Page 1 of 1

A frame options

Posted: Fri Mar 26, 2010 6:28 am

by striped tomato

Just wondering what options there are for getting a bolt in A frame for the GU rear. I know that Wizard do one, anyone else? Any experences? Have got decent articulation with the suspension at the moment but want to eliminate the lateral movement as it articulates because the driveshaft hits the auxillary fuel tank and damages both.

Steve

Posted: Sat Mar 27, 2010 12:35 pm

by nastytroll

Steve, the tailshaft will still hit the tank. I have my old A frme kicking around somewhere if you want to try it. I modded Pams sub tank for tailshaft clearance.

The tailshaft moves like a pendulum with the pivot being roughly the centre of the top 2 arms. I'm making an educated guess here and someone with some cad skills can draw it up and prove or dis prove me.

Wizards are the only commercial A frams I know of that are bolt in.

Posted: Sun Mar 28, 2010 9:11 am

by Bush65

With the stock patrol suspension the axle rolls about a theoretical fixed point on the panhard rod at the centreline of the vehicle.

If you change to a A-frame, the panhard has to be removed and the axle rolls about the pivot at the axle end of the A-frame.

The described fixed point is called the roll centre (for obvious reason)

The higher the roll centre (A-frame), the further the drive shaft will move sideways.

Posted: Sun Mar 28, 2010 6:54 pm

by striped tomato

Well explained - thanks, I understand exactly what you mean about the A frame, less so about the panhard rod but I am thinking it means it will be better

Posted: Mon Mar 29, 2010 6:25 pm

by joneso

Just wondering who has actually tried the wizard A-frame and if it improved articulation or just lateral movement? cheers

Posted: Mon Mar 29, 2010 10:17 pm

by turps

Would a 4link be better in regards to reliability?

As if theres any failure on the A frame I would have thought it was stuffed. Where as a 4link has extra mounts to take the load.

a-frame

Posted: Tue Mar 30, 2010 8:46 am

by purplebus

joneso wrote:Just wondering who has actually tried the wizard A-frame and if it improved articulation or just lateral movement? cheers

i have one in the bus. the bushes were a bit average when we put it in to see if it was any good but my thoughts- flexed the same amount as the limit was the shocks but seemed to flex easier/smoother. it suits my needs as my truck does no road driving anymore. a frame is coming out to be rebushed and new longer shocks fitted so will let you know thoughts when that is done.

As Turps suggested if you are driving a fair bit on road i would probably lean towards a 4 link rear using longer lower arms as they are more stable/safer at speed and give good travel as well.

I have a 5link front and a-frame rear for MY needs/wants, without the swaybars you can get seasick driving on the road....

Posted: Tue Mar 30, 2010 9:33 pm

by SuperiorEngineering

My opinion is forget the "bolt in a-frame" as it is rubbish, back in the 90's heaps of guys were using them now they are rare as , probably many reason's but a bolt in retains the same "short " top link points and they are just not correct for good handling geometry , its more the lower links that are the issue.

You can do whatever you want with the top and it will not makle it any better , fix the lowers and you will have a much better handling truck.

If you are really keen for an "a - frame" have a proper built "a-frame" done not a bolt in.

Guys like cheezy racing and cash jones have done good setups.

my opinion is you don't need an "a-frame" but you will get way better handling and climbing abilty from lengthening your lower arms.

we have proven this time and time again in winch challlenges with the guys using our long arms .

the only thing a "BOLT IN" a-frame is good for is eliminating the panhard rod which may get damaged during a competition, it is irelivent if your suspension cycles out of centre for the average person.

Over the years we have seen so many guys pull out their bolt in a-frames and go back to standard upper arms, any one who thinks they will get more flex from a bolt in a-frame is way of mark as the upper arms will have enough flex in the bushes.

MY GQ had long arms 18inch FOA shocks and standard type upper arms and used the whole lot of the shock and still did not max out the bushes on the uppers.

For the guys who do not know an 18 inch shock it is not what you are going to buy from tough dog ranch or EFS ect.

http://www.superiorengineering.com.au/i ... ?pag_id=10

Posted: Wed Apr 07, 2010 9:49 am

by joneso

cheers buddy was wondering a lil why no one had mentioned them much lol. with your long arm kits do they help handling much with just say 6-7inch shocks? cant decide if i wana go all out with 16-18s in the back

Posted: Thu Apr 08, 2010 10:32 pm

by BeNoS

would just like to know though

the only problem i see with the superior longer lower control arm kit is that anybody with a wags or swb it makes it alot harder to mount a slider as the arm is in the road. anybody got a solution to this? as id like to put a longer lower arm kit in my swb some day.

but any ute will have no dramas with this.

Posted: Tue Apr 13, 2010 12:16 pm

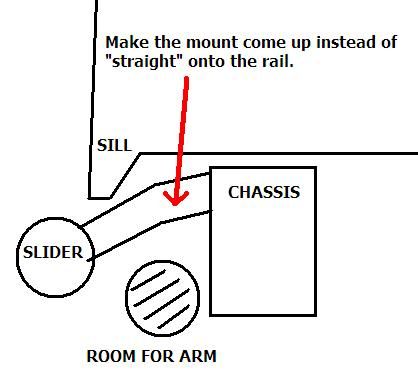

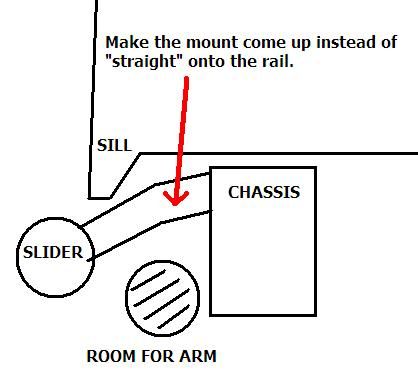

by SuperiorEngineering

We have not fitted our Long Arm Kit to SWB's as the chassis is different in the mounting area.

LWB wagons are no problems, the rear slider mount is still put in the same location but you mount the pipe up high on the chassis rail and angle it downwards to allow the up travel of the long arms, this has also been done on utes as well.

Posted: Tue Apr 13, 2010 5:05 pm

by Mrowka

Please refresh my memory and tell me what you mean by "you mount the pipe up high on the chassis rail and angle it downwards to allow the up travel of the long arms."

Pretend you are explaining everything to someone really thick, someone who has never even seen a 4x4 except maybe once in a children's storybook.

Posted: Tue Apr 13, 2010 6:32 pm

by SuperiorEngineering

Mrowka wrote:Please refresh my memory and tell me what you mean by "you mount the pipe up high on the chassis rail and angle it downwards to allow the up travel of the long arms."

Pretend you are explaining everything to someone really thick, someone who has never even seen a 4x4 except maybe once in a children's storybook.

see at the back of the sliders i have drawn a light white line outlining the angle of the rear pipe that connects the sliders to the chassis.

On a standard slider these connect in horizontally , when using long arms you angle this pipe on the angle to allow for the compression of the coil and the long arm "up Travel".

Hopefully that has helped clear it up.

Posted: Tue Apr 13, 2010 6:39 pm

by A.J.

I apologize for my pathetic MS Paint attempt, hope it helps:

Posted: Wed Apr 14, 2010 7:37 am

by nzdarin

Bush65 wrote:With the stock patrol suspension the axle rolls about a theoretical fixed point on the panhard rod at the centreline of the vehicle.

If you change to a A-frame, the panhard has to be removed and the axle rolls about the pivot at the axle end of the A-frame.

The described fixed point is called the roll centre (for obvious reason)

The higher the roll centre (A-frame), the further the drive shaft will move sideways.

Roll centre has nothing to do with causing diff traveling side ways. The main advantage of an 'A' frame is the diff can't move sideways (within the limits of the bushes anyway). Roll centre is a theoritical point the vehicle wants to pivot around when there is side loads. (cornering or side slopes) It can be argued that for an offroad truck then the higher the rollcentre the less roll you will get. Less roll will cause less weight transfer and so keep centre of gravity between the wheels longer allowing for higher cornering speeds of steeper side slopes.

The decision to use an 'A' frame over a 4 link is really down to packaging. I'm building an 'A' frame for my new truck as there won't be enough triangualtion with a 4 link due to the length of the arms and the width of the chssis. So the solution is to join the top links together (and make an 'A' frame) and heavily reinforce it. The suspension geometry is on slightly different to a 4 link. The main difference is to do with the arc the wheels travel in during articulation and as it will have a swaybar to limit articualtion it isn't and issue.

Lifted Patrol suspension geometry is crap. The long arms kits go a long way to improving this and a bolt in 'A' frame goes a long way to making it even worse!!!!

But like everything to do with suspension it is all a compromise.

Posted: Wed Apr 14, 2010 1:38 pm

by Bush65

nzdarin wrote:Bush65 wrote:With the stock patrol suspension the axle rolls about a theoretical fixed point on the panhard rod at the centreline of the vehicle.

If you change to a A-frame, the panhard has to be removed and the axle rolls about the pivot at the axle end of the A-frame.

The described fixed point is called the roll centre (for obvious reason)

The higher the roll centre (A-frame), the further the drive shaft will move sideways.

Roll centre has nothing to do with causing diff traveling side ways. The main advantage of an 'A' frame is the diff can't move sideways (within the limits of the bushes anyway). Roll centre is a theoritical point the vehicle wants to pivot around when there is side loads. (cornering or side slopes) It can be argued that for an offroad truck then the higher the rollcentre the less roll you will get. Less roll will cause less weight transfer and so keep centre of gravity between the wheels longer allowing for higher cornering speeds of steeper side slopes.

The decision to use an 'A' frame over a 4 link is really down to packaging. I'm building an 'A' frame for my new truck as there won't be enough triangualtion with a 4 link due to the length of the arms and the width of the chssis. So the solution is to join the top links together (and make an 'A' frame) and heavily reinforce it. The suspension geometry is on slightly different to a 4 link. The main difference is to do with the arc the wheels travel in during articulation and as it will have a swaybar to limit articualtion it isn't and issue.

Lifted Patrol suspension geometry is crap. The long arms kits go a long way to improving this and a bolt in 'A' frame goes a long way to making it even worse!!!!

But like everything to do with suspension it is all a compromise.

Sorry, but you are not quite right.

The original post was about solving a problem with the sideways movement of the drive shaft and clearance to an auxiliary fuel tank.

I gave a simple response, (avoiding going into too much technical detail) to help the original poster understand the issue with the drive shaft to tank clearance with the direction that he was thinking of. It is still basically correct, but to be strictly correct I should have spoken about roll axis instead of simply roll centre.

Some of what you said (directed tot my post) is not correct and needs to be sorted before others believe it to be true.

The axle assembly rolls about its roll axis, which passes through its roll centre.

With an A-frame the roll centre is the swivel joint at the diff end of the A-frame.

With a panhard rod the roll centre is located at the point on the panhard rod that is at the centreline of the vehicle. When suspension height changes (bump, droop, etc.), the angle of the panhard changes and the roll centre stays at the described point on the panhard, but because the panhard has moved relative to the vehicle and axle, the height of the roll centre has changed.

With parallel lower trailing arms, the roll axis is inclined at the same angle as the trailing arms. This is why you get roll steer when the lower links are not parallel with the road.

When the axle articulates it is pivoting about that swivel joint - the A-frame prevents that pivot point from moving sideways (neglecting any flex in the arms or mounts etc.).

Then if you care to consider all other points on the axle, those points will move along the path of an arc that is centred on the roll axis. You can think of a pendulum if that helps.

As the drive shaft is a considerable distance below the roll axis, the arcs that describes its path will show that it will move to the side as the axle articulates.

Generally for stock or small changes to stock suspension height, the roll centre will be higher for suspensions that use an A-frame than for those using a panhard.

It is possible to make the roll centre higher with a panhard, but not retaining the stock mount on the axle and a close to horizontal panhard.

Strictly speaking vehicle doesn't pivot around the roll centre as you stated.

The sprung part of the vehicle rolls around the vehicle roll axis. Both front and rear axles have their own roll centres and roll axii. The vehicle roll axis passes through the roll centres of both the front and rear axles. All three roll axii can have a different slope.

How vehicle roll axis affects body roll depends upon the height of the centre of gravity of the sprung mass relative to the vehicle roll axis.

Posted: Thu Apr 15, 2010 1:51 pm

by nzdarin

I wasn't thinking about the axle articulating so you are completely correct.

I also didn't understand what you meant with statement about 'A' frame causing sideways movement being due to distance between the mount and the driveshaft. The full explantion makes it quite clear that what you were saying originally was correct but not very clear. (to me anyway)

I also agree with basically what you said and think it is basically what I said? However you definitely described things much better! I was also simplifying things and didn't really do it very well.

We're on the same page just with a different language!