Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

moving transfer case for better fit of auto

moving transfer case for better fit of auto

Would there be any negative issues with moving my transfer case 1-1.5 inches rearward just using some 10mm plate for an adapter to get a useful sized jackshaft between my auto and transfer?

My auto:

AE71 1984 corolla 3spd Auto (Aisin-Warner A41)

720mm long from bellhousing to jackshaft input.

things to consider with my build:

Front diff forward ~27mm + 1 inch driveshaft spacer

Rear diff back ~27mm

Will be lifting transfer ~50mm to get flat belly

Will be getting new stronger driveshafts made up anyway so can correct for length.

My auto:

AE71 1984 corolla 3spd Auto (Aisin-Warner A41)

720mm long from bellhousing to jackshaft input.

things to consider with my build:

Front diff forward ~27mm + 1 inch driveshaft spacer

Rear diff back ~27mm

Will be lifting transfer ~50mm to get flat belly

Will be getting new stronger driveshafts made up anyway so can correct for length.

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

x2 on the rear tailshaft. From reading around on forums etc I don't think you start to see driveshaft angle issues until the 6 - 7" suspension lift mark. If your running 2" suspension, a 1-1.5" transfer lift would equal = 3.5" (4" at most)... Most standard spring spoa's are around 5" and theres no issues there...

what size tyres are you going to be running?

i as you know am doing the same thing, i was considering leaving the motor a little further forward to stop or hopefully prevent me from flipping on climbs. i will be running 35's and the 4afe but with your 20v i dare say you will have a sight more power than me.

does my theory have any intelligence to it at all or is it just worth scrapping it?

i as you know am doing the same thing, i was considering leaving the motor a little further forward to stop or hopefully prevent me from flipping on climbs. i will be running 35's and the 4afe but with your 20v i dare say you will have a sight more power than me.

does my theory have any intelligence to it at all or is it just worth scrapping it?

Your theory has some relevance pubic but you've got it slightly wrong.pubic wrote:what size tyres are you going to be running?

i as you know am doing the same thing, i was considering leaving the motor a little further forward to stop or hopefully prevent me from flipping on climbs. i will be running 35's and the 4afe but with your 20v i dare say you will have a sight more power than me.

does my theory have any intelligence to it at all or is it just worth scrapping it?

To build a balanced rig you would want to have the mass being the engine right between the front and rear diffs. Of course this isn't possible. If you think about driving up a really steep bank and you have all of the weight over the front diff it'll just act as more leverage for when it starts to topple over. It'll actually increase your chances of flipping. Have a look at some of the buggy's going around they either have rear mounted engines or have their front axle WAY forward to balance out everything. Its sorta hard to explain but jump on youtube and watch the vids of crawlers and other 4bys flipping and you'll get what I mean.

Dee - yeah I get what you mean. I've currently got 2inch springs, 2 inch longer shackles. so 3 inchs susp lift + 2inch max transfer lift is 5, so it should be ok.

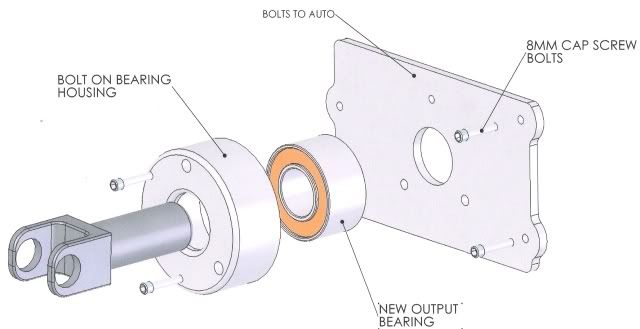

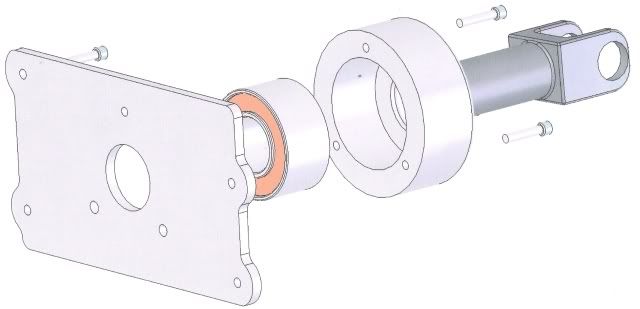

Gwagensteve had a picture floating around of a transfer lift with a vitara trimatic. It looks the goods.(hope you don't mind me posting this steve):

what I'm aiming to do is to get the engine as close to the longitudal centre of the car as possible. I have to watch out for issues with the dizzy and water outlets on the back of the motor and possibly get the plenum throttle body cut and swapped to the front of the engine.

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

i just thought the moreweight you have over the front wheels the harder it would be for the front to actually lift. same sort of theory as a front spoiler on a racing car. it is there to push weight down on the front to stop it from lifting. i know that there is not much comparison with the speeds of the 2 sports. i understand having the weight centred for performance cars.

i'll have a look at some vids to try and get my head around it, but remembering things from physics and engineering classes, calculating the force being pushed down on something and therefore the force needed to lift it is calculated by doing the following.

distance of centre of mass from centre of pivot point (in this case centre of engine from centre of rear wheels) x 9.8 (gravity) = how many newtons (force) is being applied to the front of the car.

therefore the further forward the mass is, which increases the distance between the rear wheels will increase the amount of newtons applied at the front wheels. and therefore making it harder to do a wheely so to speak.

moving the front diff forward too will also help to keep the front wheels on the ground while climbing steep inclines.

this is why lwb dont flip as much.

the same theory applies to climbing a hill on a dirt bike. you always shift your weight over the bars to keep the front wheel down.

this is only my opinion, alot of people will probably disagree. but i do think it would benefit having the motor further forward, not totally forward but i would not try and shift it as far back as possible.

and when i do flip my zook all you people can say i told you so and we can laugh about it over a schooner.

if you have a relatively high lift, that too will also make it easier to flip backwards as the weight is higher and once it goes over its balance point it will flip straight away.

i'll have a look at some vids to try and get my head around it, but remembering things from physics and engineering classes, calculating the force being pushed down on something and therefore the force needed to lift it is calculated by doing the following.

distance of centre of mass from centre of pivot point (in this case centre of engine from centre of rear wheels) x 9.8 (gravity) = how many newtons (force) is being applied to the front of the car.

therefore the further forward the mass is, which increases the distance between the rear wheels will increase the amount of newtons applied at the front wheels. and therefore making it harder to do a wheely so to speak.

moving the front diff forward too will also help to keep the front wheels on the ground while climbing steep inclines.

this is why lwb dont flip as much.

the same theory applies to climbing a hill on a dirt bike. you always shift your weight over the bars to keep the front wheel down.

this is only my opinion, alot of people will probably disagree. but i do think it would benefit having the motor further forward, not totally forward but i would not try and shift it as far back as possible.

and when i do flip my zook all you people can say i told you so and we can laugh about it over a schooner.

if you have a relatively high lift, that too will also make it easier to flip backwards as the weight is higher and once it goes over its balance point it will flip straight away.

what you are saying defintiely makes sense. i understand that it would be harder to get it to start going over but once it starts it would be harder to recover from.

watch this clip

http://www.youtube.com/watch?v=lQJh-38-dfM

and this one

http://www.youtube.com/watch?v=v7fMmHar ... re=related

full on flips but you get the idea.

i think for all round driving you'd want a balanced car. Driving down hill you will find especially in the shorty that alot of weight over the front will make the rear unload and be hard to control.

watch this clip

http://www.youtube.com/watch?v=lQJh-38-dfM

and this one

http://www.youtube.com/watch?v=v7fMmHar ... re=related

full on flips but you get the idea.

i think for all round driving you'd want a balanced car. Driving down hill you will find especially in the shorty that alot of weight over the front will make the rear unload and be hard to control.

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

would be interested in hearing gwagensteve shed some light on that transfer lift. does that bolt pass all the way through the red bushing & sandwich the mounts to the bushes?

I had the same idea, machining up some poly bushes with a bolt through the middle, but the increased "leverage" over the distance of the bushing with 33's & 6.5 tcase worried me a bit. because wouldnt the bolt on one side (shown in pic) be taking all the "pulling" pressure applied by the transfer as it twists..? (applies compression to one sides bushes and pulls on the opposite side under acceleration) If it is I think I'd prefer to make up some braced "spacers" and run the stock bush above it, to keep the mount flexible without going & welding new custom tube & eye (nissan style) mounts all over the chassis.

OR;

is there two independant threaded rods somehow attached to the bush to utilise its "elastic" properties under accel? If so, how would one go about attaching them, IE if internally threading the bush the steel thread would just gouge the poly just pull out over time?

I had the same idea, machining up some poly bushes with a bolt through the middle, but the increased "leverage" over the distance of the bushing with 33's & 6.5 tcase worried me a bit. because wouldnt the bolt on one side (shown in pic) be taking all the "pulling" pressure applied by the transfer as it twists..? (applies compression to one sides bushes and pulls on the opposite side under acceleration) If it is I think I'd prefer to make up some braced "spacers" and run the stock bush above it, to keep the mount flexible without going & welding new custom tube & eye (nissan style) mounts all over the chassis.

OR;

is there two independant threaded rods somehow attached to the bush to utilise its "elastic" properties under accel? If so, how would one go about attaching them, IE if internally threading the bush the steel thread would just gouge the poly just pull out over time?

Dee, they're urethane isolation mounts. My Dad orders them from purple pig in Melbourne. I think the dimensions are unique to his order, but on the face of it, they are a fairly generic isolation mount. They're about $27 each.

They are pretty much two 10mm bolts set into the urethane. There's no link between the two.

I first fitted them on Greg's pedicurist's car. It was an experiment and I really didn't think they'd last as they don't, on the face of it, look strong enough. They have lasted fine, so I threw a set on my 1.0 trayback (1.0's have 4 transfer mounts so I figured they'd be fine) and I've had no trouble, even with a manual, deep gearing and some abuse.

Michael's car in the pic was the last car i've run them on and it's been fine too. He was going though tension (P/S mounts) regularly when he was running rubber. He's auto now, so the shock is reduced, but the transfer still sees some big loads.

I don't know how long they'll last, but they don't induce vibration like a bolt and spacer, a stock mount can be swapped back in, and are firmer so the box doesn't crank up under high load.

I'll let you know if we have one fail.

Steve.

PS the stack of washers under the tension mount was temporary and was for tuning jackshaft angle

They are pretty much two 10mm bolts set into the urethane. There's no link between the two.

I first fitted them on Greg's pedicurist's car. It was an experiment and I really didn't think they'd last as they don't, on the face of it, look strong enough. They have lasted fine, so I threw a set on my 1.0 trayback (1.0's have 4 transfer mounts so I figured they'd be fine) and I've had no trouble, even with a manual, deep gearing and some abuse.

Michael's car in the pic was the last car i've run them on and it's been fine too. He was going though tension (P/S mounts) regularly when he was running rubber. He's auto now, so the shock is reduced, but the transfer still sees some big loads.

I don't know how long they'll last, but they don't induce vibration like a bolt and spacer, a stock mount can be swapped back in, and are firmer so the box doesn't crank up under high load.

I'll let you know if we have one fail.

Steve.

PS the stack of washers under the tension mount was temporary and was for tuning jackshaft angle

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Oh, Dank - I'd be pulling that massive tailshaft housing off your auto and seeing if you can plate the back off and shorten the output shaft - then you'd have the transfer in the stock spot and a jackshaft.

I believe a "proper" jackshaft (as in no shorter than the one in my pic) if absolutely necessary in a road driven sierra, and almost any amount of work required to have one is worth it in the long run.

Steve.

I believe a "proper" jackshaft (as in no shorter than the one in my pic) if absolutely necessary in a road driven sierra, and almost any amount of work required to have one is worth it in the long run.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

Thats a great idea Steve. I'll look into it. I know very little about autos and their internals so I'm guessing everything from the point where the box join starts to narrow down to the output only contains the output shaft and possibly a bearing on the end?Gwagensteve wrote:Oh, Dank - I'd be pulling that massive tailshaft housing off your auto and seeing if you can plate the back off and shorten the output shaft - then you'd have the transfer in the stock spot and a jackshaft.

I believe a "proper" jackshaft (as in no shorter than the one in my pic) if absolutely necessary in a road driven sierra, and almost any amount of work required to have one is worth it in the long run.

Steve.

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

Yep, that's my guess. The hassle might be in shortening the output shaft, someone like Matt at Total Traction drivelines should be able to handle this though. If the end result ended up like the cover plate in my pic above, I think that would be ideal - obviously having a custom output shafts isn't ideal, but neither is having the transfer moved back or a tiny jackshaft. (Moreso the tiny jackshaft)

Steve.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

looks good joe, pm sent...

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

thinking thinking...other than vibration are there any disadvantages for solid mounting a transfer case with an aluminum spacer (with maybe a zook body rubber?) or a 2 inch body lift block?

Remember I'll be running 251% more power and 162% more torque than a stock g13 with the 4age 20v

these gave me the idea - http://www.locktup4x4.com.au/product/ab ... ecaf3.aspx

Remember I'll be running 251% more power and 162% more torque than a stock g13 with the 4age 20v

these gave me the idea - http://www.locktup4x4.com.au/product/ab ... ecaf3.aspx

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

dank,

I have been thinking about the exact same thing. after chatting with a mate I will be having some poly (same as body lift spacers) spacers machined up, and also some female bolts to fit to the stud on the underside of the standard zuk rubber transfer mounts. This way its sandwiching the poly spacer, and all the flex/twist is still taken up in the stock mounts...

with those sort of power & torque figures on 34's I'd be more worried about your rear axles & axle splines.

I have been thinking about the exact same thing. after chatting with a mate I will be having some poly (same as body lift spacers) spacers machined up, and also some female bolts to fit to the stud on the underside of the standard zuk rubber transfer mounts. This way its sandwiching the poly spacer, and all the flex/twist is still taken up in the stock mounts...

with those sort of power & torque figures on 34's I'd be more worried about your rear axles & axle splines.

Last edited by Dee on Tue May 13, 2008 3:07 pm, edited 2 times in total.

good idea....i was thinking of just using a block with a zook body rubber or something similar for less twisting due to the increased power though....I read that christover also used sierra engine mounts to get his tranny lifted up too.

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

forgot to mention, with completely solid mounting the case up higher, I have to say I'd be a bit worried that once the motor/gearbox twist up under torque it may cause vibrations in the unis in the little jackshaft, due to the transfer not twisting with them.

Not sure about it, but may be something to think about...

And of course, if using rubber mounts, you'd want the flexible mount as close to the case as possible (above the blocks) to reduce leverage on them under wind-up...

Not sure about it, but may be something to think about...

And of course, if using rubber mounts, you'd want the flexible mount as close to the case as possible (above the blocks) to reduce leverage on them under wind-up...

i have replaced the rubber mounts with body lift poleurethane blocks and a bolt all the way through. I have had no adverse affects so far, if that counts for anything. I have left the otherside rubber.dank wrote:thinking thinking...other than vibration are there any disadvantages for solid mounting a transfer case with an aluminum spacer (with maybe a zook body rubber?) or a 2 inch body lift block?

Remember I'll be running 251% more power and 162% more torque than a stock g13 with the 4age 20v

these gave me the idea - http://www.locktup4x4.com.au/product/ab ... ecaf3.aspx

i run 4.9s and 31s 3.9 diffs and was getting alot of vibration becuae of these rubbers, changed them and all gone.

85 LWB w. FRP Canopy

Ca18det conversion in progress, Vit PS, RUF,

6.5:1's, 33x12.5 Bfg's, custom front and rear bars.

Ca18det conversion in progress, Vit PS, RUF,

6.5:1's, 33x12.5 Bfg's, custom front and rear bars.

with solid mounting ... when it should break it will rip the mount out of the mounting plate instead or the force will go to your transfer case = redzooks lovly job

i used round truck mounts lifted it about 1.5 inches stronger rubber /bigger yet still can break if it HAS to

I'd rather replace a rubber mount then to deal with what could possiably go wrong when solid fixing it

i used round truck mounts lifted it about 1.5 inches stronger rubber /bigger yet still can break if it HAS to

I'd rather replace a rubber mount then to deal with what could possiably go wrong when solid fixing it

[color=green]Vote Earth[/color]

i did a test fit of my 4afe motor attatched to the same box yesterday.

if your going to lift the transfer case t oobtain a flat belly you will also have to modify the driveline tunnel, the flat section on the bottom of the 3sp does not fit up into the tunnel completely.

have you tried fitting yours yet? did you have the same problem and if so how did you overcome it?

if need be i can take some photos to show this.

if your going to lift the transfer case t oobtain a flat belly you will also have to modify the driveline tunnel, the flat section on the bottom of the 3sp does not fit up into the tunnel completely.

have you tried fitting yours yet? did you have the same problem and if so how did you overcome it?

if need be i can take some photos to show this.

I'll be fitting mine this week just sourcing a starter motor plate to bolt on the passenger side of the engine to match the auto box. I've got a 2inch body lift so i'm not sure if its going to hit or not yet....

I'm also looking at shortening the auto but am going to see how i go with engine fitment...If you have any pics of your setup post them up would love to see hows yours sits etc....

I'm also looking at shortening the auto but am going to see how i go with engine fitment...If you have any pics of your setup post them up would love to see hows yours sits etc....

Work - KPD4X4.COM - KPD Industries Australian Distributor of Diesel Power Modules - Germany.

Play - dank's zook

Play - dank's zook

This thread came up again so I might add to it regarding the transfer lift.

There was a thread on pirate in the last 2 weeks regarding using Honda engine mounts to lift the transfer. They looked exactly the same as the Sierra transfer mounts but twice as thick. I'll see if I can find it.

Edit: http://pirate4x4.com/forum/showthread.php?t=721460

There was a thread on pirate in the last 2 weeks regarding using Honda engine mounts to lift the transfer. They looked exactly the same as the Sierra transfer mounts but twice as thick. I'll see if I can find it.

Edit: http://pirate4x4.com/forum/showthread.php?t=721460

-Mal

Zook 1, 2, 3 gone

Patrol - Wheels, engine and stuff

Zook 1, 2, 3 gone

Patrol - Wheels, engine and stuff

Who is online

Users browsing this forum: No registered users and 2 guests