Page 1 of 1

Shortening Jackshaft - how short?

Posted: Tue Mar 27, 2007 9:37 am

by lilpigzuk

How short can you run one before you start running into vibration/flogging bearing issues.Trying too compact a drivetrain setup in a project I have. I dont expect the vehicle to go over 50 kph.

Can you go as extreme as having just the UJ between the two yokes assuming the gearbox and transfer were fairly solidly mounted. Im thinking any slight twist in the transfer will load up the input/output bearings? Just throwing some ideas around.

Had a quick search but nothing really answered my question.

Posted: Tue Mar 27, 2007 10:06 am

by lay80n

Very short if you really want, as in rubber coupling short. But the shorter they are, the less angle you can run, and the alignment has to be spot on to avoid vibrations and harmonics developing. Have seen some jack shafts that were nothing more than an overgrown double cardon joint.

Layto.....

jackshaft

Posted: Tue Mar 27, 2007 4:25 pm

by Superduki

Yeah mate ive seen a 4age to toyota 4 speed box in a sierra with out the transfer moved back and it was just a uni joint between the pair. Being unbalanced it vibrated from about 75k onwards, took a fair beating though and still survived.

Cheers, Simon.

Posted: Tue Mar 27, 2007 6:11 pm

by roc box

i run 4k auto combo and run just a uni between the yokes, i set the whole lot up off the ideal angle for the uni though ,it has no vibes at 80 to 90 kmh.

Posted: Wed Mar 28, 2007 5:50 am

by redzook

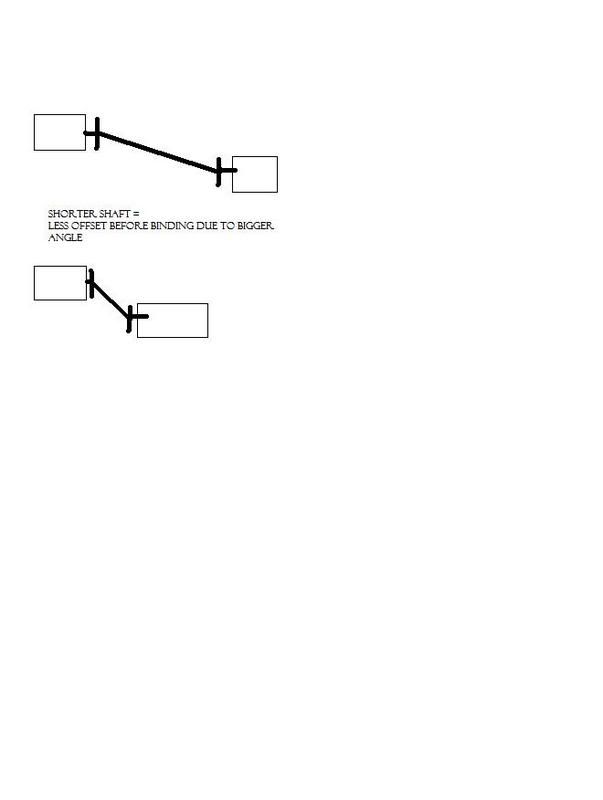

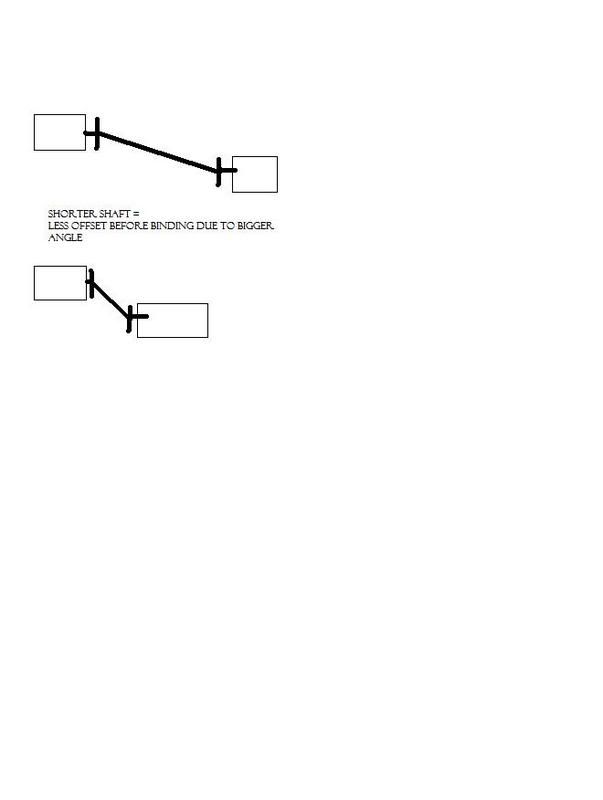

lay80n wrote:Very short if you really want, as in rubber coupling short. But the shorter they are, the less angle you can run, Layto.....

you can run the same angle no matter what length it is?

Posted: Wed Mar 28, 2007 7:55 am

by lilpigzuk

Thanks guys, just what I wanted too know

Posted: Wed Mar 28, 2007 8:00 am

by lay80n

redzook wrote:lay80n wrote:Very short if you really want, as in rubber coupling short. But the shorter they are, the less angle you can run, Layto.....

you can run the same angle no matter what length it is?

Maybe not my best explenation - better to say that the offset from the gear box to the t-case must be smaller the shorter the shaft the tighter angle the uni's must operate through for the same offset.

Hope this makes more sense

Layto.....

Posted: Wed Mar 28, 2007 12:19 pm

by lilpigzuk

All good, I followed you first time

Will try and keep gearbox and t/c "inline" to reduce any vibes...

Posted: Wed Mar 28, 2007 6:47 pm

by PAZZ

what engine an g/box u running???

Posted: Wed Mar 28, 2007 7:59 pm

by Gwagensteve

lilpigzuk wrote:All good, I followed you first time

Will try and keep gearbox and t/c "inline" to reduce any vibes...

When you go very short, be aware of the effect of movement between the gearbox and the case. As the slip yoke is in the back of the gearbox, with a very short jackshaft any differential torsional movement between the transfer and the gearbox will cause heavy side loading of the respective input shafts. It is not just misalignment that is the issue.

I would be significantly stiffening the transfer case mounts if you plan to go as short as two unis back to back. The transfer is trying to rotate around the output shaft (so the input to the T/Case is trying to go from left to right under power/overrun) while the gearbox is rolling around the line of the crank. Trying to limit the rotation of the transfer might be the best way to make these very short jackshafts reliable.

PS I have seen lots of attempts to tie the gearbox and transfer together as one unit but I don't think this is really the answer.

Steve.

Posted: Thu Mar 29, 2007 8:07 am

by lilpigzuk

PAZZ wrote:what engine an g/box u running???

Swift GTI, 413 gearbox, rock hopper transfer, feeding rangie axles

Posted: Thu Mar 29, 2007 8:11 am

by lilpigzuk

Gwagensteve wrote:lilpigzuk wrote:All good, I followed you first time

Will try and keep gearbox and t/c "inline" to reduce any vibes...

When you go very short, be aware of the effect of movement between the gearbox and the case. As the slip yoke is in the back of the gearbox, with a very short jackshaft any differential torsional movement between the transfer and the gearbox will cause heavy side loading of the respective input shafts. It is not just misalignment that is the issue.

I would be significantly stiffening the transfer case mounts if you plan to go as short as two unis back to back. The transfer is trying to rotate around the output shaft (so the input to the T/Case is trying to go from left to right under power/overrun) while the gearbox is rolling around the line of the crank. Trying to limit the rotation of the transfer might be the best way to make these very short jackshafts reliable.

PS I have seen lots of attempts to tie the gearbox and transfer together as one unit but I don't think this is really the answer.

Steve.

Thanks Steve. I was thinking the shorter the jackshaft the more "side" load on gearbox output/transfer input shafts would occur. Plan on using fairly stiff rubber mounts. and beefing up t/c mounts. Is not in a zuk chassis, so be making solid mounts for everything....

Posted: Sat Mar 31, 2007 11:51 am

by roc box

Gwagensteve wrote:lilpigzuk wrote:All good, I followed you first time

Will try and keep gearbox and t/c "inline" to reduce any vibes...

When you go very short, be aware of the effect of movement between the gearbox and the case. As the slip yoke is in the back of the gearbox, with a very short jackshaft any differential torsional movement between the transfer and the gearbox will cause heavy side loading of the respective input shafts. It is not just misalignment that is the issue.

I would be significantly stiffening the transfer case mounts if you plan to go as short as two unis back to back. The transfer is trying to rotate around the output shaft (so the input to the T/Case is trying to go from left to right under power/overrun) while the gearbox is rolling around the line of the crank. Trying to limit the rotation of the transfer might be the best way to make these very short jackshafts reliable.

PS I have seen lots of attempts to tie the gearbox and transfer together as one unit but I don't think this is really the answer.

Steve.

good point ,have addressed that issue with beefed arms and roctoy ring