

I should add I've been using the 7.8 24v since 2005 and I still have the original motor I bought. It has had some insulation replaced but otherwise it hasn't been touched. Not bad when you consider the number of winch comps it has done and it was run as a single for most of that!

But the 6hp is a far better quality motor! But when you put 24v through a 12v what can you expect?

Posted: Thu Aug 14, 2008 1:16 pm

by David_S

nzdarin wrote:I use either 2x 6hp with 24v or 2 x 7.8 24v Superduty motors.

I am a little confused. For your 6Hp motors are you putting 24V through a 12V motor or do you have 24V motors? And same question for the Superduty motors. Have you tried putting 24V through a 12V Superduty?

nzdarin wrote:The 6hp with 24v it so much faster than the 24v it isn't funny BUT the 7.8's will pull all day without any worry of overheating.

Does this mean the 6HPs with 24V are faster than the 6HPs with 12V or faster than the 24V Superduty?

David

Posted: Thu Aug 14, 2008 2:33 pm

by nzdarin

I have 6hp 12v that I put 24v through.

And I have 7.8hp hp Superduty.

6hp 12v with 24v powering it is faster and stronger than same motor with 12v and also than the 24v Superduty.

I wouldn't reconmend using the 7.8hp 12v as it is slower than the 6hp Warn motor and nowhere near the same quality. The internal tolerances appear to be way to tight and the guys that were using them originally weren't impressed and have gone back to the 6hp (with 12v powering them).

The 24v Superduty is a very reliable strong motor that just keeps on going. I use them for all club work and for training as they just keep going. While the 6hp 12v (with 24v) is great, it is a limited competition option only (unless you have a huge cheque book). I'm not sure I'd use them in a real wet NZ comp. but something like Nor-West where it is dry and most of the winches are short and technique then they would rock.

I can't for the next one as I only have one at present anyway.

The speed difference between thr 6hp and the 7.8 Superduty is amazing, but it is horses for courses. All that speed is no good if it doesn't last the distance.

My observations are on the same truck, same winch, same power supply and same everything else. ie My truck.

Posted: Thu Aug 14, 2008 3:17 pm

by David_S

THanks for that clarification NZDarin

nzdarin wrote:I wouldn't recommend using the 7.8hp 12v as it is slower than the 6hp Warn motor and nowhere near the same quality. The internal tolerances appear to be way to tight and the guys that were using them originally weren't impressed and have gone back to the 6hp (with 12v powering them).

Yeah, this is what I have found with the 7.8HP 12V as mentioned in an earlier post. If you take them apart it is a real fiddle reassembling them with the tight tolerances and also getting the through bolts aligned so that they don't foul the windings etc. And corrosion was (is? - haven't looked lately!) quite a problem too. I have a +25% gear set for the Gigglepin which I have yet to fit so this might help the speed problem a bit. At present I am using a +13% set. In hindsight I should have ditched the 7.8HP when I fitted the Gigglepin and gone for 2 6HP Warn, but I don't have "a huge chequebook". And the 7.8 HP are fine for everyday winch situations - just a bit slow.

David

Posted: Thu Aug 14, 2008 5:23 pm

by wilsy

thanks lux kid, i hadn't pulled the winch apart to have a look at the bearing shoulder size or the appx OD of the splines that engage in the final gear. Great Description, why don't you just machine up a complete new Mount for the Non Drive End, extra strength and you could fit what ever bearing's (and seals if you want) and would save welding the ears on for the tie bars.

Thanks Again

Wilsy

Posted: Thu Aug 14, 2008 5:26 pm

by lux kid

i would wilsy but im pretty lazy. my be one day.

Posted: Thu Aug 14, 2008 5:36 pm

by lux kid

nzdarin would be able to explane more about how you run 24v on your truck?

is your truck all 24v ie dash and lights and the all.

do you run a 24v alternator or to 12v.

i want to run 24v on my hilux winch pig but not realy sure how to go about it.

dont want to fry me car if i stuff up.

Posted: Thu Aug 14, 2008 5:49 pm

by David_S

lux kid wrote:im taken a stanard drum and cutting every thing off apart from the first ring from the drive end. .......hope this all makes sence.

Hi lux kid. You will need to thicken up or reinforce the first ring (flange) or it is likely to bow under the sidewards pressure of synthetic rope under heavy load - at least that's what happened to mine.

Also don't forget to consider how you will terminate your rope when designing the end bearing.

David.

Posted: Thu Aug 14, 2008 6:05 pm

by Shadow

sooooooooo

how bout them hammers

Posted: Thu Aug 14, 2008 6:10 pm

by lux kid

will do thanks david s.

with end of the rope im thinken ill make the new boss that carries the bearing long enough that i can drill and tap it for a 10mm high ten bolt.

Re: drum

Posted: Thu Aug 14, 2008 10:17 pm

by KYSI

David_S wrote:KYSI wrote:lol thanks....can anyone tell me how i go about widening the fair lead?

Generally you need to make a new one. If you are going from the std 3.5" dia drum to 2" dia you will have to use synthetic rope NOT wire as wire will not take kindly to the sharp radius. So if you are changing from wire you will have to dump your roller fairlead and buy or fabricate a hawse type fairlead from alloy, stainless steel or kevlar or something. Roller fairleads, especially ones which have had wire over them, are not recommended for synthetic rope.

You will also have to enlarge the hole in your front winch plate and probably change its vertical position to accommodate the increased vertical rope movement - 5 layers on the original drum, up to 7 on the modified. It pays to give this a bit of thought.

I got a stainless steel fairlead fabricated as in the drawing below and this has worked well for my 12" x 2" dia drum. The bolt holes would need to be amended to suit your bracket. I had a bit of concern about the possibility of heat build up in stainless as it is not a good conductor of heat - synthetic ropes don't like heat - but this has not been a problem.

David

To easy mate im a 3rd year apprentice boiler maker so that should be pretty easy to knock up .. so thanks for the drawing.....i am already running dynamic rope so thats no drama..thanks again

Posted: Fri Aug 15, 2008 11:43 am

by nzdarin

lux kid wrote:nzdarin would be able to explane more about how you run 24v on your truck?

is your truck all 24v ie dash and lights and the all.

do you run a 24v alternator or to 12v.

i want to run 24v on my hilux winch pig but not realy sure how to go about it.

dont want to fry me car if i stuff up.

My truck was 24v to start with so ran 24v everything, but when I fitted the V8 I completely removed all wiring etc and started from scratch. I now run everything 12v except the winch. I have a 12v 110amp alternator and a 1000cca battery for the truck lights etc and a 70amp 24v battery with twin 875cca 23 plate batteries just for the winch.

ie 2 akternators and 3 batteries. Simple an reliable so no electronic bits, voltage reducers or anything like that.

Posted: Fri Aug 15, 2008 2:04 pm

by lux kid

i not real good with wiring. sorry i this doesn't make sence.

so all you did was mount a 24V running in to 2 connected in series batterys.then run wire to the winch controler.

will i need a 24volt winch controler?

wouldn't the earthing of the alternator make the car 24volt?

Posted: Fri Aug 15, 2008 7:10 pm

by Shadow

lux kid wrote:

wouldn't the earthing of the alternator make the car 24volt?

nope

the car is ground, or zero volts. Pos output of 12volt altenatoer is +12volt with respect to the chassis, pos output of 24volt altenator is +24 with respect to chassis. You could even link the Pos output of the 24volt altenator to the chassis, and then the neg output of the 24volt altenator would be negative 24volts with respect to the chassis.

Posted: Fri Aug 15, 2008 11:05 pm

by lux kid

thanks shadow. makes more sence now.

many ppl run 24v on a 12v truck?

where would i find a 24v alternator. eg what model truck, what brands are good?

about to try ebay.

Posted: Sat Aug 16, 2008 7:18 pm

by nzdarin

lux kid wrote:thanks shadow. makes more sence now.

many ppl run 24v on a 12v truck?

where would i find a 24v alternator. eg what model truck, what brands are good?

about to try ebay.

Forget about getting one of a 4x4 as it will be too small for what you want. ie the standard Patrol 24v is 35amps and has the vac pump etc. I have a delco alternator that is one Repco carry on the shelf. Cost under $300 brand new.

Sometime new is cheaper and just easier.

Posted: Sat Aug 16, 2008 7:26 pm

by lux kid

i guess they would run a v type pully on them yeah.

wonder if i can get one to suit a surpintine belt.

i run commo v6.

Posted: Sat Aug 16, 2008 8:36 pm

by Shadow

lux kid wrote:i guess they would run a v type pully on them yeah.

wonder if i can get one to suit a surpintine belt.

i run commo v6.

just need to get a serpentine pulley and bolt iut to the front.

Posted: Mon Aug 18, 2008 1:18 pm

by nzdarin

I have a serpintine belt on mine.