Page 1 of 1

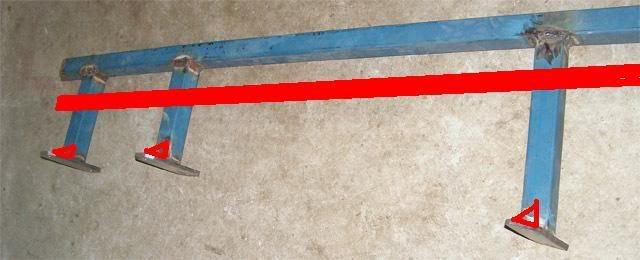

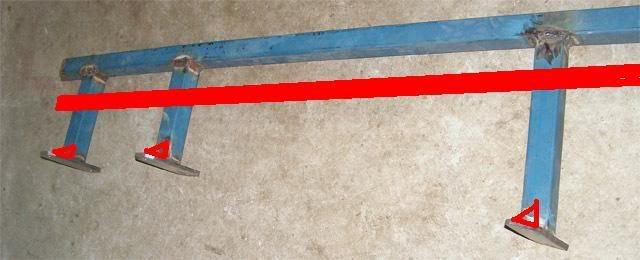

Does these sliders need bracing?

Posted: Sun Mar 04, 2007 7:42 pm

by M1S3RY

These are the sliders that i'm working on for my Paj, 50mm box welded to 10mm bar that bolted around the chassis. Does it need any cross bracing and if so where? Bare in mind that it's only a weekend warrior and my welding is fairly average (This is my first attempt)

Posted: Sun Mar 04, 2007 8:18 pm

by badger

if your not 100% confident even just a few little gussets to stop it bending up and or backwards may help.v some triangles out of the 10mm plate in the corners or sumfin

Posted: Sun Mar 04, 2007 8:55 pm

by Daisy

If your welding is fairly average.. then i'd suggest you'd put some extra gussets along the sides of the RHS going to the sliders and possibly the brackets as well.

Posted: Sun Mar 04, 2007 9:28 pm

by MART

Just a question, tube doesn,t look that thick,how thick is it because pajeros are fairly heavy,looks like it bowed a little where you welded the mounts. Next time clamp left and righht outers together when welding this will stop distortion and are you going to use u-bolts on chasis,make sure they are hi-tensile and not home madejobs. Can,t tell in photo but you need to closed end of slider tube,looks1 very good for a newby,Cheers Paul.

Posted: Mon Mar 05, 2007 7:49 am

by HotFourOk

I braced mine with triangle pieces where the support beam meets the slider part, and also where the support meets the plate mount.

It can't be overbraced

I also used 4 bolts per plate... 2 on the top, two on the bottom.

Posted: Mon Mar 05, 2007 9:26 am

by Turbz

Do you guys drill holes through your chassis rail to connect the sliders, or do you use square U bolts ?

Posted: Mon Mar 05, 2007 10:21 am

by ausyota

I would add another complete piece of RHS the full length that sits under the seam of the sill pannel.

This way when you hit something hard with them it will spread the load over the full length instead of in the 3 points of the legs.

Also a couple little triangle gussets never go astray

Posted: Mon Mar 05, 2007 11:42 am

by suzukiboy

Posted: Mon Mar 05, 2007 12:28 pm

by jeep97tj

With your welding u dont have to stop at 1 bead of weld, grind it back a bit and do another run, keep doing this until u have a solid bead of weld.

Posted: Mon Mar 05, 2007 4:45 pm

by AFeral

Easyest way to test your skids is put a jack under them if they lift the car your of to a good start. If they do not then add bracing where they bend.

As for adding more welds. Just put what you need.

Posted: Mon Mar 05, 2007 4:46 pm

by hillbilly

Those sliders look great. Wanna do some for me.

Be careful not using gussets near the chassis rails.

A decent wack, and they will fold up,and push big dints into your chassis rails.

.

Posted: Mon Mar 05, 2007 5:18 pm

by M1S3RY

Thanks for the ideas guys, my welding has improved considerably since the start (And what you can see) now that i'm using the fat rods (4mm i think).

Rear end:

Front end:

Bracing:

Posted: Mon Mar 05, 2007 5:29 pm

by rover1

if i was you i'd forget about the bracing and get hold of some 3mm plate and weld/stich underneath the rhs, so nothing can come up through the bars and your car will slide over stuff easier.

Posted: Mon Mar 05, 2007 6:55 pm

by beretta

rover1 wrote:if i was you i'd forget about the bracing and get hold of some 3mm plate and weld/stich underneath the rhs, so nothing can come up through the bars and your car will slide over stuff easier.

x2