Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Applause Alternator in Feroza

Moderator: Tiny

Applause Alternator in Feroza

Just some feedback on Feroza / Applause alternator swaps.....

Always had problems with the inner V belt slipping, squeeling, picking up

crap etc ( caused severe overheating issue in the past with a stone trapped in the water pump pulley vee ) and its not fun to tension if you

have power steering.

So decided to put an Applause pollyvee drive on. I don't have an engine

fan but it looks like the original engine fan will also fit ( check first... ).

Pollyvee belts are more resistant to crap, stronger, and transmit more power tha plain old vee belts.

What you need :

An Applause Alternator pulley ( or whole alternator )

Applause Water Pump Pulley

Applause Crank Pulley

They can be a bitch to remove ( hard to hold water pump stationary ) in

the car but possible.

The stock Alternator is nothing special, and not known for its reliability so

having a spare is cool.

A self serve wrecker will want about $50 for the lot on a bad day.

P.S. use a new belt - put the old one in the spares toolbox.

Always had problems with the inner V belt slipping, squeeling, picking up

crap etc ( caused severe overheating issue in the past with a stone trapped in the water pump pulley vee ) and its not fun to tension if you

have power steering.

So decided to put an Applause pollyvee drive on. I don't have an engine

fan but it looks like the original engine fan will also fit ( check first... ).

Pollyvee belts are more resistant to crap, stronger, and transmit more power tha plain old vee belts.

What you need :

An Applause Alternator pulley ( or whole alternator )

Applause Water Pump Pulley

Applause Crank Pulley

They can be a bitch to remove ( hard to hold water pump stationary ) in

the car but possible.

The stock Alternator is nothing special, and not known for its reliability so

having a spare is cool.

A self serve wrecker will want about $50 for the lot on a bad day.

P.S. use a new belt - put the old one in the spares toolbox.

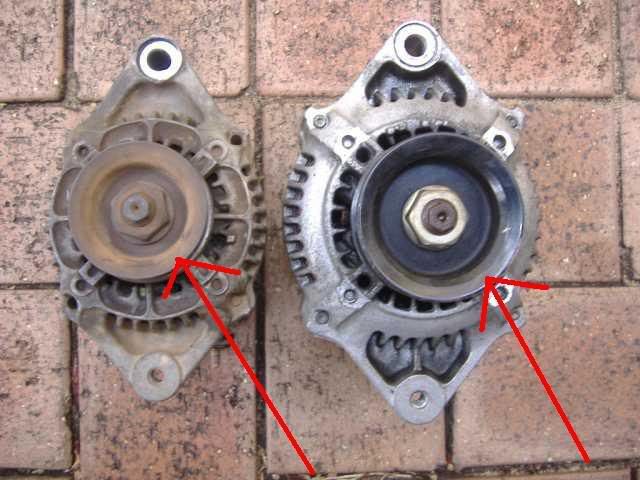

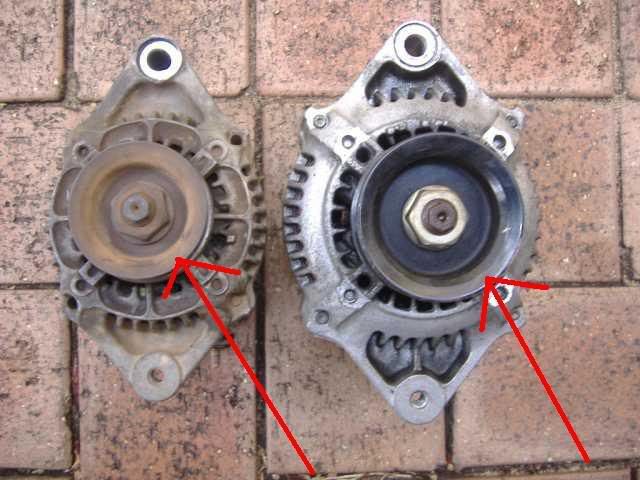

its the bottom type. Thats classed as a "PollyVee".

And as an update you need the al mounting bracket off the Applause as well as the water pump to keep it simple . They look identical but the Applause bolt pattern on the water pump boss is smaller. Can be redrilled if you have an engine fan.

Wiring connections to follow.

P.S. The Applause alternator is substantially larger ( could the Feroza one be any smaller ? ) but can't decifer DENSO speak and can't find its output.

Has to be more than the Feroza - but by how much ?

Has become a little harder if you don't have lots of spares, but so far its

still an easy and cheap upgrade.

To be continued........

And as an update you need the al mounting bracket off the Applause as well as the water pump to keep it simple . They look identical but the Applause bolt pattern on the water pump boss is smaller. Can be redrilled if you have an engine fan.

Wiring connections to follow.

P.S. The Applause alternator is substantially larger ( could the Feroza one be any smaller ? ) but can't decifer DENSO speak and can't find its output.

Has to be more than the Feroza - but by how much ?

Has become a little harder if you don't have lots of spares, but so far its

still an easy and cheap upgrade.

To be continued........

Ok - the standard Applause belt is a little to short @ 785mm, its possible but the alternator becomes a little too vertical and its hard to get the heater hose on. 800mm is much better ( 4PK800 ).

Have the diecast Applause A/C mount and compressor fitted ( as an air )

compressor and it all comes together for the front belt.

So the rear belt drives the waterpump and alt, with the front one the

air compressor and powersteer.

Overall thickness of setup is the same as stock, but instead of a V belt

and 5 row pollyvee we now have two 4 row pollyvees.

To be continued.

Have the diecast Applause A/C mount and compressor fitted ( as an air )

compressor and it all comes together for the front belt.

So the rear belt drives the waterpump and alt, with the front one the

air compressor and powersteer.

Overall thickness of setup is the same as stock, but instead of a V belt

and 5 row pollyvee we now have two 4 row pollyvees.

To be continued.

No the issue with the fan is that the Applause water pump boss is smaller

than the Feroza ( the rest of the pump is the same ). So an electric

fan will make it easier as you now don't care about the mechanical fan

but the belt angles remain the same.

In summary the advantages are ( i hope ) larger alternator, more relaible

and efficient belts and the ability to run a standard A/C compressor to

generate compressed air for tyres/ airlocker etc without doing any heavy

engineering - except for parts swapping between various engine options.

than the Feroza ( the rest of the pump is the same ). So an electric

fan will make it easier as you now don't care about the mechanical fan

but the belt angles remain the same.

In summary the advantages are ( i hope ) larger alternator, more relaible

and efficient belts and the ability to run a standard A/C compressor to

generate compressed air for tyres/ airlocker etc without doing any heavy

engineering - except for parts swapping between various engine options.

The air compressor is a bit of a gamble, unlike the "endlessair"

commercial units which are axial piston, the stock Applause unit is a vane

type.

Vane units cannot be run without oil lubrication and so will have to make

an oil seperator to get it out of the discharge air and back into the

compressor intake.

In theory this should work - and if it doesn't then it costs me virtually

nothing.

The Appluase has a nice cast mounting bracket for the A/C compressor

so its a really simple bolt on job - unless you already have A/C.

commercial units which are axial piston, the stock Applause unit is a vane

type.

Vane units cannot be run without oil lubrication and so will have to make

an oil seperator to get it out of the discharge air and back into the

compressor intake.

In theory this should work - and if it doesn't then it costs me virtually

nothing.

The Appluase has a nice cast mounting bracket for the A/C compressor

so its a really simple bolt on job - unless you already have A/C.

Ok wiring info for Feroza to Applause Alternator swap...

its easy - connect Feroza IGN terninal on Alt to IGN terminal on Applause Alt.

connect L terminal on Feroza Alt to L terinal on Applause Alt.

Leave C terminal on Applause Alt disconected. It is actually used to

decrease the charging voltage at full vehicle load - but is controlled

but the engine ECU. So its a good feature but not for a Feroza.

And the Feroza alt makes 47 Amps at full load - the Applause one 85 -

ran both on a test bench to confirm correct wiring.

its easy - connect Feroza IGN terninal on Alt to IGN terminal on Applause Alt.

connect L terminal on Feroza Alt to L terinal on Applause Alt.

Leave C terminal on Applause Alt disconected. It is actually used to

decrease the charging voltage at full vehicle load - but is controlled

but the engine ECU. So its a good feature but not for a Feroza.

And the Feroza alt makes 47 Amps at full load - the Applause one 85 -

ran both on a test bench to confirm correct wiring.

I have an applause aircon compressor set up as an air compressor. You are right about it needing oil to run, mine needs some oil every now and again, depending on how much I use it. I have put a resonablly good quality separator to filter out as much oil vapour as posible Still a little bit gets through but it is only a tiny bit and it lubes up my valves when i let the tyres down.MightyMouse wrote:The air compressor is a bit of a gamble, unlike the "endlessair"

commercial units which are axial piston, the stock Applause unit is a vane

type.

Vane units cannot be run without oil lubrication and so will have to make

an oil seperator to get it out of the discharge air and back into the

compressor intake.

In theory this should work - and if it doesn't then it costs me virtually

nothing.

The Appluase has a nice cast mounting bracket for the A/C compressor

so its a really simple bolt on job - unless you already have A/C.

The performance of the compressor is something to rave about hey, I can pump up all 4 of my 9R tyres from 15psi to 40psi and two of my mates 10R tyres in the time his blue tounge does two tyres. Allthough sometimes it gets a bit hot and cuts out for a minute or so to cool off then starts pumping again, must be some kind of mechanism in the air con.

An endless air one would be awesome as it would run without the oil and not overheat, but i think it would take a bit of messing around to get it bolted up, Applause one no probs with that.

And finally.... ( well maybee )

You need a 4PK975 belt for the power steer system.

its one row less than stock, but the guy designing the stock feroza one

must have missread his sliderule - 5 row is WAY over the top. Even four

is overspeced ( an appluuse PS system uses a 3 row )

This will leave one unused row on the idler and PS pump, or do as I do,

make new pulleys..... ( not simple or quick ).

You need a 4PK975 belt for the power steer system.

its one row less than stock, but the guy designing the stock feroza one

must have missread his sliderule - 5 row is WAY over the top. Even four

is overspeced ( an appluuse PS system uses a 3 row )

This will leave one unused row on the idler and PS pump, or do as I do,

make new pulleys..... ( not simple or quick ).

As I dont have the stock alternator any more - can't testify to the pulley,

although it "looks" to be in the same relative place. But don't know shaft

diameter......

However you do need the bottom alternator mount off the Applause as it

helps correct for the greater alternator diameter.

The longer belt also helps as explained.

although it "looks" to be in the same relative place. But don't know shaft

diameter......

However you do need the bottom alternator mount off the Applause as it

helps correct for the greater alternator diameter.

The longer belt also helps as explained.

I always learn something in your posts MightyMouse, but I think you might be a little off here. I thought the endless air compressors are also vane type but have modified seal material and a grease nipple (and some natty blue paint) to make them run without external oiling.MightyMouse wrote: commercial units which are axial piston, the stock Applause unit is a vane

type.

York piston compressors like I have in my G wagen have a sump and need no special preparation.

Now I will sit quietly in the corner whilst you explain how I am wrong, in the politest possible way

I am planning on using possible the world's smallest vane compressor (the one of Greg's old cappuccino engine) to pump tyres on my sierra, so any light you can shed on holding them together will be good.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

This is just my understanding of compressor technologies - so its bound to

be full of holes... As I understand it there are three common types.

1/ York Style - traditional crank, conrod and piston - much like an engine.

2/ Axial piston - swash plate driving an array of axial pistons

3/ Vane - close tolerance rotating vane in profiled housing ( distantly like a Rotary engine ( yes very distant... )).

The York style are great - simple, robust and don't carry significant oil

over into the discharge air - but a bit big for a small car.

The axial piston type ( which is what i thought endless air compressors

were ) use teflon rings on the axial pistons and so grease filling takes care

of the swash plate lubrication - once again with little lubricant carry

over to the discharge. They tend to be "mid size" cylindrical units.

The vane type seem to be at the smaller end of the range and rely on

oil being carried through the working chambers to lubricate the sliding

parts and form a seal. Run these babies dry and its all over she wrote.

So the vane type are a bit unique - in that the lubricant is intentionally

in the working chambers and is circulated through the A/C system.

In our case this would mean that the compressor would soon dry out -

a "bad thing" and fail. I was looking at seperating out the oil and returning

it under discharge pressure back to the intake, but on reflection that may

be dumb as the water content of the oil could become an issue.

My first attempt will be to use a "mist oiler" on the intake and a drier/water

seperator on the discharge. Given that we only are using intermittantly

when compared with a normal A/C system it might just be fine.

As i have a couple of compressors ( and there are no shortage of replacements )

its worth a try as its reasonable bolt on - and I am developing a hate

for electric compressors.

be full of holes... As I understand it there are three common types.

1/ York Style - traditional crank, conrod and piston - much like an engine.

2/ Axial piston - swash plate driving an array of axial pistons

3/ Vane - close tolerance rotating vane in profiled housing ( distantly like a Rotary engine ( yes very distant... )).

The York style are great - simple, robust and don't carry significant oil

over into the discharge air - but a bit big for a small car.

The axial piston type ( which is what i thought endless air compressors

were ) use teflon rings on the axial pistons and so grease filling takes care

of the swash plate lubrication - once again with little lubricant carry

over to the discharge. They tend to be "mid size" cylindrical units.

The vane type seem to be at the smaller end of the range and rely on

oil being carried through the working chambers to lubricate the sliding

parts and form a seal. Run these babies dry and its all over she wrote.

So the vane type are a bit unique - in that the lubricant is intentionally

in the working chambers and is circulated through the A/C system.

In our case this would mean that the compressor would soon dry out -

a "bad thing" and fail. I was looking at seperating out the oil and returning

it under discharge pressure back to the intake, but on reflection that may

be dumb as the water content of the oil could become an issue.

My first attempt will be to use a "mist oiler" on the intake and a drier/water

seperator on the discharge. Given that we only are using intermittantly

when compared with a normal A/C system it might just be fine.

As i have a couple of compressors ( and there are no shortage of replacements )

its worth a try as its reasonable bolt on - and I am developing a hate

for electric compressors.

See, I've been taken back to school yet again

I will be very keen to see how this works out. Obivously on my 660 I have a very small and relatively unique compressor which I have to work with so I don't want to destroy it as part of the experimentation process.

Thanks for the tech MightyMouse.

Having run a york compressor for years for tyre inflation, electric compressors just don't seem to cut it.

Steve.

I will be very keen to see how this works out. Obivously on my 660 I have a very small and relatively unique compressor which I have to work with so I don't want to destroy it as part of the experimentation process.

Thanks for the tech MightyMouse.

Having run a york compressor for years for tyre inflation, electric compressors just don't seem to cut it.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Been awhile since the mechanical and electrical mods were done but as the engine hadn't been started couldn't provide and feedback.

Well, finally it does actually work - charges well and at a smidge over 80 amps - worth doing for my application

Anything had to be better than the stupid single vee waterpump/alt drive.

Well, finally it does actually work - charges well and at a smidge over 80 amps - worth doing for my application

Anything had to be better than the stupid single vee waterpump/alt drive.

Yep - and on the alt tester at work it was putting out 41A when hot.

The Applause one ( and its a late model unit ) was still nudging 75 after an hour - as its more capable of getting rid of the internal heat.

It also has a built in feature that the std alt doesn't in that its got a "low output" mode. At full throttle you can have the alternator drop to around 40A to give you a little extra passing power. Its controlled by the Applause ECU but can be rigged with a switch. Havn't used this feature yet but with the new ECU it will be on the list.

The Applause one ( and its a late model unit ) was still nudging 75 after an hour - as its more capable of getting rid of the internal heat.

It also has a built in feature that the std alt doesn't in that its got a "low output" mode. At full throttle you can have the alternator drop to around 40A to give you a little extra passing power. Its controlled by the Applause ECU but can be rigged with a switch. Havn't used this feature yet but with the new ECU it will be on the list.

Do you know if the applause alternater pulley will line up with the feroza ribbed belt set up in later model ferozas? There are no help yourself wreckers left in perth and its hard to find brackets etc, even harder to find one still in an applause to compare the set up differences. The cheapest quote i can get for the alternator is $165, That beats the $400 for a recon feroza alternator.

If I read your post correctly you are saying that the inner pulley ( water pump/alternator ) on a later Feroza is a pollyvee type ?

If so then i think it will be a bolt on fit but havn't looked hard at a F310 so its a bit of a risk...

And by the way Murcod has a spare alternator listed for sale.. so that's another option

If so then i think it will be a bolt on fit but havn't looked hard at a F310 so its a bit of a risk...

And by the way Murcod has a spare alternator listed for sale.. so that's another option

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

Yes both belts in my fez are ribbed belts. When i did the applause aircon compressor conversion the belt had to be changed to 4rib from the 5rib that is standard, There has been no probs with that. the other belt which has the alternator on it is a 4rib standard, I hope it will be a straight bolt in with the applause bracket. I will keep looking for one still in an applause to compare it before i commit to the buy.

I have done the applause swap. It lined up fine withe f310 setup. i needed to change the top mounting bracket as it has a closer arc that does not line up with the applause alternator diameter.

The plug was a match for the feroza plug but i think this is causing a problem. There are only two wires on the feroza plug. I don't know how to test the ampage output but i think it is only running at the 40amp low output described earlier in this topic because of voltage drop when high drain items are turned on. Does anyone know firstly how to test alternator output amps while in a car? And also if i rewire the alternator and disconect the sensor plug will the ampage increase?

The plug was a match for the feroza plug but i think this is causing a problem. There are only two wires on the feroza plug. I don't know how to test the ampage output but i think it is only running at the 40amp low output described earlier in this topic because of voltage drop when high drain items are turned on. Does anyone know firstly how to test alternator output amps while in a car? And also if i rewire the alternator and disconect the sensor plug will the ampage increase?

mine had a sticker with the connections labeled, if its got a "C" then it should be left disconnected - if its an "S" then it goes straight to the battery. The donor vehicle for my alternator was a HC Applause ( 1.3 ) so perhaps there are differences.

My old f300's alt only had two wires in a different plug so a small adapter had to be made.

My old f300's alt only had two wires in a different plug so a small adapter had to be made.

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

If you swap the Feroza alternator pulley with the Applause pulley you will have more power at lower speed because the Feroza pulley is smaller in diameter and will run faster the Applause alternator.

www.ferozaclub.gr

[url=http://www.ferozaclub.gr][img]http://i51.photobucket.com/albums/f387/heroicentaur/forum/sign.gif[/img][/url]

[url=http://www.ferozaclub.gr][img]http://i51.photobucket.com/albums/f387/heroicentaur/forum/sign.gif[/img][/url]

That's an oversimplification when your dealing with different alternators....

I know what your trying to say, but its only true of an identical alternator as each alternator type has a different RPM/Output curve.

The Applauses alternator / pulley may well put out more current at a lower RPM than a Feroza one. That is certainly the case with mine.

Unless you have access to the manufacturers curves or actually test you won't know this.

I know what your trying to say, but its only true of an identical alternator as each alternator type has a different RPM/Output curve.

The Applauses alternator / pulley may well put out more current at a lower RPM than a Feroza one. That is certainly the case with mine.

Unless you have access to the manufacturers curves or actually test you won't know this.

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

There's two parts to the calculation...

The faster the alternator spins the greater the losses due to friction, cooling fans etc etc. This is predictable but non linear ( mostly the fan losses are quadratic )

The second is the actual power used to generate the output current and this is also highly non linear.

So as we are changing two non linear variables at the same time its really difficult to predict the end outcome.

Most manufactures err on the side of higher alternator RPM at low engine revs to ensure that batteries are not drained by sustained periods of low speed city cycle driving - especially at night.

And as far as power is concerned that's the advantage of having the "C" terminal - you can elect to half the alternators output thus increasing available engine power

The faster the alternator spins the greater the losses due to friction, cooling fans etc etc. This is predictable but non linear ( mostly the fan losses are quadratic )

The second is the actual power used to generate the output current and this is also highly non linear.

So as we are changing two non linear variables at the same time its really difficult to predict the end outcome.

Most manufactures err on the side of higher alternator RPM at low engine revs to ensure that batteries are not drained by sustained periods of low speed city cycle driving - especially at night.

And as far as power is concerned that's the advantage of having the "C" terminal - you can elect to half the alternators output thus increasing available engine power

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

Who is online

Users browsing this forum: No registered users and 1 guest