Page 1 of 1

king pin bearing shims

Posted: Sun May 31, 2009 12:55 pm

by thehanko

OK peoples,

I have pulled hubs apart too many times to count and replaced king pin bearings etc, but always done the reuse the old spacers job and hope it works, which it has done thus far.

But I just bought a little 40 series and the hubs etc are not on the vehicle to start with so i will be rebuilding from a parts bucket and will need to set up the shims correctly.

I researched it a few times but never found anything very clear and definitive.

Can anyone give clear instructions, perhaps pics or a link to something which is easy to understand?

thanking you,

oh and none of you can have the porne shots of the new rig until the wheels are on

Posted: Sun May 31, 2009 5:52 pm

by sprungupcruiser

I did mine with a mechanic mate a while back. I think you are supposed to use a hook scale and test the weight it takes to turn the swivle hub. So to do it i think we put the steering arm and the king pin on tight and tested it and that will give u some idea of how many or how big the shims you need to use. And just keep doing that until you get it right. hope that helped.

Posted: Sun May 31, 2009 7:02 pm

by Breaker Brother

sprungupcruiser wrote:I did mine with a mechanic mate a while back. I think you are supposed to use a hook scale and test the weight it takes to turn the swivle hub. So to do it i think we put the steering arm and the king pin on tight and tested it and that will give u some idea of how many or how big the shims you need to use. And just keep doing that until you get it right. hope that helped.

That's much the way we set up a King pin on a Bus or Truck, if it's to tight, take some out, and vice versa. although we don't bother with a spring scale, you get to know what it should feel like.

The best comparison I can think to give, is to adjusting a wheel bearing, you want it to spin relatively freely, but have some resistance, and no end or up and down play

Posted: Sun May 31, 2009 7:13 pm

by sprungupcruiser

i thats what we did too, i wrote that you were supposed to use it. if you can get your hands on one of those scales then it would be worth using i guess.

Posted: Sun May 31, 2009 7:19 pm

by Breaker Brother

If you wanna get fussy with them

http://cgi.ebay.com.au/Spring-balance-s ... rms=66%3A2

http://cgi.ebay.com.au/Spring-balance-s ... rms=66%3A2|

$6 and it's yours. if you need the specs I can look it up for you

Posted: Sun May 31, 2009 7:34 pm

by joel HJ60

There is an SST to set it up correctly.

It does adjust preload on the king pin bearings, BUT apparently it also centres the axle so it runs true in the seal.

Posted: Sun May 31, 2009 7:42 pm

by SIMMO84

you have to be care full that the swivel hub is centered to the axle housing otherwise you could have problems with axle seals leaking but as long as there is the same amount of shims top and bottom you should be pretty close. Another way of finding the right amount of shims is to fit the caps with no shims, tighten the bottom tight and the top as tight as you can with just a socket by hand, then get your feeler guages and measuer the gap to get the right amount of shims, again this will get it close but you will still need to fine tune it from there. hope that makes sence.

Posted: Sun May 31, 2009 10:48 pm

by thehanko

awsome guys. thanks for clearing that up. clear as muddy water with no mud in it

Posted: Sun May 31, 2009 11:36 pm

by rapid80

I haven't done this for ages but the following info is the best I can recall.If you have access to the factory service manual you'll find the sst is basically 2 pieces.One is a shaft that goes through the ball end where the king pin bearings go and the other fits inside where the axle goes and it has a sharp point that touches the shaft.You put bearing blue on the shaft then spin it so it leaves a line,then I think you turn it over and do the same again.Measure the space between the 2 lines and adjust the shims to get it to the spec.This centres your swivel hub and should give it the correct preload.If it sounds too hard do as mentioned previously and use the same number of shims top and bottom till you get the right preload but be prepared for the inner axle seal to flog out of its not centred.I can't remember any from the factory that had the same thickness shims top and bottom.There are aftermarket seals that have more flex so can handle some misalignment.

Posted: Mon Jun 01, 2009 8:49 am

by vk7ybi

1 thick shim on the bottom, shims as necessary on the top and a Marlin seal will fix it..

Posted: Mon Jun 01, 2009 9:09 am

by joel HJ60

vk7ybi wrote:1 thick shim on the bottom, shims as necessary on the top and a Marlin seal will fix it..

I hear this works too.

Posted: Mon Jun 01, 2009 9:13 am

by vk7ybi

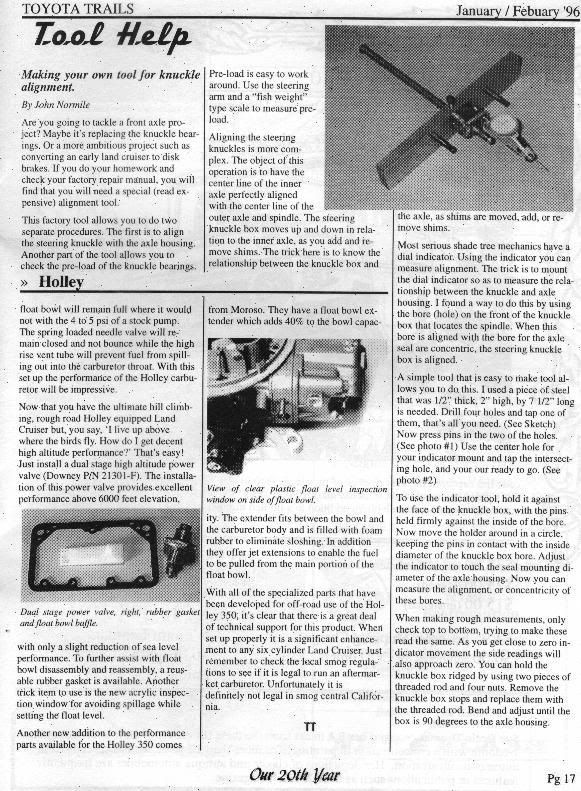

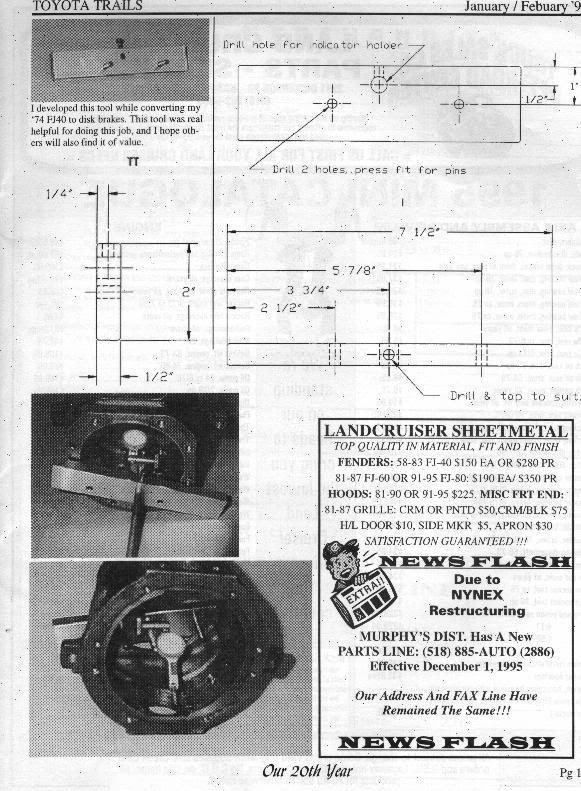

http://www.4x4wire.com/index.php?option ... &Itemid=53

Theres information out there on building a makeshift SST with a dial indicator, works when the proper SST cant be had.. Google is your friend.

Posted: Mon Jun 01, 2009 9:18 am

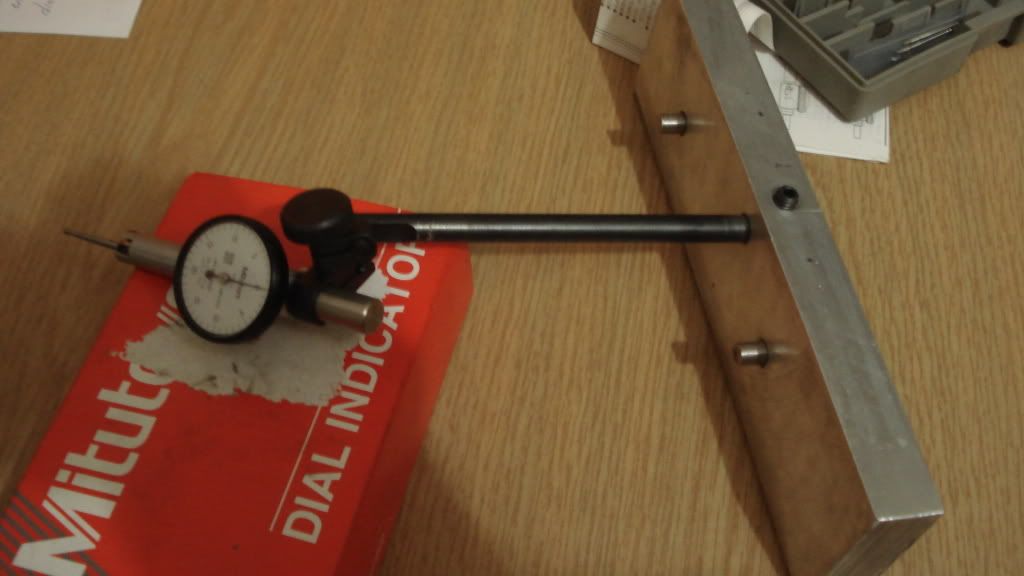

by vk7ybi

Posted: Mon Jun 01, 2009 5:52 pm

by Shaun05

I did mine some time back, and you need to set the preload and centre the wineglass to the axle seal. I found that the equal shims top and bottom method was nowhere near accurate.

The SST that you can buy probably does the job correctly, but it's pricey. About $250 I think.

So I made the one you see above. It was pretty easy. here it is.