Page 1 of 1

Fitting heads - Petrol

Posted: Fri Jun 03, 2011 1:43 pm

by thehanko

Ive fitted a head before but just have a few general questions.

Is the head bolt tightening order the same for all engines? or is there specific order for each engine? In this case a 4 cylinder dohc.

same question for cam caps?

I'm pulling a head to replace a suspected blown gasket - but of course there is a chance of a cracked head as well. Are cracks visual to the naked eye? or does it need to go to be xrayed to be checked.

I will be getting the head decked to ensure its flat,

I have the torque settings and other stages for the head refit,

vrs kit and new bolts,

is there anything else I should be doing?

the kit comes with stem seals which I've never replaced before but figure i might as well while its off - any tricks?

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 2:13 pm

by hulsty

Generally the ones I have done have been in a circular pattern from the centre, except for a GM OHC engine which had a specific pattern and angles of turn etc etc

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 2:22 pm

by thehanko

hulsty wrote:Generally the ones I have done have been in a circular pattern from the centre, except for a GM OHC engine which had a specific pattern and angles of turn etc etc

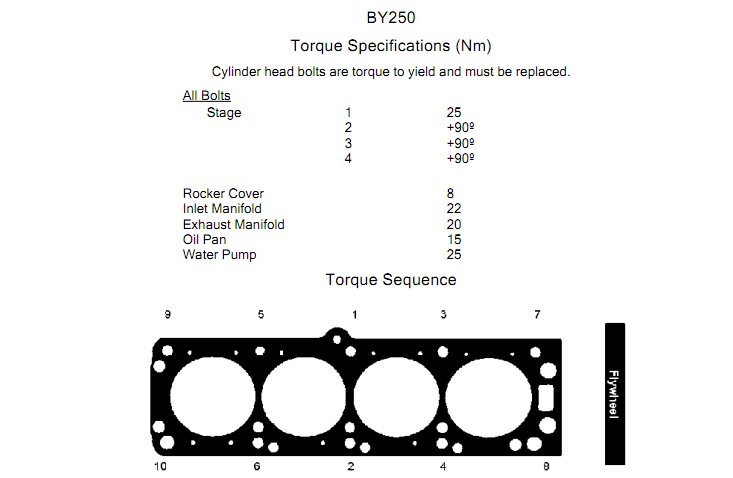

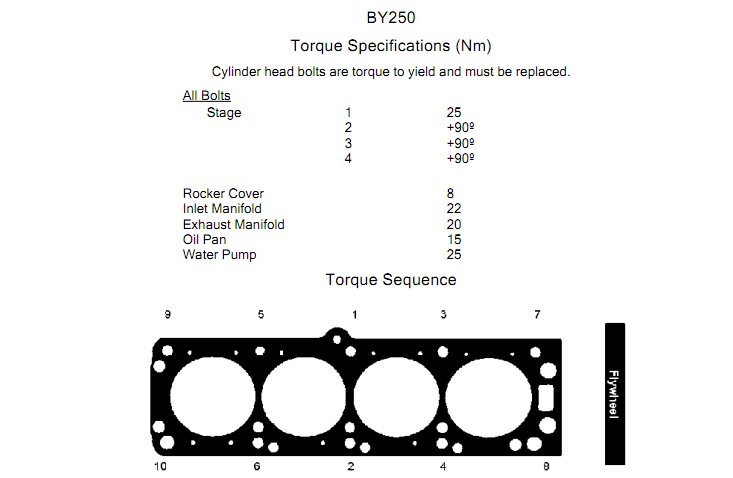

yeah this is a gm engine and it goes 25 nm then 90 deg, 90 deg 90 deg, 45 deg, so I might need to try to find the specific order for the engine its a c22sel.

thanks for the specific info. its gold.

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 2:26 pm

by UhhOhh

Check engine manual for tightening pattern it should be near the torque settings, I've seen the order jump around a bit but all have specific torqueing requirements. You'd be lucky to see a cracks, make sure to ask for a pressure test when putting it in for a face, you can get them to do the valves too if you can't be stuffed (like me!).

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 4:50 pm

by thehanko

UhhOhh wrote:Check engine manual for tightening pattern it should be near the torque settings, I've seen the order jump around a bit but all have specific torqueing requirements. You'd be lucky to see a cracks, make sure to ask for a pressure test when putting it in for a face, you can get them to do the valves too if you can't be stuffed (like me!).

I'm having trouble finding a manual apparently as its an Aussie engine not the euro variant most manuals don't cover it. I tried to find a pdf download and failed miserably lol.

Good to know the order is usually engine specific. (I knew the torque would be but wasn't sure of order).

Cheers

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 6:58 pm

by hiluxmad

sometimes the order and settings are printed on the packet that the new gasket came in.

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 6:59 pm

by UhhOhh

worst case I'd go out in concentric circles and hope for the best

I remember one engine was like this:

8 4 1 5

7 3 2 6

and another like this

8 4 3 6

7 2 1 5

If that makes sense at all, it's upto you if you think it'll make any difference or not you got the torquing steps at least which is more important.

Re: Fitting heads - Petrol

Posted: Fri Jun 03, 2011 7:00 pm

by UhhOhh

What engine is it btw?

Re: Fitting heads - Petrol

Posted: Sat Jun 04, 2011 12:01 am

by pcman

http://www.aagaskets.com/TechnicalData.aspx" onclick="window.open(this.href);return false;

select the engine and click view/download

Re: Fitting heads - Petrol

Posted: Sat Jun 04, 2011 1:53 am

by nabstud

Re: Fitting heads - Petrol

Posted: Sat Jun 04, 2011 9:44 am

by thehanko

legend

Uhhohh its a c22sel

Re: Fitting heads - Petrol

Posted: Sat Jun 04, 2011 9:48 am

by thehanko

That site is simply brilliant - not only effective but thorough!

Re: Fitting heads - Petrol

Posted: Sat Jun 04, 2011 8:38 pm

by chunderlicious

make sure you have a nice long bar to do those bolts up with... the first 90 will be fine, the second 90 youll be straining and the third youll be worying the bolts will snap.

Re: Fitting heads - Petrol

Posted: Sun Jun 05, 2011 12:24 am

by pcman

glad too help , i actually only found the site thursday so lucky for you

Re: Fitting heads - Petrol

Posted: Sun Jun 05, 2011 6:58 am

by RED60

chunderlicious wrote:make sure you have a nice long bar to do those bolts up with... the first 90 will be fine, the second 90 youll be straining and the third youll be worying the bolts will snap.

BUT make sure the aformentioned long bar (which I agree is a good idea) doesn't hit anything in its arc while tightening.....

Re: Fitting heads - Petrol

Posted: Mon Jun 06, 2011 6:47 pm

by skootin

Most heads will crack along the HOT Exhaust side of the head. If there are any significant cracks they will be visible, Pressure testing the head is the best option. Replacing the stem seals is a good option but ask to have the valves vacumm tested afterwards to make sure they are still sealing. And check the top of the block to make sure its still flat.

From past experience DOHC heads that have been HOT are bent and will need to be staightened before being surfaced.

When fitting the cam caps make sure you have the timing marks lined up correctly and gently tighten all the bolts evenly take note of the lobes that are opening the valves as the bolts will have more load on them.

Re: Fitting heads - Petrol

Posted: Wed Jun 08, 2011 12:46 pm

by thehanko

No cracks!

Its at the head builders at the moment having some pitting welded and then decking the head and they are doing the stem seals as well. Surprisingly well priced i feel.

weld the head, machine it, fit valve stems and supply vrs kit for $240 same day service.

As for thinking the bolts will snap... I remember the last one i did and was having a heart attach on the final stage of tightening lol. Getting these ones undone was pretty nerve racking as well to be honest, lots of cracking and creaking noises.

How likely is it to snap head bolts or strip threads when done to spec on a head? assuming the threads have been cleaned and oiled. I would hope extremely unlikely but interested to hear.

Thanks for the advice guys.

Re: Fitting heads - Petrol

Posted: Wed Jun 08, 2011 1:39 pm

by uglystik01

if using new head bolts and done to spec its very unlikely to snap. i have used old head bolts before on a 250 x flow but it isnt recomended on a side note it may sound obvious but make sure the socket your using is on the head of the bolt properly its very easy to start swinging on a big bar and not realise untill its too late and you have stripped the head

Re: Fitting heads - Petrol

Posted: Wed Jun 08, 2011 2:52 pm

by thehanko

uglystik01 wrote:if using new head bolts and done to spec its very unlikely to snap. i have used old head bolts before on a 250 x flow but it isnt recomended on a side note it may sound obvious but make sure the socket your using is on the head of the bolt properly its very easy to start swinging on a big bar and not realise untill its too late and you have stripped the head

Yeah good call - these are torx and i was super careful making sure they were all the way in as the oil sitting inside the bolt head kind of hydroliced and could stop complete connection.

New Bolts are cheap!

Re: Fitting heads - Petrol

Posted: Thu Jun 09, 2011 7:04 pm

by uglystik01

i find our more likely to strip heads when loosning as they are usually bloody tight so you just heave on the bar only realising when you fall on your face that it wasnt on properly...not that id do that

Re: Fitting heads - Petrol

Posted: Fri Jun 10, 2011 3:13 pm

by thehanko

uglystik01 wrote:i find our more likely to strip heads when loosning as they are usually bloody tight so you just heave on the bar only realising when you fall on your face that it wasnt on properly...not that id do that

heads all torqed down, just playing silly buggers with some heli coils in the exhaust manifold and she will be a runner again!

Re: Fitting heads - Petrol

Posted: Mon Jun 13, 2011 8:00 pm

by thehanko

All back together... But no love.

Two possibilities. Timing or wiring I guess.

I sort of lost the crank position for timing, but if I'm not mistaken it's just top dead centre cylinder 1? Correct?

Cams are correct for tdc and it'd at top dead centre as best I can tell but I suppose could be one tooth out - but the more I relook at it the less I think it's out.

It kind of started with extra fuel but wouldn't run.

There is no valve interference. I checked before I hit the key.

I love mechanics but it's times like this that just send you insane!

I guess I'll start with the basics tomorrow and check spark first then fuel before I start taking timing belts off again sigh.

Re: Fitting heads - Petrol

Posted: Mon Jun 13, 2011 8:18 pm

by uglystik01

it would be worth checking out a workshop manual for the correct timing marks as even though most engines are timed on tdc no1 its not a definite for all engines. an easy way to check is line all the timing marks up then (with the belt on) turn the crank twice if timed correctly all marks should line up again

Re: Fitting heads - Petrol

Posted: Mon Jun 13, 2011 8:39 pm

by thehanko

Cheers.

Yeah I turned by hand a few cycles to ensure the valves weren't going to collide with pistons and ensure the marks didn't change in relation to one another.

The reason I haven't bothered with a work shop manual is that from what I've read the manual are done on the euro engine and cam marks are different on the Aussie models- though I think it's only limited to the intake cam so would probably still help me as I know that part.

The odd bit is the crank pulley has a mark but there is nothing for it too line upwith??? It lines up with the edge of a bit of casting but I'm not 100% sure it's deliberate or not.

Re: Fitting heads - Petrol

Posted: Tue Jun 14, 2011 10:11 am

by thehanko

Got to love the Internet. I found a few posts last night for the same engine where people had found the crank angle sensor connection needed to be wiggled... And away she went

Always a relief to find out your not as useless as feared!

Thanks for all the advice along the way.

Re: Fitting heads - Petrol

Posted: Tue Jun 14, 2011 6:41 pm

by uglystik01

gotta love that "oh shit" moment when youve just done some major work.