Page 1 of 1

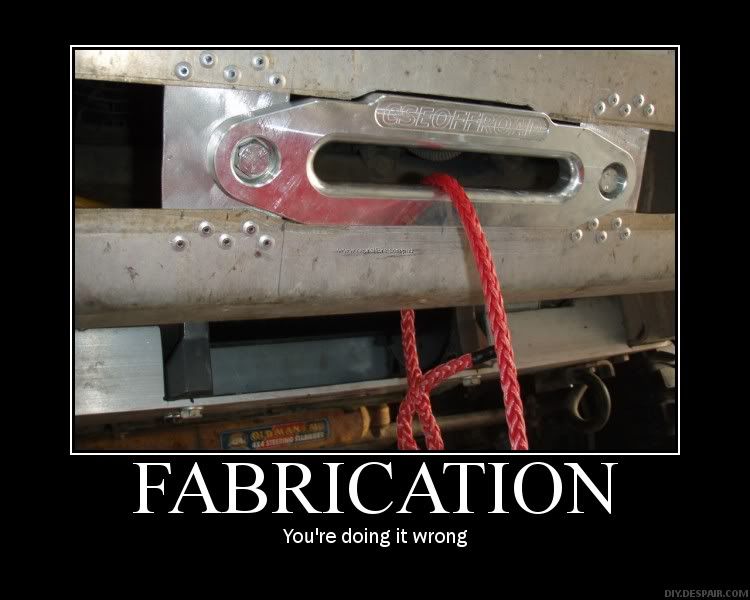

Fairlead and Rivets

Posted: Thu Dec 04, 2008 10:24 am

by me3@neuralfibre.com

And for those of you clearly entertained by such

Yes it's still POP RIVETED on - 20 x 5.5mm rivets through 2 x 6mm sheets of alloy - 10 per side.

It hasn't bent, moved, twisted or failed in 5 recoveries so far.

One (straight pull) broke the plasma rope in testing

The others were all hung up on rocks where lockers couldn't push it through.

No serious case of bogged to the chassis rails yet.

Figured it might give you all some entertainment seeing as it's a frequent topic of mirth.

I have 20 high tensile 6mm bolts in the shed (distribute the load across the alloy bar) - but can't be bothered swappign them out yet.

Hmm - maybe aircraft using rivets aint so stupid after all?

From an engineering perspective, in shear they are fine. In tension I would expect them to fail.

A 45deg line would prob be the max I would trust. A 90deg line pull would prob cause them to fail. Not many ppl skulldrag the front directly sideways.

Paul

Posted: Thu Dec 04, 2008 11:56 am

by mkpatrol

Pop rivets or another type of rivet?

Pop rivets are not really designed to carry/bear extreme loads but other typs are.

Use the correct rivet in the right application and they can be batter than good ole nuts & bolts.

An aircraft is not really a good comparison as they use millions of blind rivets in certain sections only. Mostly for flexibility, other sections are bolted depending on the loads expected (this is a whole other thread on what is used where in aircraft & it has been over 10 years since I left the industry that I cannot remember everything).

If you are only retaining the winch behind a bullbar & the loads are being taken by the bull bar then a rivet retension method would be adequate. Mind you if the correct rivets are being used then a 90 degree side pull might not be out of the question.

I would not use pop rivets for this at all though.

Posted: Thu Dec 04, 2008 12:08 pm

by chimpboy

Heh, good on you

Posted: Thu Dec 04, 2008 12:11 pm

by mkpatrol

chimpboy wrote:Heh, good on you

Who, me or me3?

Posted: Thu Dec 04, 2008 12:40 pm

by mortis35

Can you throw some pics up for us or tell us where to look if pics are up already..

Posted: Thu Dec 04, 2008 12:43 pm

by ISUZUROVER

mortis35 wrote:Can you throw some pics up for us or tell us where to look if pics are up already..

x2

I think your biggest issue is unlikely to be opverall strength, rather fatigue. I have had a few aluminium parts fail from fatigue/vibration when I tried to make them too thin. It took a few years, but it happened.

Posted: Thu Dec 04, 2008 12:46 pm

by me3@neuralfibre.com

mortis35 wrote:Can you throw some pics up for us or tell us where to look if pics are up already.. :D :D

Pics are here

http://neuralfibre.com/paul/4wd/4wd-win ... the-weight

As per before.

Paul

Posted: Thu Dec 04, 2008 1:23 pm

by nicbeer

Posted: Thu Dec 04, 2008 1:30 pm

by WICKED

Posted: Thu Dec 04, 2008 1:40 pm

by chimpboy

mkpatrol wrote:chimpboy wrote:Heh, good on you

Who, me or me3?

Paul... he got hammered over this, and I still think it's sub-optimal, but the proof is in the pudding.

Posted: Thu Dec 04, 2008 3:15 pm

by mkpatrol

chimpboy wrote:mkpatrol wrote:chimpboy wrote:Heh, good on you

Who, me or me3?

Paul... he got hammered over this, and I still think it's sub-optimal, but the proof is in the pudding.

I guess if its only the fairlead and there is no load, its just being a guide then there are no issues. Real worl circumstances just dont allow it though.

Maybe I will have to look at the thread & see when I get home as most of the pics are blocked at work.

Posted: Thu Dec 04, 2008 4:11 pm

by Jock

The winch is bolted in with high tensile bolts to the thick alloy frame. Its only the fairlead which is pop riveted and as long as the pop rivets were done properly then it will still give the same clamping force as bolts.

I like it. its different and saves weght.

Posted: Thu Dec 04, 2008 4:16 pm

by sierrajim

Jock wrote:The winch is bolted in with high tensile bolts to the thick alloy frame. Its only the fairlead which is pop riveted and as long as the pop rivets were done properly then it will still give the same clamping force as bolts.

I like it. its different and saves weght.

Until the bar takes a hit, then the rivets fail.

Posted: Thu Dec 04, 2008 7:14 pm

by zagan

sierrajim wrote:Jock wrote:The winch is bolted in with high tensile bolts to the thick alloy frame. Its only the fairlead which is pop riveted and as long as the pop rivets were done properly then it will still give the same clamping force as bolts.

I like it. its different and saves weght.

Until the bar takes a hit, then the rivets fail.

Or the middle cracks and they just pull out.

Posted: Thu Dec 04, 2008 9:22 pm

by Simo63

I would rather not use rivets when there is the option of using nuts and bolts. If you couldn't use nuts and bolts then sure, it could be a clever solution but given the option, nuts and bolts are superior no question.

However there are many large structures put together with rivets ... bridges for a start.

Posted: Thu Dec 04, 2008 10:20 pm

by mortis35

its different and if it works safely for you then good on ya for thinking outside the box.....

Posted: Fri Dec 05, 2008 7:02 am

by GRIMACE

it's uglay!

Posted: Fri Dec 05, 2008 1:57 pm

by GRPABT1

I agree looks like shite and will only be a great Idea till it fails.

Posted: Fri Dec 05, 2008 2:07 pm

by Wendle

Posted: Fri Dec 05, 2008 2:15 pm

by bogged

Wendle wrote:

GOLD

Posted: Fri Dec 05, 2008 3:05 pm

by Guy

Simo63 wrote:I would rather not use rivets when there is the option of using nuts and bolts. If you couldn't use nuts and bolts then sure, it could be a clever solution but given the option, nuts and bolts are superior no question.

However there are many large structures put together with rivets ... bridges for a start.

The are NOT held together with POP rivets.

Rivets and Pop rivets are very different animals.

Posted: Fri Dec 05, 2008 3:22 pm

by Simo63

love_mud wrote:Simo63 wrote:I would rather not use rivets when there is the option of using nuts and bolts. If you couldn't use nuts and bolts then sure, it could be a clever solution but given the option, nuts and bolts are superior no question.

However there are many large structures put together with rivets ... bridges for a start.

The are NOT held together with POP rivets.

Rivets and Pop rivets are very different animals.

RIGHT .. I CAN HEAR YOU ... GOT IT LOUD AND CLEAR

Posted: Fri Dec 05, 2008 5:56 pm

by r0ck_m0nkey

Wendle wrote:

I would have thought

"anyone can do it, not everyone should"

would be a better quote.

Posted: Sat Dec 06, 2008 11:55 pm

by Shadow

When I build a house frame, I can put a 2tonne I beam up with 4 series-500 screws holding it there. It works, beam stays there, does what it should.

Its still fucking dodgy, and thats why M16 bolts are installed ASAP.

Just because your POS dodgy crap hasnt failed and killed someone, yet, doesnt mean its anything to be proud of.

I would be embarrased to say thats my vehicle.

Posted: Sun Dec 07, 2008 9:13 am

by Skegbudley

Just worked out why this setup won't work. You didn't use checker plate. The extra bling would hold it together.

Seriously though. You might not think you will need to winch sideways but you will eventualy. Ive had to winch myself sideways twice in the last month. I feel much better knowing that I have upgraded my fairlead bolts to 12mm. You don't want it to fail when you need it the most. Like as in your foorby is looking at a 200m drop off a cliff if it fails.

Last pic shows a couple of very good reasons why not to under engineer something. I know you are in the same boat as me in this respect. Don't do it because we might bag you. Do it for the short ones.

Replace the ally plates with a section of flat steel (aprox 100 x 400 x 3) BOLTED to the inside of your bar. Slot it for the cable and use 10 - 12mm bolts to hold the fairlead on. I like your winch cradle idea. It is in tension through its strongest plane so It should work fine. Just keep an eye out for stress fractures.

Craig..

Patrol on its side up against tree. Was on 2 wheels just prior to tree stopping us.

Drag chain + 10m winch extension from sliders to another tree across the road. This was to stop the patrol from rolling if the tree broke whilst winching. Winch pulling at extreeme angle.

Can you spot the 2 reasons why I would never under engineer stuff like this.

Posted: Mon Dec 08, 2008 9:05 am

by Wooders

IMHO You are way too anal about the weight saving....

Personally there is now way I'd want an alloy mount let alone the fairlead setup. And just IMHO, but that mount isn't a lot thicker than many steel mounts.....Sorry not a fan.

Oh yeah and your maths is wrong on the weight saving since I'm sure that your alloy bumper doesn't weight 0kg

Posted: Mon Dec 08, 2008 9:57 am

by grimbo

if you are worried about weight saving do it elsewhere in the vehicle. Get rid of unneccesary stuff, change to lighter matrials where possible on non critical components. Run alloy rims instead of steel, etc etc but the saving of weight here is just false economy and stupid IMHO

Posted: Mon Dec 08, 2008 10:37 am

by Reddo

if the car is nose up and that iron man has to pull down on the bottom of the fairlead, its going to bend. The iron man is bolted flat to the frame, where it should be bolted vertically, which means the whole pulling power is on the the two back bolts, and not the front. If you worries about weight, midmount the winch and have guides - much safer and better weight distrabution through out the 4wd.

Think about it, stick a forklift prong through that fairlead and start lifting and turning on it, whatcha thing's going to happen. its the same thing, because all that winch is doing is moving a 2+ tonn Landcrusier around, Its gonng be alright for now, but how long is it really going to last? What happens if you head out bush/desert and it breaks when you really need it the most? All because you wanted to save a bag of concert. I think its foolhardy and skimping on safty