Page 1 of 2

Quick question on welding high tensile bolts?

Posted: Fri Sep 26, 2008 6:33 pm

by brendan_h

need to weld some bolts but i havent got them yet getting tomrow. what grade bolt will be alright to weld and still be strong? thanks

Posted: Fri Sep 26, 2008 7:37 pm

by ajsr

grd 8 or 10

Posted: Fri Sep 26, 2008 8:19 pm

by bazooked

need more info what u welding them to?

Posted: Fri Sep 26, 2008 8:43 pm

by lay80n

As ^^^^^ Bazooked said, what are you welding too, and what is it for?

Layto....

Posted: Fri Sep 26, 2008 8:52 pm

by Struth

The use is an important question.

Gr 8 or 12 will become brittle when welded, especially between the fusion zone and the bolt parent metal, which means the weld can snap off easy at the bolt.

cheers

Posted: Fri Sep 26, 2008 9:03 pm

by brendan_h

its accelly going to be used for a lower shock mount on a zook. welded to 304 stainless steel. thinking about it now im prob best off using a stainless steel bolt?

reason for stainless is because thats what i have lying around

Posted: Fri Sep 26, 2008 9:38 pm

by brendan_h

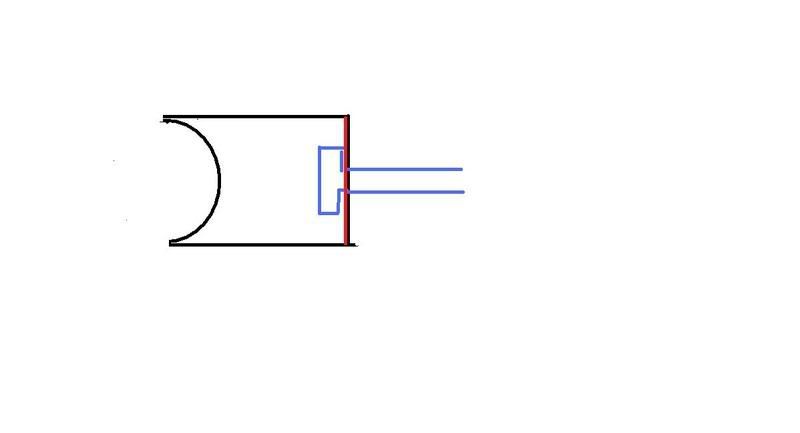

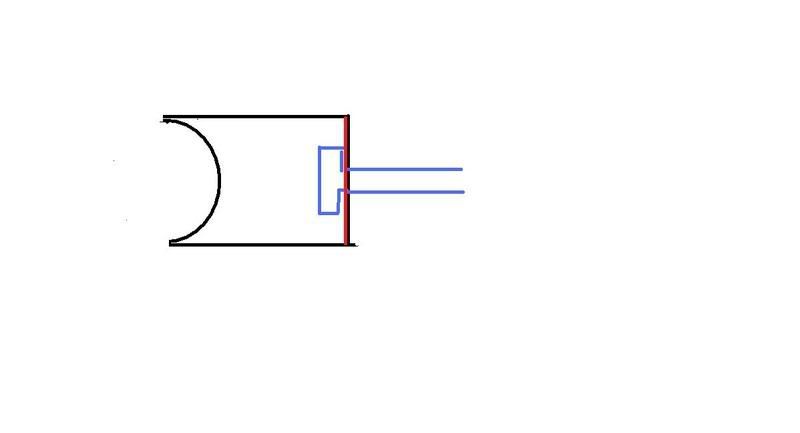

basic pic of what i want to do

RED is a washer

Posted: Sat Sep 27, 2008 1:58 am

by zagan

I take it your really meaning mild steel bolts.

probably wouldn't matter much, should be the same deal with stainless though if your doing stainless you'd want stainless wire/rods too.

Posted: Sat Sep 27, 2008 9:24 am

by brendan_h

yer im going do it in stainless. was going to use a mild steel bolt but its going to be welded to stainless so yer stainless bolt it is

Posted: Sat Sep 27, 2008 2:33 pm

by ssfabricator

dont forget the anti sieze on bolt

Posted: Sat Sep 27, 2008 2:40 pm

by brendan_h

would putting grease on the bolt be alright?

Posted: Sun Sep 28, 2008 9:31 pm

by Taff

So your going to get a stainless bolt to weld to a stainless mount because that's what you have laying around........

And then your welding a stainless mount to a steel diff housing?

I'm confused

Posted: Mon Sep 29, 2008 9:33 am

by Gwagensteve

You don't really need any strength from the weld as the weld is only holding the bolt in position. The weld isn't taking any structural load, but that depends on how you do the whole thing up. If you have a sleeve around the bolt where the shock connects, you can do the nut up tight and you'll be clamping the mount tightly. If you don't use a sleeve and just do the nut up to hold the shock in place there will be lots of bending load on the weld holding the bolt in place.

Personally, I think you can ditch the washer, it's not doing anything, and use a sleeve between the bolt and the shock bush. Then the weld is only stopping the bolt head from spinning as you do it up - I think that's be best solution.

however, a 304 bolt is going to be way behind a grade 8.8 bolt for strength. I can't see a good reason to use a 304 bolt, even if you have them lying around. A couple of 8.8 bolts and hardware will be pretty cheap.

Steve.

Posted: Mon Sep 29, 2008 10:30 am

by Bluefreak

Taff wrote:So your going to get a stainless bolt to weld to a stainless mount because that's what you have laying around........

And then your welding a stainless mount to a steel diff housing?

I'm confused

Using something like an Amacron420 rod in a DC welder, the stainless to mild steel weld will hold well... The Amacron420 is a stainless rod but performs well when welding dissimilar metals...

Posted: Tue Sep 30, 2008 1:32 am

by Gutless

For the price difference between the G8/10.9 bolts in mild steel, and the highest grade stainless bot you can get, you should be able to just buy some mild steel flat bar to do the job.

Don't forget that your shock mounts will take quite a beating. Stainless has atendancy to become brittle and crack with regular vibration/ movement which would make it a silly choice for making shock mounts out of.

Just buy the steel flat bar and some 10.9 SHCS's anddo the job properly the first time.

JMO

Peter

Posted: Tue Sep 30, 2008 1:14 pm

by q_ship

Gutless wrote:

Don't forget that your shock mounts will take quite a beating. Stainless has atendancy to become brittle and crack with regular vibration/ movement which would make it a silly choice for making shock mounts out of.

Just buy the steel flat bar and some 10.9 SHCS's anddo the job properly the first time.

JMO

Peter

x 2

the flat bar is cheap enough, nothing worse than doing a job twice

Posted: Tue Sep 30, 2008 4:11 pm

by MICK77

q_ship wrote:Gutless wrote:

Don't forget that your shock mounts will take quite a beating. Stainless has atendancy to become brittle and crack with regular vibration/ movement which would make it a silly choice for making shock mounts out of.

Just buy the steel flat bar and some 10.9 SHCS's anddo the job properly the first time.

JMO

Peter

x 2

the flat bar is cheap enough, nothing worse than doing a job twice

X3

Posted: Tue Sep 30, 2008 6:20 pm

by brendan_h

i found some steel and using steel. but will be using the stainless bolts

Posted: Tue Sep 30, 2008 9:47 pm

by just cruizin'

Why the ss bolts, mild steel are cheap as. you'll only need 1/2"x2"

Posted: Wed Oct 01, 2008 12:03 am

by Gutless

brendan_h wrote:i found some steel and using steel. but will be using the stainless bolts

Stainless bolts will fatigue far easier than mild steel G8's. You are talking about $10-$15 in bolts here....

Posted: Wed Oct 01, 2008 9:46 am

by q_ship

yeah mate use gr8 metric fine or socket head cap srew gr10.9

save some dollars thats what its all about

Posted: Wed Oct 01, 2008 3:12 pm

by brendan_h

already got the stainless bolts thats the thing

Posted: Wed Oct 01, 2008 3:50 pm

by q_ship

brendan_h wrote:already got the stainless bolts thats the thing

you will only have to replace the bolts and possibly shocks eventually if you use them. up to you

Posted: Wed Oct 01, 2008 4:13 pm

by Gwagensteve

brendan_h wrote:already got the stainless bolts thats the thing

You might have duct tape and cable ties too, that doesn't mean they're the right thing to hold your shocks on with.

So to save $10 on bolts (or less) you're going to do a dissimilar metal weld on a component that's welded in, so when the bolt breaks or the weld fails and you cant take the shock off because the bolt head is spinning you have to cut it out. It's just not worth the hassle.

I just spoke to an engineer who I'm working with ATM and without having the figures in his head, 304 stainless is like butter compared to a grade 8 bolt - it's soo much weaker.

Steve.

Posted: Wed Oct 01, 2008 4:58 pm

by brendan_h

the mounts will be made from steel now.

so it is alright to weld the bolt head to the mount to holt it in place?

now what do i do with the stainless bolts? there 316 bolts

spend 45bucks on bolts, washer, lock nuts

would it be ok to use the stainless washers and lock nuts?

Posted: Wed Oct 01, 2008 5:11 pm

by Gwagensteve

Put them on something you want to look pretty?

Alternatively, take them back and trade them on about 100 grade 8 bolts.

Steve.

Posted: Wed Oct 01, 2008 5:26 pm

by brendan_h

yer i guess i could trade them. but i will keep them never know when i will need it i guess.

would it be ok to use the washer and nut though?

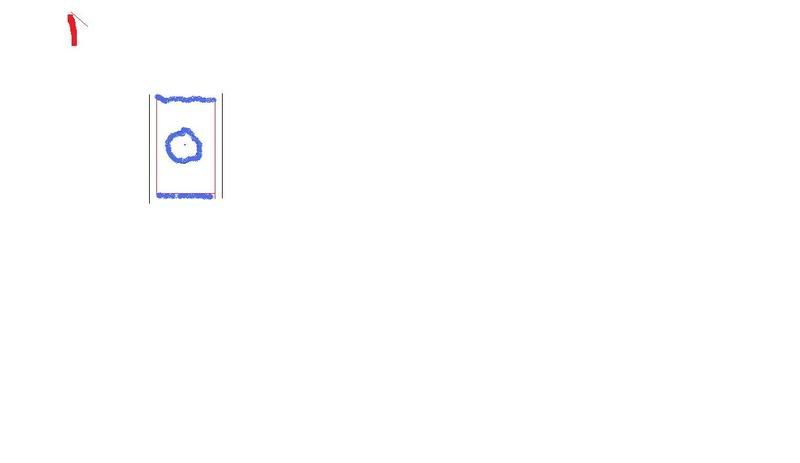

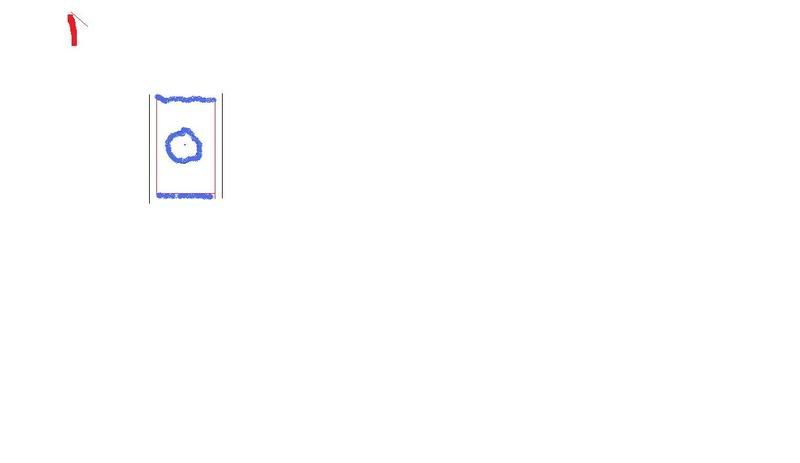

this is what i plan on doing

this is a face shot will be looking at rear wheels. the mounts is 5mm RHS cut and notched. i plan on putting a but of 3mm steel on the inside and welding it to the rhs and then welding the bolt to the 3mm plate

blue is the welds

Posted: Wed Oct 01, 2008 5:27 pm

by ISUZUROVER

Gwagensteve wrote:Put them on something you want to look pretty?

Alternatively, take them back and trade them on about 100 grade 8 bolts.

Steve.

What he said.

Posted: Wed Oct 01, 2008 6:15 pm

by brendan_h

for argument sake a 316 stainless bolt has a tenisle strength of 586MPA.

a 8.8 high tenisle bolt has a tenisle strength of 830MPA. a 4.8 high tenisle bolt has a tensile strengh of 420MPA.

a 316 stainless steel bolt has a yeild strength of 241MPA and a 8.8 has 640MPA

a regular class 4.6 bolt has a 240MPA yeild strengh

also remeber about strees loading and unloading as the shock goes up and down

Posted: Wed Oct 01, 2008 6:47 pm

by ISUZUROVER

brendan_h wrote:for argument sake a 316 stainless bolt has a tenisle strength of 586MPA.

a 8.8 high tenisle bolt has a tenisle strength of 830MPA. a 4.8 high tenisle bolt has a tensile strengh of 420MPA.

a 316 stainless steel bolt has a yeild strength of 241MPA and a 8.8 has 640MPA

a regular class 4.6 bolt has a 240MPA yeild strengh

also remeber about strees loading and unloading as the shock goes up and down

As you (quote?) above, a 316 bolt has a UTS (ultimate tensile strength) of 600MPa (rounding up).

A Metric Class 8.8 Bolt is 830 MPa

A class 10.9 bolt is 1040 MPa

A class 12.9 SHCS is 1220 Mpa

So, in terms of UTS, a class 12.9SHCS (allen bolt) is twice as strong as a 316 bolt - all other things being equal. (and about a 10th of the price). There is no way I would use anything lower than a class 8.8 bolt on a vehicle (suspension).

EDIT - and to be pedantic - Grades don't exist in metric, they are "classes". A Grade 8 (imperial) bolt is MUCH stronger than a Class 8.8 metric bolt.