Page 1 of 1

diy snorkels

Posted: Thu May 15, 2008 10:43 pm

by DUDELUX

im planning a home made snorkel for my lux. i can get some 3 inch tube and some rubber bends (some 90 degree and some 45 degree). would this be ok for my 86 lux?? 2L engine.

Posted: Thu May 15, 2008 10:56 pm

by HotFourOk

Yes.

Was there any other question here?

Posted: Thu May 15, 2008 11:29 pm

by DUDELUX

umm. how do i mount snorkel to a-pillar of truck?? are normal hose clamps ok to use where the rubber hose meets the tube??

thankyou

Posted: Fri May 16, 2008 12:43 am

by Toyo Truck

I was just contemplating this dudelux!

you beat me to it!

This was exactly what I was thinking, but even better,

can you get flexible rubber/plastic tubing and just run that

cable tied to a bit of exo cage...like some of the tuff trucks run.

Where do you get this flexible piping from in like 3M lengths?

My factory intake piping is 64-65mm OD so something around this ID

would be fine. Would clarks rubber sell it? I'm gonna call em tomoz

I've wanted a snorkel for ages...I think its time.

then I can go reeeeeeeeeeally deep

Cheers,

Bart

Posted: Fri May 16, 2008 12:10 pm

by coxy321

For a Hilux, i'd probly go with 2.5", unless you're running a 3.0L turbo diesel or a V6/V8.

Are you guys handy with a welder?? Why not buy mandrel bent exhaust sections ($8ea), and some exhaust cutoffs (free!!) and make a 1 or 2 piece snorkel?? IMO, i've seen some made up of rubber joiners and flexihose etc etc and i think they look CHEAP. And nasty.

You can copy one of the $900 custom stainless competition truck snorkels by using mild steel, and it will cost you $50 max if you do the work yourself.

Coxy

Posted: Fri May 16, 2008 1:55 pm

by Toyo Truck

Hey mate,

was thinking of this, but I can't do watertight welds...not just yet LOL

I only have a stick welder too.

Thats why I was gonna use the rubber joiners.

Plus it gives you a bit of leeway should you roll on it. It will have some

movement?

Who sells the mandrel bent doughnuts in/near Syddo?? If they are only

$8 I will do that. And just ask them for some offcut exhaust pipe yeah?

(65mm is about 2.5" anyway. give or take 0.1 of an inch.)

Cheers,

Bart

Posted: Fri May 16, 2008 2:25 pm

by thehanko

How thick is the wall on the mandrel bent pipes? you can weld stainless witha stick pretty easy, but the thickness (or lack there of) would be the hard part. the welds would not even have to be 100% water proof, a few drops in through the snorkel wont matter, they should drain through the air box anyway.

What kind of stick do you have? ive heard the inverter models are much better on thin walls.

where do you get the bends from? Also can you still fit a squarer inlet on top? as i think these look beter than just the pipe inlet on top.

Posted: Fri May 16, 2008 2:35 pm

by coxy321

Easy solution. Weld it up watertight (might as well, cause it IS a snorkel), then get yourself a flapper disc and a 6" grinder, glasses and face mask - grind away. You SHOULD be able to get a completely seamless join doing it this way - slap on some paint and it'll look a million bucks.

I generally find the mandrel bent sections have a perfect wall thickness, while actual exhaust pipe is a bees d!ck thicker, and the mandrel bent doughnuts are probably somewhere in between.

Want an example? This isn't a snorkel, but the same principles apply. This is also how i make my intake piping and exhausts. MUCH cheaper than paying a workshop to do it.

Also, using mild steel will mean you have to seal the inner surface so it doesn't rust over time. To do this, before i start welding i give the insides a good dose of brake clean or wax/grease remover, so your not scrubbing the insides out after welding. Then once its all welded up you can either a) spray down into the pipe and hope you coat everything; or b) get a small tin of etch primer, seal one end of the pipe, pour the etch primer in (not too much!), seal the other end, then roll it around so you coat ALL of the inside. Drain the excess paint/primer, let it dry for 3 days, then repeat process once more (to be sure, to be sure). EASY!

Coxy

PS. Just incase you couldn't find it, the piping i'm talking about is the BLACK pipes in the engine bay.

Posted: Fri May 16, 2008 3:41 pm

by thehanko

That finish is pretty damn good. did you just go to an exhaust place to get both the off cuts of pipe and the bends?

Posted: Fri May 16, 2008 4:09 pm

by coxy321

I always keep a few metres stock of 2.5 and 3 inch pipe. From memory it is about $70-$80 for a 3m length of 2.5", and an extra $30 for 3m of 3".

If you know someone at an exhaust shop you should almost be able to get cutoffs for free. I buy mine from Bursons direct.

The mandrel bent sections i buy from the local truck shop. You can get 30/45/90 degree bends, in pipe from 1.5" through to 6".

I MIG weld the joins (tack them first for a test fit), then spend a fair bit of time hanging off the grinder.

Coxy

Posted: Fri May 16, 2008 4:31 pm

by pubic

find someone with a tig welder, the job will look 10000000 times better, it may take a little more skill but you will get a much better job done.

use some stainless, it will NEVER RUST. if you pop into a stainless sheetmetal shop, you will be able to find a decent apprentice who is looking for a cash job. he would be able to get bends and tube from work and then knock you up something that looks great at a relatively cheap price, definately not $900 carton of piss will normally sort em out.

all comes down to preferences i guess.

just my 2 bob worth.

Posted: Fri May 16, 2008 4:50 pm

by thehanko

can stainless be painted easily? prefer black to silver

Posted: Fri May 16, 2008 5:14 pm

by Troopy93

Posted: Fri May 16, 2008 5:58 pm

by BushTuckerNed

Pretty much the same as what Gary just posted, but theres one for a GQ in here

http://www.mudrhino.com.au/DIY.htm

Posted: Fri May 16, 2008 8:45 pm

by ssfabricator

ill make a stainless snorkel one piece welded polished in 2 1/2 for around $200 will send a photo of mine if you want to send me email adress

Posted: Sat May 17, 2008 3:31 pm

by coxy321

How much for a 3" snorkel to suit TD42 GQ patrol???

Coxy

Posted: Sat May 17, 2008 6:38 pm

by ssfabricator

not much more would need the car to make it (correct angles) you chose where you want the mounting points and install yourself

snorkle

Posted: Sun May 18, 2008 3:18 pm

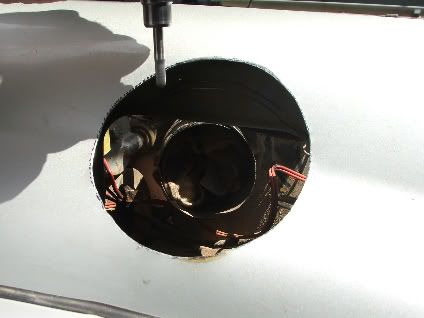

by luxembuger

G'day, here's the stainless one I fabbed up for mine a couple of weeks ago, just for an example for you. Cheers.

Posted: Sun May 18, 2008 7:47 pm

by DUDELUX

thanks troopy93 thats how im planning mine. i can get the rubber bends and tubing from a guy at work for nothing so just have to fit it.

Re: snorkle

Posted: Sun May 18, 2008 9:17 pm

by coxy321

luxembuger wrote:G'day, here's the stainless one I fabbed up for mine a couple of weeks ago, just for an example for you. Cheers.

That looks bl00dy nice. Just what i plan on doing actually (or paying someone to do). I think i'm going to run a standard snorkel head though.

Coxy

Posted: Mon May 19, 2008 2:17 pm

by Badass Bundy

PM sent

Re: snorkle

Posted: Mon May 19, 2008 3:07 pm

by TheOtherLeft

luxembuger wrote:G'day, here's the stainless one I fabbed up for mine a couple of weeks ago, just for an example for you. Cheers.

Where do I get one of those sexy looking aerials? They look tops!!!

Posted: Mon May 19, 2008 4:04 pm

by Toyo Truck

That is one nice snorkel mate!

How much did it cost you in pipe and fittings, etc mate?

Cheers,

Bart

snorkel

Posted: Mon May 19, 2008 9:06 pm

by luxembuger

G'day Bart

Three 90deg bends cost about $70 and the pipe I 'found' at work but if you had to buy it, it's worth about $190 for 6 meters.

The flex connection between the snorkel and the air filter box was $30

Then a few hours to work out the angles and tig it up and polish.

Heaps cheaper than a bought one and looks horn.

Cheers, Chris.

Posted: Tue May 20, 2008 2:44 pm

by hjgq

I went to my local exhaust place spent $90 on 2 mtrs of 3 inch and 2 90 degree bends then went to enzed and got about 800mm of flexy pipe welded it 2 coats of etch primer and 3 coats of mat black looks the goods all up about $150 -$200 all in a days work

Posted: Tue May 20, 2008 4:14 pm

by Vineboy

Hay Troopy93.

Are they also home made Hiclones I see stuffed in there?

Seriously it's a good job. What did you use to fill in around the snorkel as it goes into the fender?

Posted: Tue May 20, 2008 5:20 pm

by HotFourOk

I used rubber edging from Clark Rubber to finish off the hole cutout.

Just remember if DIYing, if you want the bend to sit nice flush into the guard, you need a teardrop shape hole, not just circular, to allow the bend to protrude into the guard.

Posted: Tue May 20, 2008 5:27 pm

by johno88

hjgq wrote:I went to my local exhaust place spent $90 on 2 mtrs of 3 inch and 2 90 degree bends then went to enzed and got about 800mm of flexy pipe welded it 2 coats of etch primer and 3 coats of mat black looks the goods all up about $150 -$200 all in a days work

sounds good have you got pics?

Posted: Tue May 20, 2008 6:45 pm

by Troopy93

Vineboy wrote:Hay Troopy93.

Are they also home made Hiclones I see stuffed in there?

Seriously it's a good job. What did you use to fill in around the snorkel as it goes into the fender?

Just some 8mm split edging from Clarke rubber, can't tell ya what the t towell is hiding, trade secret.

Posted: Tue May 20, 2008 8:18 pm

by Froon

I have a similar setup to what you're after on my GQ

If you want I'll get some more detailed pics for you on the weekend?