Page 1 of 1

Welding trailer stub axles

Posted: Wed Apr 22, 2009 2:10 pm

by sierrajim

I'm in the process of getting my head around making a basic swing arm suspension setup for my lightweight camper trailer (5-600kg loaded worth of sprung weight + tyres and brakes).

I'm looking at using these stubs

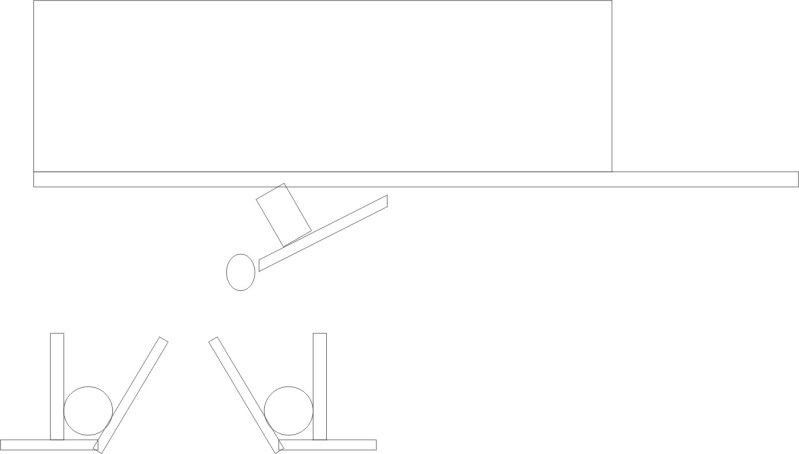

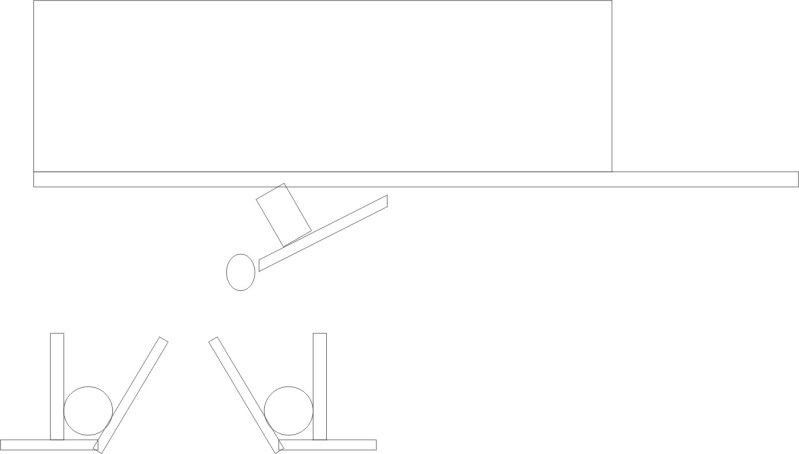

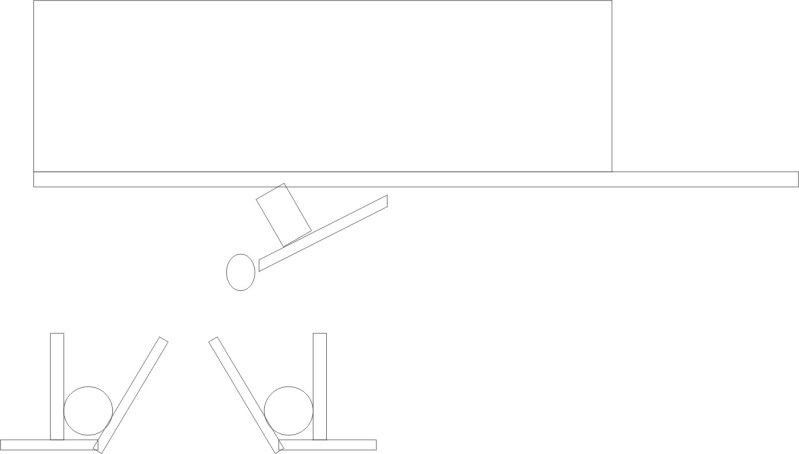

and running either a short coil or air bag. My cad type drawing

Was thinking of 50mm x 4mm RHS for the swing arm with urethane bushes on the chassis end.

Will this work? Any suggestions?

[/img]

Posted: Wed Apr 22, 2009 3:34 pm

by AFeral

Would add some tubes between one side of the arm and the other. to brace it.

Welding the axle stub will cause it to distort. This could cause problems with wheel allignment.

Posted: Wed Apr 22, 2009 4:53 pm

by Dirty

Jim,

50mm x 4mm will be fine.

Recomend that you add an adjustment on the inside mounting arm (weld bush to a bolt head and thread into the swing arm). As over time you may need adjustment.

Also mount the coils over the axle stubs, the air springs may need to be closer to the pivot point to give you the extra travel.

- David.

Posted: Wed Apr 22, 2009 7:00 pm

by KiwiBacon

Dirty wrote:Jim,

50mm x 4mm will be fine.

Recomend that you add an adjustment on the inside mounting arm (weld bush to a bolt head and thread into the swing arm). As over time you may need adjustment.

Also mount the coils over the axle stubs, the air springs may need to be closer to the pivot point to give you the extra travel.

- David.

Agreed.

I've done the sums on a similar trailer and 50x4mm RHS is heaps. I am also putting some camber/toe adjustment in like Dirty has mentioned above.

Posted: Wed Apr 22, 2009 7:30 pm

by mule75

KiwiBacon wrote:Dirty wrote:Jim,

50mm x 4mm will be fine.

Recomend that you add an adjustment on the inside mounting arm (weld bush to a bolt head and thread into the swing arm). As over time you may need adjustment.

Also mount the coils over the axle stubs, the air springs may need to be closer to the pivot point to give you the extra travel.

- David.

Agreed.

I've done the sums on a similar trailer and 50x4mm RHS is heaps. I am also putting some camber/toe adjustment in like Dirty has mentioned above.

don't cars only have toe in for braking/steering???

why would a trailer need it??

Posted: Wed Apr 22, 2009 7:48 pm

by sierrajim

Dirty wrote:Jim,

50mm x 4mm will be fine.

Recomend that you add an adjustment on the inside mounting arm (weld bush to a bolt head and thread into the swing arm). As over time you may need adjustment.

Also mount the coils over the axle stubs, the air springs may need to be closer to the pivot point to give you the extra travel.

- David.

Good thinking.

Will start doing some more detailed drawings.

Posted: Thu Apr 23, 2009 6:30 am

by KiwiBacon

mule75 wrote:

don't cars only have toe in for braking/steering???

why would a trailer need it??

To correct for any misalignment during manufacture. Mine is going to be independent suspension, so there's no beam axle to hold both axles in line.

Posted: Thu Apr 23, 2009 11:53 am

by sootygu

email sent with cad drawings of the set up i made.

Posted: Thu Apr 23, 2009 12:03 pm

by sierrajim

sootygu wrote:email sent with cad drawings of the set up i made.

Cheers mate, you're a champion!!!!

Posted: Thu Apr 23, 2009 12:16 pm

by BrettInUte

Ive seen a similar setup befor e- but the stubs were slid + bolted/clamped in

SO it was a simple job to replace a bent stub in the middle of no where.

Cheers.

Posted: Thu Apr 23, 2009 12:47 pm

by me3@neuralfibre.com

BrettInUte wrote:Ive seen a similar setup befor e- but the stubs were slid + bolted/clamped in

SO it was a simple job to replace a bent stub in the middle of no where.

Cheers.

Why do so many independent setups include spare hubs, or even axles?

It's pretty rare to bend a beam axle with leaf's. Why are the independents at more risk?

Has anyone seen one fail and care to specualate on the reason?

Thanx

Paul

Posted: Thu Apr 23, 2009 12:56 pm

by sierrajim

me3@neuralfibre.com wrote:BrettInUte wrote:Ive seen a similar setup befor e- but the stubs were slid + bolted/clamped in

SO it was a simple job to replace a bent stub in the middle of no where.

Cheers.

Why do so many independent setups include spare hubs, or even axles?

It's pretty rare to bend a beam axle with leaf's. Why are the independents at more risk?

Has anyone seen one fail and care to specualate on the reason?

Thanx

Paul

Do they actually bend often or is this another "sales feature" built in?

Posted: Fri Apr 24, 2009 5:38 pm

by Dirty

BrettInUte wrote:Ive seen a similar setup befor e- but the stubs were slid + bolted/clamped in

SO it was a simple job to replace a bent stub in the middle of no where.

Cheers.

Better of just putting a bush welder on board.

- David.

suspension

Posted: Mon Apr 27, 2009 9:05 am

by hollywood

i build trailers for a living as well as general engineering and i say dont piss ass around guessing what might work and what might not it will surely bring you undone when you least expect it. when someone wants me to build a trailer to take into hell i only use an alko irs, yes i can hear all the knockers and the uninformed blurting out all kinds of crap why not to use them, the fact is they work well, are not complicated, and you can have them made to take more weight than you need to carry. not one i have built has let me or anyone else down, i have taken my to hell and back and it will just keep on doing it. the most common fault is the person building the trailer in the first place, and the propper mounting of the axle and the assembly and welding of this project ( everybody thinks they can weld). my advice is build your trailer carefully and strong, work out how wide it needs to finish, total weight including load, what wheels you are going to run (6 stud!) and speak to your local alko dealer and give him all the info you can and he will help you out. they are simple to fit, made to your weight specs and have very little moving parts to break up, trust me you wont regret it and you can just concerntrate on the trailer side of things cheers hope this helps steve