Page 1 of 1

Mini Spool death...

Posted: Sat Feb 20, 2010 5:48 pm

by Pezooki

Hi all,

I have a 91WT Sierra with a Lockright in the front and a Mini-Spooled rear (from

www.lowrangeoffroad.com).

I have had the spool in for about a year, and it has done bugger all work. I have always treated it kindly on the bitumen to avoid putting unnecessary stress on it.

The other day, while driving home from a shooting trip (only mild 4B action), the car started pulling to one side. Upon further investigation, I discovered that the rear diff was no longer locked - not good!

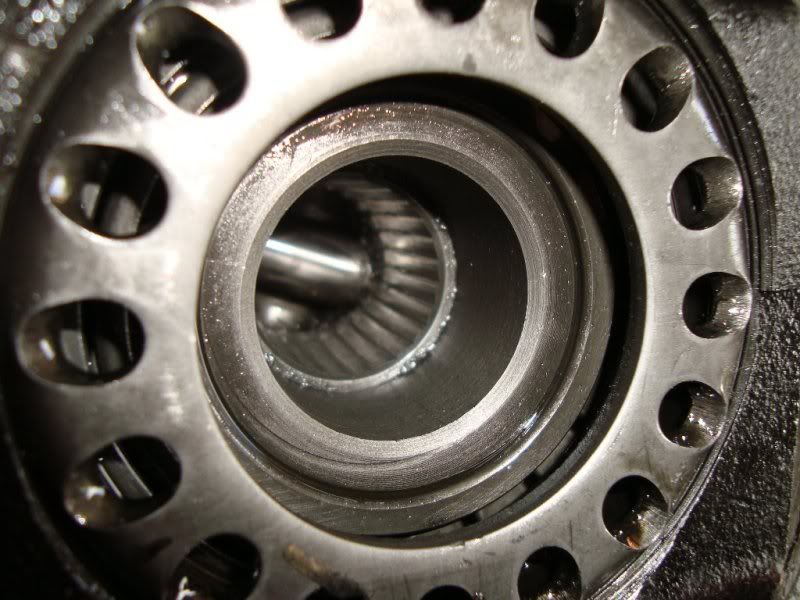

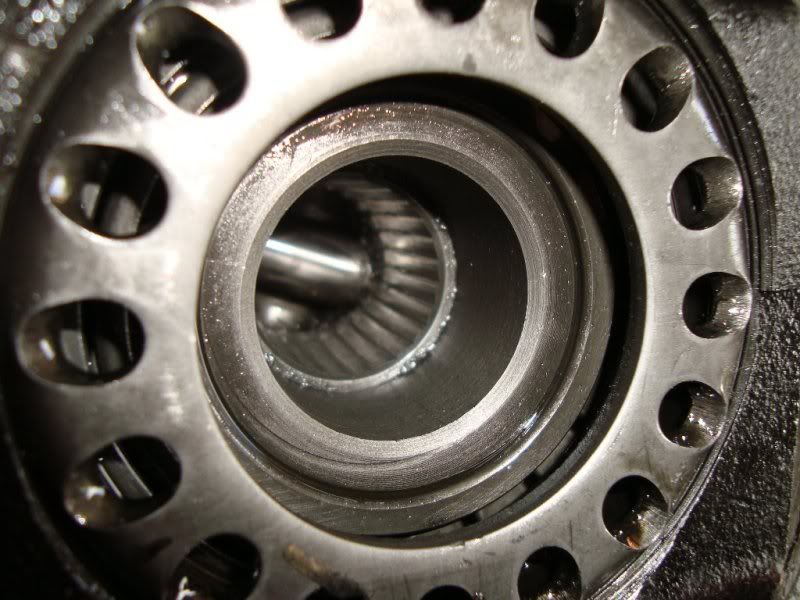

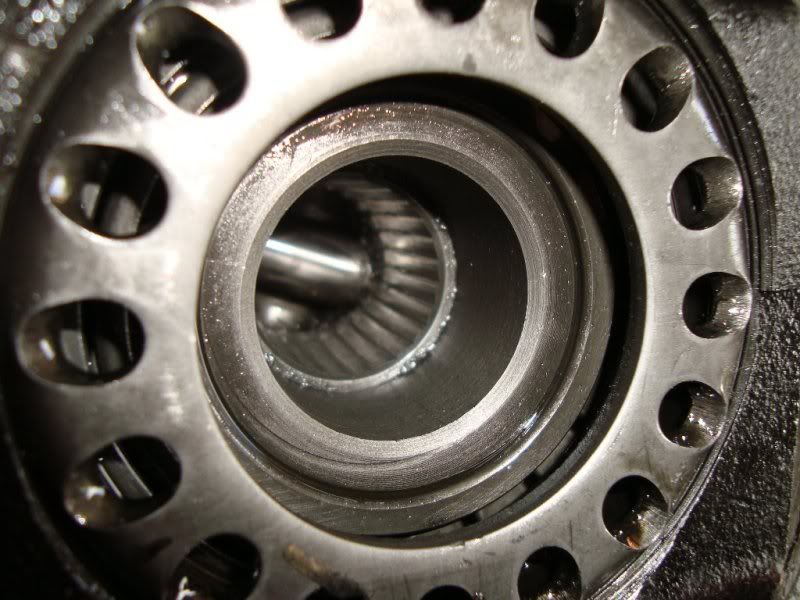

I took it home and pulled it apart, assuming that I had snapped an axle... What I found was very surprising - the inner spline on the the short axle side of the mini spool, has completely stripped out! The axle seems to still be in OK condition (surprisingly) however it has worn the axle splines down a little in the process.

Has anyone here had any failures like this before? I can only assume that the spool I got was a bad one, as I know heaps of people using them, who drive way harder than I do, who have had no problems!

What do you reckon?

Cheers,

Pez

ps - I'm looking for a replacement "short side" rear axle- PM me!!!!

Posted: Sat Feb 20, 2010 6:31 pm

by dad

I've had this happen once to a welded rear, but to both sides at once. I found tiny cracks in the side gears which would have allowed it to slip and 'round off' the axles.

Have you still got the standard center? Weld it up and throw it in, mine held up to 2 years of abuse before failing like that.

Posted: Sat Feb 20, 2010 9:16 pm

by mrRocky

maybe you were to soft on it

Refund i would try and get

Posted: Sun Feb 21, 2010 6:31 pm

by Gwagensteve

X2 - I vote incorrect heat treatment.... or the axle was heavily worn when it went in allowing excessive play, but that doesn't look like the case.

I don't daily my car, but when I pulled mine out to swap it over to my Vitara centre it looked like new (except for where the broken axle end lightly rubbed it)

Steve.

Posted: Sun Feb 21, 2010 6:49 pm

by Pezooki

Cheers for the comments guys.

Gwagensteve wrote:X2 - I vote incorrect heat treatment.... or the axle was heavily worn when it went in allowing excessive play, but that doesn't look like the case.

I don't daily my car, but when I pulled mine out to swap it over to my Vitara centre it looked like new (except for where the broken axle end lightly rubbed it)

Steve.

That's what I thought too. The axles were like new when they went in. I have sent an email to Lowrangeoffroad to see what they say.

It's a real shame - cos the reason I purchased the spool in the first place was to avoid crap like this happening!

Cheers,

Pez

Posted: Mon Feb 22, 2010 8:30 am

by Pezooki

I have received a reply from Lowrangeoffroad. The Spools only carry a 6 month warranty, so I am out of luck there.

Sean has said: "We have had a few failures in the past and 90% of the time the customer finds out that the housing is not "true." You may want to check it somehow first before you go any further."

I'm not sure about this... I put the minispool into my existing stock diff, and it was in top condition (as far as I can tell). What do you guys think?

Also:

"We are working on a full spool but think it will be several months out before they are in production."

That could be cool, but only if it doesn't do what my mini-spool has done!

Cheers,

Pez

Posted: Tue Feb 23, 2010 8:48 am

by RB zook

if you were going for a locked rear all the time why wouldnt you save the cash and just weld it. fair enough its not something you can take out if you get sick of it thou im sure would shit like that wouldnt have happened. you would have broken an axle and would have replaced if for half the price of the mini spool.

Posted: Tue Feb 23, 2010 9:15 am

by Pezooki

RB zook wrote:if you were going for a locked rear all the time why wouldnt you save the cash and just weld it.

For strength - I was doing the job properly (I'm not knocking people who run welded, im just saying...)

RB zook wrote:

fair enough its not something you can take out if you get sick of it thou im sure would shit like that wouldnt have happened. you would have broken an axle and would have replaced if for half the price of the mini spool.

Um, I think you are saying that with a welded rear this would not happen??? "Shit" like this can happen to a welded centre, and when it does it is usually worse / more carnage.

I have been unlucky with my spool, but generally speaking spools are more reliable than welded.

Cheers,

Pez

Posted: Tue Feb 23, 2010 9:18 am

by locktup4x4

From my experience if you have a bent housing the axle shaft would show signs of wear as well.

I've seen this happen with cracked locking collars like a hub gear, but the axles also showed wear.

Jason

Posted: Tue Feb 23, 2010 9:22 am

by Pezooki

Hi Jason.

Thanks for the reply.

Yep, my axles appear to be in good cond, with no unusual wear marks. The only wear that I have now is on the short-side axle splines, where the splines were spinning inside the spool. This has worn the sharp edges off the axle spline, and I am reluctant to use it again...

Anyone with a short-side axle for sale in Melb? PM me!

Cheers,

Pez

Posted: Tue Feb 23, 2010 5:11 pm

by Gwagensteve

RB zook wrote:if you were going for a locked rear all the time why wouldnt you save the cash and just weld it. fair enough its not something you can take out if you get sick of it thou im sure would shit like that wouldnt have happened. you would have broken an axle and would have replaced if for half the price of the mini spool.

I've welded quite a few sierra diffs reliably, and I welded the 1.0 diff I ran for a while in my trayback, but I now run a mini spool. The biggest reason is the ability to swap it out, as I did a couple of weeks ago when I upgraded from a WT rear diff to a vitara rear diff ( the mini spool fits both)

Whilst welded diffs work, they really are a one shot deal and often crack. They work perfectly well, but it's wise to view them as a fairly short term solution in my opinion.

If you had to pay someone to do it, a mini spool might also actually be cheaper too, and is undoubtedly stronger, excepting Pezooki's (apparently unusual) problem.

We've had a few in the club here copping a hiding with up to 35" Krawlers on them and they've been fine.

Steve.

Posted: Tue Feb 23, 2010 7:33 pm

by built4thrashing

i run a welded rear and have only ever had one problem with it. IT broke all the bolts that hold the ctr together. didnt actually bust any welds just the 10 odd bolts. bought some new ones and we were off again. One thing we did notice was that one of the axle cups in the ctr had split on opposite sides creating a sorta lockright . sometimes when it is really loaded up the axle will skip a tooth in the splines. this only happends on the blacktop.

weld it up and go crazy.

B4T

Posted: Wed Feb 24, 2010 8:01 am

by Gwagensteve

built4thrashing wrote:i run a welded rear and have only ever had one problem with it. IT broke all the bolts that hold the ctr together. didnt actually bust any welds just the 10 odd bolts. bought some new ones and we were off again. One thing we did notice was that one of the axle cupa in the ctr had split on opposite sides creating a sorta lockright . sometimes when it is really loaded up the axle will skip a tooth in the splines. this only happends on the blacktop.

weld it up and go crazy.

B4T

these are exactly the reasons why a mini spool is a good idea. Both of these problems could leave you with a broken diff and an undrivable car. The fact you are smashing an axle past a broken side gear will mean the axle is getting wrecked too

Posted: Wed Feb 24, 2010 8:02 pm

by built4thrashing

one of these days it will go bang but its been working fine now for over 3 years. Its not a daily driver and i got spares for when it does let go.

B4T