Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

extended shackles bent

Moderators: toaddog, TWISTY, V8Patrol, Moderators

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

extended shackles bent

Hi all

i have a set of 2" extended shackles from carrols springs, they've been great but i have noticed that they bend into a parellelogram shape instead of square after being bashed or when the bushes flog out a bit. It looks pretty awful and i can only imagine what it is doing to the steering geometry on road. any kind of side loading, cornering or side slopes make them shift out of square.

I was wondering who makes 2" extended shackles with a welded piece of RHS in the middle to help stiffen them? And how do you go about actually getting the bushes/pins in and out of them.

MILO

i have a set of 2" extended shackles from carrols springs, they've been great but i have noticed that they bend into a parellelogram shape instead of square after being bashed or when the bushes flog out a bit. It looks pretty awful and i can only imagine what it is doing to the steering geometry on road. any kind of side loading, cornering or side slopes make them shift out of square.

I was wondering who makes 2" extended shackles with a welded piece of RHS in the middle to help stiffen them? And how do you go about actually getting the bushes/pins in and out of them.

MILO

http://www.populationparty.org.au/

I made my first set like that ('H' pattern with RHS welded into centre), pain to fit and the bolts i used as pin rotated. Also squashed the side plates in if you did the bolts up too tight.

Made a new set same patern as origionals (welded in steped pins) but used a bit of hollow bar in centre to suport it, retained with a M16 bolt. Made them greasable as well. Now you can unbolt to change bushes as per origional, you can do the nuts up tight without squashing outa shape and they dont bend (used 10mm flat bar for the side plates).

Made a new set same patern as origionals (welded in steped pins) but used a bit of hollow bar in centre to suport it, retained with a M16 bolt. Made them greasable as well. Now you can unbolt to change bushes as per origional, you can do the nuts up tight without squashing outa shape and they dont bend (used 10mm flat bar for the side plates).

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

hey milo, yours would look exactly the same as superiors, infact so much so i thought they were. check them out first, wills havents bent so far (60 series) and his car flexes pretty huge, but his pins are bent i think??? because they are on an angle slightly.

turbos are nice but i'd rather be blown

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

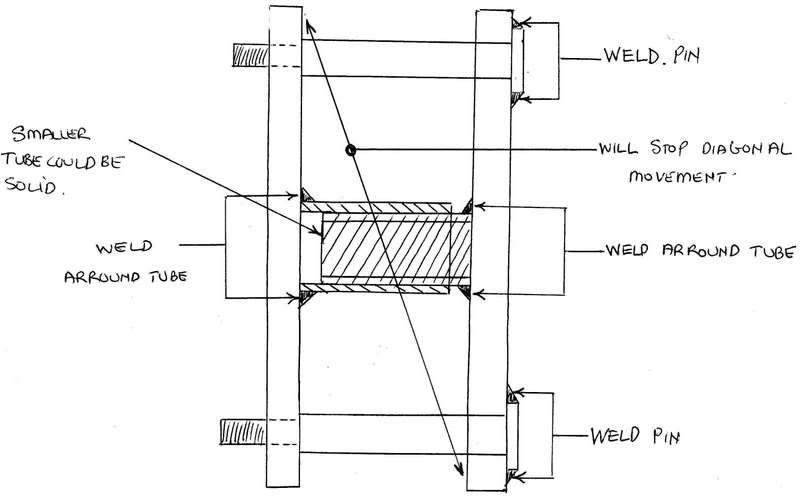

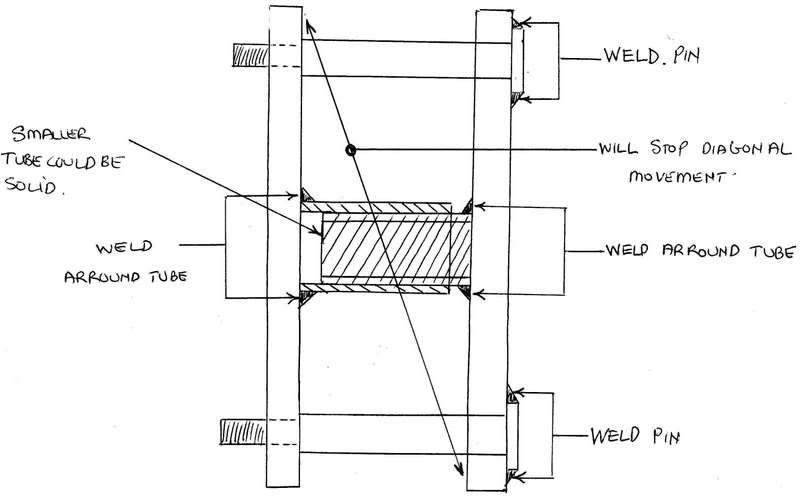

If you have got some close fitting tubes,say 4 mm wall,slip one into the other,weld one on one side and the other haha to the other side, this will stop them flexing,no extra bolts needed,simple to do,just leave a gap on the end with the smaller tube to allow for the weld Cheers Paul.

BLOWNZUK 1.3 efi,sc14 supercharger,hilux diffs,detroit lockers,stage 4 rockhopper,6 point cage,35 muddies.

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Maybe this will help,rough drawing,did it to my old zuk,used scrap metal,Ithink the two tubes had about 1\2 a mm tolerance,say the small tube/solid was 25mm and the other to slip over it,Cheers Paul.

BLOWNZUK 1.3 efi,sc14 supercharger,hilux diffs,detroit lockers,stage 4 rockhopper,6 point cage,35 muddies.

This is what I make and use

http://img.photobucket.com/albums/v167/ ... _0062a.jpg

http://img.photobucket.com/albums/v167/ ... _0062a.jpg

Adrian

www.chevtorque.com.au

www.chevtorque.com.au

Posts: 3725

Joined: Wed Jun 30, 2004 1:45 pm

Joined: Wed Jun 30, 2004 1:45 pm

Location: Blue Mountains, or on a rig somewhere in bumf*ck idaho

Who is online

Users browsing this forum: No registered users and 2 guests