Page 1 of 1

Noisy leaf springs-how should I fix it.

Posted: Wed Dec 03, 2008 7:59 pm

by sambo

About 6 months ago I laminated my rear diff and did a rear disc conversion on the 60 series. At the same time I flipped the U-bolts.

(before anyone comments, the plate ontop of the diff goes right over between the two U-bolts, effectively clamping the housing. It isn't relying on just weld.)

Then a couple of months ago the rear springs started getting really noisy. Now they make huge noises all the time. Like when I reverse out the driveway, park the car. Even go around some bends. I have retorqued the U-bolts to 123Nm as per the factory spec. but is still noisy.

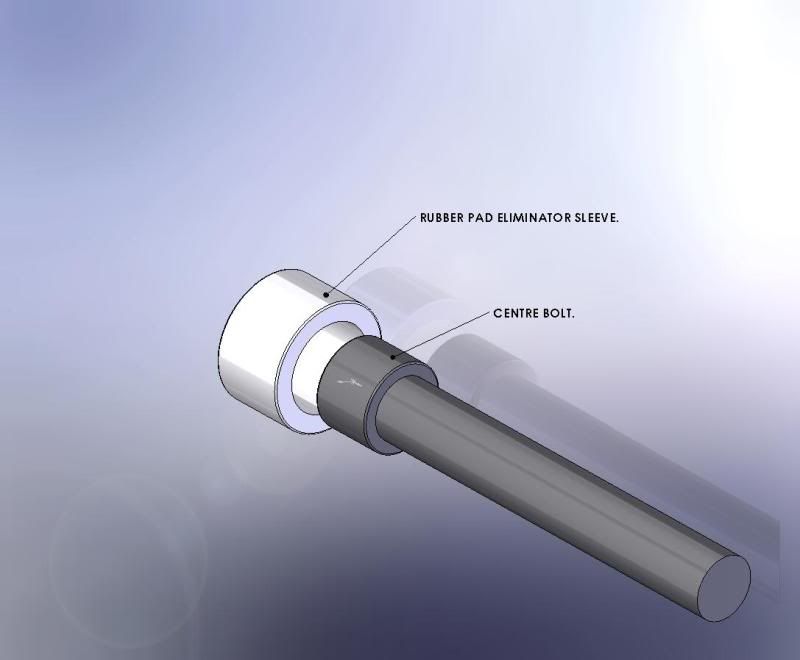

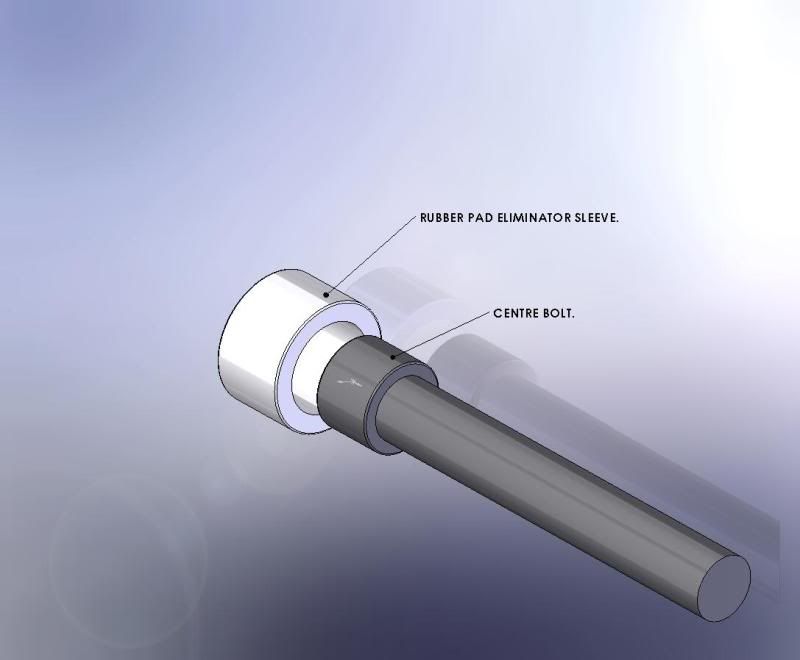

I know the noise is the springs moving. see the photo below

Could it possibly be because there is no plate under the spring or do you think one would help keep the bolts straight and also provide more friction to stop the springs moving.

I am thinking something like this.

Could be either Alloy or steel, milled out. It would also offer some protection for centre bolt.

My other line of thinking is that if I make it easier for the leaves to move then they won't suddenly move, making a big clunk. This could possibly be done with either a rubber or teflon pad between the new plate and the spring.

[/img]

Well those are basically my thoughts so far, any input would be much appreciated.

Sam

Posted: Wed Dec 03, 2008 8:27 pm

by InSanE

try spreading the leaf pack and greasing the leafs with a antiseize type grease, i work for holden and the crewmans get horrible squeeks from the rear leafs and we just split the leaf pack grease them up and there good after that.

Posted: Wed Dec 03, 2008 8:29 pm

by joeblow

is that the rubber insulator i can see in the pic? if so remove it for starters.

Posted: Wed Dec 03, 2008 8:47 pm

by sambo

originally I tried to but the top of the centre bolt hits on the diff housing. The rubber insulator spaces it away.

Posted: Wed Dec 03, 2008 8:57 pm

by joeblow

get the centre bolt right. the insulator is not designed to be used in that way without the rest of the original gear and spacers.

Posted: Wed Dec 03, 2008 10:38 pm

by ISUZUROVER

sambo wrote:originally I tried to but the top of the centre bolt hits on the diff housing. The rubber insulator spaces it away.

Make a steel spacer - that is probably your biggest issue.

Greasing the leaves will help though.

Posted: Wed Dec 03, 2008 10:53 pm

by alien

grease with graphite powder or similar though (dry lube) - wet stuff will just get sand in there and sand is not a good lubricant =)

Posted: Thu Dec 04, 2008 6:21 am

by sambo

I think the ideal solution would be to slightly shorten the centre bolt, so it doesn't stick so far out the top and bottom. How hard is is to pull out the bolt. Obviously I will need to hold the leaves together. And then is is just a case of either shortening or replacing the bolt with a new high tensile bolt.

Make a steel spacer - that is probably your biggest issue.

Do you mean to replace the current rubber one above the spring, or the new one in the model below the spring.

Sam

Posted: Thu Dec 04, 2008 9:51 am

by pridhac

My 75 used to make spring shifting type noises, especially in the wet.

I used to buy the biggest cheapest cans of WD40 type lube from Super Cheap and hit 'em with that every few weeks when they got noisy.

Easy, cheap and it worked a treat.

Posted: Thu Dec 04, 2008 10:35 am

by ISUZUROVER

sambo wrote:I think the ideal solution would be to slightly shorten the centre bolt, so it doesn't stick so far out the top and bottom. How hard is is to pull out the bolt. Obviously I will need to hold the leaves together. And then is is just a case of either shortening or replacing the bolt with a new high tensile bolt.

Make a steel spacer - that is probably your biggest issue.

Do you mean to replace the current rubber one above the spring, or the new one in the model below the spring.

Sam

I meant a steel spacer to replace the rubber one. But if you can fit a shorter centre bolt then that would be better.

Clamp the pack either side of the centre bolt with strong clamps, then remove. Best to replace the centre bolt rather than modify it. I have broken a few when I have reused them. Use a proper centre bolt.

Posted: Thu Dec 04, 2008 10:39 am

by sambo

I think I will try the graphite powder tonight and look into a new bolt.

Posted: Thu Dec 04, 2008 12:13 pm

by ISUZUROVER

sambo wrote:I think I will try the graphite powder tonight and look into a new bolt.

I would still get rid of the rubber pad ASAP. It will be allowing things to flex more than they should.

I use "spray grease" or motorcycle chain lube. Flex the springs on a ramp and lube the side that is unloaded (in extension). Spring steel is hard, so a bit of dirt and crap won't matter. I have been doing this for years and haven't had any problems.

Posted: Thu Dec 04, 2008 12:17 pm

by ToNkA

Lanolin Spray/Oil works great on leaf springs...

Posted: Thu Dec 04, 2008 12:27 pm

by sambo

Where can i get a new centre bolt from.

Posted: Thu Dec 04, 2008 12:37 pm

by exV8er

Any suspension shop shold have them.

Posted: Thu Dec 04, 2008 12:59 pm

by ISUZUROVER

exV8er wrote:Any suspension shop shold have them.

x2 - any spring works.

Posted: Thu Dec 04, 2008 1:12 pm

by grimbo

take the leaves out, give them a really good clean. Get the grinder out and clean up the edges etc. Give them another good clean and degrease. paint them with spring suitable paint. Then repack using the graphite powder. Put new bushes in as well with the right bush grease. Make sure you also retighten everything to the correct torque settings. If possible use all new bolts etc

Posted: Thu Dec 04, 2008 4:45 pm

by GRPABT1

I've always been against using lube for leaf springs. Nothing slides on steel like steel so I just clean them um with a flap wheel and whack them back together. Although graphite could work but liquids just attract dirt. I have springs now with teflon pads on the ends which are great, dunno if you can buy them by themselves?

Posted: Thu Dec 04, 2008 7:15 pm

by grimbo

the graphite seems to "repel" dust and mud buildup

Posted: Thu Dec 04, 2008 7:18 pm

by joeblow

from memory the 60's that used the rubber pad also had a larger diameter locating hole in the spring perch, you may have to machine up an adapting spigot such as the diagram below. many 4x4 shops sell eliminating kits for the rubber pads. and lube is good, molibdinum disolphide.

[/img]

[/img]

[/img]

[/img]