The units Dobinsons have that are same thickness coils right through had issues with sagging over time, and when we developed ours we went to tapered wire and variable rate, to cure this issue and stop any "coil chatter" that the dead coils gave on the early designs.

Our current design, made just for us, which we also export, is as good as they get really, giving over 100mm of extra free height for the lift, allowing much longer shocks to be used, and the spring to stay captive, so there is no unsprung movement, when articulating.

Wehave tested these coils on everything from the Canning, to everywhere in the Simpson, and everything in between since 2005, and it took 18 months and 9 coils designs before we got what we were looking for, but they work, and work well, especially if you dont want a tall truck.

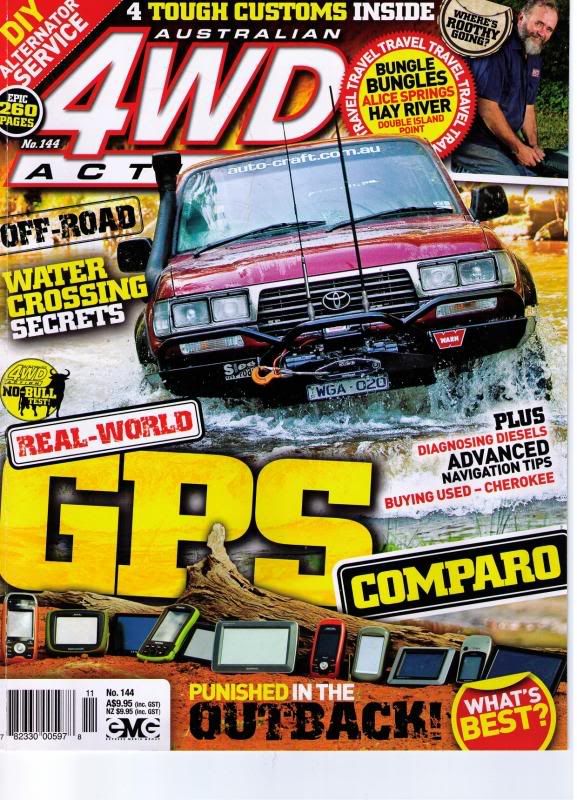

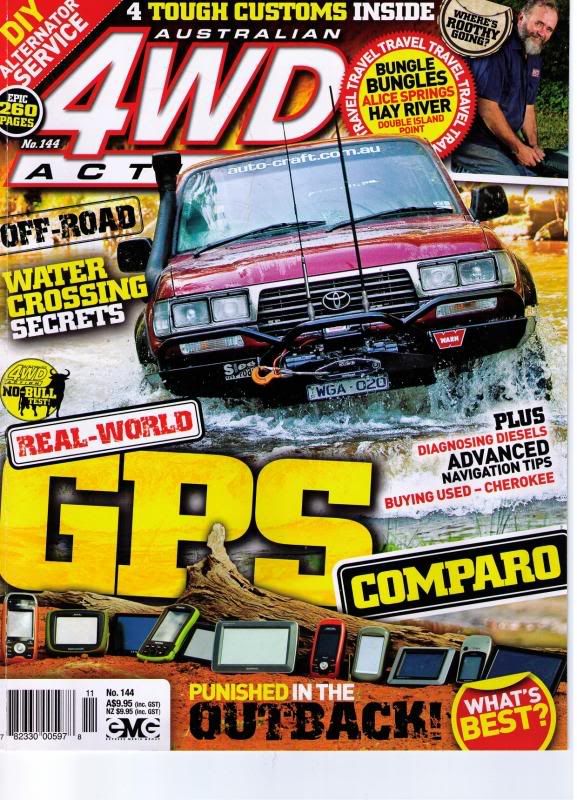

From Jan 4wd action

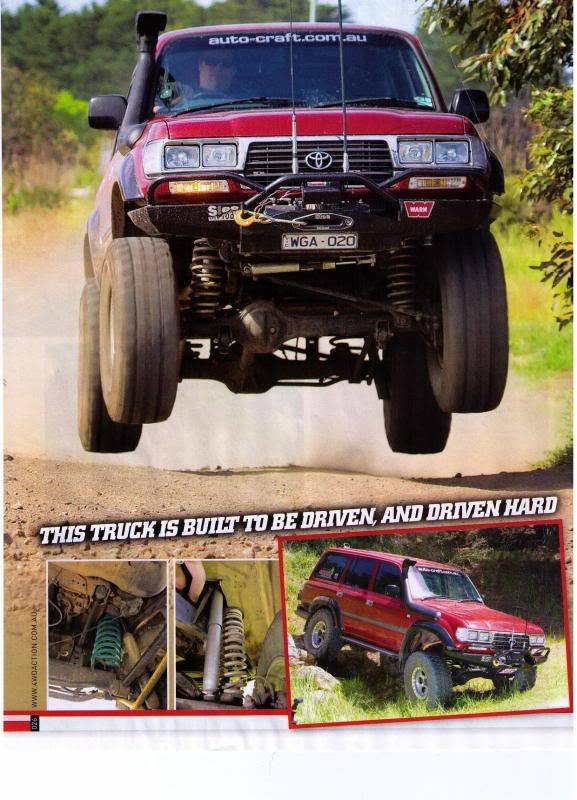

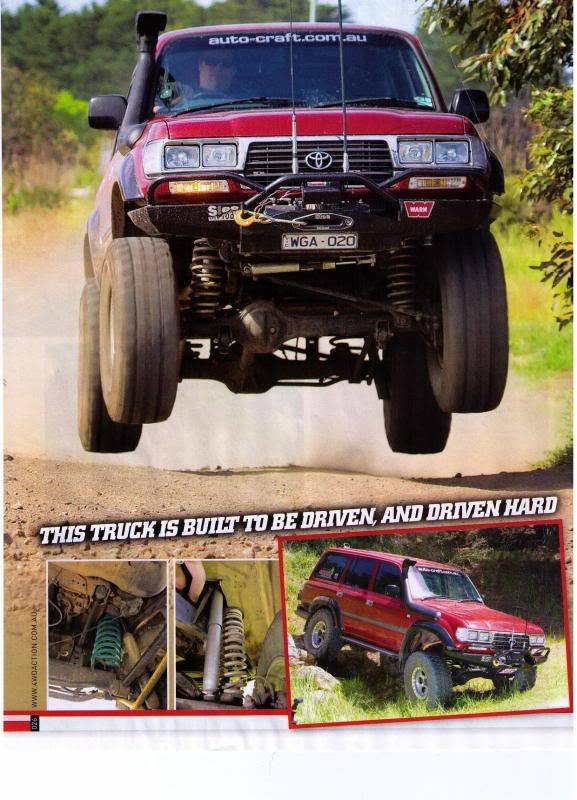

For the shoot my 80 had heavier trial rear coils [370 lb rate] as well as the 270 lb front coils, and heavier sway bars, and was pretty much unloaded, but it gives an idea of how a 3"lift on 37's can run a 12"stroke shock, keep the coils captive, and drive like a vehicle should, on road.

Like this first pic, with a heavy 4"lift coil, and our 12"stroke shock, you can see the coil comes out of the seat by over 50mm, yet the slinky 3"coil could run a 14"stoke shock, and stay captive.

We also do 100 IFS slinky long travel kits

We also developed our Patrol units at the same time, using the same technology and design software, to mkae them work.