Page 1 of 1

garrett turbo actuator and brackt

Posted: Thu Dec 24, 2009 6:17 pm

by ledgend80

ok as above am currently fitting a gt2871r to my 80 series 1hdt. the problem is the actuator and bracket dont fit between the turbo and block. so i was wondering who has fitted a garrett to there 1hdt or 1hz or other engine what bracket and actuator did you use to get it to fit. pics would be good

Re: garrett turbo actuator and brackt

Posted: Thu Dec 24, 2009 10:02 pm

by Andrew.hebble

ledgend80 wrote:ok as above am currently fitting a gt2871r to my 80 series 1hdt. the problem is the actuator and bracket dont fit between the turbo and block. so i was wondering who has fitted a garrett to there 1hdt or 1hz or other engine what bracket and actuator did you use to get it to fit. pics would be good

Slightly different use for a TD42 however i'm sure the same principle applies. I had to make up a new rod with a greater angle on it in order for the actuator to be mounted as intended on the the turbo. The alternative is to remote mount the actuator away from the turber and increase the length of rod.

Turboglide kits on TD42's use the two holes in the log style manifold to mount a braket that holds the actuator. It's then just a matter of extending the rod.

Regards

Posted: Fri Dec 25, 2009 2:42 pm

by BushTuckerNed

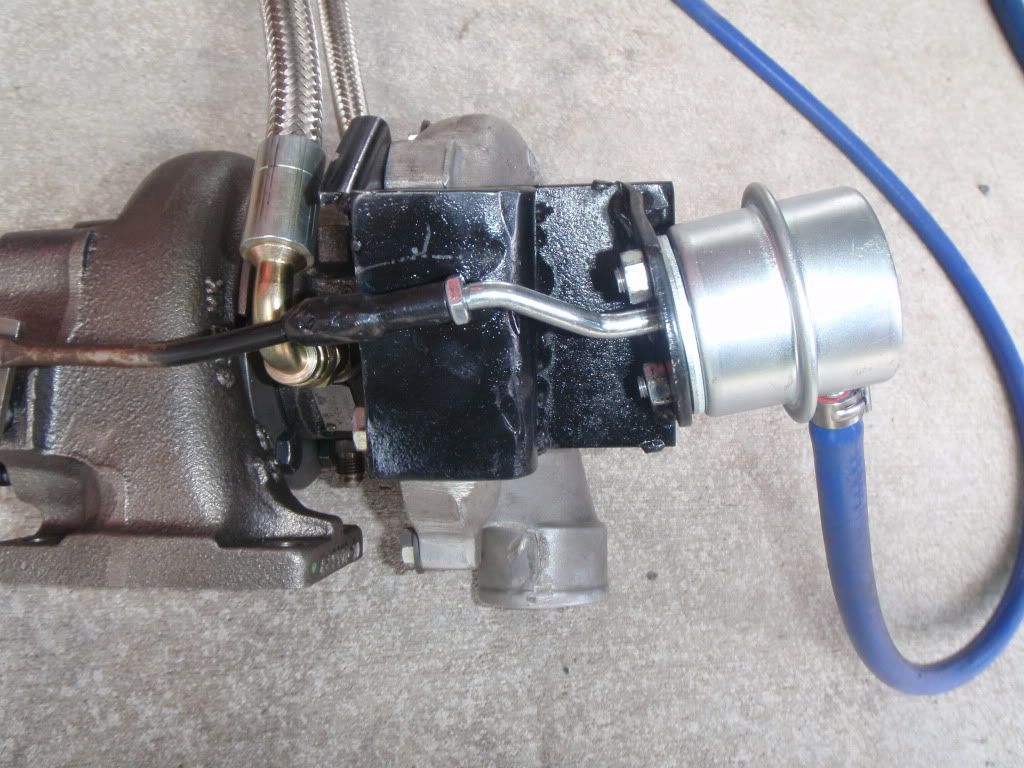

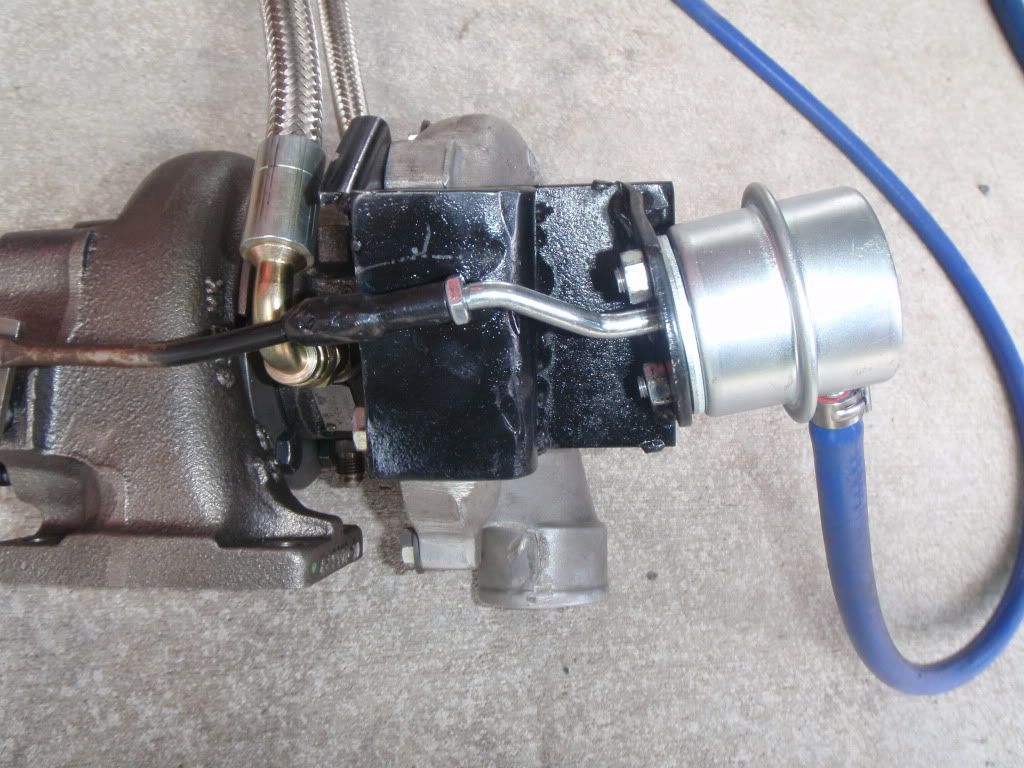

we put a garret turbo on a mates 80 a couple of days ago.

he just made a bracket to put the actuator on the other side of the turbo i think. Just bent it up out of flat bar.

I hope you can see whats going on in this pic

Posted: Sat Dec 26, 2009 6:26 pm

by ledgend80

all sorted

Posted: Sat Dec 26, 2009 6:43 pm

by Z()LTAN

waddya do mate?

Posted: Sat Dec 26, 2009 7:27 pm

by ledgend80

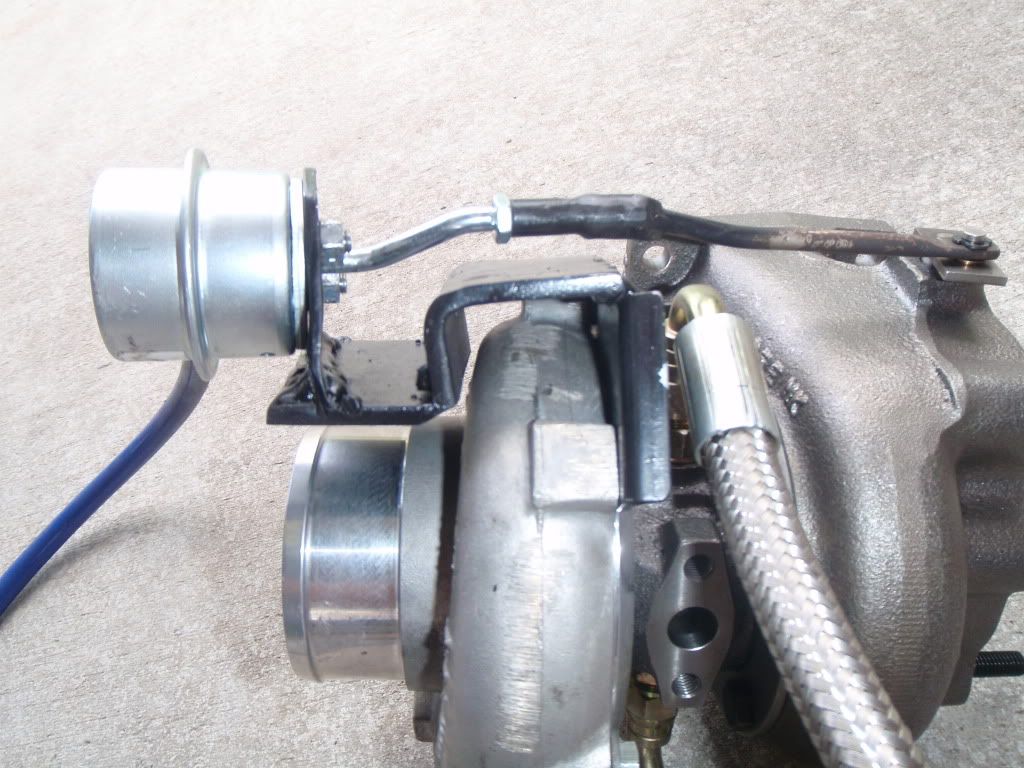

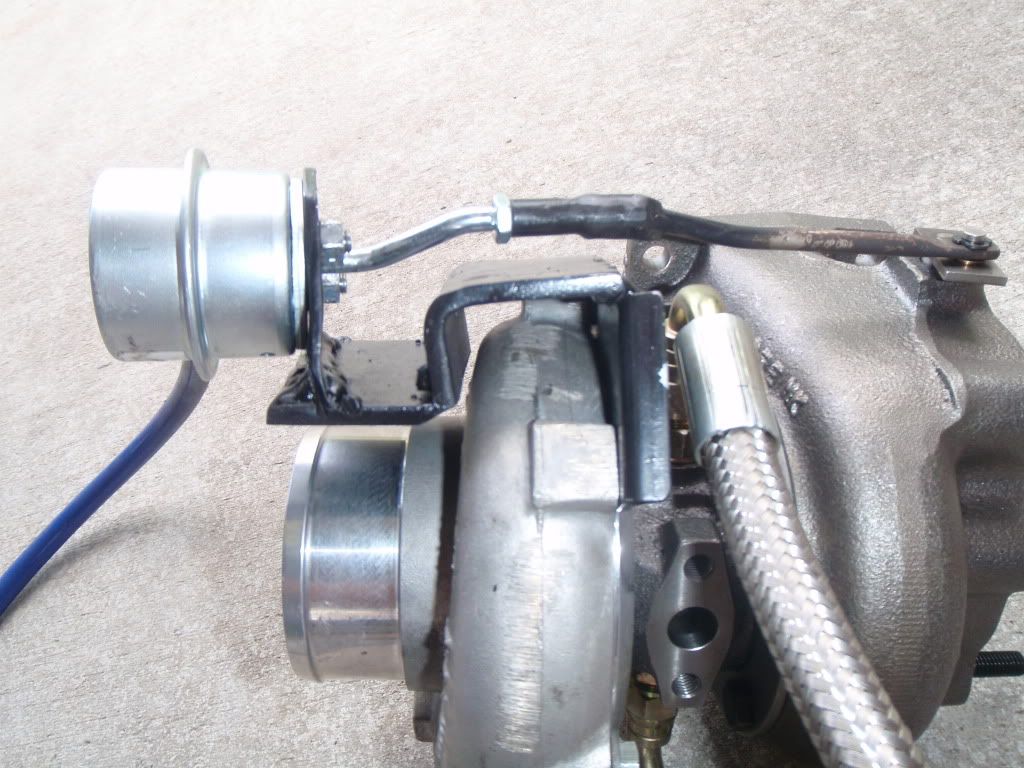

this is what i ended up doing

before

after

after

Posted: Sat Dec 26, 2009 8:00 pm

by Z()LTAN

looks like itll do the job good stuff

Posted: Sun Dec 27, 2009 8:36 am

by KiwiBacon

That'll work.

Did you stick a bike pump with guage on it to check the opening pressure? The final tweak still gets done on the engine, but it's a good starting point.

Posted: Sun Dec 27, 2009 9:43 am

by PJ.zook

You have to be a bit careful with wastegates, most only open a few mm.

Posted: Sun Dec 27, 2009 10:02 am

by Z()LTAN

make sure the linkage has a bit of preload holding the gate closed, this helps to seal the gate and stop flutter.

Posted: Sun Dec 27, 2009 11:30 am

by ledgend80

ok i pulleed the pump of my radiator pressure tester and the gate started opening at about 13psi. yes i did put some pressure on the gate to keep it closed.