Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

Boss Compressor???

Moderators: toaddog, TWISTY, V8Patrol, Moderators

Boss Compressor???

Are those BOSS compressors any good, they rate them at 100% duty cycle, and say they will obliterate a Big Bushranger Max Air?

Apparently run 3 cfm, from 3/4 hp, all oil less design....blah blah blah.

Any experiences with these would be appreciated.

Cheers, Dano.

P.S. There is some on Ebay, for about $340 plus postage.

Apparently run 3 cfm, from 3/4 hp, all oil less design....blah blah blah.

Any experiences with these would be appreciated.

Cheers, Dano.

P.S. There is some on Ebay, for about $340 plus postage.

Have the boss in my Mav.

Absolutely love it.

pumps up my 33's from 18psi to 35psi in a bees freckle under a minute.

Runs the dust off gun to clean out radiators and stuff easy.

Rattle gun will undo all 6 wheel nuts, change tyre and do em back up again.

Absolutely love it.

pumps up my 33's from 18psi to 35psi in a bees freckle under a minute.

Runs the dust off gun to clean out radiators and stuff easy.

Rattle gun will undo all 6 wheel nuts, change tyre and do em back up again.

92 LWB Ford Maverick 4.2, Dual Fuel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

as stated in the link bogged put up. i have a boss connected to a 40L airtank. 0-150psi in 7-8min...slightly restricted by the maize of fittings.

i can undo 6 wheel nuts, put them back on and move to the next wheel and undo those 6....about the 3rd or 4th nut it dropes below 110psi (cut in)...and charges back up. i change wheels and put those nuts back on while compressor is charging.....in moving the jack to the next wheel it has cut out again at 150psi.

i cannot stress enough the quality of the wiring needed..as these compressors draw up to 60amps. cost me another $100 to wire it up (100amp circuit breaker, dual battery solenoid, 4g power wire)

the vehicles engine MUST be running above idle. i have a dual battery system in a patrol ute and even on idle it struggles to keep 12v through the system....which means the compressor works harder and generates more heat. generally have a healthy 13.6v running to it.

they are 100% duty cycle but can get pretty hot....i havent run mine for more than prob 10min....thats plenty long enough.

they are an excellent 12v compressor (best on market i would say) but if i had my time again i would go belt driven off the motor.

cheers

PAUL

i can undo 6 wheel nuts, put them back on and move to the next wheel and undo those 6....about the 3rd or 4th nut it dropes below 110psi (cut in)...and charges back up. i change wheels and put those nuts back on while compressor is charging.....in moving the jack to the next wheel it has cut out again at 150psi.

i cannot stress enough the quality of the wiring needed..as these compressors draw up to 60amps. cost me another $100 to wire it up (100amp circuit breaker, dual battery solenoid, 4g power wire)

the vehicles engine MUST be running above idle. i have a dual battery system in a patrol ute and even on idle it struggles to keep 12v through the system....which means the compressor works harder and generates more heat. generally have a healthy 13.6v running to it.

they are 100% duty cycle but can get pretty hot....i havent run mine for more than prob 10min....thats plenty long enough.

they are an excellent 12v compressor (best on market i would say) but if i had my time again i would go belt driven off the motor.

cheers

PAUL

I only have a small 9L tank, not very big at all, Id be surprised if there would be any dramatic differences without it.Slunnie wrote:tj81. is that with or without an airtank?

As stated above, its all about the wiring..

92 LWB Ford Maverick 4.2, Dual Fuel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

Thanks for the replies and previous threads. Will prolly go for the Boss 3/4. Will get my own tank from the truck wreckers in Brisbane, for somewhere between $30 - $40......depending on what mood the guys are in  Have a pressure switch left over from endless air set-up on old rig.

Have a pressure switch left over from endless air set-up on old rig.

Would you guys say to run it in the vehicle, that would have been my preference, due to lack of moisture, compared to say the engine bay?

Thanks, Dano.

Would you guys say to run it in the vehicle, that would have been my preference, due to lack of moisture, compared to say the engine bay?

Thanks, Dano.

I have 1 in my 80. It take just over 3min to go from 20psi to 40psi. So it runs for about 15min non stop. It's pretty loud in the cab but it sound very grunty and hasnt skipped a beat.

I guess its fast for a 12v but slower than a constipated crap compared to my old endless which took about 1m15s just idling (when it worked).

It may have been mentioned before, but I plan on fitting a 150psi pressure switch to the tank and regulating the lockers seperately. I may even run a bigger tank and fit a second unit at a later date.

I guess its fast for a 12v but slower than a constipated crap compared to my old endless which took about 1m15s just idling (when it worked).

It may have been mentioned before, but I plan on fitting a 150psi pressure switch to the tank and regulating the lockers seperately. I may even run a bigger tank and fit a second unit at a later date.

IF IT MOVES, SHOOT IT

IF IT DOESNT, CUT IT DOWN

IF ITS GREEN, PISS ON IT

IF IT DOESNT, CUT IT DOWN

IF ITS GREEN, PISS ON IT

mine is runbehind the passenger seat in a GU ute.....and yes its loud....but u get over it quickly.

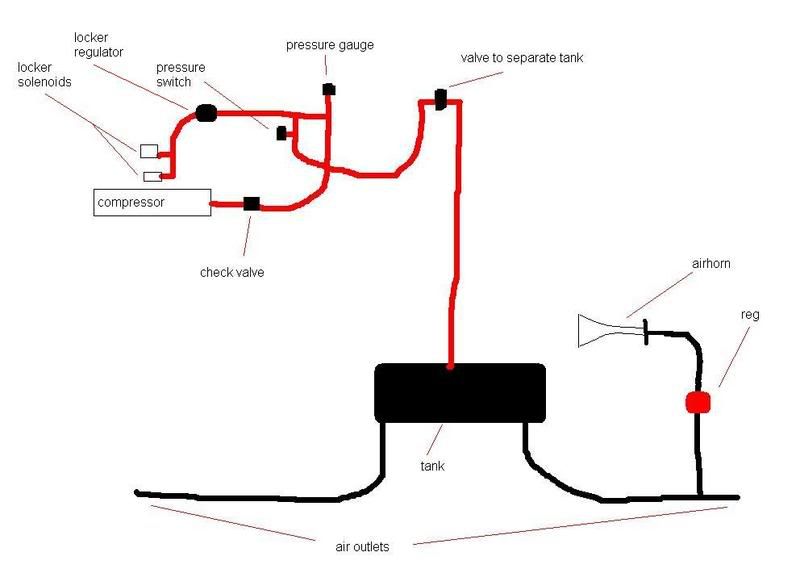

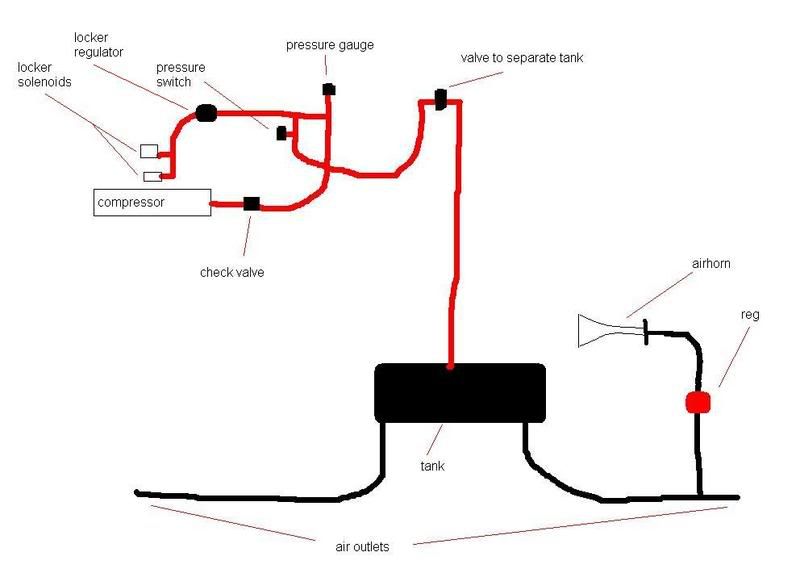

my setup it is pretty complicated but basically i have a length of hose from compressor that runs a heap of brass tees (1 has a gauge on the outlet, 1 has pressure switch, the other goes to my lockers which is regulated)....after those tees it heads up the back of my centre console to an inline valve which i can reach from seating postion. this separates the tank from the 1st section of line/tees/gauge/switch/lockers.

with this setup if i want to run the lockers (which dont require large VOLUME of air) i can close the tank and just charge the "line" (0-150 in about 2sec). the gauge works and so does the pressure switch. when charging the tank i open the valve and the pressure switch and gauge still work.

out of the tank i have 2 outlets, one on either side of the tray. from one of the lines going to the outlet is anoter tee which heads to my regulated air horn.

PAUL

EDIT> this might explain it a little better

my setup it is pretty complicated but basically i have a length of hose from compressor that runs a heap of brass tees (1 has a gauge on the outlet, 1 has pressure switch, the other goes to my lockers which is regulated)....after those tees it heads up the back of my centre console to an inline valve which i can reach from seating postion. this separates the tank from the 1st section of line/tees/gauge/switch/lockers.

with this setup if i want to run the lockers (which dont require large VOLUME of air) i can close the tank and just charge the "line" (0-150 in about 2sec). the gauge works and so does the pressure switch. when charging the tank i open the valve and the pressure switch and gauge still work.

out of the tank i have 2 outlets, one on either side of the tray. from one of the lines going to the outlet is anoter tee which heads to my regulated air horn.

PAUL

EDIT> this might explain it a little better

RE: Mounting, taken from another thread i posted in.

This is just my personal opinion, and one i came up with after considering putting it under the bonnet myself. I have several reasons:

1). The BOSS 3/4 is primarily designed and built for Air Suspension applications, and after speaking with a number of Air Suspension dealers etc, i found almost all of them suggested they were mounted inside the vehicle "somewhere"

2). The compressor has a fan cooled engine that requires clean cool air to keep it running and not to overheat. I figured that with the amount of mud, dust and heat in the engine bay, id be sentenceing this particular type of compressor to an early grave. (Ambient Temperatures, higher running temps, mud and dust in the cooling fan etc)

3). I dont find the compressor overly noisy. No more such than having an ARB mounted under the seat your sitting on. Besides in most applications when it will be running (airing up, cleaning with bow off gun, rattle gun etc) I and anyone that would normally be in the vehicle would be outside of it anyway. So in my case i didnt see it as an issue.

4). This compressor also has an external air filter ( yes i ralise it is washable and replaceable) so i figured much as the same reasons as point 2, this would be better in the cabin.

I have no doubt it would most liekely be fine in the engine bay or under the vehicle, however i beleive by putting it where it is, i have eliminated a number of variables that may cause a failure in the unit.

This is just my personal opinion, and one i came up with after considering putting it under the bonnet myself. I have several reasons:

1). The BOSS 3/4 is primarily designed and built for Air Suspension applications, and after speaking with a number of Air Suspension dealers etc, i found almost all of them suggested they were mounted inside the vehicle "somewhere"

2). The compressor has a fan cooled engine that requires clean cool air to keep it running and not to overheat. I figured that with the amount of mud, dust and heat in the engine bay, id be sentenceing this particular type of compressor to an early grave. (Ambient Temperatures, higher running temps, mud and dust in the cooling fan etc)

3). I dont find the compressor overly noisy. No more such than having an ARB mounted under the seat your sitting on. Besides in most applications when it will be running (airing up, cleaning with bow off gun, rattle gun etc) I and anyone that would normally be in the vehicle would be outside of it anyway. So in my case i didnt see it as an issue.

4). This compressor also has an external air filter ( yes i ralise it is washable and replaceable) so i figured much as the same reasons as point 2, this would be better in the cabin.

I have no doubt it would most liekely be fine in the engine bay or under the vehicle, however i beleive by putting it where it is, i have eliminated a number of variables that may cause a failure in the unit.

92 LWB Ford Maverick 4.2, Dual Fuel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

99 GU ST 4.2 Turbo Diesel, Non Intercooled, Tigerz11 w/synthetic, 35"' Bighorns, ARB Compressor, Snorkel.

Who is online

Users browsing this forum: No registered users and 4 guests