Page 1 of 1

DIY winch cradles

Posted: Fri Oct 28, 2011 9:55 am

by DUDELUX

I am planning on building a tube style winch bar for my Hilux, it will tie into my exo cage at the sides.

I have already got a design that I want to use, but the mounts will be a massive weak spot.

Ive spent many hours reading posts over on Pirate, and looking through google images, and asked some experts for advice too.

The problem is, my lux is an LN65, and there is only 4 bolt holes on the front to mount any kind of bar to.

Heres a pic to show what I mean.

You can see the upper bolt holes at the bottom corners of the radiator, the lower bolt holes are just below them.

I was reading a thread over on Pirate about how people have mounted their winch tube bars, and it seems as though they weld some plate over the top of the front crossmember, drill and tap some holes, and bolt the tube bar to that.

Heres the thread on Pirate.

http://www.pirate4x4.com/forum/showthre ... ers&page=2" onclick="window.open(this.href);return false;

About halfway down page 2, is a post by Green Truck, with a couple of really detailed pics of how he mounted his winch tube bar, I know his is a gen 1 Lux, and mine is a gen 2, but I could take alot of ideas from that.

Then I was looking on sites like LowRangeOffroad, Trail Gear, and Locktup4x4. I came across an aftermarket winch cradle, made by Trail Gear, which looks like this.

Id buy something like that, but I dont want the hitch in it, so I plan on making something similar, its just the mounts that I need some advice with.

And I was looking through a heap of build threads here looking at how people have made their own winch cradles, and how they have mounted them.

I dont want to buy an ARB or TJM winch bar, I want to make my own, using the design I have come up with, which meets my side rails, and my exo. Im not planning on running a winch just yet, but I want to have the bar winch compatible for when I get one.

Most of all, I want the bars mounts to be rock solid, as its going to be the weak spot of the whole exo

If youve made your own winch bar, even better if youve made one for a LN65 Lux(84-88). Can you please post up a few pics of how youve mounted them.

I will be running a 2inch dropped crossmember, and quite possibly a FMIC aswell.

Any advice is appreciated.

Thanks guys.

Tony

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 10:26 am

by rockcrawler31

Captive nuts and through bolting (double shear) are my favourite for such high load mounts. Personally i'd have a look at ways to have the winch cradle/bar encapsulate the chassis rails and through bolt the whole assembly. Alternatively holesaw a hole in the side of the rails just large enough to take a M12 or M14 nut, and weld said nut to the back of a fish plate that can then be welded on to the side of the rails. Obviously the fish plate follows the normal rules for boxing the side of a rail (and considering it's forward of the suspension mounts it makes it a bit less critical). Have it slightly smaller than the overall dimensions of the rail, well all the way around. You can have multiple captive nuts on the back of the plate, personally for a winch cradle on a lux i'd want a minimum of 4 M12 bolts in single shear and preferably another pair in double shear somewhere.

M

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 10:28 am

by toughnut

Why don't you just tie into the body mount holes? Also by the look of that cradle it uses a captive nut or somehting just below the body mount inside the front crossmember.

Also, have a look further back along the chassis rails for a point where you could run some bracing back to tie it in better. Either on the side or on the bottom of the chassis rails.

Another option is to weld in a threaded crush tube in the chassis rails just behind the body mounts and tie into those.

Lots of options. Just need to have a bit of a think about the forces that will be placed on the cradle and try to engineer them out as best you can. Side load is probably going to be the biggest in some situations but pulling up or down is also a big consideration.

Just had a look again. You could run a vertical plate down to pidk up the inside mount on your shackles. This would also give you a good way of protecting the shackle mounts and effectively building a ramp for them so the front slides up and over obstacles better when winching.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 10:43 am

by Struth

see below

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 10:45 am

by Struth

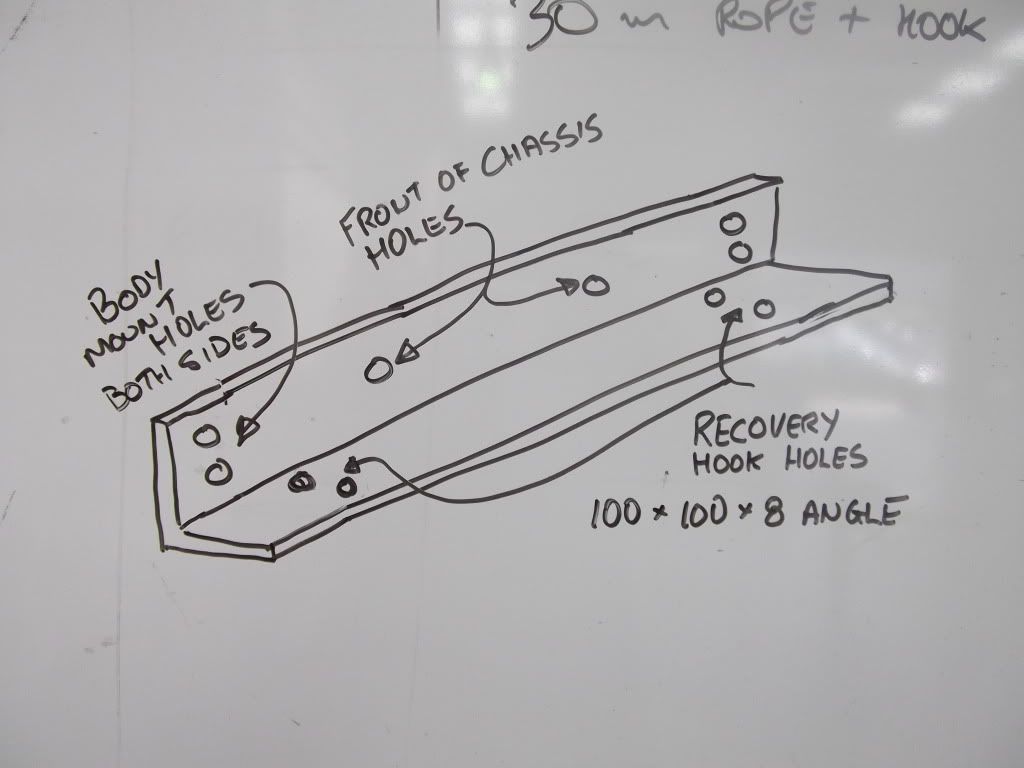

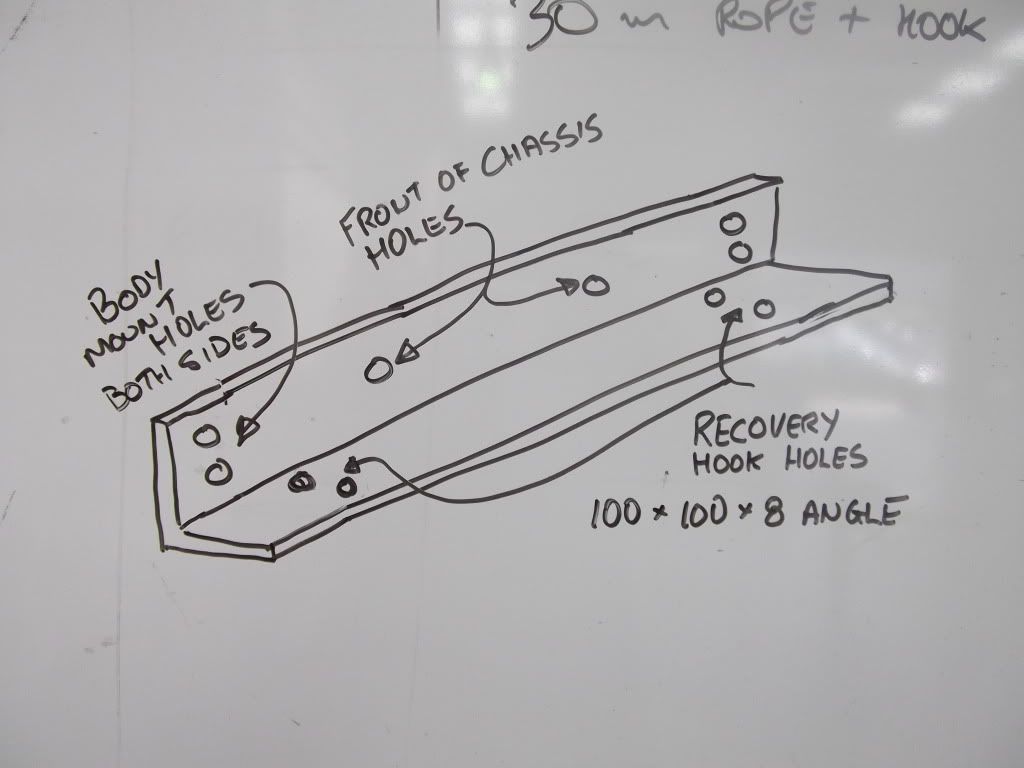

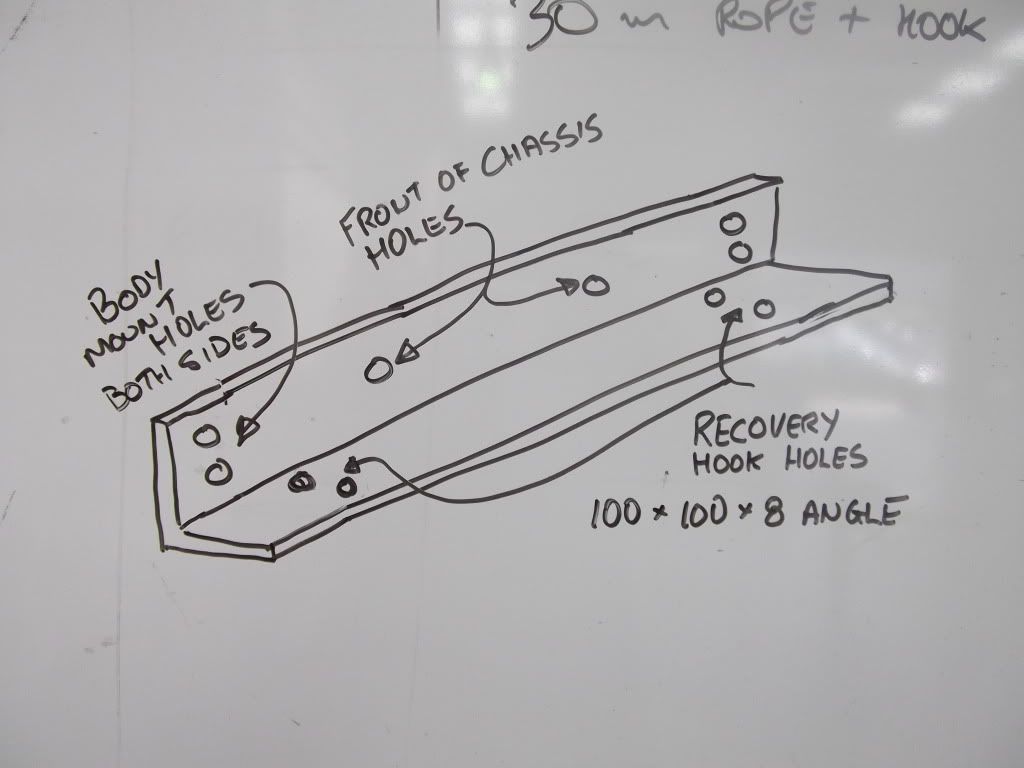

Struth wrote:You have the two holes either side under the chassis (where the recovery hook is bolted) theses are M.12 fine with captive nuts.

You should also have two holes on top of the chassis with captive nuts (behind the radiator).

And as someone else mentioned there are a further two holes either side of the chassis on the vertical face of the body mounts.

You also have 4 holes with captive nuts on the very front face of the chassis.

If yoy can utilise some of these 14 holes to bolt even a basic piece of heavy angle to, you will have a very strong mounting structure for any front barwork you like.

Still trying to get around to drawing what I mean for you, will keep at it

Cheers

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 10:57 am

by Struth

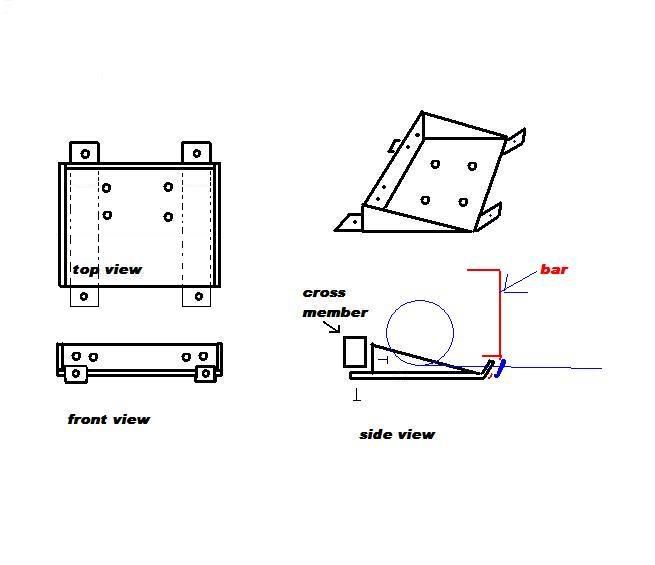

I wouild start by bolting something like this to the front of the chassis, it will give you a fairly well hidden starting point to weld any barwork too, from there stand back and work out what shape you want things to be.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 11:18 am

by rockcrawler31

Struth those mount holes would be relying on the threads to take the loads. While i'm no engineer, i'd MUCH rather have my bolts in shear. What about rotating that angle 90 degrees and having bolts go through the front x member vertically to get them in shear?

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 11:37 am

by toughnut

rockcrawler31 wrote:Struth those mount holes would be relying on the threads to take the loads. While i'm no engineer, i'd MUCH rather have my bolts in shear. What about rotating that angle 90 degrees and having bolts go through the front x member vertically to get them in shear?

Not all the bolts are taking the weight with the threads and you have the lower bolts to take the weight in shear. Your winching, while predominantly on pulling from the front. It will also have forces in other directions depending on the direction of the anchor point and the angle of the vehicle in relation to that. I agree though. If possible, I'd have more anchor points from the top, bottom or sides. You may also be able to aid this design by using a 'U' channel section coming up from underneath the front cross member so you have some metal of the winch bar behind the front cross member to add strength to the winch cradle and the front cross member.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 11:55 am

by DUDELUX

Thanks for the ideas guys, I really appreciate your help.

Ill have a chat to my engineer about some of your ideas guys, but keep the ideas coming please.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 12:14 pm

by rockcrawler31

When you eventually design it, just remember that you may eventually have to get the bastard off and on again. So make sure don't design it in a way that means the bugger is on there permanently, or is a PITA to hold while getting on.

Seriously go and plagiarize the hell out of an ARB winch bar for that model. There's no point re-inventing the wheel if it's already rolling past yer house.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 12:31 pm

by Struth

I agree fellas, last time I made a bar for this model car I also incorporated the two bolts on top of the chassis in shear.

To me it is important to keep the winch fairlead hole as low and close to chassis height as possible, to keep forces as directly in line with the actual chassis as you can. This will help avoid/reduec torsional loads on the chassis and the bar.

There are not a lot of places on these luxes to tie the bar back to much further behind the front crossmember unless you want to perform majorish surgery through the radiator panel area and past steering boxes, etc.

Cheers

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 2:28 pm

by DUDELUX

Struth wrote:I wouild start by bolting something like this to the front of the chassis, it will give you a fairly well hidden starting point to weld any barwork too, from there stand back and work out what shape you want things to be.

On this idea Struth, Ill have a 2inch dropped spring hanger welded to the bottom of the front chassis crossmember, so the holes for the recovery hooks will be covered up.

I was also looking in this thread on Pirate, about the TG Rock Defence front bars.

http://www.pirate4x4.com/forum/showthre ... ers&page=2" onclick="window.open(this.href);return false;

Towards the bottom of page 2, there are a few pics from guys that have welded some 6-8mm plate over the top of the front chassis crossmember, and drilled/tapped holes, plus welded captive nuts too.

I was thinking about doing something similar, and was talking to Struth about it, but I couldnt make a good enough pic of it for him to understand, do you see what I mean now Shaun??

Obviously, I was going to use more than the 6-8 threaded holes/captive nuts.

EDIT- Just read someone talking about a plate sold by Front Range Offroad. Did a search and found this.

http://frontrangeoffroadfab.com/nfoscom ... ucts_id=63" onclick="window.open(this.href);return false;

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 3:08 pm

by toughnut

I'd still consider actually using the body mounts and the spring hangers as mounting options. Both of these points offer fairly easy removal and hold the bolt in shear instead of pulling directly on the thread. It also means you don't have to build extra mounting points or bracing on the chassis. It gives you a pretty good spread between mounting points so you'll have the load spread over a greater area.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 4:08 pm

by DUDELUX

toughnut wrote:I'd still consider actually using the body mounts and the spring hangers as mounting options. Both of these points offer fairly easy removal and hold the bolt in shear instead of pulling directly on the thread. It also means you don't have to build extra mounting points or bracing on the chassis. It gives you a pretty good spread between mounting points so you'll have the load spread over a greater area.

Do you mean have a piece of steel angle(say 8mm), upside down to how struth has in his drawing.

And have a hole in the top(with the body mount bolt going through it(have the body lift block on the top of it)??

And use the 2 holes just above the spring hangers??

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 6:06 pm

by toughnut

Thats what i meant with the body mounts. As for the spring hangers. Just run a vertical piece of plate cut to shape so you actually put the spring bolt through it.

Re: DIY winch cradles

Posted: Fri Oct 28, 2011 6:29 pm

by georgey

Tony there are 4 threaded holes on the front xmember and then if you look under the crossmember and down the chassis rails there are about another 6-10 threaded holes.

Make a cradle that uses the front 4 holes and weld on some braces that utilise the holes underneath.

Or another option is to weld some 10mm to the top of the crossmember hanging it over the xmember forwards,brace it up,bolt your winch to this and build your bar around it so essentially its a 2 piece.Winch on one and the bar on the other.If done properly you wont even be able to tell.It will make your bar lighter to get on and off too.

Re: DIY winch cradles

Posted: Sat Oct 29, 2011 8:41 am

by DUDELUX

toughnut wrote:Thats what i meant with the body mounts. As for the spring hangers. Just run a vertical piece of plate cut to shape so you actually put the spring bolt through it.

Thats what I thought.

Justin, I have seen a winch bar on the same model as mine, and there was some bracing going along the bottom of the chassis rails, it bolted up almost under the engine mounts.

Sounds like I have alot of thinking to do, thanks guys. Please keep the ideas coming.

Would having the IFS steering box and the dropped spring hanger get in the way of any of these ideas??

Re: DIY winch cradles

Posted: Sat Oct 29, 2011 10:21 am

by thehanko

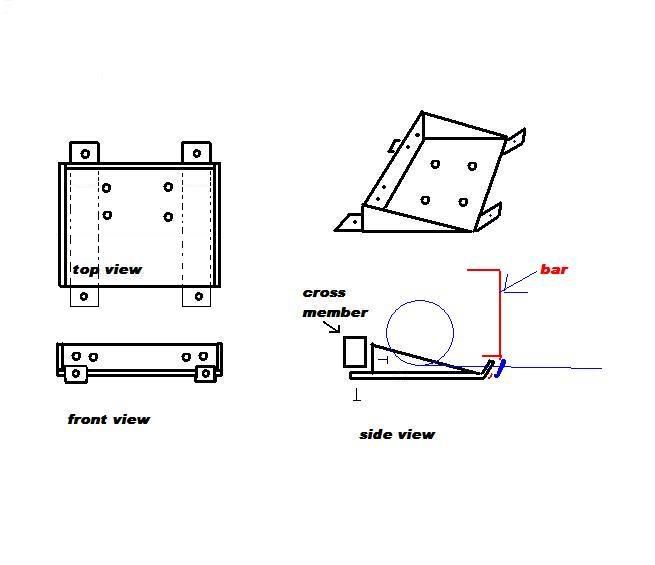

here is the cradle i made for my ln106, i think the front crossmember would be similar.

I utilised some bolts under the cross member, they were already there and bolted on other stuff.

Your winch is held on by 4 bolts - this cradle was attached to chassis with 8 from memory, 4 in tension 4 in shear - certainly never felt it was going to fail - note this was in behind a std alloy bar so the bar itself offered no support to the winch - but note that its 4 bolts on the outside of the chassis rails could also have been utilised in an all in one set up.

Re: DIY winch cradles

Posted: Sat Oct 29, 2011 12:54 pm

by 80's_delirious

I like the design of the cradle in the pic, I have the same pic saved on my PC.

You could use it as a basic design and include something like struth had sketched as part of it. I think tying it in with the shackle bolt is a good idea too.

I would look at making the gussets at the bottom of the cradle in the pic a different shape so they can have holes in them to be used as recovery points and maybe have the gusset as what ties into the shackle mount

Looks good in my head, hard to explain though

Re: DIY winch cradles

Posted: Sat Oct 29, 2011 9:06 pm

by DUDELUX

Heres a winch bar made for my model Lux, you can see the mounting setup used.

http://www.ebay.com.au/itm/TOYOTA-4RUNN ... 45fe180785" onclick="window.open(this.href);return false;

Probably wont work with the dropped spring hanger though.

Re: DIY winch cradles

Posted: Tue Nov 01, 2011 12:55 am

by georgey

cut the RHS out that is between your spring mounts on the dropped hanger and brace the outside of the hangers to the body mounts

Re: DIY winch cradles

Posted: Tue Nov 01, 2011 7:33 am

by V.W.Dave

I think now would be a good time to do a rear up front conversion withe the pre made drop hangers for the front. Doing that now will add strength to the front end and you will be able to cut out the lower radiator support and mount the winch further back for a better approach angle.

Re: DIY winch cradles

Posted: Tue Nov 01, 2011 8:54 am

by DUDELUX

Thanks guys for all your advice, I posted above about a plate from Front Range Offroad Fab in the US. I did send them an email asking about the plate, its called a Severe Use Front Frame Brace.

Heres the link again...

http://frontrangeoffroadfab.com/nfoscom ... ucts_id=63" onclick="window.open(this.href);return false;

I asked them if it would hold up to loads placed on it from winching, heres what they said in their reply....

The plate reinforces the frame enough to sustain winch loads just fine.

Heres a pic of the plate weleded on.

Im not saying Id buy it, as its just a piece of 8mm plate cut to shape with some holes in it.

Id like to have something like Thehanko posted above, but not sure how it would work with the dropped front crossmember.

Im going to have a real good look at the front crossmember on the Lux in a minute to see where the bolt holes are, and what could be used to make the winch cradle rock solid.

Thanks for ther tips and advice so far guys, keep the ideas coming.

Re: DIY winch cradles

Posted: Fri Nov 04, 2011 8:53 am

by Guy

Incorporate it to encapsulate the hangers as well ...

I would go as far as bringing that plate to go around either corner of the chassis rail ( area under the body mount) .. and box that section in.

Re: DIY winch cradles

Posted: Sat Nov 05, 2011 2:39 pm

by thehanko

lol,

I just remembered that when i made that winch cradel it was after pulling down the old bbq and trying to think of what to use the old hot plate for