Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

f300 custom control arms

Moderator: Tiny

f300 custom control arms

f300 custom control arms

hay all

looking for info on widening the a-arms on a f300 narrow-track

I'm thinking

- cleaning of slug welds and opening the box section.then stagger the cuts ,box then flat.grafting and adding the length .at the same time adding reinforcement walls inside the box and when its all closed more reinforcement walls on the outer rim to the box top . already got wide track drag link,os/ns Drive shafts and flairs. standard o/s n/s uper and lower control arms

having said this I'm more interested in other ways of getting it done

hay all

looking for info on widening the a-arms on a f300 narrow-track

I'm thinking

- cleaning of slug welds and opening the box section.then stagger the cuts ,box then flat.grafting and adding the length .at the same time adding reinforcement walls inside the box and when its all closed more reinforcement walls on the outer rim to the box top . already got wide track drag link,os/ns Drive shafts and flairs. standard o/s n/s uper and lower control arms

having said this I'm more interested in other ways of getting it done

Extensions that slide into open ends of lower control arms. Bolted from both sides gives plenty of strength. Use an alloy steel just to be sure. Don't like welded suspension components that haven't been x rayed and that's a PITA and expensive

Top arms - who cares, they carry virtually no load so bolt on extensions are fine.

For all the shagging around easier to use existing diff with longer driveshafts - and use a better steel whilst your at it.

Same with steering - make longer adjusters.

Once you have made the bits, about 2 days easy work. - Flares take longer to do properly

Top arms - who cares, they carry virtually no load so bolt on extensions are fine.

For all the shagging around easier to use existing diff with longer driveshafts - and use a better steel whilst your at it.

Same with steering - make longer adjusters.

Once you have made the bits, about 2 days easy work. - Flares take longer to do properly

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

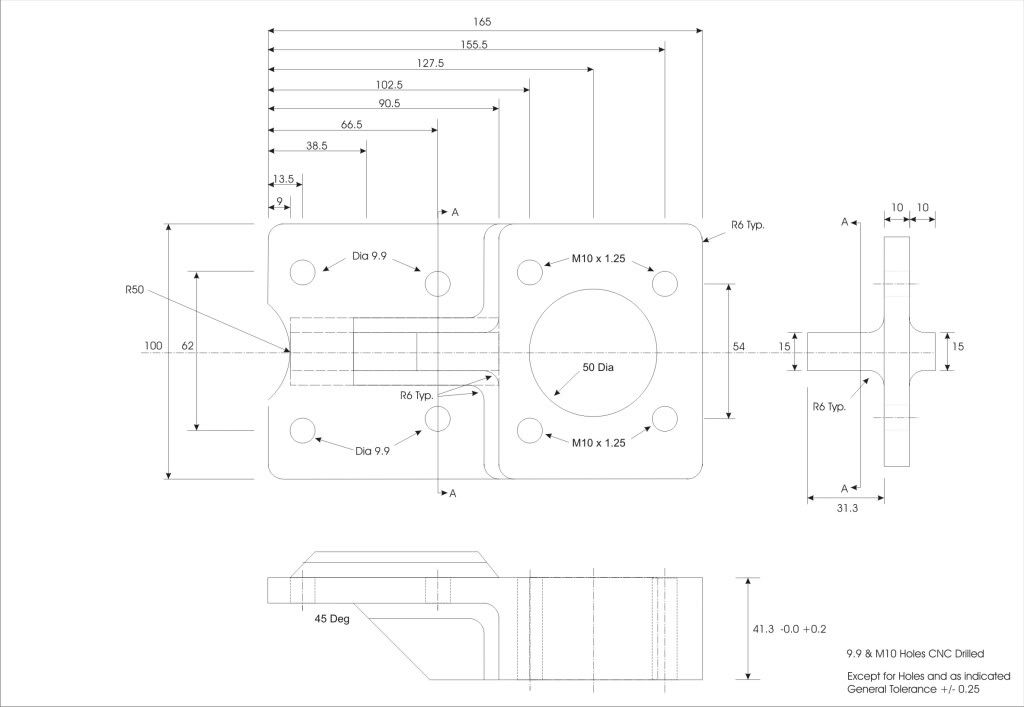

Mine are made of M200 Alloy steel - great material, not cheap, but requires carbide cutters to machine easily.

Won't break in a million years.

M10 holes are tapped trough with HT bolts from both sides ( 8 x M10 HT bolts - STRONG..... )

Insert will required some adjustment of side radii to get good fit into lower arm ends.

( usual disclaimers )

It seemed like a much better idea when I started it than it does now.

It seemed like a much better idea when I started it than it does now.

just got a quot on lower con-arms -ex..

do you think this quot is good

---------------------------------------------------------------------------

fabricator has quoted:

for P20 ALLOY STEEL price = $340 each + GST based on 2 off

Above includes delivery within Sydney metro.

We trust the above meets your requirements.

do you think this quot is good

---------------------------------------------------------------------------

fabricator has quoted:

for P20 ALLOY STEEL price = $340 each + GST based on 2 off

Above includes delivery within Sydney metro.

We trust the above meets your requirements.

Last edited by rob-lo on Tue Feb 26, 2008 6:28 pm, edited 1 time in total.

Who is online

Users browsing this forum: No registered users and 1 guest