Page 1 of 1

Tale shaft dramas

Posted: Thu Jun 21, 2007 6:13 pm

by ike181

I just got a 1986 sierra and it has been SOA and I’m havening heaps of trouble with my tale shaft. on Saturday I was driving along and it snapped 1 of the uni joints and that was all fine got a new 1 from pick a part and got home and bolted her up and the old 1 had a spacer on the diff end so I swapped it over on to the new 1.when I was putting it up I had to fully extend the shaft so about 2 inch’s of the inner locking peace was showing. took her for a test drive and it come apart with pushed the transcase up and broke all the rubber mounts(witch I’m not really worried about ezy fixed) but wat I wanna know is there anyway I can lessen the angle of the shaft or some think so the unis don’t wear out as bad? anythink

Posted: Thu Jun 21, 2007 7:04 pm

by Rabbit

Maybe lower the transfer case and the gearbox so all drive shafts are aligned better and share the load

Posted: Thu Jun 21, 2007 7:11 pm

by raqmup

Tilt the diff up slightly to reduce the angle on the shaft by either re-welding spring perches or *cough* diff/spring wedges. Not too much- or you'll wear the diff out with lack of oil in the 'right spot'. I'm no expert, just what I've seen and heard that works. My sierra's Spoa and has had the diff tilted up a bit for this reason when the Spoa was done. Run a track bar as well to stop axle wrap- good investment to stop more broken uni's as well champ. Best of luck!

Posted: Thu Jun 21, 2007 7:21 pm

by ike181

have u got any pic of your track bar i can have a look at ?? how far did u tilt ya diff ?

Posted: Thu Jun 21, 2007 9:03 pm

by MART

Tilt the diff so that the top of the rear diff flange lines up with the centre off the transfer flange .This will give some up movement when loading the drive line and make the tailshaft at the pinion end straighter when loaded. Also tilting the diff up shortens the tailshaft so if you have a spacer you might be able to remove it , wedges arn't good but if you are limited , get steel wedges and weld them or get them welded to the saddles and then locate diff on wedge holes . Traction bar is a must for SPOA and they can be souced in kit form. Also if you angle the rear off the transfer down a little this will help also , Cheers Paul.

Posted: Thu Jun 21, 2007 9:18 pm

by danman.

pauls dead right. changing that angle will definitely help your cause.

and also a trac bar is the way to go.

pauls seen how much wrap my diff gets without one. hehe one day.

dan..

Posted: Thu Jun 21, 2007 11:31 pm

by Dozoor

WTF , you blokes are telling him to tilt the diff so as to aim the diff flange at the transfer yoke ?

Posted: Fri Jun 22, 2007 7:26 am

by Gwagensteve

ike181,

Either post some photos or bring the car to a Vic club meeting.

Doozor is correct - you can't point the diff flange at the transfer unless you run a CV jointed rear driveshaft. The angles both unis in a drivshaft are on must be the same or vibration and poor uni life will result.

Basically that means you can lower the transfer, take lift out of the car, or go to a CV joint drivshaft, but before that point, you hae to know that you r traction bar is effective, your springs and bushes are in good condition, and there are no other obvious problems.

I have set up a car (SPUA) but with shackles, 2" of spring lift, and 2" of lift in the transfer, (shoudl have as much tailshaft angle as a lowish SPOA) and it doesn't vibrate or blow unis so it might not be the height that's the problem.

Steve.

Posted: Fri Jun 22, 2007 9:12 am

by Guy

You can't point the diff flange at the transfer unless you run a CV jointed rear drive shaft. The angles both unis in a driveshaft are on must be the same or vibration and poor uni life will result.

I keep on reading this, but I have found it not to be the case, from years of first hand ownership of a vehicle set up with the rear pinion pointed directly at the transfer case.

The biggest issue I found is that when you get axle wrap (and you will get it big time) is that the uni binds quite easily and can be destroyed in a very very small time frame (a day or less)

When I was running stiffer 7 or 8 leaf rear springs and had no axle wrap issues (on road) The uni would normally be killed by lack of lubrication, (mud is a poor lubricant .. as is sand) .. If I stayed out of the goop (which I could not) the uni lasted easily as long as the rear wheel bearings and I had no issues with vibrations..

The top uni lasted really well, for years infact .. that was including a daily commute from essendon to oakleigh turing 33 swampers at south eastern carpark speeds ...

Posted: Fri Jun 22, 2007 9:30 am

by danman.

Well the way i see it, you mose well have one of your uni joints straight. ( the diff one cause its easy to angle correctly) then none.

i dunno maybe im wrong..

but mines setup like this and ive been running 33's for the last year and even with axle wrap i have broken no unis yet. knock on wood.

Dan...

Posted: Fri Jun 22, 2007 9:58 am

by Gwagensteve

danman. wrote:Well the way i see it, you mose well have one of your uni joints straight. ( the diff one cause its easy to angle correctly) then none.

Im not sure what you mean here, but it is/might be possible that you can get away having your unis at different angles, but it doesn't mean it is right.

Unis when set up at an angle cchange shaft velosity as they turn. (this is fact) If two unis on the same shaft are set up at different angles, then vibration MUST occur as they are fighting each other.

This is why when one end of a driveshaft is set up with a constant velocity joint (a CV, or double cardan joint) then the uni at the other end is set up dead straight to minimise this velocity change.

If two unis on a shaft are set up at different angles, there is a fair amount of force being transmitted somewhere - into the diff, the transfer mounts, the splines on the shaft... the force has to go somewhere.

You can set up two unis any number of ways but because you have done it and got away with it doesn't mean it is right or theoretically correct.

Steve.

Posted: Fri Jun 22, 2007 10:26 am

by danman.

Trust me theory is bullshit..

im an engineer so i know theory is bullcrap.

having said this ive taken wat youve said on board steve and agree with you here somewat. it all just comes down to how much stuffing around you wanna do. i guess my cars not a daily driver so im not too fussed about making it "perfect' so to say.

Posted: Fri Jun 22, 2007 11:21 am

by Gwagensteve

I agree in so far as there are lots of things what tend to be outside spec on bush driven cars and there are always compromises.

Without seeing the car in question, it is very hard to diganose what might fix the problem, (although lowering the car will ALWAYS help) but suggesting the point the diff flange at the transfer is not a way of fixing a car with inadequate driveshaft length for the lift height. It is a band aid as it relieves the effect of axle wrap on the diff end uni and that is all.

As I often say on Outers, because someone has done it and has got away with it doesn't mean it is correct or should be recommended.

What I don't get with this case is that the nose of the diff climbs under power so the uni joint is being relaxed. I think the problem might be on overrun where the nose of the diff drops which radially increases driveline angle and can cause binding. (I have seen cars lock the rear wheels descending because of rear driveshaft bind at the diff.)

We really need to see photo's/the car.

Steve.

Posted: Fri Jun 22, 2007 4:16 pm

by MART

Okay then , you can't run cv's on the car if you are going to do 110 and use it as a daily driver , as they spin upto 5 times faster than they were designed to go , and they overheat , melt the grease and centrifugal force brakes the cv boot , so cv tailshaft conversions are only good fo slow four wheel driving , (FACT) . Now if I want my zuk to be lifted and not extend wheel base how else do you get a tail shaft to work properly. When raised with such a short tailshaft the uni's will bind under articulation and axle wrap so a solution was to rotate the diff to face the transfer pinion or in that direction to lessen the tailshaft angle and give the uni's more clearance. As for lowering the transfer down what was the point of lifting the car in the first place as ramp over angle would be decreased , plus you would have to extend shifter and make a larger hole in the floor because the shifter moves more when lengthened , so you would need a bigger boot over the shifter. So how is this possible without rotating the diff and with a traction bar fitted how could this not be better , the uni angle's are better and as for vibration I have found it to be okay and you mostly get bad vibration when your tailshaft moves in two direction's , like down and accross as in a hilux diff conversion where the rear diff is in the centre.

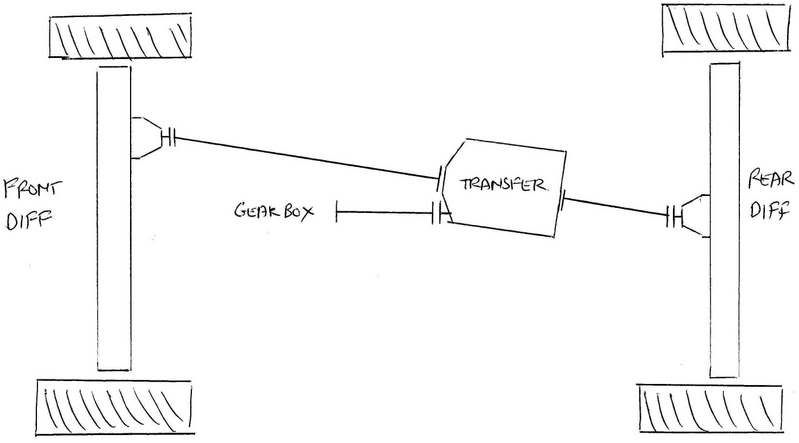

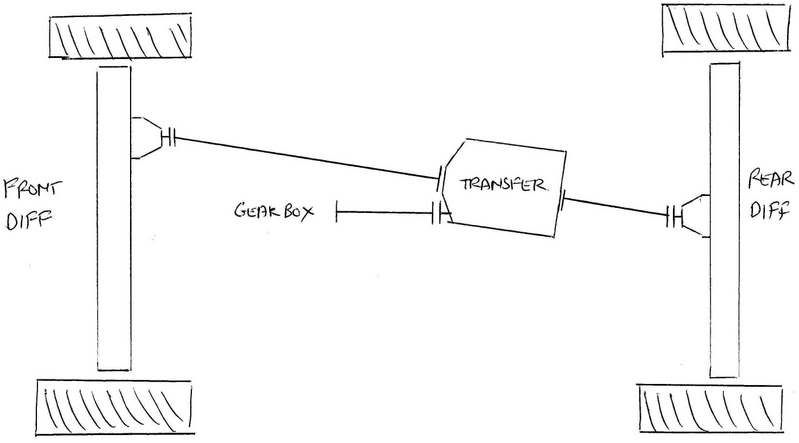

This is a simple picture of what I did to overcome this problem with a very short tailshaft. I angled the transfer in the car and slightly down at the rear and I run a cv front shaft as this is only used for four wheel driving , Cheers Paul.

Posted: Fri Jun 22, 2007 4:28 pm

by Guy

MART wrote:Okay then , you can't run cv's on the car if you are going to do 110 and use it as a daily driver , as they spin upto 5 times faster than they were designed to go , and they overheat , melt the grease and centrifugal force brakes the cv boot , so cv tailshaft conversions are only good fo slow four wheel driving , (FACT) .

This is a simple picture of what I did to overcome this problem with a very short tailshaft. I angled the transfer in the car and slightly down at the rear and I run a cv front shaft as this is only used for four wheel driving , Cheers Paul.

The type of CV shaft being refered to earlier in the thread is also know as a carden joint or a double carden joint. Not a birfield joint (Like you are refering to).

The T/case end of a hilux front driveshaft is a CV/carden joint

Posted: Sat Jun 23, 2007 11:17 am

by Gwagensteve

In your application Mart, a hilux (or MQ patrol... much cheaper although requires flange changes) double cardan joint would be ideal.

The vibration you refer to as due to the use of centered diffs is only really due to excessive angle.

universal joints are only designed to run at speed on very small angles (generally less than 5 degrees) although for short periods they will take much more. The uni doesn't know if the excessive angle is due to lift height or hilux diffs.

If you have 5 degrees of angle due to lift and 5 degrees due to misalignment - there's your vibration.

However, I think you are overstating the problem with changing the angle of the case. If the front mount of the case was raised, even a little bit, this would start to point the output of the case at the rear diff. This will then allow the rear diff to be rolled up a little bit to match (keeping the angles the same). a couple of degrees of each (only a few millimetres of adjustment on each) will make heaps of difference. The case actually hasn't been lowered at all.

Yes, the front shaft will have more (and mis matched) angles, but it only ses use at low speed so its fine.

Ironically, doing this will actually help angles on the jackshaft, as the gearbox points down to the transfer a little bit so the jackshaft usually sees slightly dissimilar angles on its unis.

Steve.

Posted: Sat Jun 23, 2007 5:48 pm

by Dozoor

steve

Love your sig

The whole exercise is longevity , strength and vibration.

When useing the unis beyond there operating perimeters you will reduce the strength and longevity and increase the vibration possability's.

IKE do as steve said take it to zook club meeting and have the guys check it out for you ,

Just the fact you have a spacer and the shaft is at full extension while stationary , if the spring mounts are standard and springs standard length this to me equalls a zook with around 3 spring lift and an axle over

So not to scare you but you may have Scary steering bits and brake lines that are to short for extension , These things could cause

a great deal of grief .

Luv mud , mart , The ENGINEER ,

Its not a problem using stuff out of its perimeters If its working for you ,

I do it myself i often use toilet paper to blow my snout , Because it works . and have also run some strange angles on shafts

Thing is they suck for stength and don,t last the 100,000 ks there supose to .

When the shaft phrases its actually like a gearing to an extent ,tiny differances in the speed of the joints , or simple hard and easy bits ,

if you add a hard bit to one end and it hasn't got the easy bit at the other

then it has non mechanical binding sort of . This is what generates

the vibrations or a stress piont in its operation that will be the piont of failure under extreme tourqe.

and this isn't the same as binding the joints mechanically , thats normally instant destuction.

Posted: Sat Jun 23, 2007 6:26 pm

by WRXZook