Page 1 of 2

solid or ifs for fast stuff

Posted: Mon Oct 19, 2009 8:22 pm

by chunderlicious

im about to start my next project, a hilux pre runner style truck and am stuck deciding what i want to do with the front suspension.

i will be getting it mod plated/ engineered and will be getting some rims made to be as positive offset as will fit on a steel rim so width isnt an issue. the rear will be a spooled h233 gq 4 linked with coilovers and bypass shox.

the front i cant decide between total chaos stage 3 caddy sysem or similar with coilover and bypass or a gq diff fully braced running flipped 80 series arms coilovers and bypass shox.

i want to retain 4x4 as it will become my weekend car and just plain having fun car. ill be running an auto but it will be behind a fairly powerful turbo motor (400hp). dont want a locker in the front and dont want to have to replace CVs or a diff centre every trip out. i dont drive stupid stuff, hardest tracks ill do with it will be something like cruiser canyon or telecom hill (steep rocky climb with big holes on the other side). the front will have about 13 inches of travel, the rear will have more so travel isnt an issue even though it will be set up for fast stuff and wont work well in the slow.

just after advice. shannon campbells ifs did awsome in the rocks and in the fast stuff.

any help appreciated

Posted: Mon Oct 19, 2009 8:57 pm

by -Scott-

For fast stuff, a solid axle is starting with a massive handicap.

It's simple physics - less unsprung weight bouncing around requires less damping to control. It may be possible to achieve a similar result with a solid axle, but an IFS is more likely to obtain the control you're after with a lot less $$$ of development.

Why no locker?

Posted: Mon Oct 19, 2009 9:00 pm

by dogbreath_48

Don't know much about the suspension except that some koh truck/buggy things with solid front are doing quite well against ifs in US speed events.

In my experience big offset rims won't be doing you any favours at high speed.

Posted: Mon Oct 19, 2009 9:26 pm

by chunderlicious

positive offset brings the tyre closer to the chassis ala making it road legal width for a hilux.

the main problem of the solid axle is the arm geometry. hence why i want flipped arms. the axle needs to move forward and up on initial impact as the arm points down slightly.

KOH rigs are going awsome against actual purpose built desert trucks but shannon campbells IFS KOH rig was so much faster than those rigs i just dont know.

when you have a locker i find i tend to puch a bit harder and try that little bit harder to get up something that you prolly shouldnt. im trying to save money...

that is seriously why i dont want one, wow, i just thought about it then.

Posted: Mon Oct 19, 2009 9:33 pm

by Slunnie

This is all my opinon on this type of stuff.

In the rough, I don't think it matters how much you try, you wont get a balanced vehicle if you dont also have balanced suspension. Meaning that if you take an independent suspension design and a solid axle suspension setup and throw every type of traction environment at it, you wont have a situation with a given setup where both will provide the same traction at all times. This balance for speed events is where the speed will come from. I would almost argue to a certain degree that balance is more important even than outright grip. So, my thoughts are that IFS should go with IRS, and a solid front should go with a solid rear for this reason. When comparing the two setups, I think that you will get more control and traction generally speaking from an IFS/IRS design.

If you troll through all of the clips with Shannon Campbell, especially the speed rock events that have been going on after his IFS buggy debuted at KOH, you'll see that he is getting so much traction out of the front end that he cant make the back end work well enough. It'll be interesting to see if his next buggy is IFS/IRS or if it goes back to Solid F&R. To control IFS is easy as there isnt a lot of unsprung weight in comparison to a solid axle, so you can either run soft shocks to provide the same level of wheel (but not body) control or you can keep a stiffly shocked setup and gain a hell of a lot of traction over rough ground. With the solid rear you will have to run a stiff setup assuming you have a fundamental weight balance in the vehicle in relation to tyres etc also. Like in Shannon's buggy, trying to make the rear maintain traction with the front means that they need to keep winding on more and more shock control, to the point where in at least 1 or 2 events you can actually see the front corner pick up and twist the chassis, and then the rear wheel which goes light will lift completely clear of the ground while the shock is releasing and you can watch the wheel drop - I'm guessing that they're at the point where they are needing to dial traction out from the front to balance the vehicle again. Shannon will know how to make the next one go a lot faster if his IFS bits are holding together.

Big offset is just done to get width. If you're starting from scratch I would try to run positive offset and setup the (longer) suspension to suit. It'll reduce the tendancy for the suspension to break your fingers when you hit things.

Posted: Mon Oct 19, 2009 10:11 pm

by chunderlicious

thats the sort of thing i wanted to hear.

i am running POSITIVE offset on road so it stays at around the same width as a lux. offroad ill be running negative 13 or 20 depending on what is available.

i do agree in sorts, but look at trophy trucks and truggys. solid rear with 40+ inches of travel and ifs with 30 in the front. they are the fastest and are alot heavier than class 1 or pro mod buggies which have close to the same power in some cases but with irs.

Posted: Mon Oct 19, 2009 10:23 pm

by PJ.zook

The trophy trucks spend tens and in some cases hundreds of thousands on research and development to get max speed and stability in an offroad environment. I would base any designs around them. Plus you have to admit, theyre IFS front ends look wicked.

Posted: Tue Oct 20, 2009 12:22 am

by Slunnie

chunderlicious wrote:i do agree in sorts, but look at trophy trucks and truggys. solid rear with 40+ inches of travel and ifs with 30 in the front. they are the fastest and are alot heavier than class 1 or pro mod buggies which have close to the same power in some cases but with irs.

Do you know exactly why they run an axled rear and the other class runs IRS?

Posted: Tue Oct 20, 2009 4:16 am

by KiwiBacon

chunderlicious wrote:the main problem of the solid axle is the arm geometry. hence why i want flipped arms. the axle needs to move forward and up on initial impact as the arm points down slightly.

Flipping your radius arms isn't going to change that at all.

Posted: Tue Oct 20, 2009 5:35 am

by rockcrawler31

KiwiBacon wrote:chunderlicious wrote:the main problem of the solid axle is the arm geometry. hence why i want flipped arms. the axle needs to move forward and up on initial impact as the arm points down slightly.

Flipping your radius arms isn't going to change that at all.

I think your being contrite and facetious. Given your background you would know very well that unless the leading arms are dead flat at ride height, any upwards movement will incur a forward movement, but as i guessed, you already know this. So then i can assume that you would also know very well that having the leading arms on top of the housing would make them closer to horizontal at ride height if not nearly horizontal at lower lift levels, meaning far less forward movement for bump travel thereby if not eliminating forward movement making it negligible.

But we know, that you already know this. So why did you write the above post? Just because we're not automotive engineers doesn't mean that we don't have a sound grasp of grade 10 geometry.

Posted: Tue Oct 20, 2009 6:54 am

by KiwiBacon

rockcrawler31 wrote:

I think your being contrite and facetious. Given your background you would know very well that unless the leading arms are dead flat at ride height, any upwards movement will incur a forward movement, but as i guessed, you already know this. So then i can assume that you would also know very well that having the leading arms on top of the housing would make them closer to horizontal at ride height if not nearly horizontal at lower lift levels, meaning far less forward movement for bump travel thereby if not eliminating forward movement making it negligible.

But we know, that you already know this. So why did you write the above post? Just because we're not automotive engineers doesn't mean that we don't have a sound grasp of grade 10 geometry.

The angle of the arms means absolutely nothing. The only thing that matters is the location of the arm pivot in relation to the ground. Because the ground is where the forces come from, not the axle centreline.

If you want to change the suspension path at the ground to less forward, then you need to shift the pivot closer to the ground.

Posted: Tue Oct 20, 2009 8:23 am

by chunderlicious

and thus the reason for wanting ifs. I have fox shox on my cruiser nd they ride great but the initial bump is savage.

So you think ifs kiwi? I like it but woulld need to fit a paj rear diff in the surf gap or something as i recon the ifs toyota diff will go off everytime i sneeze on the throttle

Posted: Tue Oct 20, 2009 8:26 am

by KiwiBacon

chunderlicious wrote:and thus the reason for wanting ifs. I have fox shox on my cruiser nd they ride great but the initial bump is savage.

So you think ifs kiwi? I like it but woulld need to fit a paj rear diff in the surf gap or something as i recon the ifs toyota diff will go off everytime i sneeze on the throttle

I think it's a years worth of solid design to come up with an IFS system with the travel and life you're expecting. Not to mention issues like steering geometry.

Without 4wd it's really easy, with a front diff it's going to be a battle to get travel without popping CV's.

Posted: Tue Oct 20, 2009 8:38 am

by Struth

KiwiBacon wrote:chunderlicious wrote:the main problem of the solid axle is the arm geometry. hence why i want flipped arms. the axle needs to move forward and up on initial impact as the arm points down slightly.

Flipping your radius arms isn't going to change that at all.

Agree, drop boxes will gain what you are after, flipped arms are virtually meaningless for anything other than axle clearence gains.

Cheers

Posted: Tue Oct 20, 2009 9:21 am

by rockcrawler31

KiwiBacon wrote:rockcrawler31 wrote:

I think your being contrite and facetious. Given your background you would know very well that unless the leading arms are dead flat at ride height, any upwards movement will incur a forward movement, but as i guessed, you already know this. So then i can assume that you would also know very well that having the leading arms on top of the housing would make them closer to horizontal at ride height if not nearly horizontal at lower lift levels, meaning far less forward movement for bump travel thereby if not eliminating forward movement making it negligible.

But we know, that you already know this. So why did you write the above post? Just because we're not automotive engineers doesn't mean that we don't have a sound grasp of grade 10 geometry.

The angle of the arms means absolutely nothing. The only thing that matters is the location of the arm pivot in relation to the ground. Because the ground is where the forces come from, not the axle centreline.

If you want to change the suspension path at the ground to less forward, then you need to shift the pivot closer to the ground.

Sorry mate, it was just supposed to be a wind up. I suck at the interwebs sarcasm.

Having said that i know what your getting at but i'm not sure i understand why, if the axle centerline is horizontally located in front of the chassis mount it can go any where BUT backwards if moving through either a upwards or downwards bump. If you go by your example, even an ifs is going to have the same problem. Even if the axle mounting point is transverse to the car, it's still above the force point i.e. at the contact patch.

Posted: Tue Oct 20, 2009 5:14 pm

by chunderlicious

i thought the main point was to get the arm horizontal to the ground. the reason the arm moves forward on a bump is because the arm angles down toward the diff. if the arm is raised at the diff end (even for argument sake, 200mm above the diff) and make the arm point downward toward the rear of the chassis. would this not make the arm move back and up, forward and down? im sitting here playing this out with pens taped to my coffee table and that is what it is doing, just as i thought it would.

i will be using a 79 series front chassis mount to move the arm down at the chassis end, but being a shallow hilux chassis im calculating the arm will still be pointing down forward. hence why i want to flip the arms on the front to bring it up at the front that little bit more.

will this not work?

Posted: Tue Oct 20, 2009 6:05 pm

by Gwagensteve

Interesting point about flipping arms. Have a look at the arms you are planning on using relative to horizontal axle centreline. From memory, toyota arms are very heavily cranked - i.e the rear mount on the axle is much higher than the front mount. If the line drawn though the two radius arms mounts places them above the axle centreline in "normal" orientation, , once you flip the arms, the arm angle might actually get steeper not flatter.

PS for speed and moderate off road use, IFS is where it's at. I've been faster offroad in a vitara with a calmini kit in it than I've ever been in a live axled car - all those offroad race cars can't be wrong.

Steve.

Posted: Tue Oct 20, 2009 6:22 pm

by Squeak

IFS front set up

The Gen 3 caddy kit doesn't retain 4wd. You would be looking at the Gen 2 kit which runs 10" coilovers to give you 12" of travel. You can get a bit more if you change your bump stops aroung a bit.

The caddy kit is designed for pre-runner type events where speed is essential. The problem you will ecounter with this kit is that you will destroy an idler arm almost every event and possibly bend steering arms due to the leverage force applied to them by moving the wheel further away. Hence the reason they offer the upgraded parts for your steering system. Total Chaos however don't do a RHD version of there idler arm.

Running positive offset rims on the front will sort of defeat the purpose of the Caddy kit as you are effectively moving the arc radius closer to the chassis and therefore reducing your wheel travel. If your going to the trouble of getting it enginneered then why not just run neutral offset rims or rims that provided you with a similar wheel track to the rear GQ diff.

IFS compared to SAS (for a prerunner)

Big expensive prerunners run there front IFS systems with a tilt backwards that means when the wheel hits a bump it moves back and up allowing a smoother ride over large whoops. Standard IFS has a slight rearwards movement in its upwards arc.

A solid front tends to move forwards and up in it's arc radius. By flipping the arms you don't change the arc radius but you reduce the amount of forwards movement in the radius as the diff moves up. This is because the radius arms sit in a more horizontal plan reducing the feeling of the vehicle wanting to drive over the front diff.

Posted: Tue Oct 20, 2009 6:27 pm

by Slunnie

Squeak wrote:

A solid front tends to move forwards and up in it's arc radius. By flipping the arms you don't change the arc radius but you reduce the amount of forwards movement in the radius as the diff moves up. This is because the radius arms sit in a more horizontal plan reducing the feeling of the vehicle wanting to drive over the front diff.

Is this assuming the locating bolts on the diff are raised above the diff also. I would expect the shape of the radius arm to be irrelevent, but it having more to do with the location of the mounting points to the chassis and the axle.

Posted: Tue Oct 20, 2009 6:28 pm

by KiwiBacon

chunderlicious wrote:will this not work?

No.

You could make arms that dropped down vertically, then up at a 45 deg angle before coming back down onto the diff.

The arc of the axle and tyre would be exactly the same. Hence the bump response is the same (apart from these contorted arms having more flex of course).

Posted: Tue Oct 20, 2009 8:24 pm

by chunderlicious

but its changing the angle of the arm in relation to the ground... not the arm itself, but the centreline between chassis mount and diff mount is being raised closer to horizontal. i think we are thinking of 2 different things here.

as a non related example;

you are talking of one of those Z shaped draglinks that people in huge lifted trucks run, and then thinking it is then running at the same angle as the panhard and it will not cause bump steer.

i am saying instead of the Z arm, lets lower or raise the panhard to run horizontal to the draglink thus actually reducing bumpsteer.

i want to mount the arms as horizontal to the ground as possible. lowering the chassis mount and for lack of a better term, raising the diff mount.

squeak,

The positive offset rims are for onroad use/ modplating. offroad i will run normal rims as stated above.

I am aware the caddy3 kit is 2wd. i was using it as an example of what i wanted arm wise. i could have said arms like blitskreig make but then i would have had to answer alot of they only do 2wd arms. so chose the chaos kit. as for the idler stuff. it can all be changed and beefed. the lhd idler is just bolted to the opposite side of the chassis. allready looked into that

as for the rest of the steering components, they would all be strengthened to suit the new use of the vehicle.

I would be running porsche CVs no doubt as the width in the front would be custom. i think i would also need some nice custom spindles made to handle the speed and torture i would give it. cv angle isnt a problem, they run porsche CVs in the rear of big buggies so...

gwagen, the arms are nearly flat. nissan arms have the mental crank hence why they flex so bad in the front.

ive decided on solid front just for ease of install and after talking to the mod plater this arvo he is much happier to put his name next to a custom solid axle than a custom ifs at this time. unless i can get some good info for him he said every piece would need testing and as there are custom chassis mounts for it, they would need testing aswell. so he recommended solid.

Posted: Tue Oct 20, 2009 9:21 pm

by Struth

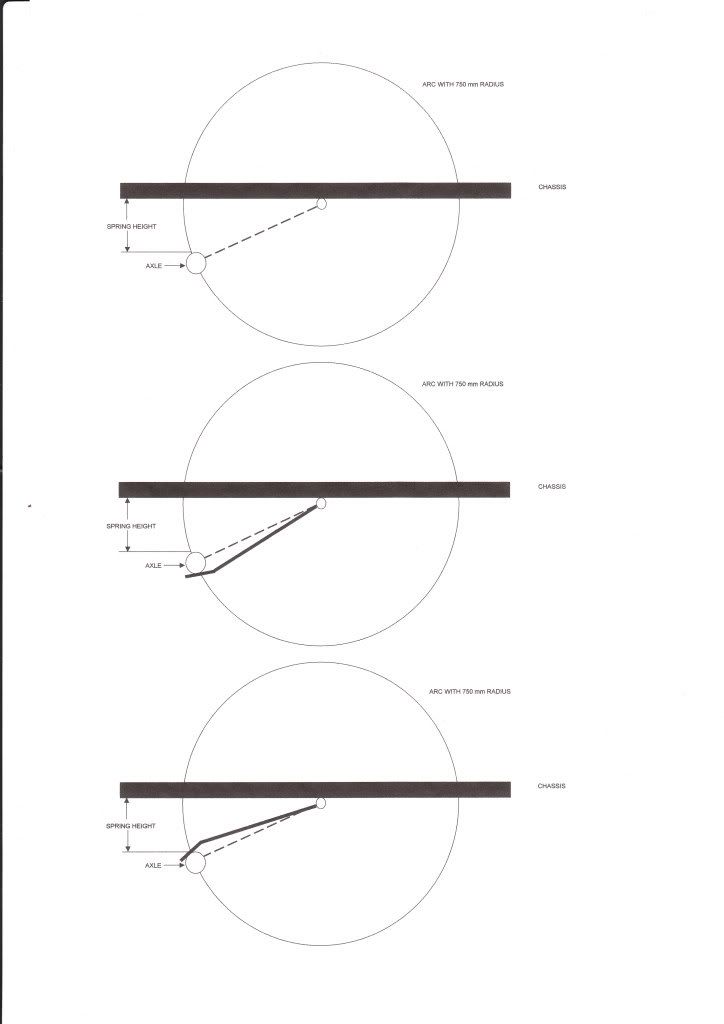

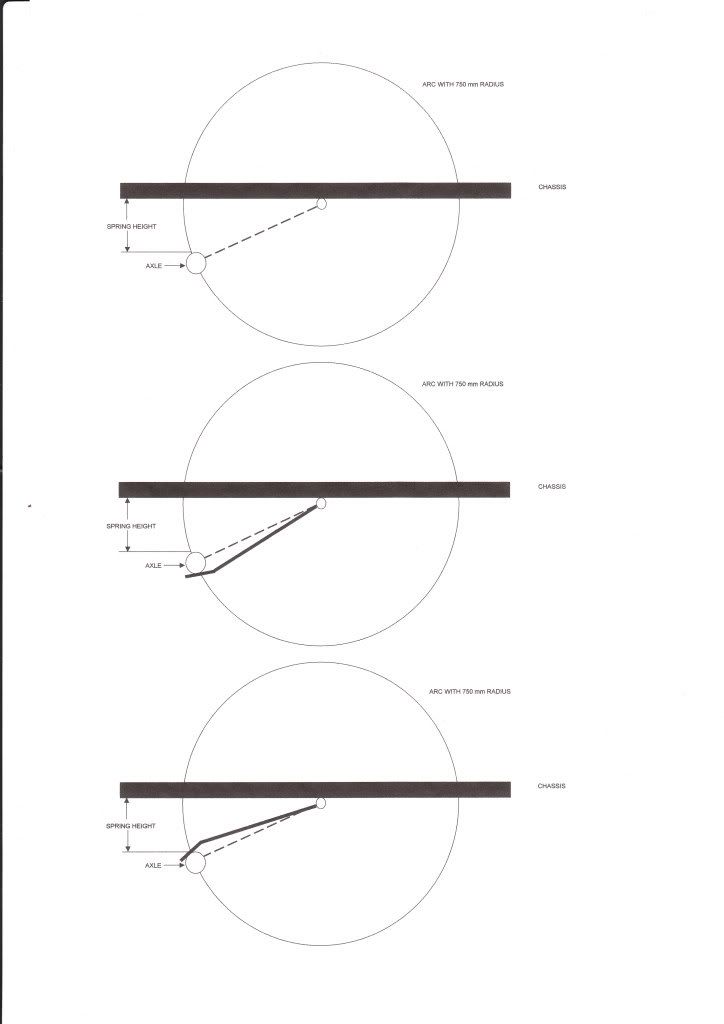

I used this sketch once before to explain how placing the radius arm on top of the diff has no effect on the arc the axle centres scribe when the suspension is either compressed or extended.

It's the relationship between the chassis mount end of the arm and axle centre that needs to be altered to avoid the diff travelling forward when the suspension is compressed, either by lowering the chassis connection of the radius arm or bringing the axle centre closer to the chassis(lowering the suspension).

The only benefit I could see from putting the radius arm above the axle is better clearence, and possibly (I haven't thought too hard on this one) better articulation before the radius arm bushes create bind.

The dotted line represents the true radius line the axle will travel, not the false radius line created by the radius arm.

It is the dotted lines angle that needs to be brought horizontal to acheive what I think you are chasing. Longer radius arms will also help achieve the same result , albeit they would have to be pretty long to help the situation.

Posted: Tue Oct 20, 2009 9:27 pm

by Slunnie

Awesome, well illustrated. Thanks Struth.

Posted: Tue Oct 20, 2009 10:10 pm

by chunderlicious

thanks struth

guess ill get used to the bump then

Posted: Wed Oct 21, 2009 9:51 am

by leehamescort

Total Chaos kit with a Supra 8" would be sweet as!!

Plenty of flex plus a strong front diff.

I've done the supra diff in my surf and given it some serious abuse, cant seem to break it. I can break the CV's but that still takes a seriously hard landing at full noise. (running Yuri CV's could prevent that too)

http://www.toyotasurf.asn.au/forum/view ... hp?t=19571

Go the IFS!!

catcha

Leeham

Posted: Wed Oct 21, 2009 10:13 am

by Struth

^^^^^ well worth a look, these boys have put a lot of thought and R&D into this setup.

Cheers

Posted: Wed Oct 21, 2009 10:21 am

by -Nemesis-

Leeham, you rock. I had no idea anyone had done that!

I had been thinking of a Paj or GM center one day, but I like the Toyota theme.

My only catch is I only want the 2" body lift and 2" max susp (currently stock height susp on 33's.) I need the strength for power reasons.

Posted: Wed Oct 21, 2009 7:29 pm

by -Scott-

leehamescort wrote:Total Chaos kit with a Supra 8" would be sweet as!!

An 8" front diff? Wow, that sounds pretty cool.

I wish my IFS had an 8" diff.

Oh, hang on...

Posted: Thu Oct 22, 2009 8:44 am

by leehamescort

-Scott- wrote:

An 8" front diff? Wow, that sounds pretty cool.

I wish my IFS had an 8" diff.

Oh, hang on...

Ahh yes but does yours have nice long drive shafts that reduce the CV angles so that the CV's dont go "pop"

I was toying with using the Paj front end but the Supra has additional advantages!!

catcha

Leeham

Posted: Thu Oct 22, 2009 5:39 pm

by Bitsamissin

Ahhh c'mon Leeham I'll pit my HP 8" front Jabber diff against any 8" Tojo diff IFS or live

Crownwheel is almost twice as thick - even I was surprised when I had them side by side.

HP 8" Jabber diff breakages are rare as hens teeth.

Nice job on the front end though mate very creative and a brilliant upgrade for the 4 Runner/Surf guys who want to keep the IFS.