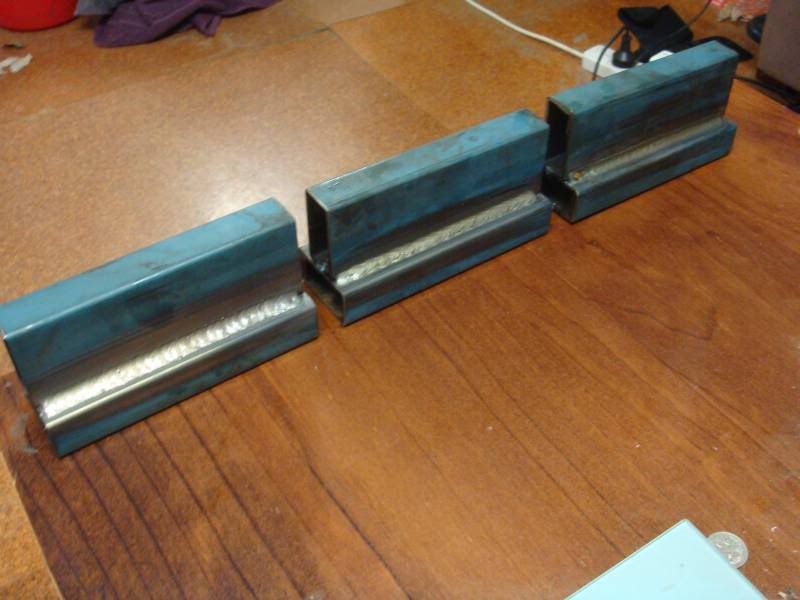

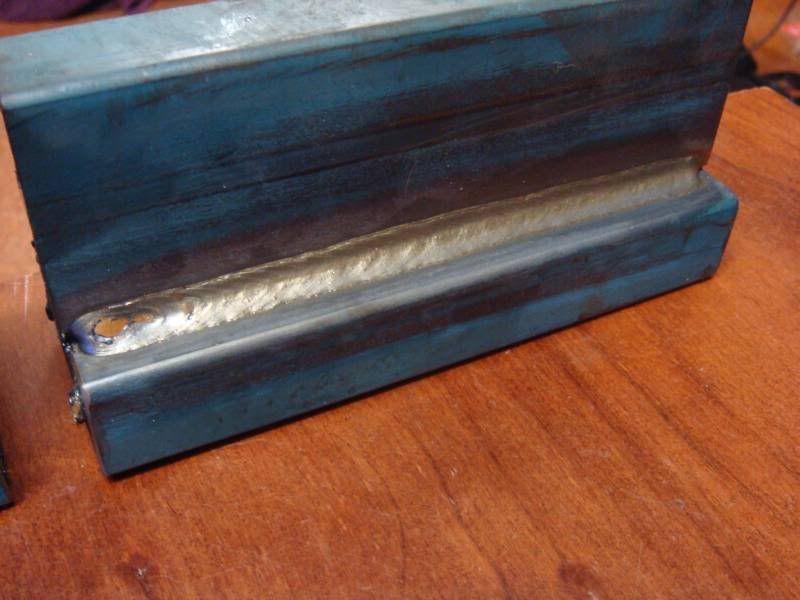

rockcrawler31 wrote:I have a question about this. I started on MIG, went to ARC and have found that can actually get a better looking weld (better "structurally" looking not just pretty) with arc than i can with MIG. It seems like my mig welds just sit on top of the joint or fillet and produce a raised up bead instead of burning in like the arc does. I've noticed that the MIG welds here all seem to have a decent amount of burning in so i started thinking about it. Is it better to run a smaller wire with a faster wire speed so that you can run a higher amperage for a given job? that way you get good burn in without the issue of your wire burning back into the gun?

I've just found that chipping slag and working on thinner materials with arc is a bit of a pain even though i'm getting ( i think) better welds.

Although having said that, sometimes in tight spots it's easier to get an electrode in than a MIG gun.

Also on vertical ups, if you're using MIG is it bad to do a short run, pause, do a short run and so on to stop the weld pool running and falling off? Kind of like and extended tac, tac. I mean, you're still going to have a fair bit of heat travelling up into the oncoming weld zone to preheat it right?

Sorry if these are all complete noob questions

Milo, if you weld seems to be bulgy (too high deposition rate) then a lot of the time this can be because the welding machine is either to low powered for the job or settings are wrong (too high wire feed or too low volts).

What gas are you using, gas choice makes a lot of difference in the weld deposition and wether or not enough heat is being generated to create a truly liquid weld pool. Most of the argosheild type gases will do for mild steel.

Vertical up with a MIG needs to be done with a xmas tree pattern for the first run, which means you lay a spot of weld then move up to lay another spot of weld then drop to the left, pause, across to the right, pause then up above the spot previously laid then drop left, pause, across right, pause up again.

The spots act as a bridge or support for the left to rights which prevent the weld simply falling away from the job. each time you drop to the left you should pause just above a spot.

Geez that probably makes no sense to someone who hasn't seen it.

Anyway, second runs on vertical ups are then done with a simple weave in the up direction.

Cheers

i like to thank my sponsors wild turkey and buds customs

i like to thank my sponsors wild turkey and buds customs