Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

TURBO EGT OR ENGINE EGT

Moderators: toaddog, Elmo, DUDELUX

TURBO EGT OR ENGINE EGT

Gday all, just a query on if you guys who fit pyrometers to t/diesels if a engine temp (before turbo ) or a temp post turbo . Which is more accurate measure of tuning set up, as alot of energy is used in the turbo and results in a lower temp(turbo egt) , where as engine egt is IMO a better indication of engine health and set up......

Any info appreciated...cheers all....

Any info appreciated...cheers all....

pre turbo (ie in exaust manifold) is better as there is a temp drop across the turbo. some people have an estimation of the temp drop however i have seen it where that estimation has been out by a large amount.

imho these days with ECU controlled turbo and variable turbos becoming more comman fitting EGT sensors after the turbo is not a good idea anymore.

imho these days with ECU controlled turbo and variable turbos becoming more comman fitting EGT sensors after the turbo is not a good idea anymore.

Definitely pre turbo and ideally as close to the inlet as practical. I have had a turbo'd petrol car and many of the aircraft I've maintained all have had TIT (Turbine Inlet Temp) indication. If you're pulling a load or making a lot of power you want to know the inlet temp. Upstream is helpful but not 100% ideal. Downstream is a waste, you'll cook the turbo and not even know it. Unless you have a lot of $$ for repairs go with the inlet.

Mozza, I ordered an EGT this weekend and was intending to install post turbo for simplcity and assume it was reading 100 deg less. I found some great information on this site which has convinced me to change to a pre-turbo fitment.

http://www.thermoguard.com.au/instal.html

Have a read of the technical articles on that site as well.

http://www.thermoguard.com.au/instal.html

Have a read of the technical articles on that site as well.

80's 1HDT GXL CRUISER

I have to disagree with this, as EGT measurement is more for determining combustion characteristics ( overfueling etc.) than whether your going to melt your turbo, thus as close to the exhaust valve as possible is best.IBCRUSN wrote:Definitely pre turbo and ideally as close to the inlet as practical. I have had a turbo'd petrol car and many of the aircraft I've maintained all have had TIT (Turbine Inlet Temp) indication. If you're pulling a load or making a lot of power you want to know the inlet temp. Upstream is helpful but not 100% ideal. Downstream is a waste, you'll cook the turbo and not even know it. Unless you have a lot of $$ for repairs go with the inlet.

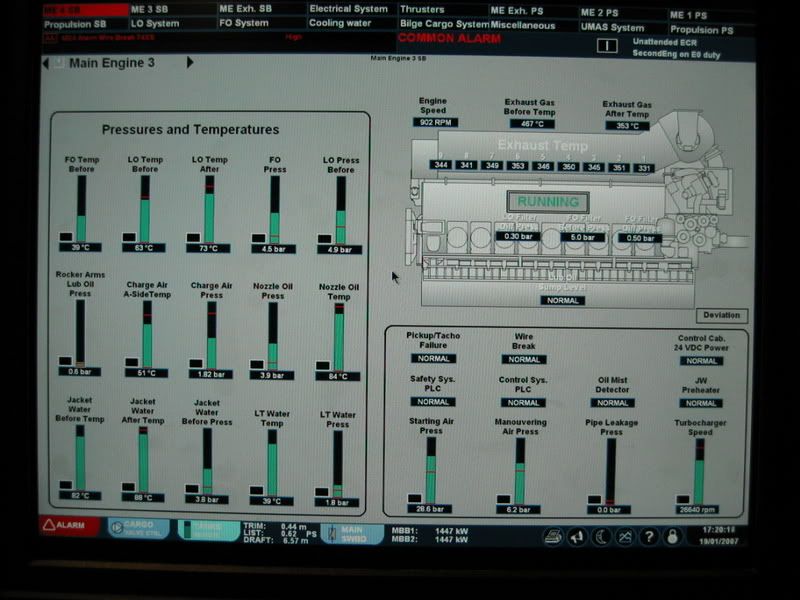

Exhaust gas temps increase between cylinder outlet and turbo inlet due to the pressurisation of the gases against the nozzle ring before emission to the blades. On the engines I work with this is in the order of a 100 degree c increase. Due to the pressure drop across the turbo you then see a drop in temperature at the turbo outlet and this generally brings temps back in line with cylinder exhaust temperatures.

Here is a screen shot of a 9 cylinder engine running at 78% load showing the cylinder exhaust temperatures and pre and post turbo temperatures.

Sorry for the delay in getting back to this.

BTW is that info from an ocean going vessel?

Just looking at the pic attached kind of states my point that knowing the turbo inlet temp is far more important than after the turbo outlet. For the longevity of turbo inlet temp is important information.KaMo wrote:I have to disagree with this, as EGT measurement is more for determining combustion characteristics ( overfueling etc.) than whether your going to melt your turbo, thus as close to the exhaust valve as possible is best.

BTW is that info from an ocean going vessel?

Again since my experience is not with diesels my presumptions may be a little off. Based on your statement above it sure sounds like one would want to know the temp of the gas when it gets to the T wheel not after the turbo.KaMo wrote:Exhaust gas temps increase between cylinder outlet and turbo inlet due to the pressurisation of the gases against the nozzle ring before emission to the blades. On the engines I work with this is in the order of a 100 degree c increase.

I agree totally and it applies to all turbo charged engines. The whole premise is to take the heat energy from the exhaust to drive the turbine wheel which is a direct drive to the compressor wheel. Often one can get away with running no muffler (exhuast is reasonably quiet) if the turbo is efficient enough and extracts maximum heat.KaMo wrote:Due to the pressure drop across the turbo you then see a drop in temperature at the turbo outlet and this generally brings temps back in line with cylinder exhaust temperatures.

Who is online

Users browsing this forum: No registered users and 3 guests