Notice: We request that you don't just set up a new account at this time if you are a previous user.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

If you used to be one of our moderators, please feel free to reach out to Chris via the facebook Outerlimits4x4 group and he will get you set back up with access should he need you.

Recovery:If you cannot access your old email address and don't remember your password, please click here to log a change of email address so you can do a password reset.

the other way to make a weber work off road

the other way to make a weber work off road

ok this used to be a thread about fuel pumps.

BUT

all the weber stuff was in here too. so i'll just change the title to save me having to move pics and stuff to a different thread

BUT

all the weber stuff was in here too. so i'll just change the title to save me having to move pics and stuff to a different thread

Last edited by brad-chevlux on Sun Jun 29, 2008 7:45 pm, edited 1 time in total.

http://www.mothfukle-engineering.com/

4130warrior wrote:A squirt every second or so

haha yeah good one. but how big is the squirt?

we are trying i new setup with two pumps but the mechanical pump needs to out flow the other pump for every thing to work right.

any one know if the 1600 pumps flow more than the 1300 pumps?

http://www.mothfukle-engineering.com/

in theory it should due to being a larger sized motorbrad-chevlux wrote:4130warrior wrote:A squirt every second or so

haha yeah good one. but how big is the squirt?

we are trying i new setup with two pumps but the mechanical pump needs to out flow the other pump for every thing to work right.

any one know if the 1600 pumps flow more than the 1300 pumps?

[color=green]Vote Earth[/color]

unless to save on having to make two pumps they just over pump the 1300.ofr57 wrote:in theory it should due to being a larger sized motorbrad-chevlux wrote:4130warrior wrote:A squirt every second or so

haha yeah good one. but how big is the squirt?

we are trying i new setup with two pumps but the mechanical pump needs to out flow the other pump for every thing to work right.

any one know if the 1600 pumps flow more than the 1300 pumps?

anyway i the car in question at my house now, so i'll test it this weekend

http://www.mothfukle-engineering.com/

I have no idea about flow rates but 1.3 and 1.6 fuel pumps are different. The 1.3 pump flows more fuel than the engine needs, that's why they have a return.

For a carby application I'd leave the mechanical pump in it.

Just make sure it's working properly - they seem to start to give trouble at around 16 years old.

Steve.

For a carby application I'd leave the mechanical pump in it.

Just make sure it's working properly - they seem to start to give trouble at around 16 years old.

Steve.

[quote="greg"] some say he is a man without happy dreams, or that he sees silver linings on clouds and wonders why they are not platinum... all we know, is he's called the stevie.[/quote]

thing is we need a pump that can out flow what the engine needs at full power, while the engine is idleing.Gwagensteve wrote:I have no idea about flow rates but 1.3 and 1.6 fuel pumps are different. The 1.3 pump flows more fuel than the engine needs, that's why they have a return.

For a carby application I'd leave the mechanical pump in it.

Just make sure it's working properly - they seem to start to give trouble at around 16 years old.

Steve.

it will all make sence when i post up the info and pics of the final product

http://www.mothfukle-engineering.com/

NIK wrote:Could you use an electric pump?

Carter rotary pump 60-70GPH at 4psi Is one that Im looking at.

Nik

we are using two pumps, carter 35GPH pump and a second pump.

problem is the second pump will be pumping airated (spelling) petrol.

so an elec pump may not last to long. a diaphram pump won't mind pumping a bit of air.

the 1300 pump is 20gph @ 4psi at 2000rpm. we need 35gph @ 0- 1psi at idle.

if the carter pump could pump safly pump the return feul i could use a 1600 pump tp feed.

http://www.mothfukle-engineering.com/

NIK wrote:Hurry up,my 38 is going tosarge this week and it makes the 32/36 look like the stock carb

Nik

i'm not going to rush it, it has to be done right, or there is no point.

alot of carefull modification needs to be made to carb and if i get it wrong the whole body of the carb will be scrap.

and this feul pump issue is being a far PITA.. might need to down size the elec pump. but we dont want to use a solid stat pump like the Mr gasket pumps or the facet pumps

http://www.mothfukle-engineering.com/

neil_se wrote:Did you end up finding an answer to this? I'd like to be a cheapskate and use my g13a fuel pump for my g16a conversion (it didn't come with one and a new fuel pump will cost more than the engine did), but i'm not sure it'll flow enough.

the 1300 pump will work fine with 1600 engine

http://www.mothfukle-engineering.com/

NIK wrote:You still working on this?

My 38 has been sargified put on a ported manifold and is on its way back!

Whats the hold up?

Nik

all sorts of hold ups. and i'm in no real hurry just yet. the bloke that owns the zook isn't due back in Australia untill midway through next month.

the carb is ready and sitting on the bench along with the new pumps, adapter, air filter and new MSD HV coil. i'll make a trip out to his place this week to pick the zook up. should have it running this weekend.

i did see the carb you had sarge work his tricks on. It looks good. he's basicly done what we normaly do with the holley carbs. Though i can't see what he's done inside.

trust me i'll tell you all about it when it's finished

http://www.mothfukle-engineering.com/

read the above post.gaser wrote:is my car going soon im home in a few weeks or will i have to drive the

new one.

thanks scott

it'll be ready. i'd have had it on and running last week, but your olds went to the island and locked the place up. funny thing is, i dont think your dad even used it. the bloody thing is still sitting in the same place i left it.

i'll go grab it off them tomorrow. i 'borrowed' a heap of jets, air bleeds and emulsion tubes from work. i'll see if i can get the A/F meter too and have half way decent tune in it by the time you get back.

but i think barry wants you to pay for using it. (cos the sensor cost shit loads)

http://www.mothfukle-engineering.com/

ok first off. i solved the fuel pump issue. By running a return with a restrictor between the elec pump and carb, i can cut the flow rate entering the carb to the needed amount by changing the restrictor size.

next...

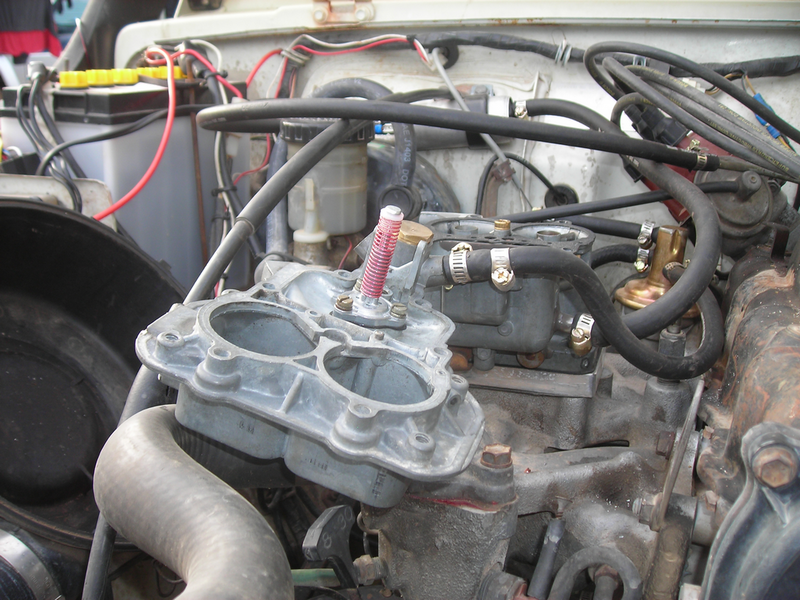

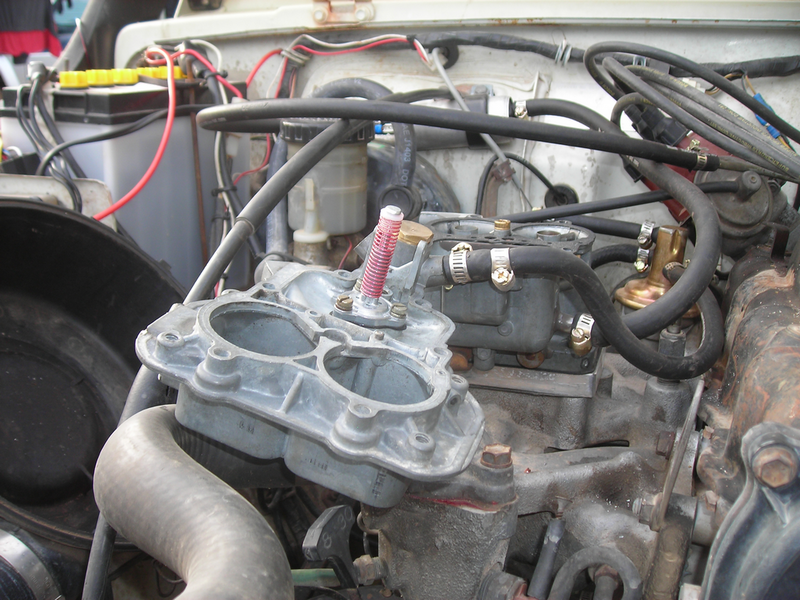

i picked the car up tonight, removed the old carb and fitted the weber.

you can't see my mods int he pics. they'll come later when it's setup right.

a shot down the top of the carby.

next...

i picked the car up tonight, removed the old carb and fitted the weber.

you can't see my mods int he pics. they'll come later when it's setup right.

a shot down the top of the carby.

http://www.mothfukle-engineering.com/

OK

the weber is on and running. As you can see from the pics, it's bolted on the 'right' way around, and there is no need for and bowl vent mods or extended breather pipes.

the fuel level is set at regular road car hight, not at 'zook off road' hight.

have been testing for a few days, first was on a rather large pile of dirt at the back of our workshop and tonight i took a long drive down a corrigated dirt road to find a steeper 'something' to drive on. What i found, was i could drive up such a steep incline that the the 31" ETs were loosing traction.

(and i was worried to go any steeper)

Never had a hint of floading or starving for fuel going up forward or in backward..

I'll get some pics of the setup maybe tomorrow.

But just for nik, because i know i've got you stumped so far. there is no needle and seat...............

the weber is on and running. As you can see from the pics, it's bolted on the 'right' way around, and there is no need for and bowl vent mods or extended breather pipes.

the fuel level is set at regular road car hight, not at 'zook off road' hight.

have been testing for a few days, first was on a rather large pile of dirt at the back of our workshop and tonight i took a long drive down a corrigated dirt road to find a steeper 'something' to drive on. What i found, was i could drive up such a steep incline that the the 31" ETs were loosing traction.

(and i was worried to go any steeper)

Never had a hint of floading or starving for fuel going up forward or in backward..

I'll get some pics of the setup maybe tomorrow.

But just for nik, because i know i've got you stumped so far. there is no needle and seat...............

http://www.mothfukle-engineering.com/

That last bit cracked me up

Im reading going wtf thats just not possible!!!

My 38 isset up with the restrictor on the return side so the carb can take what it needs but any excess will bypass.

Even without the needleand set you wouldstill need to control the fuel in the bowl. My old 32/36 mounted backwards with lowered float etc would suck air/stumbleforasplit second uphill and flood down hill even with the vent mod.

I found fuel runs out the aux jets long before the breather came into play.

MORE INFO

Nik

Im reading going wtf thats just not possible!!!

My 38 isset up with the restrictor on the return side so the carb can take what it needs but any excess will bypass.

Even without the needleand set you wouldstill need to control the fuel in the bowl. My old 32/36 mounted backwards with lowered float etc would suck air/stumbleforasplit second uphill and flood down hill even with the vent mod.

I found fuel runs out the aux jets long before the breather came into play.

MORE INFO

Nik

Ok. i thought you may have got it from the last bit.

we run two fuel pumps, one feeds the carb, the other scavenges the carb.

No float and no needle and seat.

the trick to getting it to work climbing hills is where you put the scavenge pipe. the scavenge pipe set the fuel level. but you need to scavenge from the right spot.

the reason it took so long was finding the right scavenge pipe to use and finding the right stop to put it.

the other problem is metering the fuel that enters the carb.

the previous questions about the fuel pumps should make a little more sence now.

http://smg.photobucket.com/albums/v227/ ... bervid.flv

we run two fuel pumps, one feeds the carb, the other scavenges the carb.

No float and no needle and seat.

the trick to getting it to work climbing hills is where you put the scavenge pipe. the scavenge pipe set the fuel level. but you need to scavenge from the right spot.

the reason it took so long was finding the right scavenge pipe to use and finding the right stop to put it.

the other problem is metering the fuel that enters the carb.

the previous questions about the fuel pumps should make a little more sence now.

http://smg.photobucket.com/albums/v227/ ... bervid.flv

Last edited by brad-chevlux on Fri Jul 04, 2008 7:43 pm, edited 1 time in total.

http://www.mothfukle-engineering.com/

86slowsierra wrote:im interested to see how it goes on an outing.

Is it just a hose clamp that regulates the intake?

The hose clamp you're talking about, hold the metering jet in place.

I didn't have anything to use that was a 'snug' fit in the hose.

the jet size is worked out using the estimated BSFC of the engine, the expected HP output, the working feul pessure. That gives a usfull starting point, then a bit or trial and error.

still have some durability testing to do.

http://www.mothfukle-engineering.com/

Who is online

Users browsing this forum: No registered users and 1 guest