Page 1 of 3

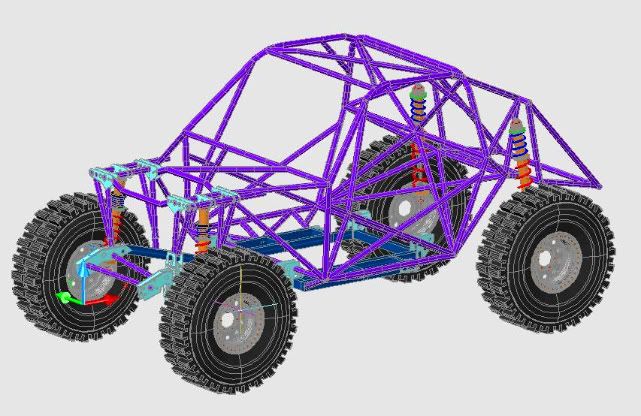

Taifun TAT

Posted: Tue Dec 29, 2009 6:40 pm

by TaifunOffroad

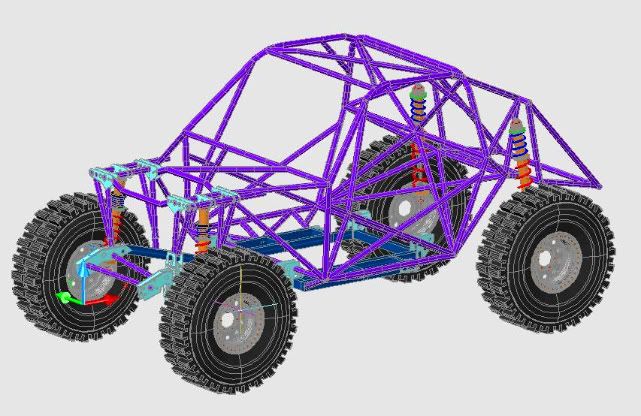

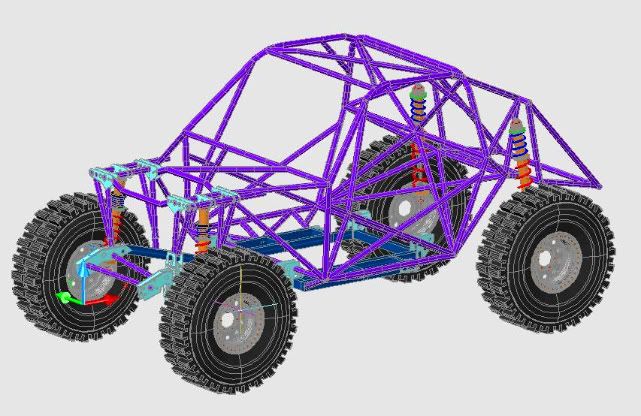

In October 2009 we started the construction of two extreme offroad cars. We’ll try to post pictures in various stages of the execution. The two cars are similar but not identical. One of them has Volvo portal axles and the other one normal axles(back HDJ80 with front Y60). In terms of tehnical data, they are equipped with 4000cc, 286hp,V8 BMW engines, manual gearboxes, 38.5/11/16 Bogger wheels, Race Runner Remote Coil-Over suspension 14” front and 16” back, duble winches 8274 with duble blockers. The car’s total height is1820mm, wheelbase is 2650mm, as for their weight, one reaches 1350kg(without the fuel but with all the other liquids included).

Posted: Tue Dec 29, 2009 7:59 pm

by oozuk

awesome workmanship, can't wait to see more pic's

Posted: Tue Dec 29, 2009 8:12 pm

by bad_religion_au

awesome, i'll be watching this build.

any reason you start with RHS chassis instead of making it all round tube?

Posted: Tue Dec 29, 2009 8:14 pm

by v840

You guys get my vote for cleanest workshop evar!

What transfer cases are you running behind the Beemer V8?

Will be watching for sure, great start.

Posted: Tue Dec 29, 2009 8:47 pm

by coxy321

Best first post i've ever seen - way to start off!!!

The work sounds and looks top quality - keep the pics coming!!

Posted: Tue Dec 29, 2009 11:40 pm

by Gabriel

Hy guys,

Well, the cars you see are designed and engineered by me. I'm a member of this forum since...a lot of years...;p-)).

I've started in 2000 with an Y60, which in meantime change in such a way that is not a Nissan anymore...but this is another story!

So, the cars: today we just mocked-up the engine, G/B and the T/case. Which, to answer the question, is a Mercedes G 463 (permanent 4x4), divorced (as you already know.;-)).

The general idea of the cars is to be able to compete in our off road competitions, which are an amalgam of rockcrawling, mudd bogging, baja races and winching. So, after 10 years of modifying cars this are the dimensions, tires, winches, etc that I consider appropriate for this kind of races. In few words: rally raid engineering and technology applied for extreme off roading!

Thank you all for the good words and we hope to do not disappointe you!

Gabi Nicolae

Posted: Tue Dec 29, 2009 11:45 pm

by RN

No Miss Romania posters on the workshop walls??

What's going on?

Posted: Tue Dec 29, 2009 11:48 pm

by Gabriel

bad_religion_au wrote:awesome, i'll be watching this build.

any reason you start with RHS chassis instead of making it all round tube?

Well, as I said: after a lot of years I learned to learn from others, mainly because I spent a lot of money doing mistakes. This structure is not my invention, but it has been done previously by the VW Race Touareg for the Dakar (btw, we are the first romanians ever registered to compete in the Dakar, cars category;-). The reason is simple and effective: when you build a car from scratch, the most important thing is to be sure that the base, or the arms fits, are square and right. By experience I know (and seems that VW knows also...) that to get a structure right is much easier and with a far better result if you start with a rectangular tube instead of round. All the rest of the structure is with round tube, a special alloy ordered by us to a big factory here in Romania. This material exceed with 90% the FIA regulations for the structures, saving in the same time 20% of the weight.

Will come back with more pictures today!

thanks for looking,

Gabi Nicolae

Posted: Tue Dec 29, 2009 11:49 pm

by Gabriel

RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))

Posted: Wed Dec 30, 2009 1:09 am

by TaifunOffroad

Posted: Wed Dec 30, 2009 1:16 am

by FKT08

Looks like top quality work. Keep us posted, will love to see the end product.

Posted: Wed Dec 30, 2009 12:56 pm

by nottie

What a breath of fresh air seeing something that damn cool that is not from America

Posted: Wed Dec 30, 2009 5:41 pm

by bad_religion_au

Gabriel wrote:bad_religion_au wrote:awesome, i'll be watching this build.

any reason you start with RHS chassis instead of making it all round tube?

Well, as I said:

thanks for looking,

Gabi Nicolae

Makes sense to me now! good to see a good idea that's outside what we see all the time! thanks for the reply.

Posted: Wed Dec 30, 2009 5:46 pm

by RED60

While the workmanship looks schmick, I'm not sure I'm happy with a clean floor, no hooter posters or "brand" names on anything........... mmm I say something wicked this way comes.........

Posted: Tue Jan 05, 2010 4:33 am

by TaifunOffroad

Posted: Tue Jan 05, 2010 7:45 am

by chunks

Very nice, and awesome looking workshop!

Posted: Tue Jan 05, 2010 9:59 am

by RAY185

Subscribed.

Don't know why this reminds me of...

Russian guy in Armageddon wrote:Russian components, American components... ALL MADE IN TAIWAN!!!

Will be checking this thread often.

Posted: Tue Jan 05, 2010 11:13 am

by RN

Gabriel wrote:RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))

I don't hate her either.

http://www.examiner.com/x-12090-Pageant ... Constantin

http://www.examiner.com/x-12090-Pageant ... Constantin

Posted: Tue Jan 05, 2010 11:23 am

by MightyMouse

VERY, VERY impressive.

It something that most of us dream about but few have the knowledge / facilities / money and sheer patience required to build things to this standard.

I'm looking forward to seeing more of the build.

Taifun TAT

Posted: Fri Jan 08, 2010 12:08 am

by TaifunOffroad

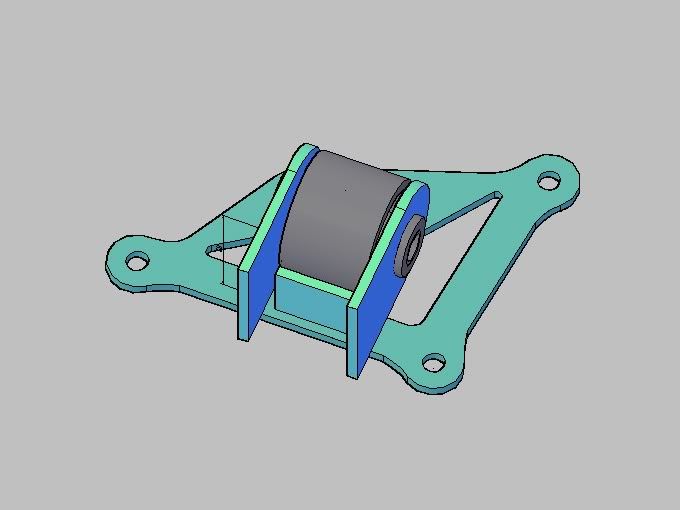

Here are some pictures with welds - made with a MIG Welding Equipment.

The both space frames are ready and we are in the process of welding together.

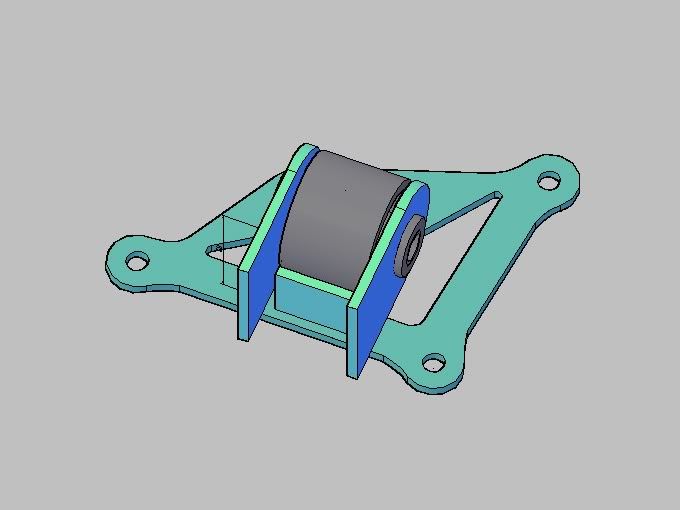

Also you can see the g/box and t/case cross member.

The ACAD file is one of the t/case supports that bolts to the cross member.

Posted: Fri Jan 08, 2010 1:45 am

by DamTriton

RN wrote:Gabriel wrote:RN wrote:No Miss Romania posters on the workshop walls??

What's going on?

;-)))) Well, not! I hate this kind of posters, especially in our shop. But I don't hate Miss Romania!!! At all!;-))

I don't hate her either.

http://www.examiner.com/x-12090-Pageant ... Constantin

http://www.examiner.com/x-12090-Pageant ... Constantin

MightyMouse wrote:VERY, VERY impressive.

It something that most of us dream about but few have the knowledge / facilities / money and sheer patience required to build things to this standard.

I'm looking forward to seeing more of the build.

I think shes pretty close to finished

and I don't think you wil see much more of the "build".

Maintanance is always the costly bit though

Back on topic....

Posted: Fri Jan 08, 2010 9:39 am

by coxy321

Camel Toe anyone?

Have you guys done simulated tests on the stress/load on that support junction? It'd be interesting to see what sort of stress is there with seven points coming to one.

Super neat weld job by the way!

More pics

Posted: Fri Jan 08, 2010 9:44 am

by chimpboy

Sometimes I say to myself, "sure, my car is cool... but what would Count Dracula drive?"

Now we know

Posted: Fri Jan 08, 2010 5:02 pm

by MightyMouse

Welding looks like TIG not MIG to my very inexperienced eye.....

I would have expected TIG with the mention of alloy steel earlier on.

Posted: Fri Jan 08, 2010 5:33 pm

by Gabriel

MightyMouse wrote:Welding looks like TIG not MIG to my very inexperienced eye.....

I would have expected TIG with the mention of alloy steel earlier on.

Hello,

Sorry, it was our "internet - IT" guy who made the confusions... Of course it is TIG, with a specific alloy wire. But, you know, the IT and building cars do not have a close relationship...;-)))

Thanks for looking,

Gabi

PS: the Dracula staff...nice ;-))

Posted: Fri Jan 08, 2010 5:37 pm

by Gabriel

coxy321 wrote:Camel Toe anyone?

Have you guys done simulated tests on the stress/load on that support junction? It'd be interesting to see what sort of stress is there with seven points coming to one.

Super neat weld job by the way!

More pics

Yes, we used a program (I can't tell you the program name because then I would have to shoot you ;-))) in order to simulate the loads and more important the effort dissipation in case of roll over (I know, its not good, but you can expect tis kind of accident). The first results was great, and because of that we mounted some more triangulated bars then in the first drawings. Anyway... We will see if the theory matches the real life in april, when the cars must race.

thanks,

Posted: Sat Jan 09, 2010 8:54 am

by awill4x4

Gabi. Do you have any specs on the tubing and welding filler wire you can share?

Regards Andrew.

Posted: Sat Jan 09, 2010 2:09 pm

by KiwiBacon

Very cool. Subscribing.

Taifun TAT

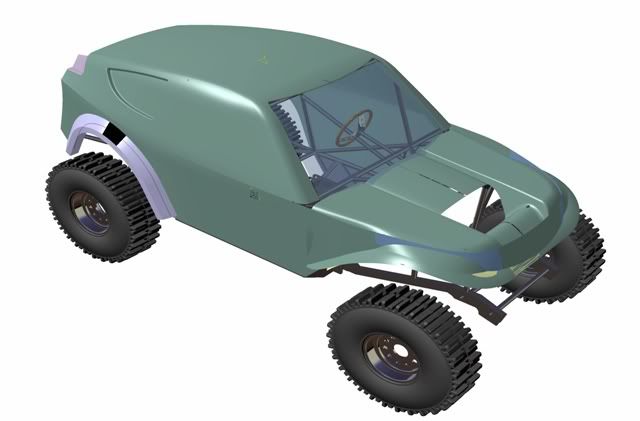

Posted: Tue Jan 12, 2010 10:23 pm

by TaifunOffroad

Posted: Wed Jan 13, 2010 9:51 am

by coxy321

Jeez that workshop is tidy! You guys even have special white outfits for visitors! (joke).

The drafts look like a Raid Rally type vehicle.

Good work - keep the photos coming!!