Page 4 of 20

Posted: Sun Jul 13, 2008 5:22 pm

by matt.mcinnes

Popped down to see Awill4x4 today to pick up the end plates that he has tacked together ready for machining.

After more testing of my system the pre intercooler temp seems to be around the 42C mark just cruising around. The air intake is not ideal been between the radiator and Turbo, Snorkel is next on my list, this should improve things greatly.

Post intercooler temp cruising is sitting around 22C

Ambient around 11C

On the couple of runs/test on the way to Awill4x4 the pre temp rises to the usual 82C, post temps only rising to 28C max after bleeding the air out.

You can see in the pic below the circled pre and post test points using the same sensors.

Posted: Sat Jul 19, 2008 8:54 am

by matt.mcinnes

Test core is ready for Awill4x4 to weld up so we can pressure test the new end caps. Only another 70 more to make

if they pass test.

The two end plates will be ready Tuesday for the TB42 too

Posted: Sat Jul 19, 2008 10:27 am

by KiwiBacon

Looking good (again).

So what's the diameter and thickness of the scaffold tube?

Posted: Sat Jul 19, 2008 12:37 pm

by matt.mcinnes

KiwiBacon wrote:Looking good (again).

So what's the diameter and thickness of the scaffold tube?

Smart Aluminum scaffold tube.

6m Scaffold Tube O/D 48.41mm wall thickness 4.47mm

Posted: Sat Jul 19, 2008 12:47 pm

by KiwiBacon

matt.mcinnes wrote:KiwiBacon wrote:Looking good (again).

So what's the diameter and thickness of the scaffold tube?

Smart Aluminum scaffold tube.

6m Scaffold Tube O/D 48.41mm wall thickness 4.47mm

Tis a strange size. OD is basically 40NB (48.3mm) but the thickness is between SCH40 and SCH80.

Posted: Sat Jul 19, 2008 12:53 pm

by matt.mcinnes

KiwiBacon wrote:matt.mcinnes wrote:KiwiBacon wrote:Looking good (again).

So what's the diameter and thickness of the scaffold tube?

Smart Aluminum scaffold tube.

6m Scaffold Tube O/D 48.41mm wall thickness 4.47mm

Tis a strange size. OD is basically 40NB (48.3mm) but the thickness is between SCH40 and SCH80.

When I first enquired after Ali tube to suit I was told they had nothing close, luckily I decided to have a look at the web site to see what might suit. Scaffold tube is a 0.1 mm perfect fit. Infact you need to take a core with you as the tolerances the scaffold tube is made too can mean you get a length that is just a tad too small in the I/D

Posted: Sat Jul 19, 2008 1:10 pm

by matt.mcinnes

You can see here the refinement to the original prototype. O/D has been reduced slightly as well the hight of the end cap. Plus the addition of skimming one side, this in some configurations may mean more sides skimmed flat.

Once these test ok I will have them manufactured, I think a batch of 100 will be ordered as they are generic to whatever the intercooler design comes up with.

Posted: Sat Jul 19, 2008 10:52 pm

by benhl

I likey likey - and want one

Posted: Sun Jul 20, 2008 11:33 am

by matt.mcinnes

benhl wrote:I likey likey - and want one

Once the tests have been carried out on the end caps on the test core which Awill4x4 picked up yesterday for welding and the first of the TD42 intercoolers is complete me and Awill4x4 will have to sit down and cost one.

These are never going to be a cheap intercooler, but you get what you pay for. This is a highly efficient intercooler that has no more piping other than water, so minimal lag and very little pressure drop. Works as well at low speed. With a very robust construction, which will suit off road applications well. It will be easy to fit too. No big air to air you have try and hide away.

We have yet to see how good these get in a high boost application my 2F is only running 8PSI but my money is on them just becoming more efficient. Their is nothing to stop you adding an ice box to the system for competition application either.

Posted: Sun Jul 20, 2008 8:18 pm

by lukiss99

A mate from work introduced me to this site when he saw this thread about the laminova cores. I have since purchased a set of 4 cores and am in the process of designing a housing for them. They will be used on the engine that I'm also in the process of building, Nissan's old RB30E bottom end with twincam VCT head from the RB25DET. I'm hoping to run at least 1bar of boost pressure, so should be a good test for the core's efficiency.

Question I have though, I understand the whole idea of air flows over the outside and the coolant through the center. But what I don't get is why the main bore has a restriction orifice at one end, and it appears to have extra water jackets around the outer edge? Or is that just structural bracing? Did you leave the restriction plate in yours?

You can see in this photo how one end of the core has the restriction and the other end is open.

The other question I have, is you mention that vibration is a problem, hence you rubber mounted your housing. There is a group called ESSTuning and they make supercharger kits for BMW's utilising the laminova cores. They mount the cores in a custom manifold complete with inlet runners and fuel rail to bolt direct onto the head of the engine.

There is no rubber mounting, perhaps there is lower tolerance between the cores and the housing to prevent vibrational damage?

Interestingly though, they only use 3 cores in their design, and instead of using an endcap for each core it looks like they have 1 plate to seal the o-rings and another plate to channel the cooling water. Also, it looks like the cooling water is making 2 passes as the outlet/inlet fittings are only at 1 end of the manifold, yet with 3 cores the water flow through each would not be equal?

http://forum.e46fanatics.com/attachment ... 1158881641

http://forum.e46fanatics.com/attachment ... 1154736085

http://forum.e46fanatics.com/attachment ... 1158881641

Posted: Sun Jul 20, 2008 9:46 pm

by matt.mcinnes

The centre block off plate is their to force the water through the cooling channels, to make the centres from solid Aluminum would be costly and cause problems with in the extrusion process when cooling and add weight. So it's easier to add an insert after. I left ours in.

The rubber mounts are more of a precaution as these cores mount and are held in place on rubber O-Rings. You don't find many M3 BMW's off road either

2 cores would be sufficient 3 ideal in our calcs but more is better, all depends on HP, calculate the in take area of the cores against the size of your throtle body. Each additional core gives you more heat soak, better cooling and less restriction to air flow.

The 3 core set up is intriguing and baffling, with the inlet and outlet at the same end. If you ran the cores in series the inlet and out let would be at opposite ends, the cooling effect of each core would also be degraded with each pass. I dont think the photos tell all, they are keeping some of their design to themselves. I think I have an idea how they do it but would have to see one to be sure. I suspect the two outer cores flow in one direction and the center core is the return. The second link sugests this in the photo where you can see the water chanels from each core.

Have a few cores here too

Posted: Tue Jul 22, 2008 12:50 am

by awill4x4

Out of curiosity I welded a tube around Matt's prototype sample and did a pressure test on the charge air side of the core to check out whether increased boost pressure would allow air to escape past the sealing O rings into the water side of the intercooler.

I pumped it up to 50 psi with no leakage so I'm very happy with the efficiency of the O ring seals.

Regards Andrew.

Posted: Tue Jul 22, 2008 4:14 am

by matt.mcinnes

awill4x4 wrote:Out of curiosity I welded a tube around Matt's prototype sample and did a pressure test on the charge air side of the core to check out whether increased boost pressure would allow air to escape past the sealing O rings into the water side of the intercooler.

I pumped it up to 50 psi with no leakage so I'm very happy with the efficiency of the O ring seals.

Regards Andrew.

If you can't get 50 PSI of air past the seals you don't need to worry about low pressure water

Time for some real Awill4x4 magic while I find a machine shop to make the end caps in bulk

Posted: Wed Jul 23, 2008 6:38 pm

by Cliffy

Fantastic thread heaps of info. Keep up the good work.

I have some experience with heat exchangers (industrial) the coolant enters the exchanger in the oppisite direction to the media to be cooled. So there is a greater temperature gradiant between the two. From what I have observed in cooling fluids you can get within 2 degrees of the coolant inlet temperature to the cooled outlet temperature. However this is in fluids.......

Is it possible to make a dual pass Laminova intercooler without going to 8 cores.

Where is the best source for cores, yep tried ebay, and what prices are people paying.

Posted: Wed Jul 23, 2008 6:42 pm

by Shadow

Cliffy wrote:Fantastic thread heaps of info. Keep up the good work.

I have some experience with heat exchangers (industrial) the coolant enters the exchanger in the oppisite direction to the media to be cooled. So there is a greater temperature gradiant between the two. From what I have observed in cooling fluids you can get within 2 degrees of the coolant inlet temperature to the cooled outlet temperature. However this is in fluids.......

Is it possible to make a dual pass Laminova intercooler without going to 8 cores.

Where is the best source for cores, yep tried ebay, and what prices are people paying.

its possible to make a dual pass with 2 cores id have thaught

Posted: Wed Jul 23, 2008 8:09 pm

by matt.mcinnes

Cliffy wrote:Fantastic thread heaps of info. Keep up the good work.

I have some experience with heat exchangers (industrial) the coolant enters the exchanger in the oppisite direction to the media to be cooled. So there is a greater temperature gradiant between the two. From what I have observed in cooling fluids you can get within 2 degrees of the coolant inlet temperature to the cooled outlet temperature. However this is in fluids.......

Is it possible to make a dual pass Laminova intercooler without going to 8 cores.

Where is the best source for cores, yep tried ebay, and what prices are people paying.

I have only seen the oil coolers with double and triple pass cores. Nothing in the intercooler range. Ebay has been the only source of cores I have seen other than the manufacture. Prices were around the $100 for 4 mark but the last lot were up to $200 for 4 in the US.

Posted: Wed Jul 23, 2008 8:21 pm

by matt.mcinnes

Posted: Wed Jul 23, 2008 8:29 pm

by Shadow

500psi of air?

thats exceptionally dangerouse. i thaught it was good practise to use water to test pressures above 100psi.

Posted: Wed Jul 23, 2008 8:43 pm

by matt.mcinnes

Shadow wrote:500psi of air?

thats exceptionally dangerouse. i thaught it was good practise to use water to test pressures above 100psi.

You miss read I think

Posted: Wed Jul 23, 2008 9:01 pm

by Shadow

matt.mcinnes wrote:Shadow wrote:500psi of air?

thats exceptionally dangerouse. i thaught it was good practise to use water to test pressures above 100psi.

You miss read I think

must have

my bad D:

Posted: Sat Aug 02, 2008 5:40 pm

by matt.mcinnes

Popped in to see Awill4x4 after he sent me a MSG saying he was Lamanovering

The test subject currently looks like this.

Dropped the rocker cover in I picked up from Halls4x4 to help with fabrication to go with the Old head Awill4x4 had. This will all help in spacing out the intercooler. Awill4x4 wants to make sure this will fit a stock un-lifted Mav or Nissan TD42, although the test subject does have a 2" body lift.

Awill4x4 will now graft the intercooler onto the intake manifold in his own inimitable style

Posted: Sat Aug 02, 2008 7:53 pm

by RED60

Just lookin' at your design again MM. Would there be any downside to making the endplates as a 1 piece unit. If the endplates are cnc machined the accuracy wouldn't be a problem. You may be able to get an even tighter spacing of tubes and get an overall smaller crossection of the unit.. Still good work boys..

Posted: Sat Aug 02, 2008 9:10 pm

by matt.mcinnes

RED60 wrote:Just lookin' at your design again MM. Would there be any downside to making the endplates as a 1 piece unit. If the endplates are cnc machined the accuracy wouldn't be a problem. You may be able to get an even tighter spacing of tubes and get an overall smaller crossection of the unit.. Still good work boys..

These end plates are precision drilled and then machined out to their correct size. No CNC work just old school

but just as good. CNC is great for repeats though.

The only real draw back is initial set up costs for a single end cap and this may not suit each application depending on core layout. Although I have reduced the size compared to mine the core layout is also different due to the air in and air out feeds. If we were to make a run of these intercoolers then it may be worth looking into, but the design we have for the individual end caps will suit any core configuration and these are easy to mass produce and sealing is kept simpler.

The intercooler size is set by it's internals rather than the end caps in MKII so switching to an individual end caps would give us no real gains when 4 core run in parallel. I can envisage some applications that my suit single end caps better but these tend to be more V8 and V6.

So on the whole no real down side, but no up side either comes down to cost per unit and the number of units made.

laminova intercooler

Posted: Sun Aug 03, 2008 11:04 pm

by busman

Went for a spin with Matt tonight to do some testing as it's hard for him to drive and watch the laptop. Very impressive! The inlet temps didn't go past 30 degrees even after a couple of full throttle full boost runs and dropped very quickly once the throttle was lifted. Air temp was 12 i think, Matt can confirm this and the pod filter is in the engine bay straight off the turbo sucking in engine bay air which was at approx 50 degrees. Once his snorkel is fitted the temps may drop another 5-6 degrees.

Posted: Sun Aug 03, 2008 11:10 pm

by matt.mcinnes

Did a little more testing this evening with the help of Busman Tks.

All the sensors are now working including the settings for the boost.

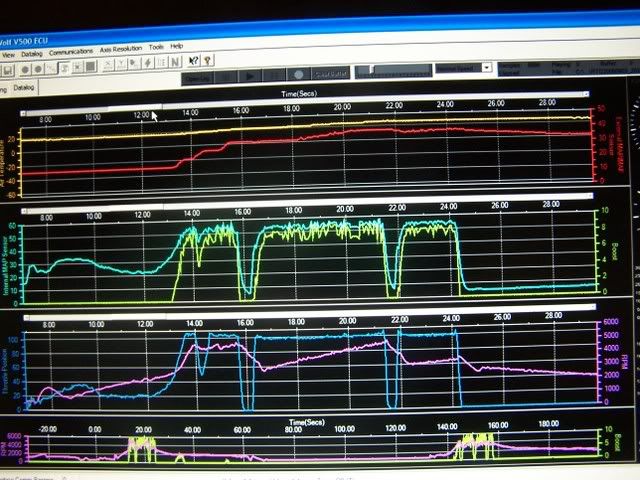

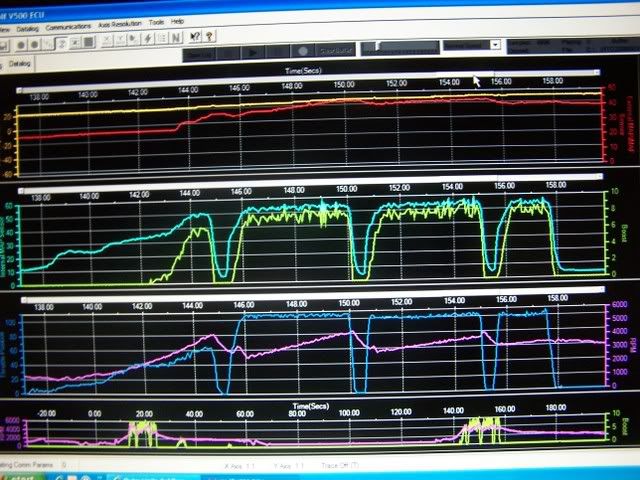

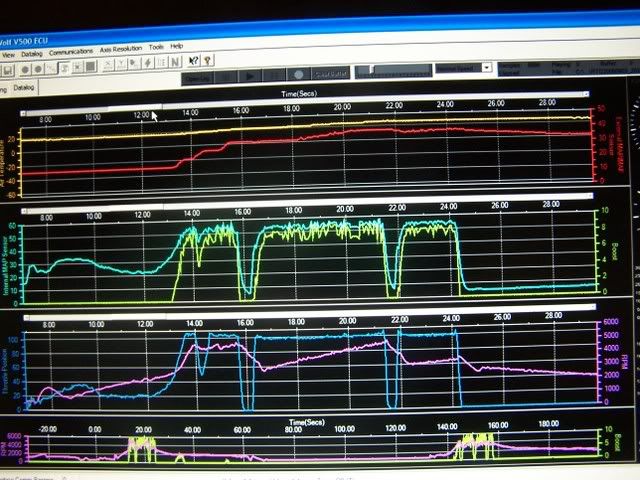

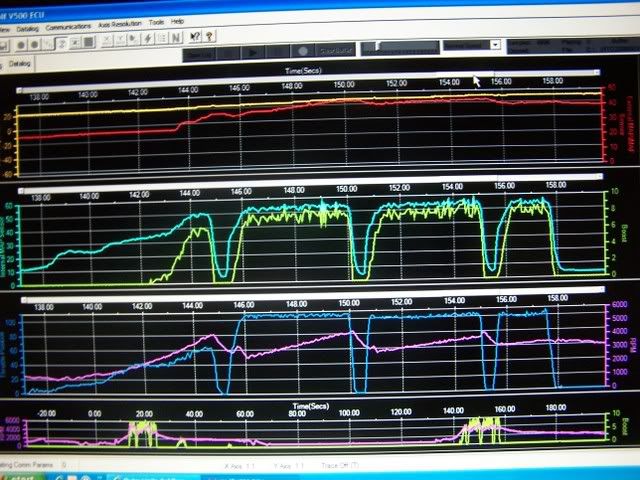

My Laminova intercooler is working well. The 2 graphs below show the intake temp in yellow and the pre intercooler temp in red in the top section. Note the red has a corection factor of *1.82 to the scale, yellow is 1 to 1. The scales are also different but they show well how the intercooler reacts to boost. As Busman says once a snorkel is fitted intake temps should be reduced, this will be passed on to post intercooler temps bringing them down further as currently the intake sits between the Turbo and the Radiator. Ambient was at 12.

So first run, Pre intercooler starts at 31 rising to 73 post 18 rising to just to 25 (This is colser to what I expext to see once the snorkel is fitted as this was before the engine bay was up to temp as in the second run.

The second run Pre intercooler starts at 45 rising to 82 post 21 rising to 29

Posted: Sat Aug 09, 2008 10:46 am

by ELF_83

am interested in building this kind of cooler for my car as i was just going to modify the plenum and get a custom intercooler core and put on my own tank, how efficient do you thinkit will be with heat soak into the cooling fluid on long full throttle high boost runs, like in sand im usually running around 14psi and have had it on 25psi for a fair while, also the ambient temps up this way are around 35'c on a good day. how much water you got in the resivour and how big the radiator?

Posted: Sat Aug 09, 2008 2:35 pm

by matt.mcinnes

ELF_83 wrote:am interested in building this kind of cooler for my car as i was just going to modify the plenum and get a custom intercooler core and put on my own tank, how efficient do you thinkit will be with heat soak into the cooling fluid on long full throttle high boost runs, like in sand im usually running around 14psi and have had it on 25psi for a fair while, also the ambient temps up this way are around 35'c on a good day. how much water you got in the resivour and how big the radiator?

I don't like to predict results for different applications but the results from mine are excellent @ 8PSI, the one we are currently building for will be running 15PSI so far more of a test, but my moines on the cores as they have great heat soak and dissipation. I run a Mazda 121 radiator for the intercooler water with it's thermo fan.

Posted: Wed Aug 13, 2008 2:52 am

by matt.mcinnes

Ordered a 100 end caps on Monday as they will be generic to the various intercooler designs, the final design of the end cap has done away with the weld on dash 8 fitting it will now be machined as part of the end cap it's self making the final part look more professional.

Delivery in 2 weeks

So were good for making 12 interccolers now

Next up 4 x 6m lenghts of Scaffold Tube to machine up.

I think I have created a monster

PS

Tks to Busman for hocking one of the end caps around to see about a price at a few places he knew too.

Posted: Thu Aug 21, 2008 3:15 pm

by matt.mcinnes

Well the first 2 are ready to test the other 98 will be ready Tuesday.

Posted: Thu Aug 21, 2008 3:21 pm

by GUJohnno

That's some excellent work you're doing there.

Will be interesting to see some pricing when it's done.