I bought the whole lot as a kit 18months ago, the solenoid supplied is suppose to be 100amp continuous duty - HOWEVER it only has one trigger point on the solenoid (think it may be a intermitterent type)

It is wired up to my custom rear fuse panel (supplied with fused battery cable from 2nd battery to rear of car).

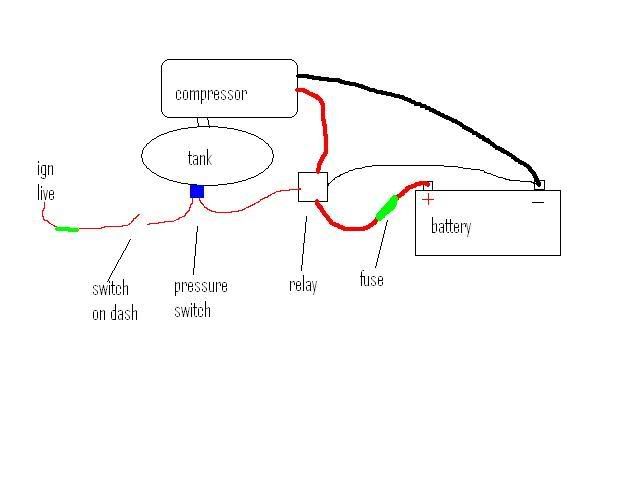

I have a +12v ign supply through a dash mounted switch, this then runs through the air tank pressure switch and to solenoid.

Now the solenoid switches on, but when I turn off the dashboard switch, the compressor continues to run

From searching, I believe that the solenoid is actually an intermittment type (switches off after set time)

I have fitted a 150psi pressure relief valve, but want to put a pressure gauge in as a visual check - I therefore did not allow the compressor to run too long until I put the gauge in!

Am I right that this solenoid is an intermittent type??

If I use a continuous solenoid, I assume I need to have two +12V triggers (one to each trigger pole) to throw the solenoid in and out - is this correct??

OR

could I use a Narva 70amp (or 100amp) conventional 4pin relay instead (i prefer these over the solenoids!)??

If I use this, then I assume I can use one +12v ign switching supply and normal rocker switch?

What do you people think?