Page 1 of 1

Custom hawse fairlead

Posted: Sun Dec 26, 2010 12:47 pm

by AFeral

Widened the drum on my warn high mount now need suitable hawse fairlead. Who does custom one's ?

Feral

Re: Custom hawse fairlead

Posted: Sun Dec 26, 2010 4:43 pm

by sprungupcruiser

Could you not get something laser cut or machined? probably cheaper I would think.

Re: Custom hawse fairlead

Posted: Sun Dec 26, 2010 5:03 pm

by AFeral

Laser cutting would not work as corners of the rope slot need chamfered. Yes I could get someone to machine one how many $$$ though. Thought I would ask her first if someone already has their CNC machine programed would be fairly easy to change a few measurements and work from there. Rather than programing from scratch.

Re: Custom hawse fairlead

Posted: Sun Dec 26, 2010 11:10 pm

by DamTriton

It wouldn't take long to manually file the aperture from a laser cut blank

Re: Custom hawse fairlead

Posted: Thu Dec 30, 2010 7:59 pm

by tuf045

router on router table to make the chamfer is how i have seen it done

Re: Custom hawse fairlead

Posted: Thu Dec 30, 2010 8:34 pm

by bru21

I made mine out of 44mm steel elbows, and 2 short lengths of pipe- and intergrated it into the bar. Worked very well and was kind on the rope due to the bigger radius

Re: Custom hawse fairlead

Posted: Thu Dec 30, 2010 10:47 pm

by hokey

i've seen on a few cars around my area what seems to be some steel rod bent around the hole and welded on. would be fairly simple to do i'd imagine

Re: Custom hawse fairlead

Posted: Thu Dec 30, 2010 10:56 pm

by Zuri92

do what these 2 guys said, easy, cheap, and exactly what you require.

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 6:07 am

by pigletracing

done it a few times by welding 2 U bolts (large leaf spring ones) together, smoothing them up, then weld them over the hole.

but make sure you get rid of all the sharp edges !!!

cheers "PIGGY"

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 9:41 am

by Modified Toy

Use some small steam pipe mandral bends and weld them up to your hole size ,clean up what you can with a grinder and file the rest.

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 10:44 am

by Roctoy

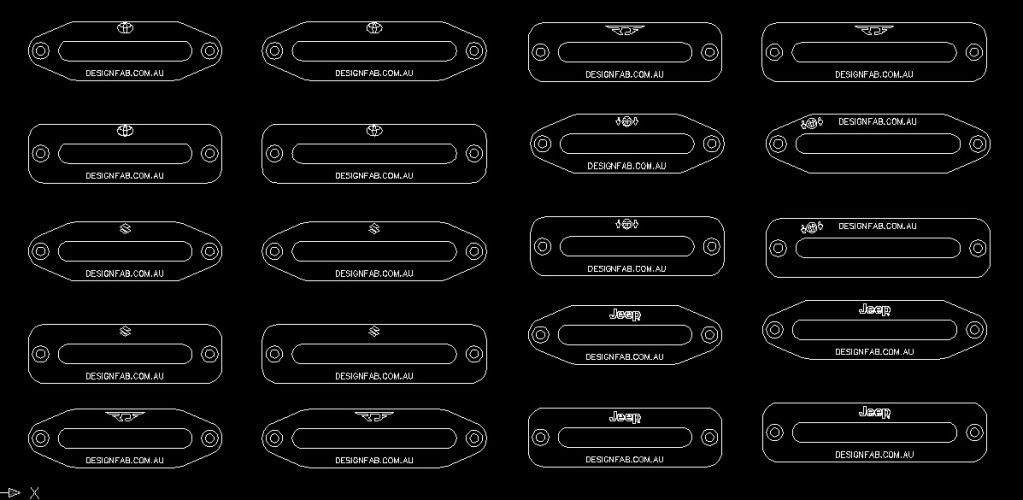

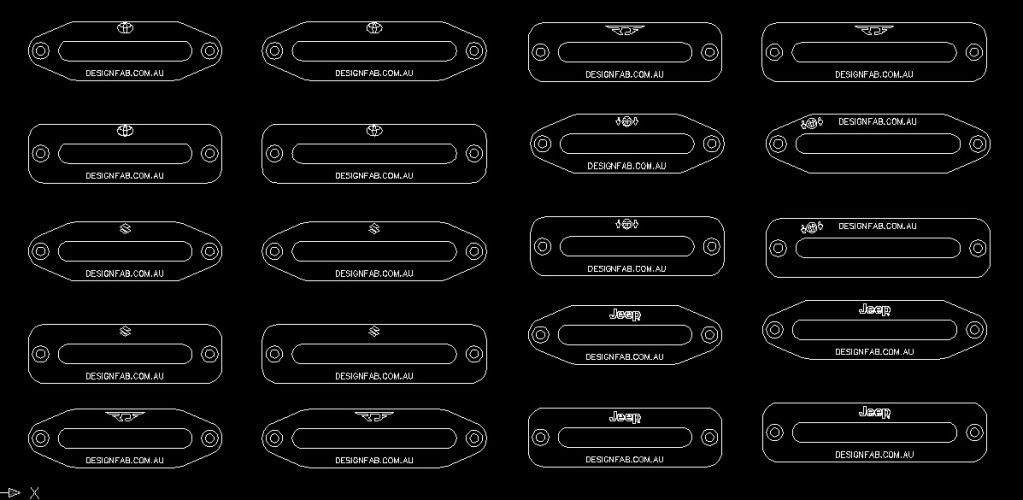

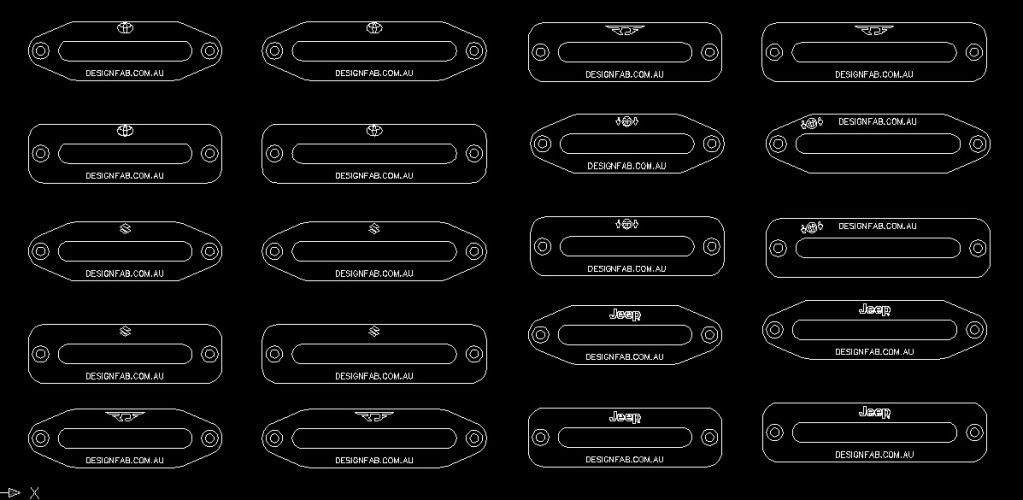

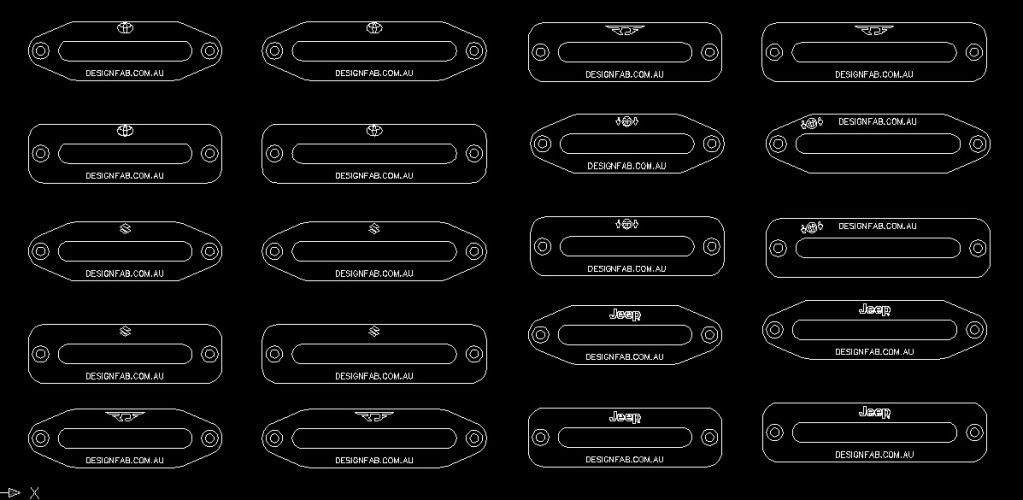

I'm about to CNC router cut a heap of Hawse Fairleads in the next few weeks from a composite plastic material. Lighter and stronger than aluminium, with none of the friction heat issues caused by running rope through them at high speeds. They will have a smooth radius edge around the rope slot and recessed mounting bolt holes. As you can see there are already a heap of different options for vehicle logos etc. It wouldn't be a problem to do team names either for a small additional fee.

I haven't finalised prices for them yet, but i will be able to do custom sizes and designs to suit different winch setups.

Stay tuned

cheers Chris

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 12:19 pm

by ISUZUROVER

Roctoy Designfab wrote:I'm about to CNC router cut a heap of Hawse Fairleads in the next few weeks from a composite plastic material. Lighter and stronger than aluminium, with none of the friction heat issues caused by running rope through them at high speeds. They will have a smooth radius edge around the rope slot and recessed mounting bolt holes. As you can see there are already a heap of different options for vehicle logos etc. It wouldn't be a problem to do team names either for a small additional fee.

I haven't finalised prices for them yet, but i will be able to do custom sizes and designs to suit different winch setups.

Stay tuned

cheers Chris

How can they be lower friction - unless you are using glass reinforced teflon???

I note you don't have any variants with offset mounting holes???

Colours? Rough price difference to a stock al item?

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 12:27 pm

by Roctoy

They are not lower friction, they just disipate the heat better than aluminium does. They are cut from Black HDPE engineering plastic.

The standard ones are the same mounting hole offset as every other hawse fairlead about 250mm approx, but this can be changed to suit whatever is needed, for different drum widths etc.

They will be a similar price to the aluminum ones on the market already, i will try to keep them as cheap as i can.

Note they are not a new idea, just no one makes them in Australia.

Here's a review from Pirate in 2003 on a similar product.

http://www.pirate4x4.com/tech/billavist ... index.html

Cheers Chris

Re: Custom hawse fairlead

Posted: Thu Jan 06, 2011 2:48 pm

by V.W.Dave

Roctoy Designfab wrote:They are not lower friction, they just disipate the heat better than aluminium does. They are cut from Black HDPE engineering plastic.

The standard ones are the same mounting hole offset as every other hawse fairlead about 250mm approx, but this can be changed to suit whatever is needed, for different drum widths etc.

They will be a similar price to the aluminum ones on the market already, i will try to keep them as cheap as i can.

Note they are not a new idea, just no one makes them in Australia.

Here's a review from Pirate in 2003 on a similar product.

http://www.pirate4x4.com/tech/billavist ... index.html

Cheers Chris

Well hurry up

I need one and will be happy to pay you over arb or tjm for one.

Let me know when to send the money.

Re: Custom hawse fairlead

Posted: Wed Feb 23, 2011 4:50 pm

by SIM79

Roctoy Designfab wrote:I'm about to CNC router cut a heap of Hawse Fairleads in the next few weeks from a composite plastic material. Lighter and stronger than aluminium, with none of the friction heat issues caused by running rope through them at high speeds. They will have a smooth radius edge around the rope slot and recessed mounting bolt holes. As you can see there are already a heap of different options for vehicle logos etc. It wouldn't be a problem to do team names either for a small additional fee.

I haven't finalised prices for them yet, but i will be able to do custom sizes and designs to suit different winch setups.

Stay tuned

cheers Chris

Have the prices been sorted out?

Re: Custom hawse fairlead

Posted: Wed Feb 23, 2011 8:39 pm

by Jcas24

Nice, look forward to hearing more about these

Re: Custom hawse fairlead

Posted: Thu Feb 24, 2011 9:58 am

by Roctoy

i have confirmed prices, but i am now looking at a slightly different way of manufacturing them.

Re: Custom hawse fairlead

Posted: Thu Mar 31, 2011 9:45 am

by Roctoy

got the first batch yesterday!

they turned out really nice.

check the misc for sale section i've got heaps of stuff for sale in there atm, including these.

Re: Custom hawse fairlead

Posted: Thu Mar 31, 2011 12:10 pm

by GUtripper

Re: Custom hawse fairlead

Posted: Thu Mar 31, 2011 12:17 pm

by Roctoy

hmmmm gigglepin stuff is sexy!

Re: Custom hawse fairlead

Posted: Thu Mar 31, 2011 12:26 pm

by GUtripper

Not to mention exxy...... but good.

Re: Custom hawse fairlead

Posted: Thu Mar 31, 2011 4:49 pm

by SIM79

Looks good

Re: Custom hawse fairlead

Posted: Fri Apr 01, 2011 12:08 pm

by ISUZUROVER

Roctoy Designfab wrote:They are not lower friction, they just disipate the heat better than aluminium does. They are cut from Black HDPE engineering plastic.

They look nice.

However I don't see how you can claim they dissipate heat better than Al.

Al has a thermal conductivity of ~250 W/m.K at 25oC. HDPE is ~0.6 W/m.K at the same temp.

So the Al should dissipate heat about 300x faster than HDPE (for the same area).

Even special $$$ plastics designed to be used as heatsinks only get up to around 100-150 W/m.K

EDIT

By offset I meant this type:

Re: Custom hawse fairlead

Posted: Fri Apr 01, 2011 12:34 pm

by Roctoy

ISUZUROVER wrote:Roctoy Designfab wrote:They are not lower friction, they just disipate the heat better than aluminium does. They are cut from Black HDPE engineering plastic.

They look nice.

However I don't see how you can claim they dissipate heat better than Al.

Al has a thermal conductivity of ~250 W/m.K at 25oC. HDPE is ~0.6 W/m.K at the same temp.

So the Al should dissipate heat about 300x faster than HDPE (for the same area).

Even special $$$ plastics designed to be used as heatsinks only get up to around 100-150 W/m.K

EDIT

By offset I meant this type:

hmmmm i've just checked your figures and they are close enough to being true, your engineers status has been renewed for another 12 months

That'll teach me for making claims based on someone elses similar product overseas.

Rock Buggy Supply in the USA do these and they've been given hell by Pirate4x4 and survived well.

Be that as it may, is there a way you calculate accurately how quickly a material builds up heat from friction in the first place? My personal experience machining this stuff is that it just doesn't get as hot as aluminium (i end up with the bits of offcuts in my boots sometimes and it's just scratchy, but when maching ally in tha same way it friggin burns!) simple example. I would think that running synthetic rope through it would be the same. The coefficient of friction, kinetic, for the HDPE that these are made from is 0.22. How does this compare to aluminium? ( I am by no means a metallurgist? )

All good and well, theres a few of them in the field now and i'd appreciate any feedback positive or negative. I'm just giving something a shot, if it works it works.

As for the offset ones, yes i am getting some of them cut in the near future, just want to see how the first lot work out.

Chris

Re: Custom hawse fairlead

Posted: Fri Apr 01, 2011 12:55 pm

by ISUZUROVER

Roctoy Designfab wrote:ISUZUROVER wrote:Roctoy Designfab wrote:They are not lower friction, they just disipate the heat better than aluminium does. They are cut from Black HDPE engineering plastic.

They look nice.

However I don't see how you can claim they dissipate heat better than Al.

Al has a thermal conductivity of ~250 W/m.K at 25oC. HDPE is ~0.6 W/m.K at the same temp.

So the Al should dissipate heat about 300x faster than HDPE (for the same area).

Even special $$$ plastics designed to be used as heatsinks only get up to around 100-150 W/m.K

EDIT

By offset I meant this type:

hmmmm i've just checked your figures and they are close enough to being true, your engineers status has been renewed for another 12 months

That'll teach me for making claims based on someone elses similar product overseas.

Rock Buggy Supply in the USA do these and they've been given hell by Pirate4x4 and survived well.

Be that as it may, is there a way you calculate accurately how quickly a material builds up heat from friction in the first place? My personal experience machining this stuff is that it just doesn't get as hot as aluminium (i end up with the bits of offcuts in my boots sometimes and it's just scratchy, but when maching ally in tha same way it friggin burns!) simple example. I would think that running synthetic rope through it would be the same. The coefficient of friction, kinetic, for the HDPE that these are made from is 0.22. How does this compare to aluminium? ( I am by no means a metallurgist? )

All good and well, theres a few of them in the field now and i'd appreciate any feedback positive or negative. I'm just giving something a shot, if it works it works.

As for the offset ones, yes i am getting some of them cut in the near future, just want to see how the first lot work out.

Chris

HDPE => steel has a friction coefficient of ~0.2

vs

AL => steel of ~0.5 (possibly shlightly lower if highly polished).

So the HDPE does have a friction advantage. (however not enough to outweigh the reduced conductivity).

I suspect the reason the swarf is cooler is (a) it takes less energy to remove it and (b) the plastic is less able to absorb heat from the machine tool during the time it is in contact with it.

Re: Custom hawse fairlead

Posted: Fri Apr 01, 2011 1:06 pm

by Roctoy

righto then i might have to change the wording on my marketing.

you've got to admit though, less friction = less heat, i was on the right track

cheers

Re: Custom hawse fairlead

Posted: Sat Apr 02, 2011 9:46 am

by ISUZUROVER

Roctoy Designfab wrote:righto then i might have to change the wording on my marketing.

you've got to admit though, less friction = less heat, i was on the right track

cheers

maybe...

Coefficients of friction (COF) are tested against steel, but the friction of UHMWPE (the winch rope) on Al or HDPE may not be directly correlated with the COF of Al on steel or HDPE on steel.

However, if they are: Then the Al will generate more heat, but be able to "wick" it away faster to the rest of the Al. If the cable is sitting in one spot on the fairlead, I doubt HDPE could have an advantage, but if it is moving (e.g. side-side) across the fairlead then the cable temp may stay lower.

How much would it cost to make some in glass reinforced PTFE??? It has a COF of 0.05

If the price was reasonable I would be up for one.

Rock Buggy Supply in the USA do these and they've been given hell by Pirate4x4 and survived well.

you've got to admit though, less friction = less heat, i was on the right track