Page 1 of 1

18v - 12v converter

Posted: Mon May 14, 2007 1:05 am

by Seafarer

Can anyone tell me where i can get my hands on a 18v - 12v converter? Need to be compact so that i can place it within the engel fridge. Purpose is for adding a 12V fan to the fridge.

Posted: Mon May 14, 2007 10:27 am

by Penguin

I'd be going to Jaycar or Dickie's and getting an LM7812 regulator chip. Three connections and really compact.

Mike

Posted: Mon May 14, 2007 6:03 pm

by 84ZOOKSTA

i have switch mode converters that are rated at 7 amp cont and 10amp peak.

There work from 15-38 volts and reduce it down to 13.2v.

There are available in different sizes etc.

http://www.pacificaerials.co.nz/LMR/LMR ... ters.htm#1

I have one here if you like and there around $60 each for the 7 amp version (5024) if you want the lower current version i am sure you can order through the site or i can order one in for you.

Cheers

Simon..

Posted: Mon May 14, 2007 7:40 pm

by Seafarer

Not very cluey on electrics. Wouldn't 13.2v burnt the 12V fan?

The reason for saying so is that i have a burnt fan as a result of connecting straight to the positive and negative of the engel fridge compressor.

Posted: Mon May 14, 2007 9:39 pm

by -Scott-

Seafarer wrote:Not very cluey on electrics. Wouldn't 13.2v burnt the 12V fan?

The reason for saying so is that i have a burnt fan as a result of connecting straight to the positive and negative of the engel fridge compressor.

No. Most "12V" devices can handle 14 - 15V, as these are typical automotive voltages. 18V is stretching the friendship too far.

Although I agree that a 7812 is the best technical solution, a simple in-line resistor is probably the easiest. Choosing the resistance and power rating is the trick - do you have a power or current rating for your 12V fan?

Posted: Tue May 15, 2007 7:37 am

by Seafarer

-Scott- wrote:Seafarer wrote:Not very cluey on electrics. Wouldn't 13.2v burnt the 12V fan?

The reason for saying so is that i have a burnt fan as a result of connecting straight to the positive and negative of the engel fridge compressor.

No. Most "12V" devices can handle 14 - 15V, as these are typical automotive voltages. 18V is stretching the friendship too far.

Although I agree that a 7812 is the best technical solution, a simple in-line resistor is probably the easiest. Choosing the resistance and power rating is the trick - do you have a power or current rating for your 12V fan?

These are the specs off ebay... couldn't find any on the manufacturer's website.

Part Number....................... KD1209PTS1-6

Manufacturer...................... SUNON

Size, In.............................. 3.62" x 3.62"x 1.00"

Size, mm............................ 92mm x 92mm x 25mm

Voltage.............................. 12 volts DC (10.2 to 13.8)

Power Leads...................... 2

Current............................... 0.23A

Watts.................................. 2.76

RPM ...................................3200

Flow CFM (Max)................ 50.0

Noise (dBA)....................... 33.0

Bearing Type..................... Lubricated, Sintered Bronze Sleeve

Material-Venturi.................. UL94V-0 Plastic

Material-Propeller.............. UL94V-0 Plastic

Termination ....................... 2-10" Leadwires w/ Molex 4 -pin male connector

Life Expectancy-MTBF...... 60,000 hours

The fan was burnt nevertheless when it was connected to the 2 black wires underneath the engel fridge compressor. Fridge was on mains but would have thought that the electrical unit of the fridge would have converted 240V to 12V or something thereabouts.

Posted: Tue May 15, 2007 9:39 am

by chimpboy

Someone will correct my dodgy maths, but I think this means your fan has just over 50 Ω of resistance when running, which means a 25 Ω resistor in series with it should do the trick. You should also fuse it since these fans will burn out if something stops them from spinning.

How come you need a fan?

Posted: Tue May 15, 2007 6:04 pm

by Seafarer

chimpboy wrote:

How come you need a fan?

To improve the efficiency of the fridge as i believe the amp sacrificed to the fan would result in a net gain as the compressor would be working less hard.

Posted: Tue May 15, 2007 10:55 pm

by -Scott-

chimpboy wrote:Someone will correct my dodgy maths, but I think this means your fan has just over 50 Ω of resistance when running, which means a 25 Ω resistor in series with it should do the trick. You should also fuse it since these fans will burn out if something stops them from spinning.

How come you need a fan?

My dodgy maths concurs. The 25 Ω resistor will be dissipating around 1.4W - a 2W resistor would do the job, a 5W will remain cooler.

Fuse is an excellent idea. 14V over 25 Ω will create almost 0.6A. That's a low fuse rating.

OK, go for a 10W (0.6A x 14V = 8.4W) resistor and the fan can stall for as long as it wants. Make sure the resistor is somewhere the heat won't create a problem.

Good luck,

Scott

Posted: Wed May 16, 2007 1:23 pm

by Top Cat

Why dont you just wire it up from the cars 12V supply?

If you want it to come on and off with something in the fridge then add a relay in.

Posted: Wed May 16, 2007 1:50 pm

by chimpboy

Top Cat wrote:Why dont you just wire it up from the cars 12V supply?

If you want it to come on and off with something in the fridge then add a relay in.

Why didn't I think of that?

Posted: Wed May 16, 2007 7:40 pm

by Seafarer

Top Cat wrote:Why dont you just wire it up from the cars 12V supply?

If you want it to come on and off with something in the fridge then add a relay in.

too many wires... anyway rocked up to DSE this afternoon and got all the stuff for this.

http://www.gpsoz.com.au/faninstall.htm

Thanks everyone.

Posted: Thu May 17, 2007 4:28 pm

by Top Cat

Seafarer wrote:Top Cat wrote:Why dont you just wire it up from the cars 12V supply?

If you want it to come on and off with something in the fridge then add a relay in.

too many wires... anyway rocked up to DSE this afternoon and got all the stuff for this.

http://www.gpsoz.com.au/faninstall.htm

Thanks everyone.

lol..........OMG.

Surely you jest.........lol.

Posted: Fri May 18, 2007 2:03 am

by Seafarer

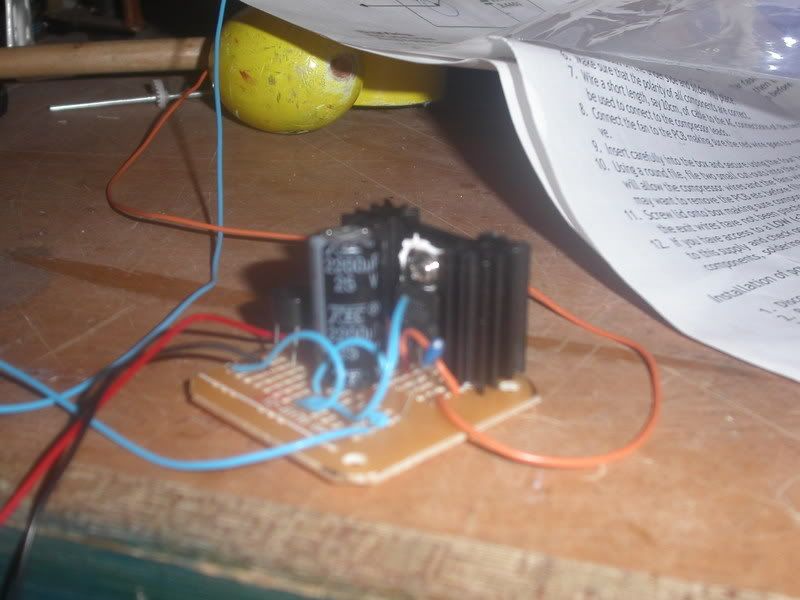

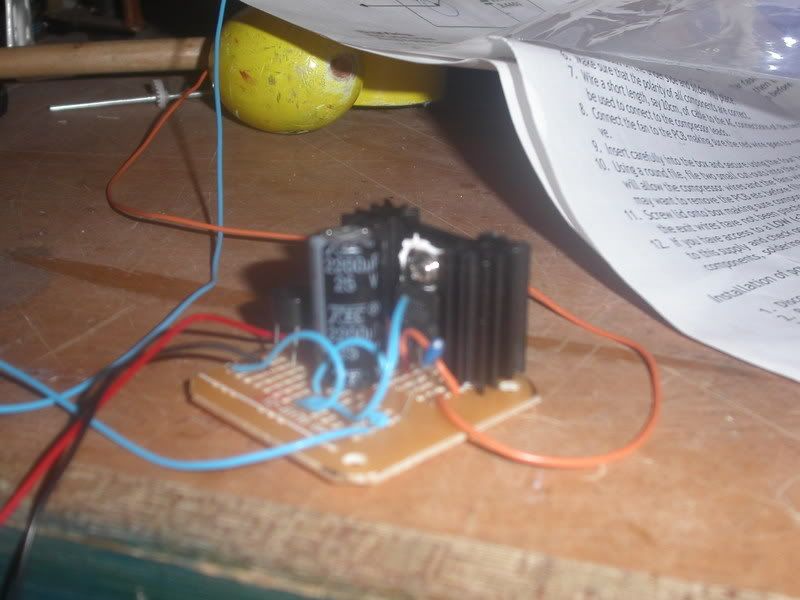

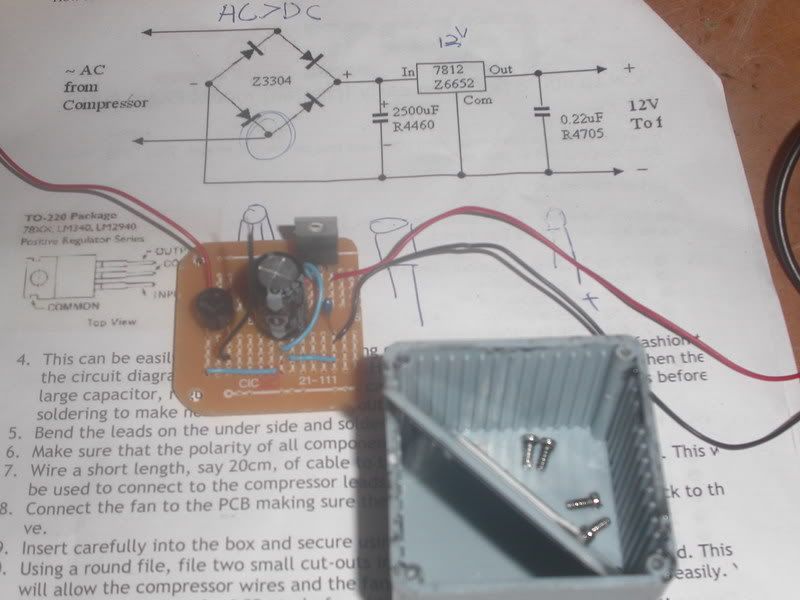

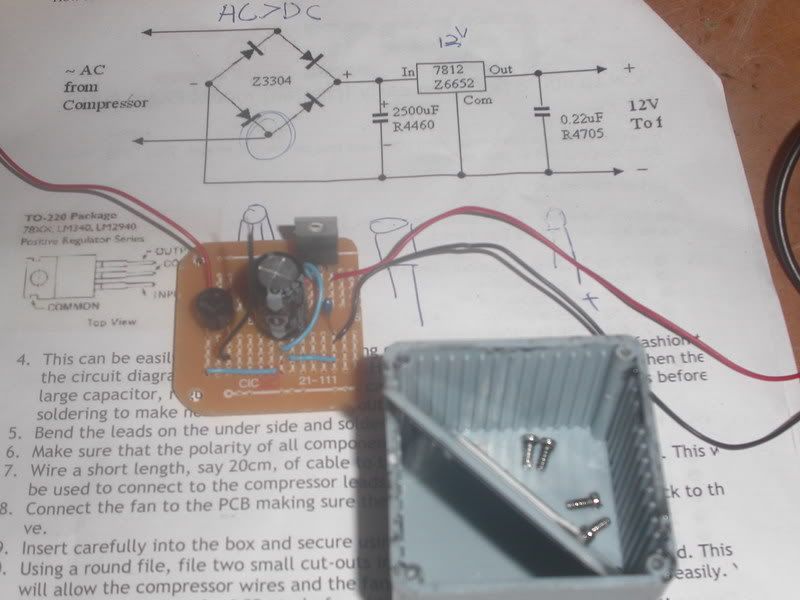

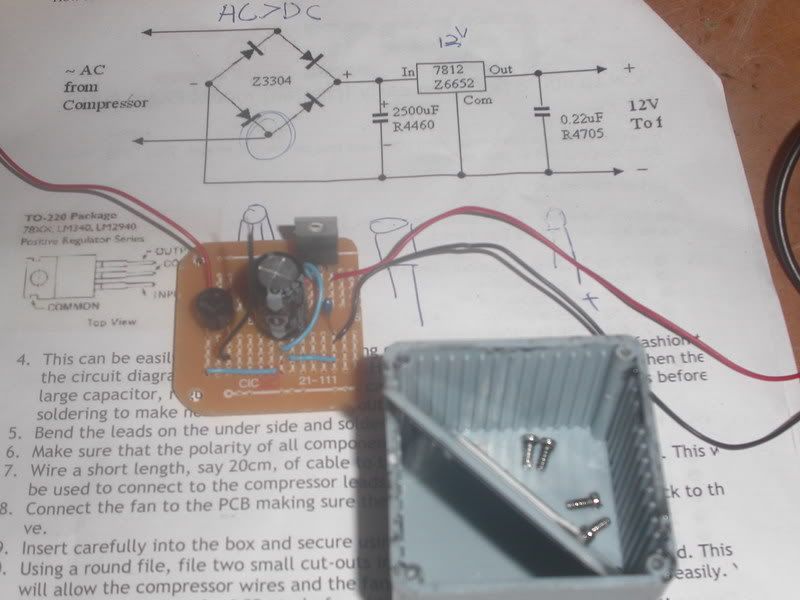

Being not the brightest light bulb when it comes to electrics.... anyway i have soldered the kit and wired up the the fan as per diagram below and it works fine when the input is via the car battery but with the fridge on mains and the kit wired up to the 2 black wires coming out of compressor the fridge's transformer made an awful noise and compressor doesn't run. Can anyone help or offer some advice? I have since disconnected and the fridge is back in operation.

The kit

Posted: Fri May 18, 2007 9:38 pm

by Seafarer

Just measured and the voltage going into the compressor when the fridge is running and on mains read 18.8v - 18.9v.

Help please...

Posted: Sat May 19, 2007 9:48 am

by -Scott-

Double check your bridge rectifier (the four diodes connected to the AC.) I suspect one or more diodes is wired incorrectly, so the compressor sees a short at some point in the AC cycle.

Or I could be completely wrong again.

Posted: Sat May 19, 2007 7:30 pm

by Seafarer

-Scott- wrote:Double check your bridge rectifier (the four diodes connected to the AC.) I suspect one or more diodes is wired incorrectly, so the compressor sees a short at some point in the AC cycle.

Or I could be completely wrong again.

That did the trick but not for long... the fan ran for 2 minutes before stopping. ... checked the kits and it's output had dropped to 1.5v..... WHY?... this is getting bigger than ben hur for me.

Posted: Tue May 22, 2007 1:06 pm

by Dooley

Makes sense to me scott.

Check to make sure everything is orientated correctly and all joints are good and not 'dry'. There is also the possibility that with the dodgy bridge your 7812 may be stuffed, although they are usually pretty solid.

edit:

Another thought, just musing, I'm a little tired so someone may need to check my even dodgier maths.

I'm assuming it's 18V AC from the compressor ?

If so 18V AC through full wave rectification is roughly 25.5V, take away diode drops and we'll just say it's 24V. Now if you're dropping that down to 12V, the regulator is going to be dropping 12V accross it. I'll just use 0.25A for simplicity sake, but if the fan draws that full current.

The regulator will be trying to dissipate 3W of heat. Now looking at the datasheet, thermal resistance junction to air is 65C/W. So 65 degrees celcius for every watt of heat, over ambient temp, without a heatsink.

So this leads me to ask. Have you heatsinked them fairly well ?

If not could be that your driving it to thermal shutdown, 2 minutes sounds like a reasonable time for it to start cooking.

Given that it is in a car, where ambient temps on a hot day could go to 50C+, unless you want to let your car sit there with the air con running before you turn the fan on, which isn't that practical, also depending on where you put it it might not cool down for a long time anyway. You may need a heatsink with a thermal resistance of around 5C/W. 10C/W

should be fine but ideally you want to keep it as cool as reasonably possible and you can get some normal sized heatsinks at that sort of rating.

Posted: Tue May 22, 2007 6:48 pm

by Seafarer

Dooley wrote:Makes sense to me scott.

Check to make sure everything is orientated correctly and all joints are good and not 'dry'. There is also the possibility that with the dodgy bridge your 7812 may be stuffed, although they are usually pretty solid.

edit:

Another thought, just musing, I'm a little tired so someone may need to check my even dodgier maths.

I'm assuming it's 18V AC from the compressor ?

If so 18V AC through full wave rectification is roughly 25.5V, take away diode drops and we'll just say it's 24V. Now if you're dropping that down to 12V, the regulator is going to be dropping 12V accross it. I'll just use 0.25A for simplicity sake, but if the fan draws that full current.

The regulator will be trying to dissipate 3W of heat. Now looking at the datasheet, thermal resistance junction to air is 65C/W. So 65 degrees celcius for every watt of heat, over ambient temp, without a heatsink.

So this leads me to ask. Have you heatsinked them fairly well ?

If not could be that your driving it to thermal shutdown, 2 minutes sounds like a reasonable time for it to start cooking.

Given that it is in a car, where ambient temps on a hot day could go to 50C+, unless you want to let your car sit there with the air con running before you turn the fan on, which isn't that practical, also depending on where you put it it might not cool down for a long time anyway. You may need a heatsink with a thermal resistance of around 5C/W. 10C/W

should be fine but ideally you want to keep it as cool as reasonably possible and you can get some normal sized heatsinks at that sort of rating.

Thanks Dooley and Scott.. heatsink.... nope haven't got that guess its back to dick smith for another set of parts and a heat sink now. will this do?

http://www.dse.com.au/cgi-bin/dse.store ... View/H3403

BTW, the input is between 18.8 VAC - 18.9 VAC

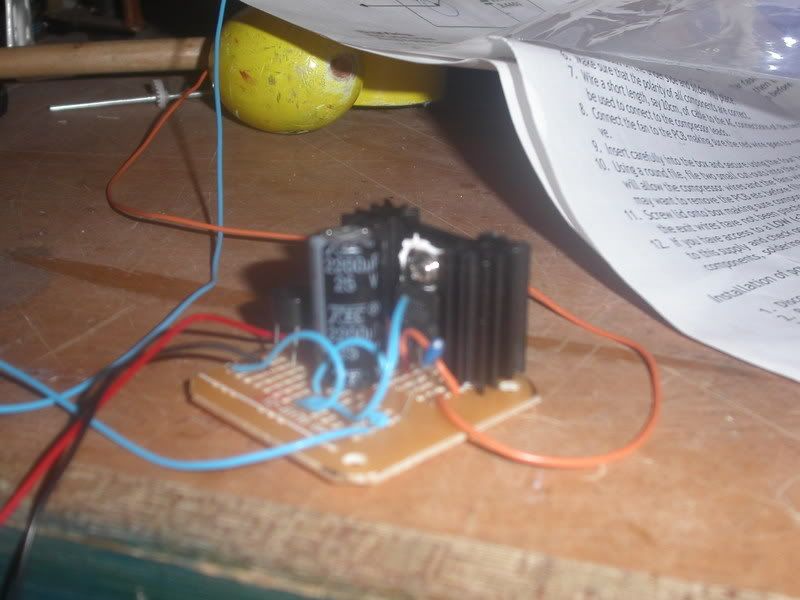

a pic of the kit i had assembled and it is suppose to fit and sealed inside the grey box beside it.

Posted: Tue May 22, 2007 7:44 pm

by -Scott-

Seafarer wrote:Dooley wrote:Makes sense to me scott.

Check to make sure everything is orientated correctly and all joints are good and not 'dry'. There is also the possibility that with the dodgy bridge your 7812 may be stuffed, although they are usually pretty solid.

edit:

Another thought, just musing, I'm a little tired so someone may need to check my even dodgier maths.

I'm assuming it's 18V AC from the compressor ?

If so 18V AC through full wave rectification is roughly 25.5V, take away diode drops and we'll just say it's 24V. Now if you're dropping that down to 12V, the regulator is going to be dropping 12V accross it. I'll just use 0.25A for simplicity sake, but if the fan draws that full current.

The regulator will be trying to dissipate 3W of heat. Now looking at the datasheet, thermal resistance junction to air is 65C/W. So 65 degrees celcius for every watt of heat, over ambient temp, without a heatsink.

So this leads me to ask. Have you heatsinked them fairly well ?

If not could be that your driving it to thermal shutdown, 2 minutes sounds like a reasonable time for it to start cooking.

Given that it is in a car, where ambient temps on a hot day could go to 50C+, unless you want to let your car sit there with the air con running before you turn the fan on, which isn't that practical, also depending on where you put it it might not cool down for a long time anyway. You may need a heatsink with a thermal resistance of around 5C/W. 10C/W

should be fine but ideally you want to keep it as cool as reasonably possible and you can get some normal sized heatsinks at that sort of rating.

Thanks Dooley and Scott.. heatsink.... nope haven't got that guess its back to dick smith for another set of parts and a heat sink now. will this do?

http://www.dse.com.au/cgi-bin/dse.store ... View/H3403

BTW, the input is between 18.8 VAC - 18.9 VAC

a pic of the kit i had assembled and it is suppose to fit and sealed inside the grey box beside it.

I reckon Dooley's nailed it - one cooked regulator.

The 19V AC you're reading is either RMS or average voltage - depending on your multimeter. The peak voltage could be about 40% higher, and this is what the rectifier is converting to DC. You lose 1.4V over the diodes, and end up with about 25.5V DC running into your regulator.

The heatsink on your link is rated at 28 degrees per Watt. At 3W and an ambient of 50 degrees the regulator case will be approaching 130 degrees (50 + (3 x 28)), and the "junction" (the silicon bit that does the work) will be hotter again.

Traditionally, 150 degrees is the upper end of recommended junction temps, and you're trapping the heat in a small box. I don't think the small heatsink is good enough.

Two choices - find a bigger heatsink, or use the small heatsink and mount your regulator so that the fan is blowing over it.

Whatever heatsink you use, you'll need a heatsink compound to ensure good heat transfer.

Good luck,

Scott

Posted: Thu May 24, 2007 4:17 pm

by Dooley

Well you may need to get creative, this is why I never end up casing my little projects up.

As Scott said you could use the fan, still would be a good idea to use a little heatsink on it at the same time. That could reduce the effectiveness of the fan though, however that leads me to the idea that you could have a pathetic little fan to blow on it, running off the 12v rail as well.

Another idea is what you could do is, don't know how well it would go as you seem to have soldered your reg pretty far down so if you do try might need to desolder it or get a new one but maybe take the edge of the proto board down so the back of the regulator is right on the edge. Then bolt a biggish heatsink to one side of your case and cut a chunk out of your case and bolt the regulator to the heatsink, the legs will be bent slightly at an angle in a slight sort of zig zag. Another idea is to use a heatsink as the base or top, although looking at the type of case it looks like a bit of a pain.

Heres the 1st heatsink suggestion, I drew a little picture.

As a side note, this heat issue is one of the reasons they often use switch mode. For TAFE I have to build a switch mode power supply for a Luxeon LED, 3W and no heatsink.

Let us know how it goes or doesn't... I don't envy you in trying to case it up.

If you do get really stuck and to the point of giving up, I have all the parts needed in my parts stash and reckon I could pull it off or look into making a switchmode for you, there is a very simple fixed 12V chip (Buck converter) that needs only a few more components than your kit that is 94% efficient (no heatsink) that I've found, won't be able to get it from dickies though, if you do want to go that way let me know as I can get the parts for that when I got some parts from the US again.

Last resort though as it will have to travel to the other side of the country, well a switchmode would be fairly easy for me to send. A linear with heatsink though, eh... not so much.

Posted: Thu May 24, 2007 8:34 pm

by drivesafe

Hi Seafarer, Could I make a suggestion, when you got to get your replacement regulator, get an insulation kit for that regulator and an aluminium box to put your PCB in.

Using the insulation kit, secure the 7812 to the aluminium box and then the whole box will act as the heat sink.

Cheers.

Posted: Thu May 24, 2007 9:15 pm

by Dooley

Didn't think of that.

Be a little careful though, it's sometimes hard to tell if the chassis will be adequate.

Posted: Mon May 28, 2007 8:38 pm

by Seafarer

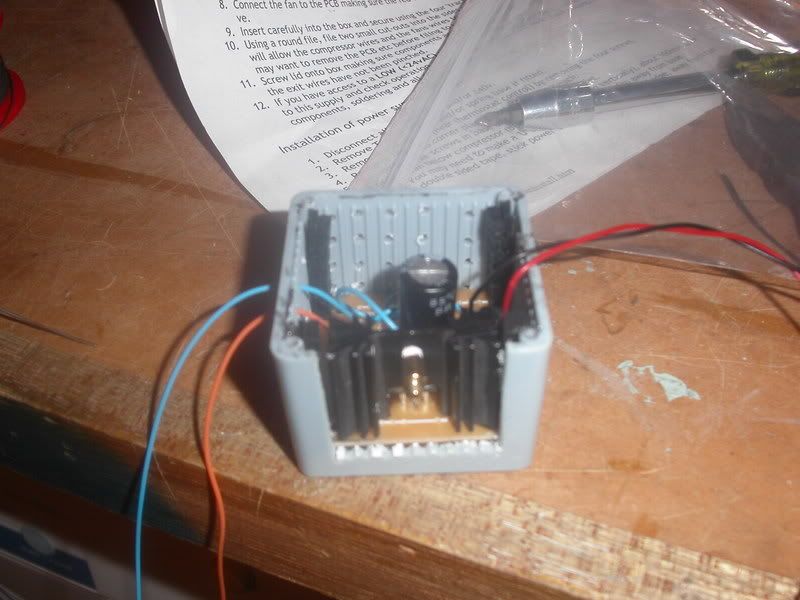

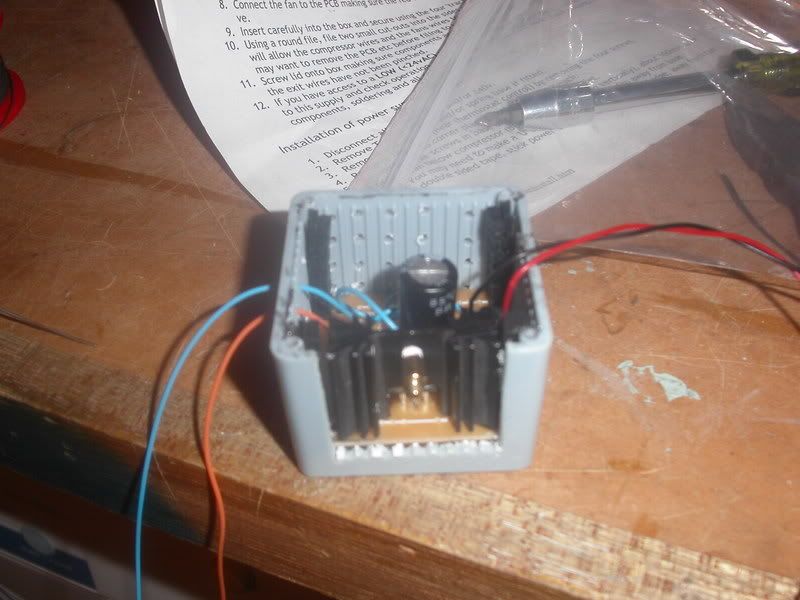

Success

The fridge and fan have been in operation for 24 hours now. With the fan the fridge temp does get pulled down alot quicker.

Below is a couple of piccies of the converter with heat sink added and box cut and drilled to promote airflow. Thanks to Dooley, Scott and drivesafe for the pointers. Much appreciated Dudes.

Posted: Mon May 28, 2007 8:46 pm

by chimpboy

Well done! I really thought this thread was going to turn out badly

Posted: Tue May 29, 2007 9:07 pm

by Top Cat

haha yeah i have been reading this with interest........I suspect you wish you had done it my way now.........but lets be honest.........if you had done that you wouldnt have learnt all you have from the experience now would you........lol

Well done to those who sorted it for him.

Posted: Thu May 31, 2007 7:56 pm

by -Scott-

Seafarer wrote:Success

The fridge and fan have been in operation for 24 hours now. With the fan the fridge temp does get pulled down alot quicker.

Below is a couple of piccies of the converter with heat sink added and box cut and drilled to promote airflow. Thanks to Dooley, Scott and drivesafe for the pointers. Much appreciated Dudes.

Now THAT is what I call a heatsink!

Top result!

I'm assuming it's 18V AC from the compressor ?

I'm assuming it's 18V AC from the compressor ?