Page 1 of 2

Towbar as recovery point - discussion

Posted: Thu Jul 19, 2007 6:21 pm

by me3@neuralfibre.com

I know this one does the rounds occasionally, but I hadn't really seen a thorough discussion on it.

I use my towbar as a rear recovery point (Hayman Reese style - Toyota factory unit).

Myself and my friend use them in 2 different ways.

I pull out the tongue and drop in a high tensile 12 or 14mm bolt in place of the pin - going through the eye of the strap. Tht way it is highly unlikely to deform like the standard steel pin. I figure the load will stay in the correct directions without deformation, and the high tensil bolt is the same diameter as the pin of a rated shackle. Finally, if the pin did let go, the small peice of steel is low mass compared to an entire shackle.

My friend uses the tongue and towball. Instead of going around the skinny part of the ball, he puts the entire tongue through the loop, puts a twist in it, and then puts the new loop formed by the twist around the ball. This locks it on making it unlikelyt to fall off. It also transfers the pull to the base of the towball and the tongue, not the skinny neck. Again - low projectile risk.

Now I see shops selling tongue's with a rated shackle attached and think 3 things.

1. Why is this superior to either of the methods I use? And why would I spend the $ and want the KG in the car?

2. Why is it common for forums (yes info from the intenet) to rant about the towbar not being rated for this work, when commercially avaialable equipment is being made to do the same thing? (although most recovery equip is not rated with SWL anyway, or used as if it was). My personal opionion on this is that the towbar is far more solid than the chassis rails, ans it's pretty well attached w/ 6 or 8 bolts. VERY low risk.

3. The common practice of putting a shackle onto the snatch strap can ensure the worst situation. Assuming it goes onto a factory loop - that is why you are using the shackle - to go through a loop (arguments on appropriate rating aside on these), the factory loop or chassis mounting point is probably the weak point. It will fail first, and you just supplied the 2kg mass to go on the end of the huge rubber band aimed directly at the other car.... At least using the towbar it rules this scenario.

Personally I prefer hooks at the front, and the towbar at the rear as my recovery points. If onyl I could find hooks to fit the 100 Series mounting holes.

Thanx

Paul

Posted: Thu Jul 19, 2007 8:00 pm

by j-top paj

i use one of those receiver hitch things. done plenty of recoverys with it and its seems to be fine so far.

im keen to hear how this discussion goes

Posted: Thu Jul 19, 2007 8:31 pm

by +dj_hansen+

The good thing about the receiver hitches are they are easily accessible, especially if you have an aftermarket rear bar that require you to stick your hand up behind a mass of steel plate to get to the split pin to release the receiver pin.

As to using the tow ball, rated or not, i feel is risky now matter how you do it.

And if your using the factory loops on the front, you will find they are not rated for recovery (by toyota) and should be replaced with properly rated hooks (available cheaply from most shops) or something like the outback ideas rated loops which are made as a direct replacement with properly rated bolts.

There has been a dozen or so threads of varying discussion over the years, not flaming you Paul, but like alot of questions relating to the basic concepts of 4WD are getting to be done to death.

Posted: Thu Jul 19, 2007 8:51 pm

by V8Patrol

Towbars are for TOWING !

Recovery hooks correctly fitted to the chassis rails are for snatching.

I have a towbar here that was ripped clean off of the chassis rails from snatching, it sheered 3 X 3/8" engine bolts off of one side then twisted itself off of the other side also distroying 3 more 3/8" bolts and bending the mounting plate like a bit of tin + severly damaging that side chassis rail !!

Once freed from its captive placement on the chassis rails, the entire towbar then embedded itself into the front of a troopy( snatching vehicle ) @ gross knots, ...... it required an oxy to remove it !

This towbar was a custom made unit and has 10mm plate as mounts and the main cross member is made from 100X100 X 6mm tube, it has two 16mm plates for towing............ ( heavy duty towing of farm equipment )

I wasnt present when this happend but I got the job of removing the towbar from the troopies bullbar and front body work, needles to say the troopy owner will NEVER snatch off of a towbar ever again......

300mm higher and the owner would have been dead from the 35KG towbar !

Towbars are for TOWING.......

Recovery hooks correctly fitted to the chassis rails are for snatching.

That is all

Posted: Thu Jul 19, 2007 8:51 pm

by BASSYK

j-top paj wrote:i use one of those receiver hitch things. done plenty of recoverys with it and its seems to be fine so far.

im keen to hear how this discussion goes

agreed i use one aswell

they are easier to use than both of the methods you have desciribed

have you ever tried threading the end of a strap into the receiver hitch underwater in a boghole

its a lot easier to put the strap onto a hook

Posted: Thu Jul 19, 2007 10:46 pm

by just cruizin'

V8Patrol wrote:I have a towbar here that was ripped clean off of the chassis rails from snatching, it

sheered 3 X 3/8" engine bolts off of one side then twisted itself off of the other side also distroying 3 more 3/8" bolts and bending the mounting plate like a bit of tin + severly damaging that side chassis rail !!

This towbar was a custom made unit and has 10mm plate as mounts and the main cross member is made from 100X100 X 6mm tube, it has two 16mm plates for towing............ ( heavy duty towing of farm equipment )

I wasnt present when this happend but I got the job of removing the towbar from the troopies bullbar and front body work, needles to say the troopy owner will NEVER snatch off of a towbar ever again......

300mm higher and the owner would have been dead from the 35KG towbar !

I'm not saying that this didn't happen, but as you say you weren't there to witness the event so who really know what went on under want circumstances.

But if the process steered 3 engine bolts, which I assume you mean high tensile units want would have happened with a rated hook/mount held on by two bolts.

Surely if the method used did that much damage a different method should have been considered.

Greg

Posted: Thu Jul 19, 2007 10:53 pm

by j-top paj

just cruizin' wrote:

But if the process steered 3 engine bolts, which I assume you mean high tensile units want would have happened with a rated hook/mount held on by two bolts.

good point,

if a towbar it attached by say 12x5/8 bolts (6 per side) and these bolts are hi tensile or 8.8 graded then why would a hook that it attached by 2 bolts be any better?

Posted: Thu Jul 19, 2007 11:01 pm

by Emo

I use my Hayman Reece hitch and pin and have had no problems.

It might pay to check that the bolts attaching the towbar to the vehicle are suitably rated though.

Posted: Thu Jul 19, 2007 11:20 pm

by j-top paj

i went out and inspected my towbar and its atached by 6 high tensile 1/2" bolts through the chassis and 2 1/2" 8.8 bolts through the rear step in the middle (not sure exactly what its atached to thats solid)

i would hope that its solid enough to recover from BUT there is a good point that has been made, a towbar is for towing.

if my towbar says "towing only" or whatever it is then why would it be suitable for other applications?

its rated at 2.8t for towing so how much would it be rated at for snatching? 5t maybe?

whats a snatch strap rated for? 11t?

what do they break at? 18t?

Posted: Thu Jul 19, 2007 11:44 pm

by Jeeps

V8Patrol wrote:I have a towbar here that was ripped clean off of the chassis rails from snatching, it sheered 3 X 3/8" engine bolts off of one side then twisted itself off of the other side also distroying 3 more 3/8" bolts and bending the mounting plate like a bit of tin + severly damaging that side chassis rail !!

That only happens if a Toyota or Nissan (landbarge) is used. Occasionally with a V8 too...

Posted: Thu Jul 19, 2007 11:49 pm

by j-top paj

for towing or for being recovered?

Posted: Fri Jul 20, 2007 6:42 am

by doddzee

In Nz it is to be common practice to fit rated 10000lb recovery hooks front and rear, but does not seem to be in aussie.

Recovery hooks make it so simple, no stuffing around with shakles and pins which are usually burried in the mud when you are in need of recovering anyway.

With a little bit of know how they are easy to fit.

Or club required rated hooks front and rear fitted properly to certian specifications, see links

http://www.ccvc.org.nz/CCVC-SAFETY-0002 ... 050803.pdf

Posted: Fri Jul 20, 2007 7:26 am

by V8Patrol

just cruizin' wrote:V8Patrol wrote:I have a towbar here that was ripped clean off of the chassis rails from snatching, it

sheered 3 X 3/8" engine bolts off of one side then twisted itself off of the other side also distroying 3 more 3/8" bolts and bending the mounting plate like a bit of tin + severly damaging that side chassis rail !!

This towbar was a custom made unit and has 10mm plate as mounts and the main cross member is made from 100X100 X 6mm tube, it has two 16mm plates for towing............ ( heavy duty towing of farm equipment )

I wasnt present when this happend but I got the job of removing the towbar from the troopies bullbar and front body work, needles to say the troopy owner will NEVER snatch off of a towbar ever again......

300mm higher and the owner would have been dead from the 35KG towbar !

I'm not saying that this didn't happen, but as you say you weren't there to witness the event so who really know what went on under want circumstances.

1/ these are mates of mine so I tend to take their word for what went on.

2/ The vid of the inital recovery showed 2 rigs attempting to winch the stuck rig out, it's then stopped and re-started & showed one winching vehicle and the troopy about to start snatching. The vid then shows about 4 snatches before stopping, at this time the group had decided to do some digging to relieve the grip on the stuck rig.

The vid never restarted even to show the aftermath of the damage.

just cruizin' wrote:But if the process steered 3 engine bolts, which I assume you mean high tensile units want would have happened with a rated hook/mount held on by two bolts.

The most common bolt size on older towbars is 3/8 bolts, more modern towbars run 1/2" bolts........ recovery hook bolts are generally 5/8"......

Perhaps one of the boards engineering students will do some sheer loads on the various bolt sizes for us ....

just cruizin' wrote:Surely if the method used did that much damage a different method should have been considered.

Greg

In hind sight ..... thats always true !

One issue was the 3 bolt connection, one of the 3 bolts 'acted' as a "hinge" on which the other two bolts were then placed into a far higher level of sheer.

2nd issue is that the towbar was designed, like ALL towbars for towing and not for the shock of snatching which obviously exceeded the rating of the bolted connection.

3rd problem was that the towbar was that strong it didnt bend but instead placed all the shock load into the 3 bolt connection.

4th issue was that this particular towbar was set lower than the chassis rails ( as is the case with 99.9% of towbars ), but this unit hung down 6" below the chassis rails giving even a far higher leverage over the bolt pattern.

All easy stuff to see .................... after the fact !

Towbars have a rating ...... IE: how much weight they are built to TOW....

How many of you have actually done the maths and figured out what sort of load is placed on a 2tonne towbar thats fitted to say a troopy and is being recovered by another troopy ???????????????

Fine for a 'normal towing situation' but snatching

I am yet to see a towbar with a snatching rating.....

I am yet to see a manafacturer put a snatching rating on a towbar .......

Thats because they are designed for TOWING

Posted: Fri Jul 20, 2007 7:35 am

by V8Patrol

j-top paj wrote:if my towbar says "towing only" or whatever it is then why would it be suitable for other applications?

its rated at 2.8t for towing so how much would it be rated at for snatching? 5t maybe?

whats a snatch strap rated for? 11t?

what do they break at? 18t?

Now your stating to think correctly

so how many of you now want to put a towbar under roughly 5 times the load its designed to handle

think of it this way......

would you load up trailer with 5 times the weight of the maximum load rating of the towbar and expect nothing to go wrong ?

Use ya towbar for what its designed for........

towing

Posted: Fri Jul 20, 2007 8:37 am

by me3@neuralfibre.com

j-top paj wrote:i went out and inspected my towbar and its atached by 6 high tensile 1/2" bolts through the chassis and 2 1/2" 8.8 bolts through the rear step in the middle (not sure exactly what its atached to thats solid)

i would hope that its solid enough to recover from BUT there is a good point that has been made, a towbar is for towing.

if my towbar says "towing only" or whatever it is then why would it be suitable for other applications?

its rated at 2.8t for towing so how much would it be rated at for snatching? 5t maybe?

whats a snatch strap rated for? 11t?

what do they break at? 18t?

Testing snatch straps - [url]ttp://

www.lizardlegs.com.au/blackrat/news.asp[/url] doen by 4wd monthly showed most break +/- 10% of their rated load - so 9000kg for most. Testing warn winches article I saw again showed they often fail their cable at max load. The rating for the steel cable si within 10% of max load. ie. Most recovery kit we use in 4wd use has no safety margin, not even a real operating margin. Obviously the shackles tested above are different - they have a margin over 5 times. Interestingly they are rated SWL 3.5ton and most people are happy to use them in series with their 9ton snacth strap.

BUT - mention using the 3.5ton rated towbar and the stress starts.

Remember the towbar is a rated working load, not a failure load. It's designed to do that 3.5 ton daily for the next 10 years over bad roads. I agree the long lever types on some utes are under added stress. It's more the method of attachment I think about.

I can't get recovery hooks to fit the 100 series (front) using the factory captive nuts - hole spacing is different. The chassis is boxed there, so very difficult to get nuts in there and secure them.

Paul

Posted: Fri Jul 20, 2007 8:40 am

by rvh96

it really depends on the design of the tow as V8 patrol says some tow bar designs place a lot of leverage on the mounting bolts and chassis rails(ie some hilux bars hang down 200mm below the chassis mounts) increasing the load on the bolts many times over.most 4wd on the market now have eyes welded the chassis rails and a lot of people use these for recovery with a d shackle but these loops are no more than tiedowns for shipping the vehicle and are not designed for recovery, only hooks that are bolted to the chassis (not welded)should be used for this purpose

Posted: Fri Jul 20, 2007 8:44 am

by just cruizin'

Keep in mind the safety factors involved with all these peice of equipment, most shckles are only rated to 3.2T or 4.7T but straps are 9T or 11T. From the tests that have been carried out, check 4WD monthly etc etc, most straps fail with in 20% of their so called "Rated" limit, Shackles on the other hand are lifting devices therefore have a safety factor of about 10, ie 4.7T shackle should fail around 47T. Before anyone gets ancy, Yes I know of shackles that have failed as well.

What the safety factor of a tow bar is, who knows, and yes they should only be used for towing, they are not a lifting device therefore would not have the same safety factors. But given real world experience and the common bogged/stuck vehicle situation they are more then adequate for the job.

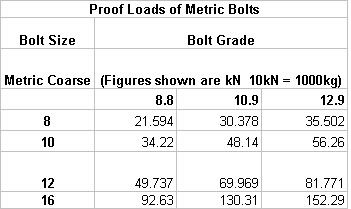

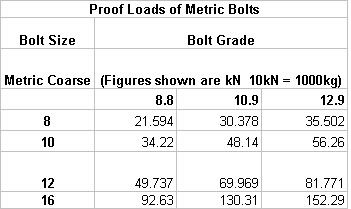

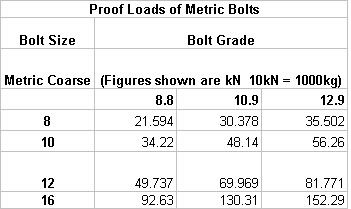

The proof load of a screw made from a particular material is the maximum load the screw can withstand without permanent deformation.

Posted: Fri Jul 20, 2007 9:18 am

by me3@neuralfibre.com

just cruizin' wrote:Keep in mind the safety factors involved with all these peice of equipment, most shckles are only rated to 3.2T or 4.7T but straps are 9T or 11T. From the tests that have been carried out, check 4WD monthly etc etc, most straps fail with in 20% of their so called "Rated" limit, Shackles on the other hand are lifting devices therefore have a safety factor of about 10, ie 4.7T shackle should fail around 47T. Before anyone gets ancy, Yes I know of shackles that have failed as well.

What the safety factor of a tow bar is, who knows, and yes they should only be used for towing, they are not a lifting device therefore would not have the same safety factors. But given real world experience and the common bogged/stuck vehicle situation they are more then adequate for the job.

The proof load of a screw made from a particular material is the maximum load the screw can withstand without permanent deformation.

Do you know if those loads are in tension or shear? I would also have thought the not insignificant friction of the clamped joint would add to the shear strength, although possibly not reliably enough to count on.

Thanx

Paul

Posted: Fri Jul 20, 2007 9:58 am

by Highway-Star

me3@neuralfibre.com wrote:

Do you know if those loads are in tension or shear? I would also have thought the not insignificant friction of the clamped joint would add to the shear strength, although possibly not reliably enough to count on.

Thanx

Paul

Pre-tensioning does increase load bearing potential in shear; and it can be significant when tensioned high.

Also anyone who puts the strap around the towball, DONT!!! This is not smart, it can shear the towball off, turning it into a cannon ball. If you choose to use your towbar, put the D-shackle through the towball hole in the tonque; or even better buy the rated thing.

ATM all I have on the back of my car for recorvery is the towbar, and the standard tie down ring; I know which I'd rather use for snatching. That said the rated recovery hooks are cheap to buy, and so long as you can figure out a sensible way to fix it to your chassis, this is the best option by far.

Posted: Fri Jul 20, 2007 12:19 pm

by just cruizin'

Given the thickness of the chassis on a Sierra just give the end of the strap to the driver and tell him to hang on.

Posted: Fri Jul 20, 2007 2:23 pm

by Gwagensteve

A) Proof loads are in shear.

B)V8 patrol, I understand your point, but as you commented it wasn't a commercially available towbar and by what you explain had all the bolts in the same plane

C)I have had my 2500kg Gwagen recovered from heavy stucks by sierras and no damage has occured to a sierra chassis/recovery point as a result.

so proof load of a 12mm bolt in shear is 50 tonnes, and a 10mm at 34 tonnes, so the 2 12mm bolts holding a recovery hook will fail at 100tonnes in tension, the 8 bolts holding a towbar on would require 250tonnes to break them all.

Yes, I know that I am using some rubbery figures here by assuming all bolts are in tension, but I hole you get my point.

I think the messages here are:

The single 12mm bolt in shear over a 40mm span Paul talked about in his first post is going to be the weak link.

The relaively soft tow pin through the receiver will also be the weak link.

The strap will be even weaker.

I have no problem trusting a commercial tow bar for recovery, far more so than a chinese hook bolted through the chassis with unknown hardware, with unknown backing.

Loose and owner modified stuff is also a big worry. (and I think V8patrols example might be an example of this)

Part of the key is that recovery points that attach in only one plane are far more likely to fail.

Just some of my thoughs.

Steve.

Posted: Fri Jul 20, 2007 2:31 pm

by me3@neuralfibre.com

[quote="Highway-Star

Also anyone who puts the strap around the towball, DONT!!! This is not smart, it can shear the towball off, turning it into a cannon ball. If you choose to use your towbar, put the D-shackle through the towball hole in the tonque; or even better buy the rated thing.

quote]

Think of this a little differently. Don't put the strap around the ball - put the tongue through the strap, ball and all, then put a twist in it, and put this twist over the ball. Now the force is tightening the strap arond the tongue, and the base of the ball is simply acting as a lump to stop it sliding off.

I don't tend to do this cause it gets my snatch all greasy, an no-one likes a greasy snatch.

BUT - it does seem to be a very strong method. You would have to shear the towball shaft bolt twice at the base to make it let go - I think the hitch pin would shear first.

Paul

Posted: Fri Jul 20, 2007 3:12 pm

by Gwagensteve

If I am visualising this correctly it will be both spreading the eye a fair bit and with the twist I think it would result in a fair strength reduction.

Having the towing tongue in place in any car with a receiver hitch is dumb when offroad IMHO.

Patrols, landcruisers, jackeroos, pajeros (hummers!) and I am sure others already have the best possible recovery point allowed for - they have a pintle hitch pattern on the rear crossmember. Why more people don't use pintles for recovery escapes me. I have used one for years. They are kind to straps, work at all angles, retain the strap, remove one shackle from the recovery and are fiersomely strong.

I have even built my new rear crossmember on by Zook to take one.

Steve.

Posted: Fri Jul 20, 2007 4:58 pm

by KiwiBacon

IMO using the pin (or a bolt in place of the pin) in your square receiver to snatch is a bad idea.

You've got roughly 8 times the bending load on the bolt compared to the same bolt holding in a square receiver subject to the same load.

If a bolted join slips, then the joint has already failed. Bolts which haven't been tightened up properly (higher strength bolts need higher torques to work) can move and damage themselves. The result being they fail at a load a lot less than they should.

I want to see pictures of the towbar that sheared off 3 3/8" bolts. It sounds like the high moment load on a close group would have worked and damaged the bolts.

hooks

Posted: Fri Jul 20, 2007 5:59 pm

by jkv6

i have put the strap up the receiver hitch to snatch and a hitch with shackle thing and feel the shackle is better when pulling on an angle as pulling from receiver hitch on any angle can rub the strap up the sharp edge of hitch the receiver shackle set up removes this prob and if bogged easy to put strap on shackle as knee deep mud trying to figure if you have the pin in right etc pain in the arse

on a tow bar not hitch type what we used to do remove tow ball and put shackle pin in tow ball hole

as for stress loads on tow bars did nt 4wd monthly or 4x4 australia do a test on just how stress is transfered to bar (if straps used right is not that great will try to find mag )

Posted: Fri Jul 20, 2007 6:02 pm

by steven101

j-top paj wrote:

its rated at 2.8t for towing so how much would it be rated at for snatching? 5t maybe?

Think about it logicaly but, you your landcruiser already weighs 2.6 tonne or so if your stuck in mud up to about the hub the car is meant to be between 2 to 3 times its orginal weight to tow out, If its higher than that the weight goes up with it....

2.6 tonne x 2 = 5.2 tonne

2.6 tonne x 3 = 7.8 tonne

Starting to get my drift?

Unless it is some sort of simple pull up a hill thats required the tow bar is inadequate for making a tow..

Posted: Fri Jul 20, 2007 6:13 pm

by truK

The other advantage with using a tow bar setup as opposed to a single recovery hook is that the towbar will distribute the load more evenly between both chassis rails. Assuming the bolts are correctly rated this would be my preference as this will spread the loading throughout the chassis rails more evenly (over 4-8 bolts depending on tow bar) then the concerntration of 2 bolts per hook.

To get around this twisting/warping of chassis rails when using single recovery hooks, you can use 2 (such as on the front of a vehicle) and place one on each chassis rail and then use a sling (chain or webbing) to spread the load between the hooks more evenly. Its important that the length of sling is long enough so that the angle it makes between the 2 recovery hooks is as actue as possible because when that angle is wider (shouldn't be more then 60 degree) it will result in a compressive force that pinches the front/rear chassis rails together and this inturn places more stress on the sling that links them (if i could draw a diagram it would be heaps easiler to explain).

As others have said, with any recovery setup it will only be as strong as the weakest link. This is normally the strap because it will cause less damage then if a shackle were to let go, but either way its going to be hitting with a lot of force.

Always use rated gear!

Posted: Fri Jul 20, 2007 6:29 pm

by me3@neuralfibre.com

There was a formula kicking round the British? army uses as a rough tool for winching load. It has factors for terrain material, incline, depth stuck and immobilised wheels.

Can't google it for the life of me.

Paul

loads

Posted: Fri Jul 20, 2007 9:29 pm

by jkv6

just fond an old 4wd monthly mag which states (recovery guide)

"as2741 says a 3.2 tonne wll shackle must not fail at less than 16tonnes"

"the 3.2 tonner didnt break until 27.2 tonnes" "4.7 tonne example was an incredible 33.7 tonnes" these are rated for lifting

also "there is no compulsory standard for ANY 4wd recovery gear" so in other words your 10000lb recovery points are made to which standard atleast a shackle has an AS to comply to but a recovery point? could i sell you a piece of card board with 10000lb writen on it and sell it as a recovery point???????? a tow bar is rated to australian standards which is more than any recovery point

i know things may changed since this mag was put out but have a look on the box your hooks came out of is there a standard on it ie AS?????

Posted: Fri Jul 20, 2007 9:40 pm

by kevdog

hmmm.... i have snatched a bogged fourby ( forerunner ) by the towbar that was stuck in sand mud and was mildy surprised when the towbar itself ( not mounting bolts or welds , the 2 inch round pipe part) snapped and bent hideously... after wards i noted that some keen bloke had drilled and screwed the trailer plug into the pipe. this was th point that the bar snapped, obviously weakened...

how could you ever be sure from a cursory glance that nothing potentially weakening had been done to someones bar ( assuming that you are snatching someone you dont know).

maybe also we should consider that the leverage on the mounting points of a tow bar would be much larger than the leverage on the two bolts that hold the rated hook that you mount to your chassis....

having said all that i myself snatch from my hayman reece style rear bar with a high tensile 16mm bolt through where the towbar pin normally goes...