Page 1 of 1

Winch mount design?

Posted: Fri Feb 20, 2009 12:14 pm

by thehanko

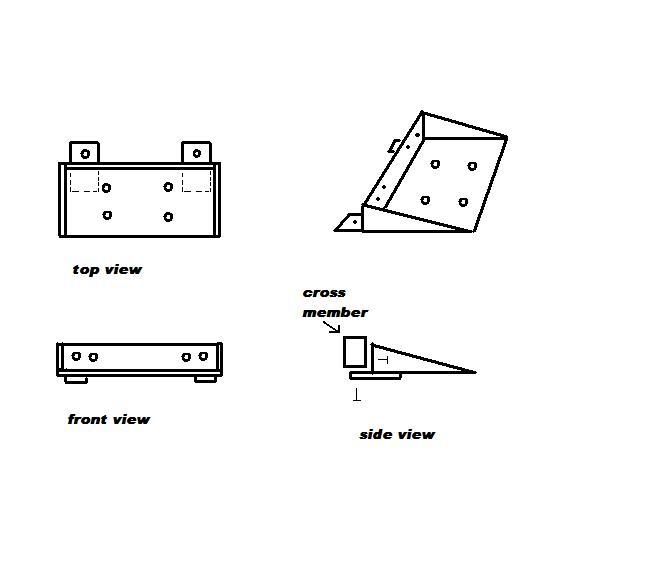

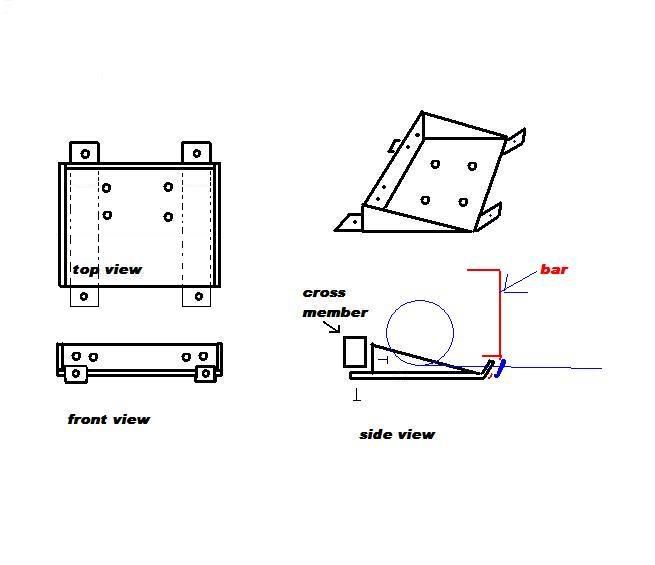

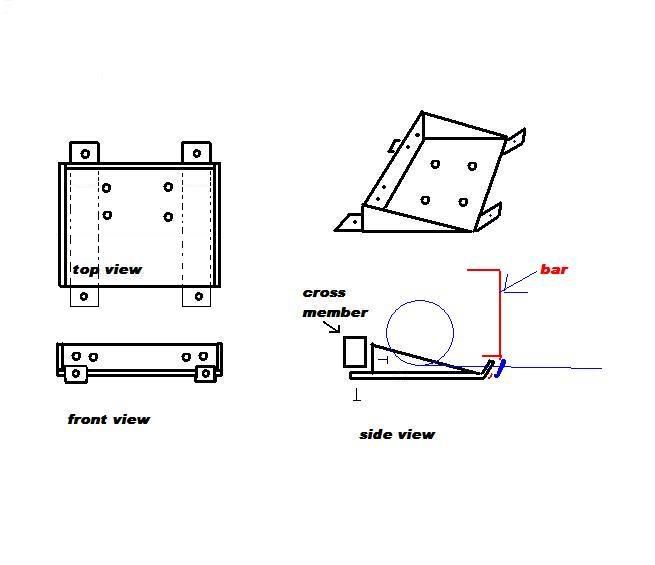

OK, so from searching all over this is the design i have come up with, however i would like imput as to its suitability as i have found very little information on this topic anywhere.

I have an alloy bar on an ln 106 hilux, so need a steel winch mount.

here is my rough design. made from what i think is 10mm steel plate that i have lying around - im sure the steel is overkill thick but its available.

So basically the winch would sit onto it flat with the rope spooling out between the winch and the flat mount.

four bolts would go from the backing plate into the chassis crossmember and 2 into the bottom of the cross member up through the tabs at the back.

is this ok or is it not a good idea. its not how i origionally thought i would do it, but from the pics i have found seems like the way its done.

Posted: Fri Feb 20, 2009 4:49 pm

by RED60

Generally speaking, bolts only have about 1/2 the strength in shear that they do in tension. Just keep that in mind. Having said that, if you can somehow "hook" your winch cradle around your chassis so the bolts are only holding it in position that would be good. Have fun

Posted: Sat Feb 21, 2009 9:09 am

by thehanko

RED60 wrote:Generally speaking, bolts only have about 1/2 the strength in shear that they do in tension. Just keep that in mind. Having said that, if you can somehow "hook" your winch cradle around your chassis so the bolts are only holding it in position that would be good. Have fun

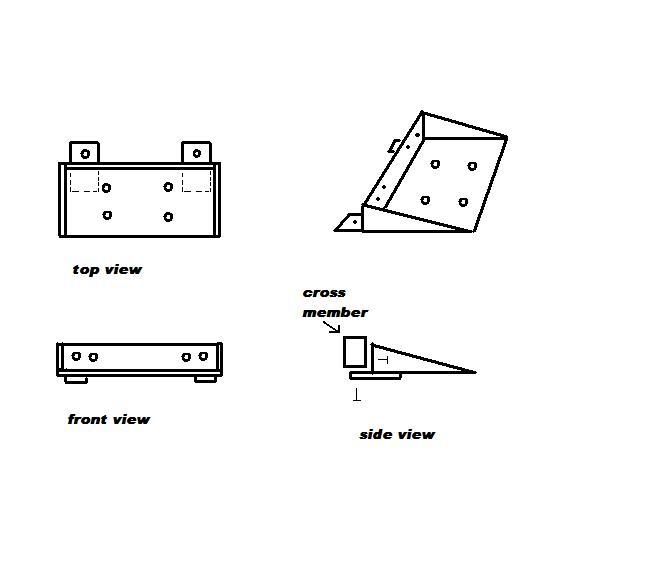

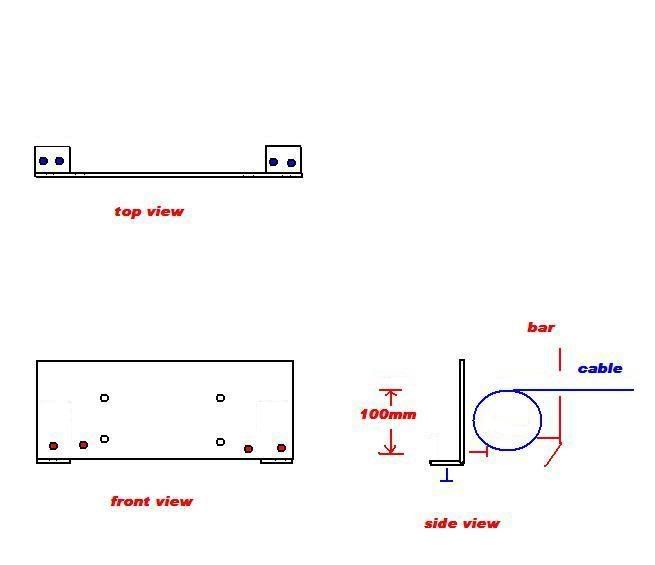

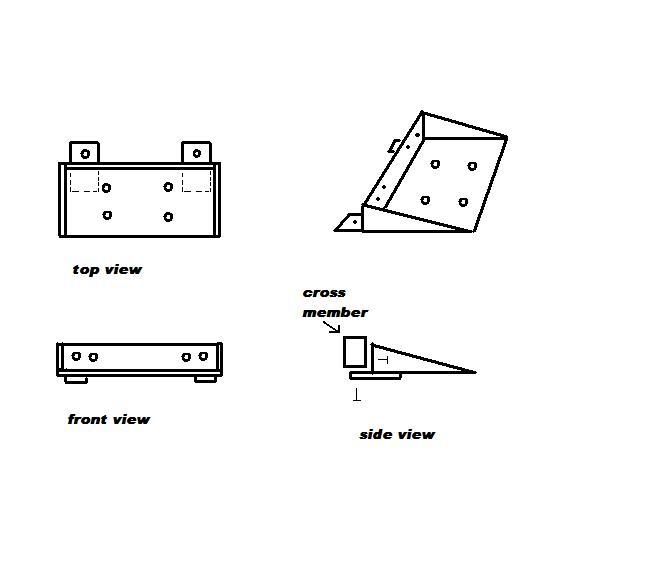

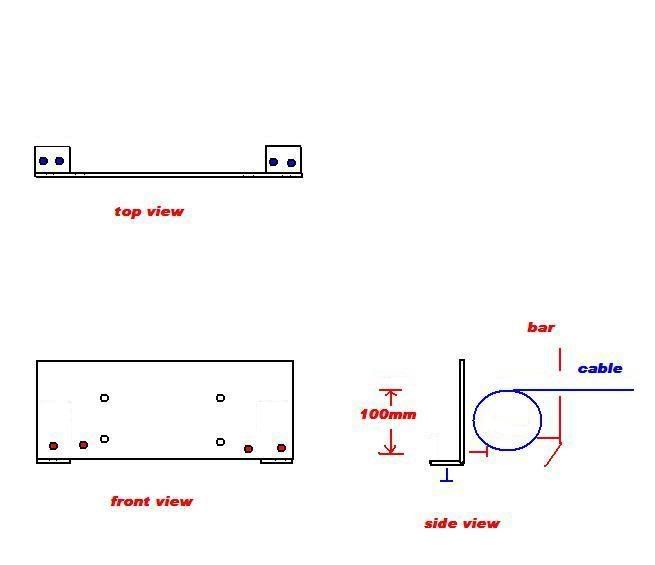

yeah makes sence, I was origionally thinking of mounting the winch to a flat plate across the cross member, but all the pics i found on line showed it set flat like the design above.

no space to hook around the chassis.

is a design like this better? as its also less work to make.

My only concerns with this are that with where the current cable hole is cut into the bar the cable needs to wind on at the top of the winch which will create alot more load/torque through the bolts at the bottom.

ie 4250 kg or 42500 N about a point 0.1m away will be 4250Nm. will the 4 bolts / cross member deal with that? and is my maths correct or at least close enough. I realise i havent take the bolts under the cross member into account.

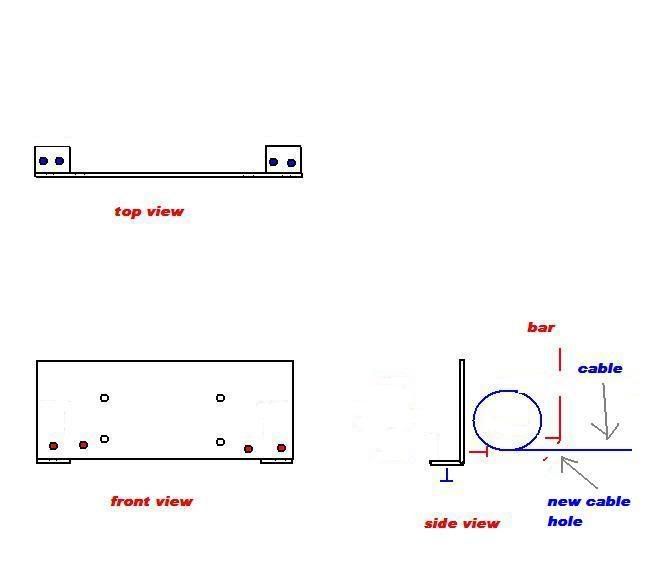

another option is to cut a new cable hole lower in the bottom part of the bar.

then the bolts are simply under tension which should be alot stronger.

would the plate bow out in the middle? or is it ok as the winch bolts on 1/3 of the way in from each side.

Posted: Sat Feb 21, 2009 1:40 pm

by thehanko

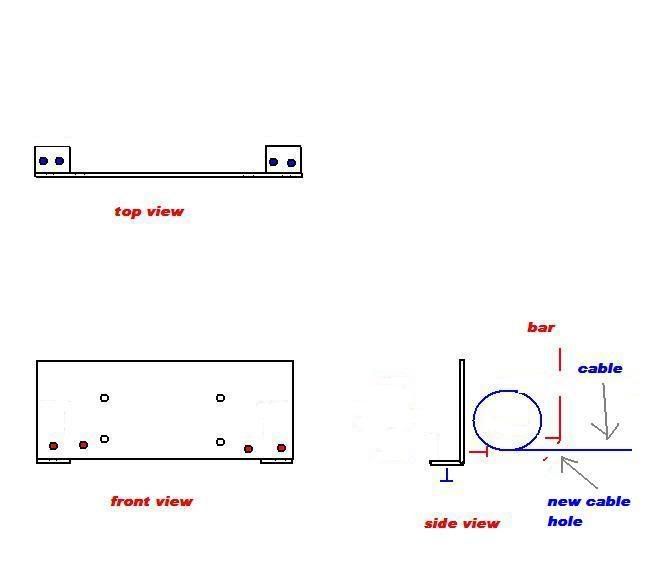

ok so newest design yet. heaviest but i think the best.

This way, the base of the mount acts like a bash plate, but also braces up the alloy bar where the fairlead will be put in.

the full plate also stops it acting like a mud scoop.

so apart from the extra weight - is there anything wrong with this?

Posted: Sat Feb 21, 2009 2:17 pm

by Shadow

only problem i can see is that your using bolts instead of pop rivets.

Pop rivets will save alot of weight.

Posted: Sat Feb 21, 2009 2:44 pm

by thehanko

Shadow wrote:only problem i can see is that your using bolts instead of pop rivets.

Pop rivets will save alot of weight.

oh no but I am, its just that they are so small that they dont show up on these low resolution pics.

if you zoom right in you will see them

cheers