Page 1 of 1

Longer Rear Leafs

Posted: Fri Jun 01, 2007 8:21 pm

by just cruizin'

Got a set of 2" springs for the right price, thanks Basketcase, and as I currently have a RUF setup I was thinking of getting some longer main and secondary leafs made up so that I can use the standard main & second in the front pack and 1" longer ones in the rear. This should help the shackle angle on the rear as at the moment the 2" shackles are nearly vertical.

What's the thoughts on this. Leafs should cost about $30-35 each.

Posted: Fri Jun 01, 2007 8:30 pm

by Gwagensteve

Sounds reasonable.

I have moved the rear shackle hangers forward about 50mm on a recent build and it helps the car squat and droops really well. This car runs 2" bumpstop spacers so inverting the shackles is not a problem.

Steve.

Posted: Fri Jun 01, 2007 8:47 pm

by just cruizin'

With 2" shackles a 1" longer spring shouldn't invert it, I just wonder whether I should go a little longer?

Posted: Fri Jun 01, 2007 8:49 pm

by Gwagensteve

Could probably go 2" over stock with shackles that length.

Steve.

Posted: Fri Jun 01, 2007 9:06 pm

by just cruizin'

I'll check the clearance on the rear tyre when flexed to determine where I go with the bolt hole, happy to push the diff back 1" but better check, might go 1/2 - 3/4". Drive shaft could be an issue too, might need a spacer. On that spacer to the transfer or diff?

Posted: Sat Jun 02, 2007 6:42 am

by redzook

Gwagensteve wrote:Sounds reasonable.

I have moved the rear shackle hangers forward about 50mm on a recent build and it helps the car squat and droops really well. This car runs 2" bumpstop spacers so inverting the shackles is not a problem.

Steve.

helps the car squat?

i have no idea really bout leaf springs but the only reason it would be squatting would be that it has axle rap wouldnt it?

unless u have a really long track bar wich is pretty much impossible in a zuk

(that would give it a squat figure below 100)

Posted: Sat Jun 02, 2007 7:20 am

by bigmick

does he mean the suspension travling up and down bye squat and droop.

maybe>

Posted: Sat Jun 02, 2007 10:00 am

by nicbeer

Cruisin - let us know the measurments if u get any,

I am thinking about the same but doing slightly longer in the back and front.

What impact would it have running 1" longer spring but get the centre hole back to std spot so the longer bit would be towards the rear.

Nic

Posted: Sat Jun 02, 2007 7:07 pm

by just cruizin'

nicbeer wrote:Cruisin - let us know the measurments if u get any,

I am thinking about the same but doing slightly longer in the back and front.

What impact would it have running 1" longer spring but get the centre hole back to std spot so the longer bit would be towards the rear.

Nic

That would help it flex, by keeping the hole in the standard postition relative to the front of the spring the axle would be in the same position. But as with a RUF conversion moving the diffs out, even a little can help.

Had a look today and 1" will get the shackle angle I'll looking for. Plus I'll only need mains thus halfing the cost.

Posted: Sat Jun 02, 2007 7:52 pm

by Guy

redzook wrote:Gwagensteve wrote:Sounds reasonable.

I have moved the rear shackle hangers forward about 50mm on a recent build and it helps the car squat and droops really well. This car runs 2" bumpstop spacers so inverting the shackles is not a problem.

Steve.

helps the car squat?

i have no idea really bout leaf springs but the only reason it would be squatting would be that it has axle rap wouldnt it?

unless u have a really long track bar wich is pretty much impossible in a zuk

(that would give it a squat figure below 100)

knowing Steve I would say he just menas keeping it low .. ( Not as in Squat/anti-squat)

Posted: Sat Jun 02, 2007 9:34 pm

by Gwagensteve

No, I do actually mean sqaut, as in... well, squat.

A very "angled" shackle results in a low "initial" rate in the suspension. A vertical shackle, or a slightly inverted shackle, imparts a higher initial rate in the suspension as the force from the spring is applied closer to in line with the shackle. as such, it takes quite a large force to make the shackle commence its movement as it is effectively trying to compress the shackle.

An angled shackle can move very freely when force is applied by the spring, leading to a low initial rate and encouraging the car to settle onto its bumpstops when loaded.

This is a bit of old school drag race tech. It was discussed in an issue of Petersens last year sometime I think.

For a number of reasons, I build cars with 2" bumpstop spacers and as such the rear shackle mount can be moved well forward as the bumpstop spacer prevents the shackle from needing to move as far.

when we did this, the 2" we "lost" due to the spacer was immediately gained in droop (yes, we measured this) as the biggest limiter to droop in the suzuki rear end (apart from shocks) is the shackle going to fully in line with the spring.

I am a very firm believer in running a car with only 1-2" of compression. In my experience, this makes for predictable, safe behaviour in cars used for general recreational work (not speed comps or racing)

The modified rear shackle hanger only enhances this.

Hope this makes sense.

Steve.

Posted: Sat Jun 02, 2007 9:39 pm

by Sean

correct me if I'm wrong, but in a solid axle when one wheel goes up doesn't the other have to go down. So if you limit compression to 1 - 2 inches then doesn't that mean you will only get 1-2 inches of droop?

cheers,

Sean

Posted: Sat Jun 02, 2007 9:50 pm

by Gwagensteve

Not at all. when one wheel go up, the other doesn't have to go down, it could stay where is it, go up too, or go down, it all depends what force is acting on the suspension at the time.

Bumpstop position and height will dictate how much force is applied to the drooped wheel to force it down.

That's one of the reasons I also move the bumpstops in line with the chassis at the same time as I move them down.

Because the bumpstops are well inboard on the axle of where the force is being applied (the compressed tyre) the bumpstop acts as a pivot, but because the compressed bumpstop is closer to the compressed wheel, the drooped wheel probably droops 2" for each 1" the compressed wheel moves up.

remember too that vertical travel is the same measured at the wheel or at the bumpstop, but diagonal articulation is greatest at the outside edge of the tyre, so 8" travel can turn in to 16" or more of articulation at the tyre, all dependent on bumpstop location, track width etc.

Hope this makes sense. I am looking for relevant photo's but can't find any.

Steve.

Posted: Sat Jun 02, 2007 9:54 pm

by Sean

ahh yes that makes sense.

i was going off the lego rock crawler that i made.(yes i know i'm a bit old for lego)

cheers,

Sean

Posted: Sat Jun 02, 2007 10:54 pm

by CairnsZook

You drive a Zook - you're not too old for lego

Posted: Sun Jun 03, 2007 8:22 am

by Gwagensteve

Photobucketofsh*t started working for me again - here goes:

I have found a couple. The first shows a front end with N76 shocks and inboarded a lowered bumpstops. This car is running RUF but still has widetrack spring spacing. note there is about 2" of compression in this photo. the car is on flat ground. (note - car is unfinfshed here so no commends about the front body mount)

The second is of the same car at full articulation. you should be able to get a sense of the leverage from the tyre to the bumpstop forcing the wheel down. It is hard to see, but there is about 6" clearance from the axle to the bumpstop, the springs are fanning open (no clips) and the car is nicely balanced. Both compressed wheels (front and rear) are hard on the bumpstops. the opposing tyre at this point will tuck into the guard so you can get a sense that you can gain for more articulation than vertical travel.

PS with the lego thing.... I had heaps of lego when I was a kid and built It's a shame they never made heims though- 4 links would have been cool

Posted: Sun Jun 03, 2007 9:00 am

by Gwagensteve

Back on topic, here is a photo of "a car I came across in the bush one day" with 2" bumpstop spacers and the rear shackle hanger moved forward 2". The effect on shackle angle should be very similar to running 2" longer springs. PS the car is very balanced here, and it is EXTREMELY steep and off camber -

You can make out the shackle angles in this shot.

About this steep and off camber. This is my car about 2m further down the hill.

(didn't go over - just kept it rolling and it came back.)

Steve.

Posted: Sun Jun 03, 2007 7:28 pm

by NIK

That makes alot of sense

So in saying this would it be more benificial to install longer springs or just move the shackle mount. Ive never run bump stops but Im thinking I should now.

Nik

Posted: Sun Jun 03, 2007 7:39 pm

by Gwagensteve

You could do either, but ultimately, you will have the potential for more outright travel with the longer leaf, but camber, durability, pack design etc might make it a hassle.

Bumpstops are your friend

The confidence you will have in your car on compound angles will increase dramatically, spring life will increase and you might even get more total articulation.

Steve.

Posted: Sun Jun 03, 2007 8:03 pm

by NIK

Sounds good, Ive always though more travel was the goal but what you say makes alot of sense. Sheet metal is my front bumpstop and I still have the overload leaves in the rear to limit axle wrap until I do something about it so they are my rear bump stops

Sorry for abit of hijacking but do you have any pics of upper rear shock mounts Steve?

Nik

Posted: Mon Jun 04, 2007 7:38 am

by Gwagensteve

Yep, a couple, I will post them when I am back at home.

Steve.

Posted: Mon Jun 04, 2007 7:27 pm

by Sean

completely off topic but hey,

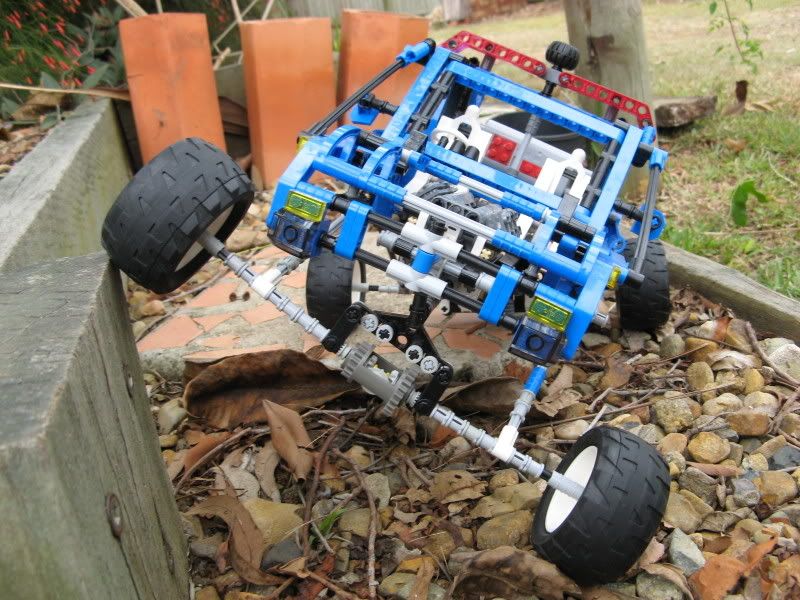

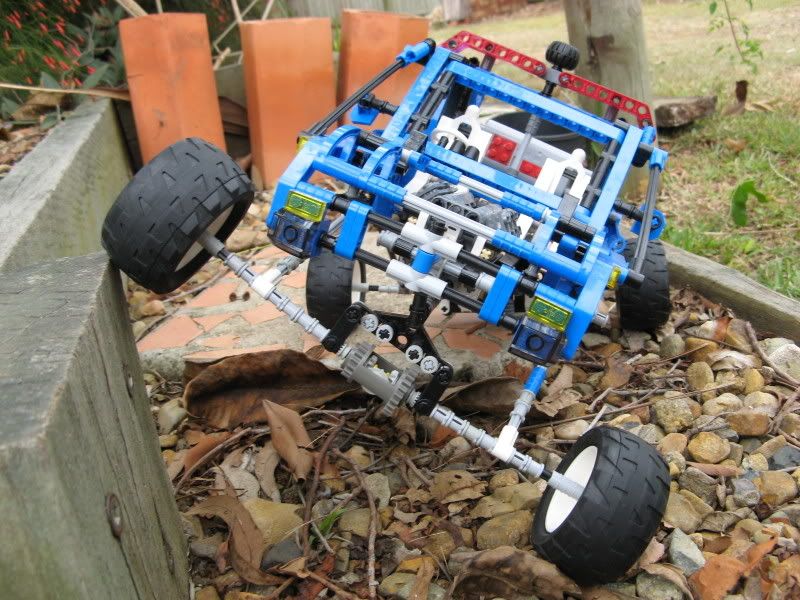

here is the lego beast, was IFS but now solid axle and now has drive through the diffs.

cheers,

Sean

Posted: Mon Jun 04, 2007 7:33 pm

by Gwagensteve

You're right.... that's completely off topic. Did you post that in the RC section and get flamed?

Nice work though - Lego has changed a bit since I was a kid.... *stares dreamily off into the distance*

Steve.