Page 1 of 1

feroza bash plate help?

Posted: Sun Jun 24, 2007 5:25 pm

by ooh304

hey just found this link

http://www.warfs.org/content/view/60/63/

if anyones used it or has made a bash plate let me know iam keen to put one on. thanks.

Posted: Mon Jun 25, 2007 7:40 am

by MightyMouse

Have seen this before - and made some quick checks on the dimensions

and it seemed OK.

But havn't got around to making one so your feedback is appreciated.

Others who have fitted bash plates ( not Feroza's ) comment that mud

buildup is a real problem - so make sure you can clean off the crap.

There's also some mixed opinion on their value, so believe that you

are more likely to get grounded out on a bash plate.....

Posted: Mon Jun 25, 2007 11:06 am

by Goatse.AJ

I've run mine (Mike Hennessy's original one) for the last 4 or 5 years and it has worked fantastically. Mine is a little different to Jason's, so I'll try to find the specs on it and take a couple of pics later in the week.

Mine got a workout on a big rock yesterday

IMHO, the protection it offers gives huge piece of mind, knowing that the tranny case is hanging out exposed as it is without the plate.

I've never had problems with build up of mud and carp (and I've done a decent amount of playing in the mud), but the plate is fitted in such a way that it is easy to clean with a high pressure washer or simply to unbolt and remove for cleaning if needed.

Posted: Tue Jun 26, 2007 5:12 pm

by Clint

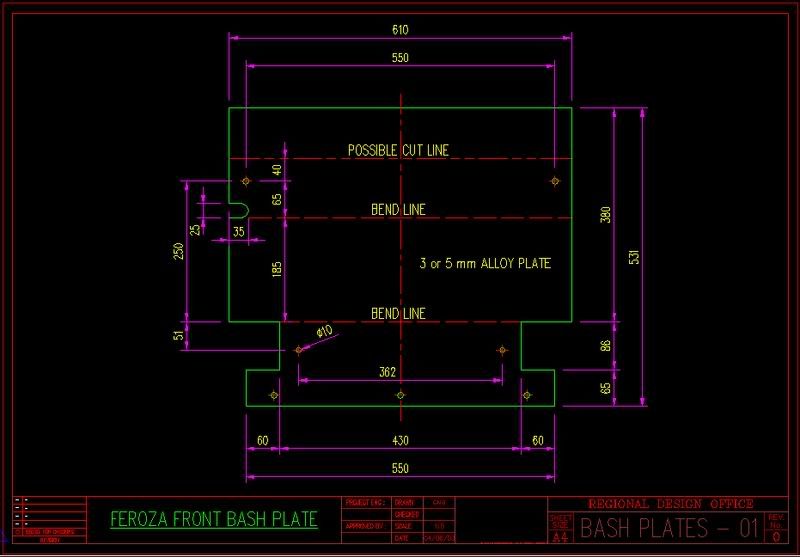

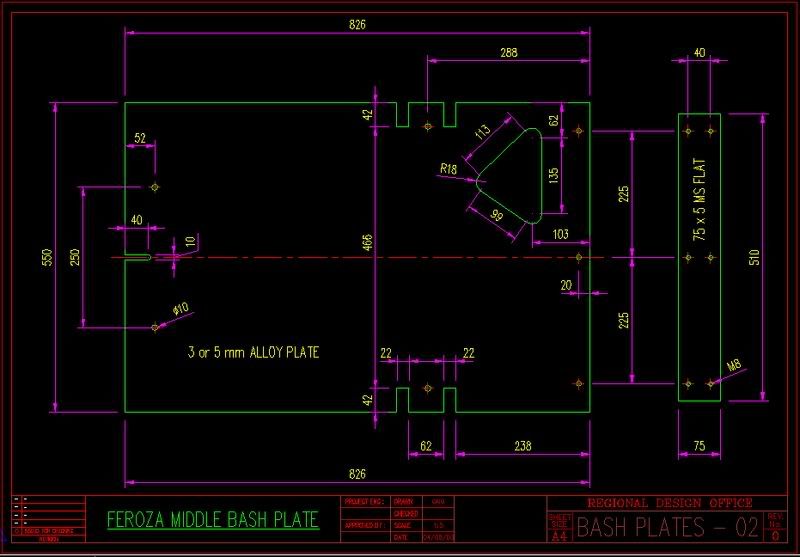

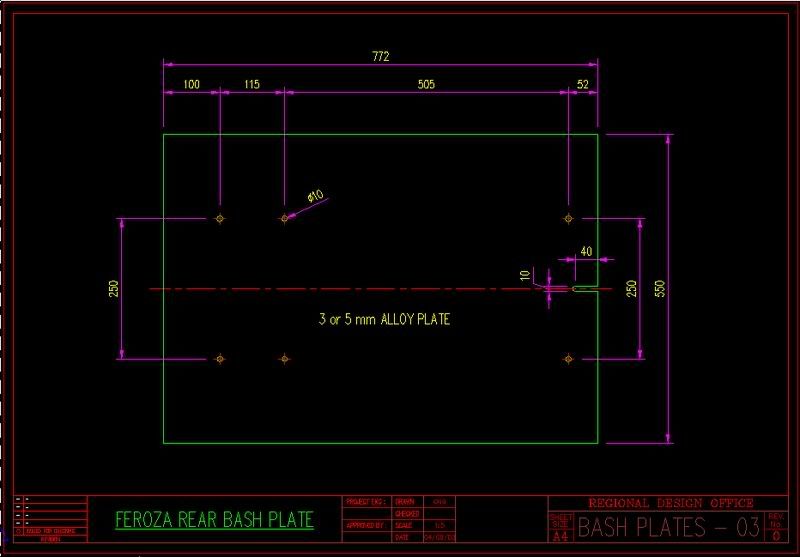

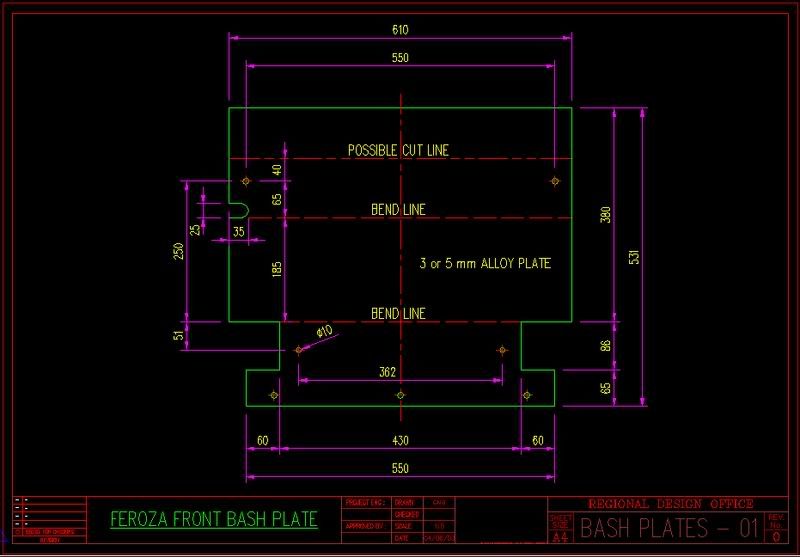

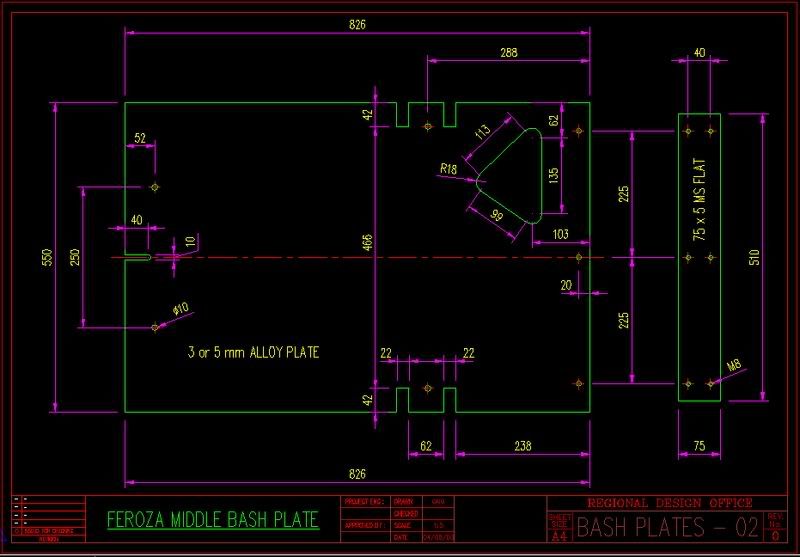

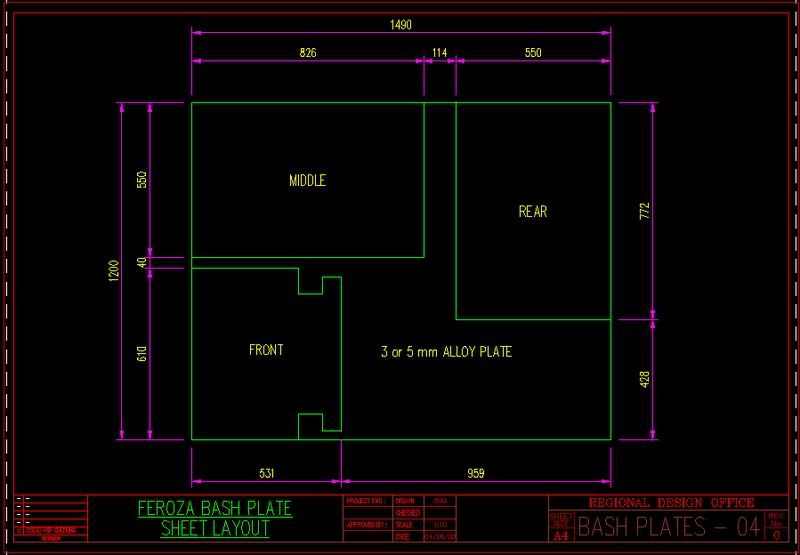

I have made almost a full length bash plate out of 5mm alloy plate. It is in 3 peices, 1st peice replaces the existing bash plate at the front. The 2nd peice bolts to it and goes back to the gearbox crossmember. The 3rd peice goes from the grb xmember to the xmember where the torsion bars are adjusted and finishes just infront of the muffler. All sections bolt into existing tapped holes on xmembers etc.

I have used countersunk bolts so that it is a smooth surface when sliding over things. No hex bolt heads sticking out to get hung up on.

I do have some drawings if anyone is interested however i did have to do some slight modifications to make it fit the new chassis.

I can also take some pics if you like, just let me know.

It works quite well, it has copped a bit of abuse and has bent a little but i would prefer that than punching a hole through the transfer case or something. Build up of mud etc doesn't seem to be a problem.

Posted: Tue Jun 26, 2007 5:37 pm

by ooh304

hey clint sounds like a sweet system you got there can you post pics and stuff. thanks.

Posted: Tue Jun 26, 2007 7:00 pm

by Clint

No worries i will take some pics tomorrow if the rain stops.

I will also see what i can do to get my drawings up on here as well.

Posted: Thu Jun 28, 2007 6:19 pm

by Clint

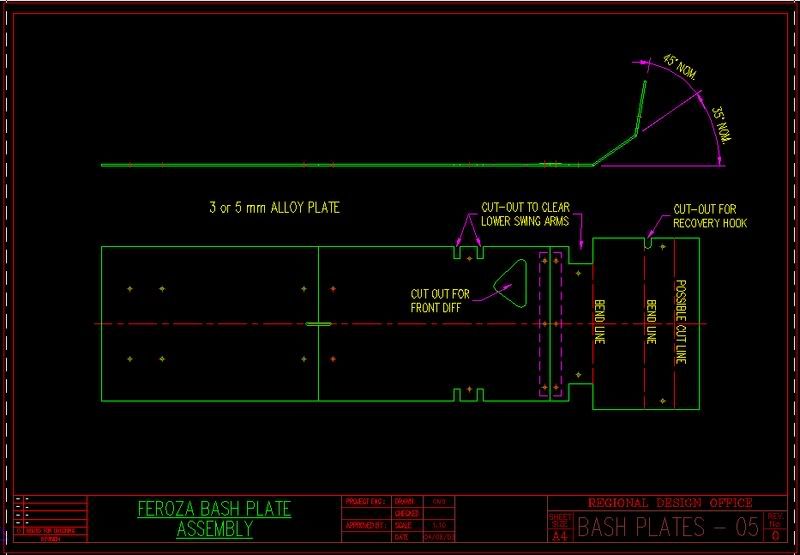

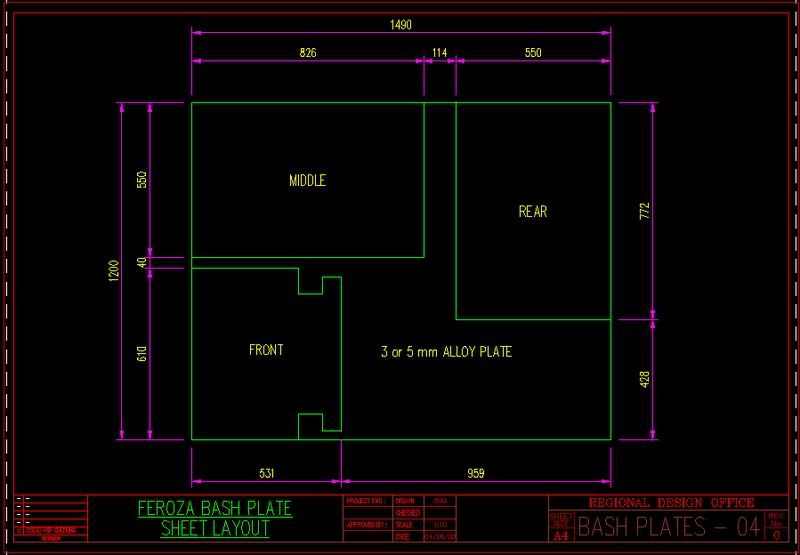

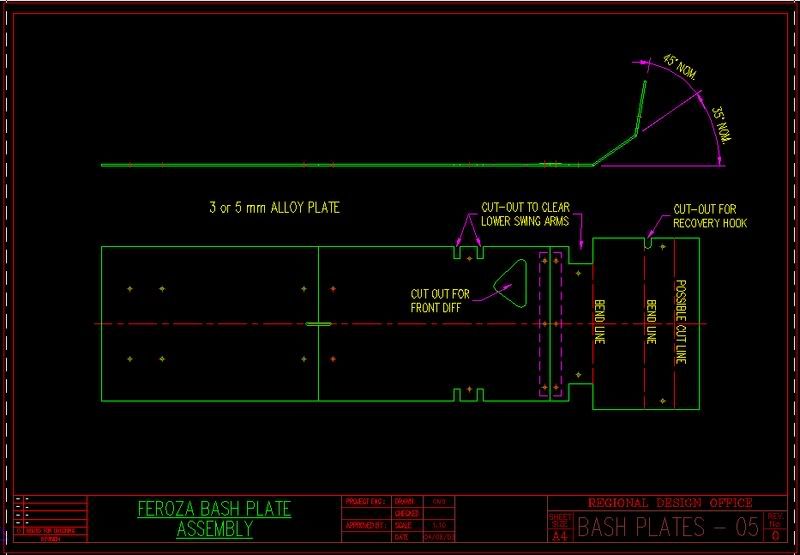

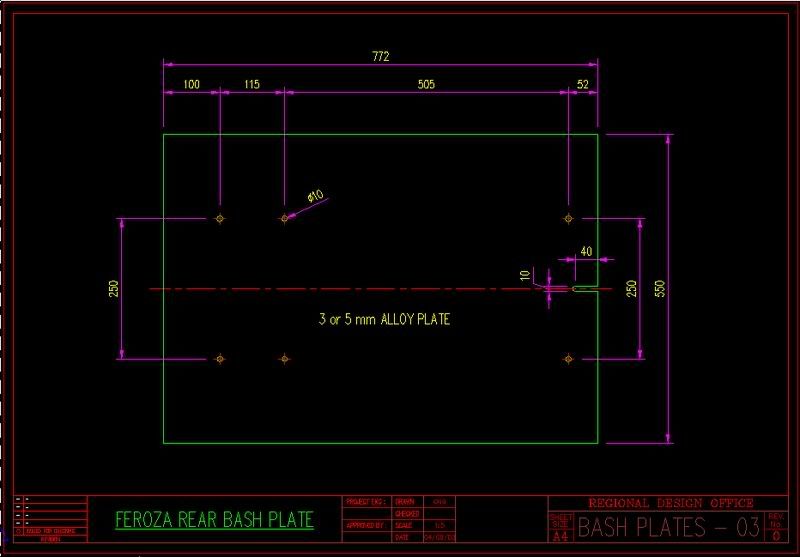

Here are the drawings i did when i made mine.

The dimensions should be pretty close but i recommend you check them on your own rig before cutting and drilling $$ worth of steel.

I did have to 'tweak' mine a little to fit on the new chassis, mainly just open up the cutouts a bit around the swingarms.

The angles i have put in for the bends are approx only. You will have to adjust it to fit as you go.

I have also been meaning to make a triangular dish type of peice to weld over the diff where the cutout is.

Was gunna make it out of something a little thicker because it will hang down a bit a cop a lot of knocks.

I will get to it one day.

Hope these make sence (sp?). I will post some pics soon.

Posted: Thu Jun 28, 2007 6:44 pm

by Clint

Couple of pics. They have had a bit of a workout as you can see and are still holding up ok.

Nothing a lil bit of panel beating won't fix anyway.

Don't have the rear one on at the moment, it was rubbing on the cat a bit.

Will have to adjust the zorst.

Posted: Thu Jun 28, 2007 6:46 pm

by Clint

I just noticed the peice of string or somethin hanging off the front.

Will have to go out and get rid of it i think.

Posted: Fri Jun 29, 2007 5:28 pm

by HotFourOk

Nooo!... It might be holding your suspension arm together

Posted: Sat Jun 30, 2007 12:41 pm

by ooh304

wow thanks clint thats a huge help.

Posted: Mon Jul 02, 2007 5:33 pm

by Clint

ooh304 wrote:wow thanks clint thats a huge help.

No worries.

If you end up making one let me know how ya go.

Posted: Sat Sep 06, 2008 2:56 pm

by Goatse.AJ

BUMP

Posted: Fri Jan 09, 2009 8:26 am

by DAT MAN

Just bumping this to the top to show a mate

Posted: Sun Mar 08, 2009 7:58 am

by Clint

ooh304 wrote:wow thanks clint thats a huge help.

Did ya end up makin one mate?

Would love to see some pics.

Posted: Sun Nov 22, 2009 10:37 pm

by mik_08

Hi Clint,

i'm thinkin of making a set of these plates up myself, when you said that there are changes to suit newer chassis what year would that change be? Mine's a '95 narrow. also wondering what material & thickness you used? I can get a sheet of 3mm mild steel and some angle bar to strengthen it for free. would that do it? I'm hoping so coz its... free:) and would i need the angle bar to strengthen it?

Posted: Sun Nov 22, 2009 10:47 pm

by mik_08

Just had a thought... would a single strip of angle bar down the centre give more strength there and stop it from bowing up from the 2 chassis rails either side?... just a thought

Posted: Mon Nov 23, 2009 8:19 am

by MightyMouse

Across is more the issue - angle down the centre wont really stop it bowing up.

You would be amazed just how much bracing is required to stop the whole lots bending if your "headbutting" a rut or rock

Also the two bolt holes at the front of the chassis aren;t really strong enough fore serious impact - i've got a box section ( part of the winch cradle ) across the front of the chassis with five bolts supporting the front of the plate.

Also ( yes i do go on....... ) watch the heads of the bolts underneath... a bit of "rubbing" on stuff and the heads end up stuffed and unmovable.

I run large countersunk "washers" about 20mm dia and 5mm thick with countersung cap screws recessed into them. Protects the whole lot from getting ground away.

Posted: Mon Nov 23, 2009 11:46 am

by Goatse.AJ

MightyMouse wrote:......

Also ( yes i do go on....... ) watch the heads of the bolts underneath... a bit of "rubbing" on stuff and the heads end up stuffed and unmovable.

I run large countersunk "washers" about 20mm dia and 5mm thick with countersung cap screws recessed into them. Protects the whole lot from getting ground away.

I run Allen Bolts. Problem solved.

If they get mangled, then vice-grips will do the job..

Posted: Mon Nov 23, 2009 12:30 pm

by MightyMouse

AJFeroza wrote:I run Allen Bolts. Problem solved.

If they get mangled, then vice-grips will do the job..

cap screws ARE "Allen Bolts" aka Unbrako.

Vice grips work on rounded normal bolts as well but agree cap screws are better once you clean the crap out of the internal hex.

A disadvantage of any bolt without protection is they get ground away allowing the skid pan to come loose. Large "washers" as described won't prevent it but delay the inevitable substantially. Large washers also support the skid pan over a larger area which is good.

Posted: Mon Nov 23, 2009 12:49 pm

by Goatse.AJ

MightyMouse wrote:AJFeroza wrote:I run Allen Bolts. Problem solved.

If they get mangled, then vice-grips will do the job..

cap screws ARE "Allen Bolts" aka Unbrako.

....

Didn't read that bit

Posted: Thu Dec 10, 2009 4:21 pm

by mik_08

Thanks for your help guys and for the plan clint. skid plates are on with cap screws countersunk into 5mm washers (suprisingly quick to turn outa some 20mm bar) YAY! time for a play! Then derust the plate and finish with something. Any suggestions? Somone suggested rust converting then spray-on coldgal (Does this stuff etch itself onto the steel?) or black underbody paint. Any preferences or other suggestions?

Posted: Sat Dec 12, 2009 2:43 pm

by DanielC

Powder coat for sure.

Cold gal doesn't really etch itself to the steel. It will rub off and rust will come.

Shouldn't cost much to powder coat.

Last price I saw was $40 for a wheel so all your plates shouldn't be too hard. Just ring with dimensions and ask.

Posted: Tue Dec 22, 2009 6:40 pm

by mik_08

I would be powder coating but keeping it in good nick with rocks, and ruts etc would be a pain, especially if it needs to be stripped and recoated completely if the coats get damaged. I made it so i didn't have to worry about the fez's belly... not to add something else to be carfully with. hence "bash/skid plate"

Think I'll be rust converting the a couple of coats of rust kill so I can touch up easily.

Thanks for the input though guys. next stop... bar work

Posted: Wed Dec 30, 2009 6:57 am

by MUMSRIG

I had a set of plates very similar to the design above. Made mine from 6mm alloy and it saved the day on many an occasion.

I made an asthetically pleasing plate for the front though and it also did a decent job...

Here is a pic or two:

I'll have a dig and see if I have any better photos that actually show the bash plates. Gotta have some somewhere.

Posted: Thu Dec 31, 2009 9:09 pm

by MightyMouse

Yep - make it STRONG first time especially in the middle section in front of the diff. If it gets pushed up the diff is very vulnerable and will break its mounts off

You can lift the diff front a little as I've detailed elsewhere - it all helps.