Page 1 of 1

MQ 4 Link Rear Conversion

Posted: Wed Nov 01, 2006 11:06 pm

by bubs

Now that my last project a BMW with an Nissan RB20 engine conversion is complete here is the next one, with a Nissan flair again.

Here we have a leaf sprung MQ ute, it is getting a triangluated 4 link rear.

Now on to the pics.

Here is the victim

Another shot showing the original leaf suspension

Stripping the rear end apart

Housing out from under the patrol amd all unnessary mounts removed

Start of upper link mounts

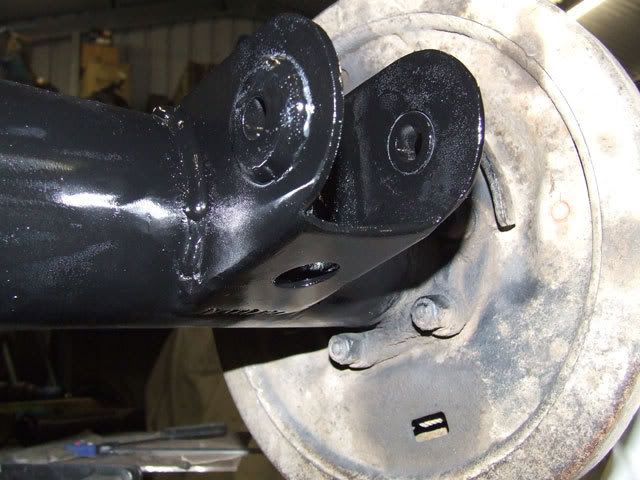

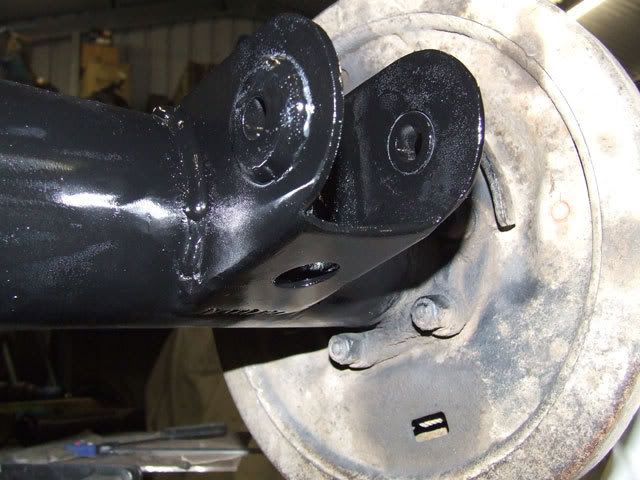

Front close up view - notice bushes welded into prevent ovaling of holes

Rear distant view

Close up view

Tommorow I will complete the upper link mount and get the lower mounts hopefully installed as well. Coil mounts will be done friday to be ready to make control arms on saturday.

Enjoy

Buddy

Posted: Thu Nov 02, 2006 2:33 am

by RMP&O

Looks good man....but I would push that diff back as far as you can since doing all the custom work. Either that or hack the chassis off right behind the new suspension. Way to much overhand in the rear on all MQ/MK's IMHO.

Keep the pics coming.

Posted: Fri Nov 03, 2006 2:14 pm

by bubs

RMP&O wrote:Looks good man....but I would push that diff back as far as you can since doing all the custom work. Either that or hack the chassis off right behind the new suspension. Way to much overhand in the rear on all MQ/MK's IMHO.

Keep the pics coming.

The owner is getting a new fuel tank and will lob the back off the chassis, the wheel base is long enough as it is

Posted: Fri Nov 03, 2006 4:51 pm

by bubs

Didn't do any last night as I went out last night. But this afternoon I got an hour on it. Heres the latest

Angely rear view

Straight on rear view

Front angely view

More tommorow

Posted: Mon Nov 06, 2006 6:49 am

by shakes

nice looking welds, love the can of "spray and cook" in the background.

just one question (and forgive my ignorance cause I still got alot to learn) how are you guys working out the angles and whatnot? I understand some is basic maths but knowing what drive's & handles ok as opposed to something that handles like a pig??

Cheers

Simon

Posted: Mon Nov 06, 2006 9:40 am

by Eddy

shakes wrote:nice looking welds, love the can of "spray and cook"

best and cheapest anti spatter spray around ....

Posted: Mon Nov 06, 2006 11:48 am

by PJ.zook

Nice work love custom stuff, you gonna bugger off those stone age drum brakes and use discs?

Posted: Mon Nov 06, 2006 5:38 pm

by bubs

Eddy wrote:shakes wrote:nice looking welds, love the can of "spray and cook"

best and cheapest anti spatter spray around ....

Actually its shit the spray and cook, i was desperate, got some more real anti spatter now

Posted: Mon Nov 06, 2006 5:39 pm

by bubs

shakes wrote:nice looking welds, love the can of "spray and cook" in the background.

just one question (and forgive my ignorance cause I still got alot to learn) how are you guys working out the angles and whatnot? I understand some is basic maths but knowing what drive's & handles ok as opposed to something that handles like a pig??

Cheers

Simon

Download the 4 link calculator and read the posts by strangerover (sam) on pirate.

Posted: Mon Nov 06, 2006 5:40 pm

by bubs

PJ.zook wrote:Nice work love custom stuff, you gonna bugger off those stone age drum brakes and use discs?

Its not my car, so no I wont be

Posted: Mon Nov 06, 2006 5:41 pm

by bubs

Finished upper link mounts / truss - also welded back on the brake line t-piece holder

Front View

Now undercoated awaiting the end, there are a few spots that will get hit with the sander before final painting.

There is more done since these photos i'll post them tommorow

Posted: Tue Nov 07, 2006 10:12 pm

by bubs

More lower mounts done

Hard to see but both lowers done

Close up

Underneath detail

Control arms are almost done to, I fawked up the coil mounts (I couldn't read my own hand writing

)so they will have to wait till tommorow.

Posted: Wed Nov 08, 2006 6:39 am

by V8Patrol

bubs wrote:Finished upper link mounts / truss - also welded back on the brake line t-piece holder

Front View

Querry ........

The material thickness ??? it looks like its 3mm pl from the pics but I'm asuming its thicker ..... yeah ?

2ndly....

past experiance has taught me that brackets welded to the diff tend to break off unless the plates extend down past the factory seam weld on the diff tube, rotational stress's seem to be the main issue especially when the bracketry has any major height over the heighest point of the pumpkin such as youve done.

I can see that the load has been spread along the length of the housing realy well, just curious as to if there's enough across the housing...

Interesting project .....

Kingy

Posted: Wed Nov 08, 2006 6:45 am

by bubs

yes the plate is thicker than 3mm

in regards to extending past the weld line of the housing I have not had that problem before. I do have about 150 degrees of the housing on each bracket. I had planned on adding more bracing along the length of the housing. As it is, it is no worse than standard GQ/GU trailing arm mounts.

Buddy

Posted: Wed Nov 08, 2006 9:56 am

by bazooked

looks like 3.2mm

Posted: Wed Nov 08, 2006 12:23 pm

by pongo

What sort of reinforcement is on the Bush holes. Is it just a washer welded on or is it a bit better than that?

Looks very

Good work

Posted: Wed Nov 08, 2006 4:57 pm

by bubs

bazooked wrote:looks like 3.2mm

wrong

Posted: Wed Nov 08, 2006 4:58 pm

by bubs

pongo wrote:What sort of reinforcement is on the Bush holes. Is it just a washer welded on or is it a bit better than that?

Looks very

Good work

A lot better than that, i'll get a pic tonight I had 50 bushes CNC machined

Posted: Thu Nov 09, 2006 8:25 am

by +dj_hansen+

Once again bubs... that is some awesome fabrication.

No wonder you never get your own sh!t3 finished.. your always workin on some1 elses

Never the less.. that is still awesome mate... arms up

Posted: Sun Nov 12, 2006 1:56 pm

by bubs

A close up of the bush that goes in the link mounts, cause some one asked to see

Frame rails cleaned of all unesscary leaf spring stuff

Start of coil pads

Coil in place

Close up with coil on of thingy that holds in centre

Same without coil

Posted: Sat Nov 18, 2006 12:08 am

by bubs

Hmm one step closer

- shes gone now

Links in - 9ish pm tonight

Rear shot - 9ish pm

Flexing - 11pm

Overall - about to go on trailer at 11:30pm

Posted: Sat Nov 18, 2006 8:35 am

by redzook

just a question why didnt you just make it out of thicker material?

Posted: Sat Nov 18, 2006 11:57 am

by bubs

because thats what everyone else does

heaps of guys on pirate are using 3/16 plate for link mounts without failure, standard nissan is only 4mm plate

Posted: Mon Nov 20, 2006 2:21 pm

by Timmeh

hi, nice work on the coil set-up, and the write up which you have done!! Just a quick question, what shocks are you using with this set-up ?