Page 1 of 2

another spoa question

Posted: Sat Jul 12, 2008 9:18 am

by zookkid

sorry i couldn't find the info i needed in the bible..

When you do a spring over conversion (say with 2'' springs and shackles) do you need a high steer knukle and a drop pitman arm or can you just run a dropped pitman arm??

Posted: Sat Jul 12, 2008 9:53 am

by Gwagensteve

You don't need a dropped pitman arm with a high steer knuckle, but you do need a high steer knuckle.

Your're talking about 8" of lift there though+ tyres.

Steve.

Posted: Sat Jul 12, 2008 10:16 am

by zookkid

so u will need a high steer knuckle no matter what?...is that so it doest hit the leaves? how come you only need 1? does any one have any pics?

cheers

Posted: Sat Jul 12, 2008 11:10 am

by alien

take a look under the front of the zuk, from the front... youll see the drag link (this is the bar that goes from knuckle to steering box) and the tierod (connects between the two knuckles). Now imagine leaving that all as-is but moving the leaves above the diff - you're going to run into some serious clearance issues! The idea of crossover or hi-steer is to move the draglink or both the draglink and tierod above the leaves again - this not only makes steering better, but clearances the leaves.

Also - you dont need the full knuckle - i've got a bolt on system engineered on mine - PM me for info.

Posted: Sat Jul 12, 2008 11:43 am

by joeblow

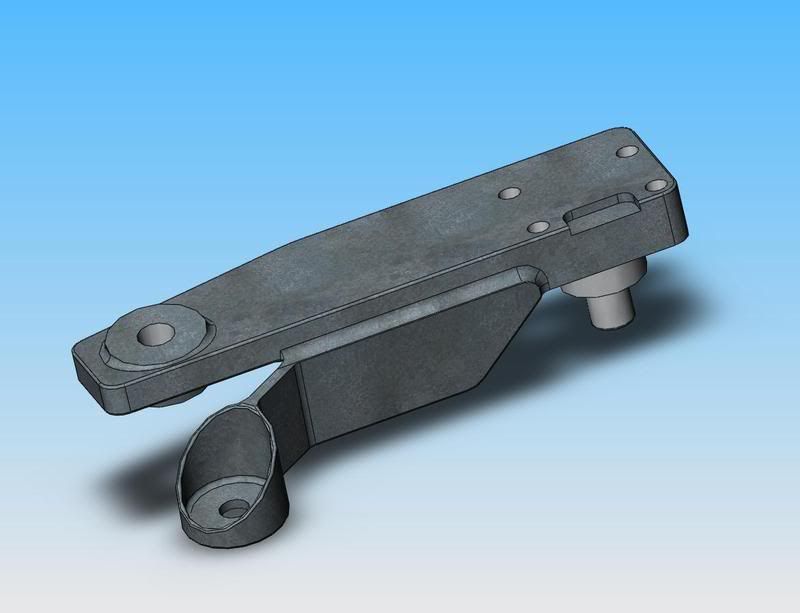

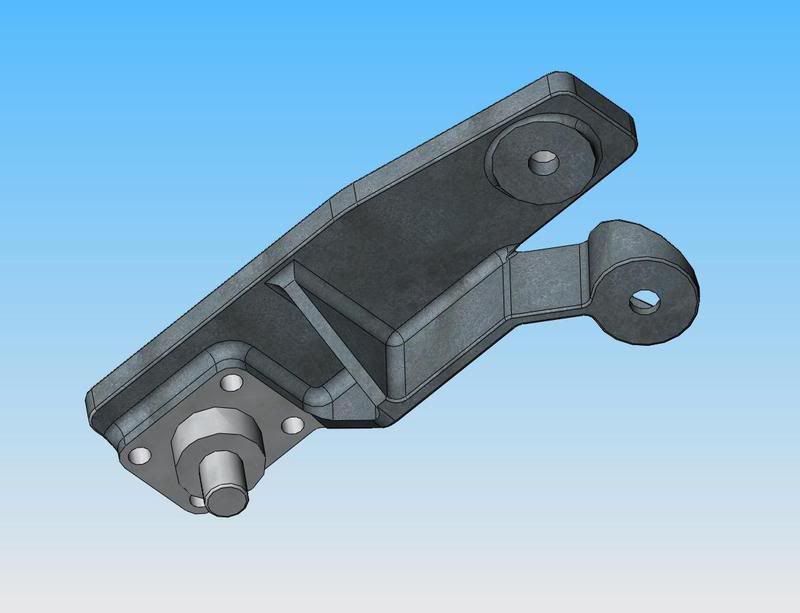

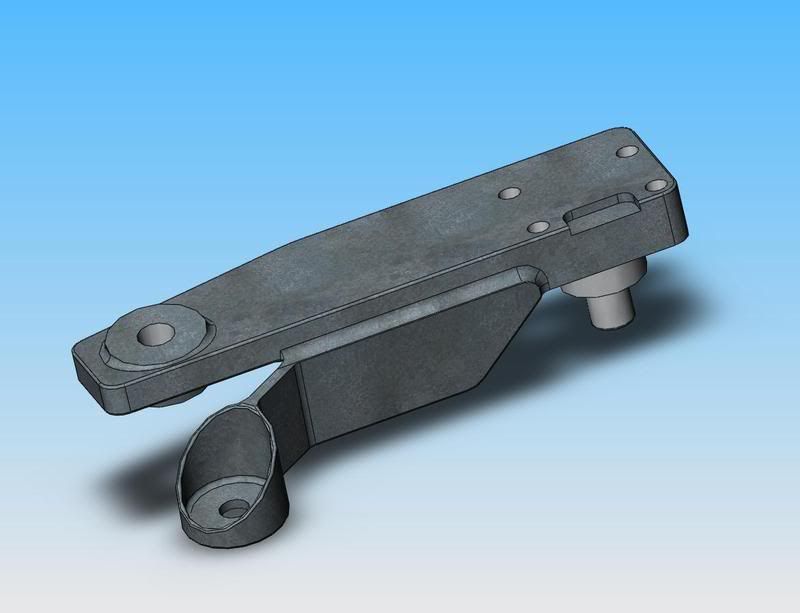

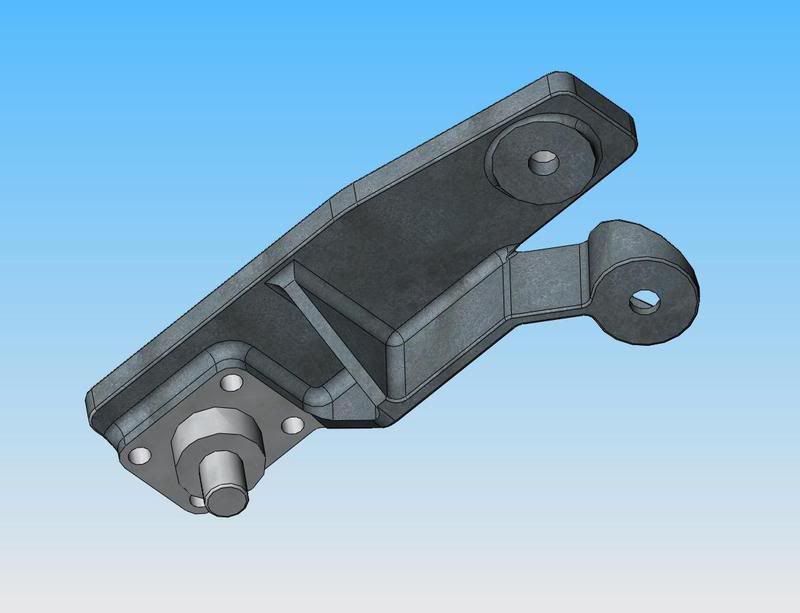

this one just relocates the drag link.and this sort of stuff has to be x-ray tested.

and don't use 2 inch springs with a spring over.use your current leaves and add an old man emu xl to each pack.

Posted: Sat Jul 12, 2008 11:46 am

by zookkid

er.....i already sold them to norm84

why wats wrong with 2'' springs?

what do you think take a leaf or 2 out?

that thing looks freaky!! were do you get it from? and it goes on the passenger side knuckle?

Posted: Sat Jul 12, 2008 12:08 pm

by grimbo

zookkid wrote:er.....i already sold them to norm84

why wats wrong with 2'' springs?

what do you think take a leaf or 2 out?

that thing looks freaky!! were do you get it from? and it goes on the passenger side knuckle?

What's wrong with 2" leaves? nothing until you use them in a SPOA then you have suddenly lifted the car about 6+". That is a huge amount oflift. What size tyres are you going to use? You are also making the car wider by at least 6" as well aren't you or else you are building a very tall, very narrow rig that wil be quite scary to use.Also you are building thiswith the aid ofan engineer so it isal legal and engineered aren't you?

Posted: Sat Jul 12, 2008 12:57 pm

by get it up there

i bought this set up from low range off road only a month or 2 ago.. i just did a hilux diff conversion, which obiously meant i needed this high steer kit. You can also pm me for any more pics/info

Posted: Sat Jul 12, 2008 1:51 pm

by Gwagensteve

joeblow wrote:this one just relocates the drag link. and this sort of stuff has to be x-ray tested.

Please explain how fillet welds and T Butt welds can be "X-Ray tested"

Posted: Sat Jul 12, 2008 2:53 pm

by scooby_74

Allians got a high steer zuke and passed the lane change test.

His high steer was made from one piece of metal and machined to be pass by the engineer.

Posted: Sat Jul 12, 2008 2:59 pm

by joeblow

Gwagensteve wrote:joeblow wrote:this one just relocates the drag link. and this sort of stuff has to be x-ray tested.

Please explain how fillet welds and T Butt welds can be "X-Ray tested"

not my field, just doing what the engineer wants and have all certificates for the process( and guidelines from the lab).....oh and something about a dye test. i wait with great anticipation for your reply.

Posted: Sun Jul 13, 2008 11:50 am

by alien

yeah the engineer wouldnt pass ANYTHING that had been welded on the steering - it all had to be machined, and machined from a specific type of metal too (so it wouldnt fatigue). There was also the question of how it mounted too - the standard merc arm style fix was considered way too dangerous...

All enquiries about my steering setup are best addressed to the man who made it: Brian @ Suzistore (Perth) - 08 9250 4650

www.suzistore.com.au

Posted: Sun Jul 13, 2008 2:39 pm

by rustyzook

you could do a "z-link" to get ya self outta truoble, but totaly illegal and trust me if you like to accutly have steering, do hi-steer!!

Also make sure u lengthen ya shafts my 1ltr is SPOA and i was driving back to nundle from the forest yesti and the shaft came out and riped my break lines inhalf, thoes of you who know the road know thats not something you want to happen!

Photo, i dont recomend doing this, its really bad and illegal!

Posted: Sun Jul 13, 2008 7:15 pm

by grimbo

are they lift blocks or just lifted spring perches in the front of that?

Posted: Sun Jul 13, 2008 7:31 pm

by alien

thats a MASSIVE SPOA!! The perches are high and the shackles are ginormous! leaves have a bit of arc on them too =) how tall you reckon the lift alone is? 9"?

Posted: Sun Jul 13, 2008 8:18 pm

by Turbo Tonka

muz's zook is the scariest thing ive ever seen on the roads

even more than mine....No lift blocks tho i dont think,just big springs and shackles

Posted: Sun Jul 13, 2008 8:22 pm

by grimbo

alien wrote:thats a MASSIVE SPOA!! The perches are high and the shackles are ginormous! leaves have a bit of arc on them too =) how tall you reckon the lift alone is? 9"?

probably the scariest looking setup I've seen for awhile, and chuck the P plate in and

How in gods name is that thing anywhere near legal or engineered?

Posted: Sun Jul 13, 2008 8:27 pm

by Taff

looks bodylifted as well?

I would black out my ## plate too if i drove that.....

Posted: Sun Jul 13, 2008 9:03 pm

by zook4fun

hes got to be the slowest p plater around, if he took any corner at any speed above 20ks he'd be on his side

looks to have some body lift in there as well, look where the bottom of his grill is to his front bar mount.

and its n/t!

Posted: Mon Jul 14, 2008 8:32 am

by Gwagensteve

joeblow wrote:

not my field, just doing what the engineer wants and have all certificates for the process( and guidelines from the lab).....oh and something about a dye test. i wait with great anticipation for your reply.

Most NDT labs hate vehicle work like this as there is generally no direction as to how it is to be inspected or clear acceptance codes, unlike, for example, pressure vessel fabrication.

Engineers, without fail, specify X-Ray, with no knowledge on what can and can't be X-rayed. I've had engineers ask for X-Ray of all sorts of things that can't be inspected with that method.

However, labs will, sometimes, happily take your money and do what you ask even if it's not a valid test - it's easier than having an argument with you or the engineer. If you ring a lab and say "I need something X-rayed" most labs will say "OK" and do what they can with it.

I've seen plenty of NDT reports that aren't worth the paper they are written on in my 12 years in the industry, and unfortunately, some of the worst are for vehicle modification work like this.

The fact is, the only valid inspection method for the welds on you arm is magnetic particle inspection, not dye penetrant, although dye penentrant will be a more relevant test than trying to X-ray that configuration. The only weld that could even vaugely be X-rayed is the gusset to tube weld and even that's going to look crap. None of the welds could be X-rayed in a way that would reveal a fusion defect, the most critical defect for t his weld configuration.

What's a "guideline" from a lab? Are any test restrictions noted? What's the acceptance code for the report? Are you getting two separate reports, one for X-Ray and one for Dye Penetrant? Are the reports NATA endorsed?

Steve.

Posted: Mon Jul 14, 2008 9:37 am

by joeblow

yep, very well known NATA endorsed lab:)

Posted: Mon Jul 14, 2008 9:44 am

by Gwagensteve

That's not what I asked - are the reports NATA endorsed and are there any restrictions on the report?

Posted: Mon Jul 14, 2008 11:19 am

by joeblow

A- where is your badge

B- i could post everything that is on these reports to make you happy ( and go off topic), but i'm not here to do that. things have been done with the right processes to please the authorities, not you.

Posted: Mon Jul 14, 2008 11:45 am

by Gwagensteve

joeblow wrote:A- where is your badge

B- i could post everything that is on these reports to make you happy ( and go off topic), but i'm not here to do that. things have been done with the right processes to please the authorities, not you.

No, on the basis of the information you have supplied, the work has not been done "with the right processes" And whilst your engineer might be happy, the "authority" for the work carried out by an NDT lab isn't your engineer, it's NATA. There is a perception that NDT makes something well designed, strong, or fit for purpose. It doesn't. (Some engineers also believe this, sadly)

You're posting a solidworks drawing of a part and saying "it has to be X-ray tested" which is false and misleading.

If it was X-rayed, there is no way an unrestricted report could be issued and you (or a report with any real meaning) , and members of this board have the belief that if something is X-rayed, it must be good. It is possible to weld something that will pass an x-ray but fall apart the moment it's put into use.

The X-ray is the last check of an item to ensure it's acceptable. Up until that point, the controls are in design, materials, and then welding parameters.

Steve.

Posted: Mon Jul 14, 2008 11:49 am

by Guy

joeblow wrote:A- where is your badge

B- i could post everything that is on these reports to make you happy ( and go off topic), but i'm not here to do that. things have been done with the right processes to please the authorities, not you.

Looks good to me.

what sort of $$ are you asking for them Joe.

Posted: Mon Jul 14, 2008 1:04 pm

by Gwagensteve

Just to be clear - I am not bagging Joe's arm, although for the record I would purchase a snake histeer knuckle if I needed to do this, I woudn't spend this long designing, building and testing soething I could bolt on.

My point is that only that X-raying a part doesn't make it better or stronger in any way. It will only detect defects in the weld where the geometry of the part will allow. In the case of Joe's part, that's effectively nowhere. his is not a reflection of Joe's design, it's only a result of the weld configurations under examination.

If an unsuitable items like this is X-Rayed, it's configuration results in a test restriction, this information must be included on the NDT report and should mean the engineer requests a more suitable test because the NDT report is a waste of money and time.

Steve.

Posted: Mon Jul 14, 2008 4:29 pm

by Guy

Gwagensteve wrote:Just to be clear - I am not bagging Joe's arm, although for the record I would purchase a snake histeer knuckle if I needed to do this, I woudn't spend this long designing, building and testing soething I could bolt on.

My point is that only that X-raying a part doesn't make it better or stronger in any way. It will only detect defects in the weld where the geometry of the part will allow. In the case of Joe's part, that's effectively nowhere. his is not a reflection of Joe's design, it's only a result of the weld configurations under examination.

If an unsuitable items like this is X-Rayed, it's configuration results in a test restriction, this information must be included on the NDT report and should mean the engineer requests a more suitable test because the NDT report is a waste of money and time.

Steve.

Thanks for showing the background for your reasoning.

Posted: Mon Jul 14, 2008 5:48 pm

by Gaywagensven.

all hail the all mighty master gwagensteve, his input to this thread is yet again so valuable, please.. lets all hail

Posted: Mon Jul 14, 2008 6:00 pm

by ZUKPOWER

Gaywagensven. wrote:

all hail the all mighty master gwagensteve, his input to this thread is yet again so valuable, please.. lets all hail

who the fark is this twat?

Posted: Mon Jul 14, 2008 7:01 pm

by jimbo jones

its a tosser with double membership should be deleted